Abstract

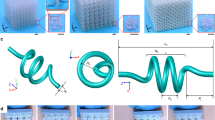

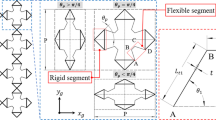

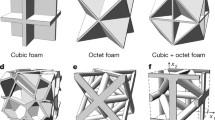

Developments of soft network materials with rationally distributed wavy microstructures have enabled many promising applications in bio-integrated electronic devices, due to their abilities to reproduce precisely nonlinear mechanical properties of human tissues/organs. In practical applications, the soft network materials usually serve as the encapsulation layer and/or substrate of bio-integrated electronic devices, where deterministic holes can be utilized to accommodate hard chips, thereby increasing the filling ratio of the device system. Therefore, it is essential to understand how the hole-type imperfection affects the stretchability of soft network materials with various geometric constructions. This work presents a systematic investigation of the imperfection sensitivity of mechanical properties in soft network materials consisting of horseshoe microstructures, through combined computational and experimental studies. A factor of imperfection insensitivity of stretchability is introduced to quantify the influence of hole imperfections, as compared to the case of perfect soft network materials. Such factor is shown to have different dependences on the arc angle and normalized width of horseshoe microstructures for triangular network materials. The soft triangular and Kagome network materials, especially with the arc angle in the range of (30\(^{\circ }\), 60\(^{\circ }\)), are found to be much more imperfection insensitive than corresponding traditional lattice materials with straight microstructures. Differently, the soft honeycomb network materials are not as imperfection insensitive as traditional honeycomb lattice materials.

Similar content being viewed by others

References

Wang, Y., Naleway, S.E., Wang, B.: Biological and bioinspired materials: structure leading to functional and mechanical performance. Bioactive Mater. 5, 745–757 (2020)

Liu, Z.Q., Zhang, Z.F., Ritchie, R.O.: Structural orientation and anisotropy in biological materials: functional designs and mechanics. Adv. Funct. Mater. 30, 1908121 (2020)

Wegst, U.G., Bai, H., Saiz, E., et al.: Bioinspired structural materials. Nat. Mater. 14, 23–36 (2015)

Meyers, M.A., McKittrick, J., Chen, P.-Y.: Structural biological materials: critical mechanics-materials connections. Science. 339, 773–779 (2013)

Aydin, O., Zhang, X.T., Nuethong, S., et al.: Neuromuscular actuation of biohybrid motile bots. Proc. Natl. Acad. Sci. USA 116, 19841–19847 (2019)

Fernandes, M.C., Aizenberg, J., Weaver, J.C., et al.: Mechanically robust lattices inspired by deep-sea glass sponges. Nat. Mater. 20, 237–241 (2020)

Gao, Y., Guo, Z.B., Song, Z.Q., et al.: Spiral interface: a reinforcing mechanism for laminated composite materials learned from nature. J. Mech. Phys. Solids. 109, 252–263 (2017)

Gao, C., Hasseldine, B.P.J., Li, L., et al.: Amplifying strength, toughness, and auxeticity via wavy sutural tessellation in plant seedcoats. Adv. Mater. 30, 1800579 (2018)

Lee, K.H., Yu, K., Al Ba ba a, H., et al.: Sharkskin-inspired magnetoactive reconfigurable acoustic metamaterials. Research. 2020, 4825185 (2020)

Yang, C.H., Suo, Z.G.: Hydrogel ionotronics. Nat. Rev. Mater. 3, 125–142 (2018)

Yuk, H., Zhang, T., Parada, G.A., et al.: Skin-inspired hydrogel-elastomer hybrids with robust interfaces and functional microstructures. Nat. Commun. 7, 12028 (2016)

Xu, J., Wang, S.H., Wang, G.J.N., et al.: Highly stretchable polymer semiconductor films through the nanoconfinement effect. Science. 355, 59–64 (2017)

Kim, K., Kim, B., Lee, C.H.: Printing flexible and hybrid electronics for human skin and eye-interfaced health monitoring systems. Adv. Mater. 32, 1902051 (2020)

Yang, Z.H., Zhai, Z.R., Song, Z.M., et al.: Conductive and elastic 3D helical fibers for use in washable and wearable electronics. Adv. Mater. 32, 1907495 (2020)

Yao, S.S., Zhu, Y.: Nanomaterial-enabled stretchable conductors: strategies, materials and devices. Adv. Mater. 27, 1480–1511 (2015)

Kumar, K.S., Chen, P.Y., Ren, H.L.: A review of printable flexible and stretchable tactile sensors. Research. 2019, 3018568 (2019)

Nie, S., Cai, M., Wang, C.J., et al.: Fatigue life prediction of serpentine interconnects on soft elastomers for stretchable electronics. J. Appl. Mech.-Trans. ASME. 87, 011011 (2020)

