Abstract

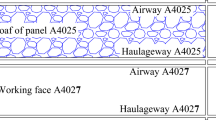

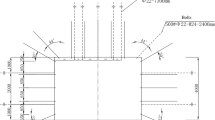

The large deformation of deep soft rock roadways and the corresponding support technology are important to the coal mining industry. This study investigated the large deformation mechanism and the concrete-filled steel tubular support technology of a ventilation shaft roadway (VSR) on the basis of a well-documented engineering case. The mechanical parameters of the rock surrounding the VSR were evaluated in accordance with the geological strength index, and the failure modes of the VSR were summarized and analyzed on the basis of geological background and field survey results. The VSR exhibited asymmetrical deformation and the fracture of the 29U-shaped steel support at the side and vault. The deformation, stress, and plastic zone of the VSR without support and with the original support scheme were investigated using the Three-Dimensional Distinct Element Code, and the depth of the plastic zone was verified in accordance with the equivalent radius theory. Dramatic and multiple disturbances, the low strength of the surrounding rock, and the insufficient strength of the support caused the deformation of the VSR. The bottom of the two side walls of the original roadway was prone to inward deformation. Thus, the shape of the original roadway section was optimized by converting it from a straight wall with a semi-circular arch into an inclined wall with a semi-circular arch. A composite concrete-filled steel tubular support scheme is proposed and can be divided into active and passive support. The composite support scheme was verified through numerical simulation and a field application. The monitoring results obtained from the numerical simulation and on-site analysis reveal that the composite support scheme can control the large deformation of the VSR.

Similar content being viewed by others

Data availability

All the data and material generated or analyzed during this study are included in this manuscript.

References

Accident Investigation Department of State Administration of Coal Mine Safety (2019) Accident analysis report of National Coal Mine in 2019. Beijing, State Administration of Coal Mine Safety

Bai QS, Xia YY, Liu XX, Yang ZH (2012) Mining roadway support technology based on rheological analysis in Malin coalmine. Eng Proc 16:1129–1134

Brady BHG, Brown ET (2006) Rock mechanics for underground mining, 3rd edn. Springer Science and Business Media, New York

Cao C, Ren T, Chirs C (2014) Introducing aggregate into grouting material and its influence on load transfer of the rock bolting system. Int J Min Sci Techno 24(3):325–328

Chen DD, Wang E, Xie SR, He FL, Wang L, Zhang Q, Wu XY, Jiang ZS, Li YB, Shi SH (2020) Roadway surrounding rock under multi-coal-seam mining: deviatoric stress evolution and control technology. Adv Civ Eng 2020:9891825

Chen KF, Xu GA, Jing HW (2009) Study on failure law and control technology of deep soft rock roadway. Report by China University of Mining and Technology, Xuzhou (in Chinese)

Dai P, Yang L, Wang J, Zhou YH (2019) Compressive strength of concrete-filled stainless steel tube stub columns. Eng Struct 205:110106

Du ZF, Qin BT, Tian FC (2016) Numerical analysis of the effects of rock bolts on stress redistribution around a roadway. Int J Min Sci Techno 26(6):975–980

Fairhurst CE, Hudson JA (1999) Draft ISRM suggested method for the complete stress-strain curve for intact rock in uniaxial compression. Int J Rock Mech Min 36(3):279–289

Gao FQ, Stead D (2014) The application of a modified Voronoi logic to brittle fracture modelling at the laboratory and field scale. Int J Rock Mech Min 68:1–14

Gao YF, Wang B, Wang J, Li B, Xing F, Wang ZG, Jin TL (2010) Test on structural property and application of concrete-filled steel tube support of deep mine and soft rock roadway. Chin J Rock Mech Eng 29(S1):2604–2609

Gurocak Z (2011) Analyses of stability and support design for a diversion tunnel at the Kapikaya dam site. Turkey B Eng Geol Environ 70(1):41–52

Heng P, Lepourry C, Somja H, Palas F (2020) Behaviour of a joint between a U-shaped steel-concrete beam and a concrete-filled steel tubular column. J Constr Steel Res 175:106322