Shi, L., Jia, K., Gao, Y.Y., et al.: Highly stretchable and transparent ionic conductor with novel hydrophobicity and extreme-temperature tolerance. Research. 2020, 2505619 (2020)

Xiang, Y.H., Zhong, D.M., Wang, P., et al.: A general constitutive model of soft elastomers. J. Mech. Phys. Solids. 117, 110–122 (2018)

Yu, B., Kang, S.Y., Akthakul, A., et al.: An elastic second skin. Nat. Mater. 15, 911–918 (2016)

Chen, Q.Z., Harding, S.E., Ali, N.N., et al.: Biomaterials in cardiac tissue engineering: ten years of research survey. Mater. Sci. Eng. R-Rep. 59, 1–37 (2008)

Engelmayr, G.C., Cheng, M.Y., Bettinger, C.J., et al.: Accordion-like honeycombs for tissue engineering of cardiac anisotropy. Nat. Mater. 7, 1003–1010 (2008)

Lee, A., Hudson, A.R., Shiwarski, D.J., et al.: 3D bioprinting of collagen to rebuild components of the human heart. Science. 365, 482–487 (2019)

Roach, D.J., Yuan, C., Kuang, X., et al.: Long liquid crystal elastomer fibers with large reversible actuation strains for smart textiles and artificial muscles. ACS Appl. Mater. Interfaces. 11, 19514–19521 (2019)

Zhang, Y.H., Zhang, F., Yan, Z., et al.: Printing, folding and assembly methods for forming 3D mesostructures in advanced materials. Nat. Rev. Mater. 2, 17019 (2017)

Lu, T.Q., Chen, Z.Q., Qi, H.J., et al.: A micro-structure based constitutive model for anisotropic stress-strain behaviors of artery tissues. Int. J. Solids Struct. 139, 55–64 (2018)

Wu, L., Mao, G.Y., Nian, G.D., et al.: Mechanical characterization and modeling of sponge-reinforced hydrogel composites under compression. Soft Matter. 14, 4355–4363 (2018)

Lin, C., Lv, J.X., Li, Y.S., et al.: 4D-printed biodegradable and remotely controllable shape memory occlusion devices. Adv. Funct. Mater. 29, 1906569 (2019)

Jang, K.-I., Chung, H.U., Xu, S., et al.: Soft network composite materials with deterministic and bio-inspired designs. Nat. Commun. 6, 7566 (2015)

Ma, Q., Cheng, H., Jang, K.-I., et al.: A nonlinear mechanics model of bio-inspired hierarchical lattice materials consisting of horseshoe microstructures. J. Mech. Phys. Solids. 90, 179–202 (2016)

Liu, J., Zhang, Y.: A mechanics model of soft network materials with periodic lattices of arbitrarily shaped filamentary microstructures for tunable Poisson’s ratios. J. Appl. Mech.-Trans. ASME. 85, 051003 (2018)

Yan, D.J., Chang, J.H., Zhang, H., et al.: Soft three-dimensional network materials with rational bio-mimetic designs. Nat. Commun. 11, 1180 (2020)

Deshpande, V.S., Fleck, N.A., Ashby, M.F.: Effective properties of the octet-truss lattice material. J. Mech. Phys. Solids. 49, 1747–1769 (2001)

Tankasala, H.C., Deshpande, V.S., Fleck, N.A.: Tensile response of elastoplastic lattices at finite strain. J. Mech. Phys. Solids. 109, 307–330 (2017)

Vighotti, A., Deshpande, V.S., Pasini, D.: Non linear constitutive models for lattice materials. J. Mech. Phys. Solids. 64, 44–60 (2014)

Yang, W., Liu, Q., Gao, Z., et al.: Theoretical search for heterogeneously architected 2D structures. Proc. Natl. Acad. Sci. USA 115, 7245–7254 (2018)

Jia, Z., Liu, F., Jiang, X.H., et al.: Engineering lattice metamaterials for extreme property, programmability, and multifunctionality. J. Appl. Phys. 127, 150901 (2020)

Chen, H., Zhu, F., Jang, K.I., et al.: The equivalent medium of cellular substrate under large stretching, with applications to stretchable electronics. J. Mech. Phys. Solids. 120, 199–207 (2018)

Liu, J., Zhang, Y.: Soft network materials with isotropic negative Poisson’s ratios over large strains. Soft Matter. 14, 693–703 (2018)

Ma, Q., Zhang, Y.: Mechanics of fractal-inspired horseshoe microstructures for applications in stretchable electronics. J. Appl. Mech. 83, 111008 (2016)

Liu, J., Yan, D., Zhang, Y.: Mechanics of unusual soft network materials with rotatable structural nodes. J. Mech. Phys. Solids. 146, 104210 (2021)

Ni, X.Y., Guo, X.G., Li, J.H., et al.: 2D mechanical metamaterials with widely tunable unusual modes of thermal expansion. Adv. Mater. 31, 1905405 (2019)

Zhang, H., Guo, X., Wu, J., et al.: Soft mechanical metamaterials with unusual swelling behavior and tunable stress-strain curves. Sci. Adv. 4, eaar8535 (2018)

Lu, B.Y., Yuk, H., Lin, S.T., et al.: Pure PEDOT:PSS hydrogels. Nat. Commun. 10, 1043 (2019)

Lei, M., Hong, W., Zhao, Z., et al.: 3D printing of auxetic metamaterials with digitally reprogrammable shape. ACS Appl. Mater. Interfaces. 11, 22768–22776 (2019)

Xin, X., Liu, L., Liu, Y., et al.: 4D Printing Auxetic Metamaterials with Tunable, Programmable, and Reconfigurable Mechanical Properties. Adv. Funct. Mater. 30, 2004226 (2020)

Sadri, B., Goswami, D., de Medeiros, M.S., et al.: Wearable and implantable epidermal paper-based electronics. ACS Appl. Mater. Interfaces. 10, 31061–31068 (2018)

Ling, S.J., Zhang, Q., Kaplan, D.L., et al.: Printing of stretchable silk membranes for strain measurements. Lab Chip. 16, 2459–2466 (2016)

Ashley, B.K., Brown, M.S., Park, Y., et al.: Skin-inspired, open mesh electrochemical sensors for lactate and oxygen monitoring. Biosens. Bioelectron. 132, 343–351 (2019)

Park, J., Choi, S., Janardhan, A.H., et al.: Electromechanical cardioplasty using a wrapped elasto-conductive epicardial mesh. Sci. Transl. Med. 8, 344ra86 (2016)

Cai, M., Nie, S., Du, Y.P., et al.: Soft elastomers with programmable stiffness as strain-isolating substrates for stretchable electronics. ACS Appl. Mater. Interfaces. 11, 14340–14346 (2019)

Zhu, J., Fox, J.J., Yi, N., et al.: Structural design for stretchable microstrip antennas. ACS Appl. Mater. Interfaces. 11, 8867–8877 (2019)

Huang, Z., Hao, Y., Li, Y., et al.: Three-dimensional integrated stretchable electronics. Nat. Electron. 1, 473–480 (2018)

Han, M., Chen, L., Aras, K., et al.: Catheter-integrated soft multilayer electronic arrays for multiplexed sensing and actuation during cardiac surgery. Nat. Biomed. Eng. 4, 997–1009 (2020)

Liu, J.X., Song, H.L., Zhang, Y.H.: Toward imperfection-insensitive soft network materials for applications in stretchable electronics. ACS Appl. Mater. Interfaces. 11, 36100–36109 (2019)

Chen, C., Lu, T.J., Fleck, N.A.: Effect of imperfections on the yielding of two-dimensional foams. J. Mech. Phys. Solids. 47, 2235–2272 (1999)

Fleck, N.A., Qiu, X.M.: The damage tolerance of elastic-brittle, two-dimensional isotropic lattices. J. Mech. Phys. Solids. 55, 562–588 (2007)

Seiler, P.E., Tankasala, H.C., Fleck, N.A.: The role of defects in dictating the strength of brittle honeycombs made by rapid prototyping. Acta Mater. 171, 190–200 (2019)

Pasini, D., Guest, J.K.: Imperfect architected materials: mechanics and topology optimization. MRS Bull. 44, 766–772 (2019)

Ma, Y., Feng, X., Rogers, J.A., et al.: Design and application of “J-shaped” stress-strain behavior in stretchable electronics: a review. Lab Chip. 17, 1689–1704 (2017)

Lee, C.H., Ma, Y., Jang, K.-I., et al.: Soft core/shell packages for stretchable electronics. Adv. Funct. Mater. 25, 3698–3704 (2015)

Acknowledgements

This work is supported by a grant from the Institute for Guo Qiang, Tsinghua University (Grant No. 2019GQG1012). Y.Z. acknowledges support from the National Natural Science Foundation of China (Grant Nos. 11722217 and 11921002), the Tsinghua University Initiative Scientific Research Program (#2019Z08QCX10) and the Henry Fok Education Foundation.

Author information

Authors and Affiliations

Corresponding author

Additional information

Executive Editor: Xi-Qiao Feng.

Rights and permissions

About this article

Cite this article

Liu, J., Zhu, X., Shen, Z. et al. Imperfection sensitivity of mechanical properties in soft network materials with horseshoe microstructures. Acta Mech. Sin. 37, 1050–1062 (2021). https://doi.org/10.1007/s10409-021-01087-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10409-021-01087-x