Hoek E, Brown ET (1997) Practical estimates of rock mass strength. Int J Rock Mech Min 34(8):1165–1186

Hoek E, Carranza-Torres CT, Corkum B (2002) Hoek–Brown Failure Criterion–2002 Edition. Proceedings of the Fifth north American Rock Mechanics Symposium, Toronto. 267–273

Hong ZJ, Zuo JP, Liu C, Zhang ZS (2019) Hydration and microstructure of nano-clay cement material in ion erosion solution. Mater Lett 252:27–30

Huang WP, Yuan Q, Tan YL, Wang J, Liu GL, Qu GL, Li C (2018) An innovative support technology employing a concrete-filled steel tubular structure for a 1000-m-deep roadway in a high in situ stress field. Tunn Undergr Sp Tech 73:26–36

Itasca Consulting Group (2013) 3DEC Users’ Manual. Itasca Consulting Group Inc, Minneapolis

Kang HP (2021) Seventy years development and prospects of strata control technology for coal mine roadways in China. Chin J Rock Mech Eng 40(1):1–30

Kang HP, Lin J, Fan MJ (2015) Investigation on support pattern of a coal mine roadway within soft rocks—a case study. Int J Coal Geol 140:31–40

Li G, Ma FS, Guo J, Zhao HJ, Liu G (2020a) Study on deformation failure mechanism and support technology of deep soft rock roadway. Eng Geol 264:105262

Li QH, Shi WP, Yang RS (2016) Deformation mechanisms in a coal mine roadway in extremely swelling soft rock. Springerplus 5:1310–1323

Li SC, Wang Q, Wang HT, Jiang B, Wang DC, Zhang B, Li Y, Ruan GQ (2015) Model test study on surrounding rock deformation and failure mechanisms of deep roadways with thick top coal. Tunn Undergr Sp Tech 47:52–63

Li W, Chen B, Han LH, Lam, D (2020b) Experimental study on the performance of steel-concrete interfaces in circular concrete-filled double skin steel tube. Thin Wall Struct 149:106660

Liu DJ, Zuo JP, Wang J, Li P, Duan K, Zhang DM, Guo S (2019) Bending failure mechanism and strengthening of concrete-filled steel tubular support. Eng Struct 198:1–20

Liu DJ, Zuo JP, Wang J, Zhang TL, Liu HY (2020) Large deformation mechanism and concrete-filled steel tubular support control technology of soft rock roadway-A case study. Eng Fail Anal 116:104721

Marinos P, Hoek E (2001) Estimating the geotechnical properties of heterogeneous rock masses such as flysch. B Eng Geol Environ 60(2):85–92

Ren H, Zhu YJ, Wang P, Li P, Zhang YQ, Wang XZ, Li YY (2020) Classification and application of roof stability of bolt supporting coal roadway based on BP neural network. Adv Civ Eng 2020:8838640

Shen BT (2014) Coal mine roadway stability in soft rock: a case study. Rock Mech Rock Eng 47(6):2225–2238

Tan XJ, Chen WZ, Liu HY, Chan AHC, Tian HM, Meng XJ, Wang FQ, Deng XL (2017) A combined supporting system based on foamed concrete and U-shaped steel for underground coal mine roadways undergoing large deformations. Tunn Undergr Sp Tech 68:196–210

Tu HS, Tu SH, Wang C, Hao DY, Zhu DF (2018) Mechanical analysis of a vertical-wall, semicircular-arch roadway and a repair technique using double-shell support. Environ Earth Sci 77(13):509–527

Wang H, Zheng PQ, Zhao WJ, Tian HM (2018a) Application of a combined supporting technology with U-shaped steel support and anchor-grouting to surrounding soft rock reinforcement in roadway. J CentSouth Univ 25(5):1240–1250

Wang Q, Jiang B, Li SC, Wang DC, Wang FQ, Li WT, Ren YX, Guo NB, Shao X (2016) Experimental studies on the mechanical properties and deformation & failure mechanism of U-type confined concrete arch centering.Tunn Undergr Sp Tech 51:20–29

Wang Q, Jiang B, Pan R, Li SC, He MC, Sun HB, Qin Q, Yu HC, Luan YC (2018b) Failure mechanism of surrounding rock with high stress and confined concrete support system. Int J Rock Mech Min 102:89–100

Wu AX, Chen SM, Wang YM, Chen X (2018) Failure mechanism and supporting measures for large deformation of soft rock roadway in Baluba copper mine. Arch Min Sci 63(2):449–464

Xie HP, Wang JH, Wang GF, Ren HW, Liu JZ, Ge SR, Zhou HW, Wu G, Ren SH (2018) New ideas of coal revolution and layout of coal science and technology development. J China Coal Soc 43(5):1187–1197

Xu ZL (2006) Elasticity. Higher Education Press, Beijing, pp 35–55

Yan H, Hu B, Xu T (2012) Study on the supporting and repairing technologies for difficult roadways with large deformation in coal mines. Eng Proc 14:1653–1658

Yang TH, Jia P, Shi WH (2014) Seepage-stress coupled analysis on anisotropic characteristics of the fractured rock mass around roadway. Tunn Undergr Sp Tech 43(7):11–19

Yu KP, Ren FY, Puscasu R, Lin P, Meng QG (2020) Optimization of combined support in soft-rock roadway. Tunn Undergr Sp Tech 103:103502

Yu Y, Zhu C, Chong D (2015) Catastrophe mechanism and disaster countermeasure for soft rock roadway surrounding rock in meihe mine. Int J Rock Mech Min 25(3):407–413

Zhang XN (2019) Study on mechanical properties and model test of concrete filled steel tubular arch frame. Dissertation, China University of Mining and Technology, Beijing

Zhang YB, Liu XR, Liu X, Wang SY, Ren FY (2019) Numerical characterization for rock mass integrating GSI/Hoek-Brown system and synthetic rock mass method. J Struct Geol 126:318–329

Zhao Y, Yang YL, Xu SQ, Liu JP, Chen YF (2020) Shear connection of reinforcement stiffened cold-formed U-shaped steel and concrete composite beam. Eng Struct 219:110862

Zuo JP, Cao GM, Sun YJ, Wang JT, Chen Y (2016) Destructive mechanics of mining surrounding rock and practice of cooperative control in full space. Science Press, Beijing, pp 246–256

Zuo JP, Wen JH, Li YD, Sun YJ, Wang JT, Jiang YQ, Liu L (2019) Investigation on the interaction mechanism and failure behavior between bolt and rock-like mass. Tunn Undergr Sp Tech 93:1–14

Funding

This study was supported by the Beijing Outstanding Young Scientist Program (BJJWZYJH01201911413037), Shannxi Coal Group Key Project (2018SMHKJ-A-J-03), Natural Science Foundation of China (No. 51878658, NO 51508584 and NO.51622404), Key Laboratory of Geotechnical and Underground Engineering (Tong ji University), Ministry Education (KLE-TJGE-B1705), and Yueqi outstanding scholar Award Program by CUMTB.

Author information

Authors and Affiliations

Contributions

Jianping Zuo, Haiyan Liu, Dejun Liu, Jun Wang, Tangliang Zhang, and Fei Xu contributed to the study conception and design. Haiyan Liu and Dejun Liu performed the numerical simulation, and Haiyan Liu, Dejun Liu, Jun Wang, Tangliang Zhang, and Fei Xu performed the field test. The first draft of the manuscript was written by Jianping Zuo, and all the authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Rights and permissions

About this article

Cite this article

Zuo, J., Liu, H., Liu, D. et al. Study on large deformation mechanism and concrete-filled steel tubular support technology for ventilation shaft roadway. Bull Eng Geol Environ 80, 6245–6262 (2021). https://doi.org/10.1007/s10064-021-02331-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10064-021-02331-1