Abstract

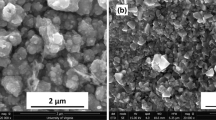

The Cu(In0.7Ga0.3)Se2 nano solar cell pn junction structure consist of six layers of Al/CIGS/nano-CIGS/CdS/ITO/PET with thicknesses about 200, 500, 70, 100, 150 nm and 170 um were deposited by thermal evaporation technique at vacuum pressure 2 × 10–5 mbar respectively. where the ITO/PET conductive flexible substrate with sheet resistance 15 Ohms per sq. The X-ray diffraction analysis showed that as-deposited thin films CIGS and CdS are polycrystalline where optical energy gap and carrier concentration are found that 1.15 and 2.38 eV with p = 3.58 × 1010 cm–3 and n = 3.11 × 1013 cm–3 respectively. CIGS nano solar cell thin films are deposited on CdS/ITO/PET with assistance of inlet Argon gas vacuum pressure at 1, 5, 20 mbar by thermal evaporation technique at room temperature by using Inert gas condensation (IGC) is the method by which one can deposit films with high purity as deposition is done in low vacuum. The high magnification SEM image of CIGS nano-structures synthesized at 20 mbar revealed that the particles have exact spherical shape with sizes ranged from few nanometers to hundreds nanometers due to agglomeration effect. It was found that the grain size and the root mean square of surface roughness increases as Argon gas pressure increase. Therefore the structure of CIGS thin films has been changed from polycrystalline to nanostructure and have been found with increase Argon gas vacuum pressure from 1mbar to 5 mbar and then 20 mbar will increase grain size at 2θ = 32° from 15.9, 18.9 and 25.7 nm with decrease optical energy gap from 1.54, 1.44 and 1.26 eV respectively. The results showed the efficiency increase from 1.37% of CIGS/CdS to 2.01% of CIGS nano thin films of solar cells.

Similar content being viewed by others

References

Javed, A., Turk. J. Phys., 2007, vol. 31, pp. 287–294.

Lauwaert, J., Puyvelde, L.V., Lauwaert, J., et al., Solar En. Mater. Solar Cells, 2013, vol. 112, pp. 78–83.

Park, S.U., Sharma, R., Ashok, K., et al., J. Crystal Growth, 2012, vol. 359, pp. 1–10.

Mustafa, F.I., Gupta, Sh., Goyal, N., and Tripathi, S.K., Phys. Status Solidi C, 2009, vol. 6, no. S1, pp. 135–138.

Harrison, M.T., Kershaw, S.V., Burt, M.G., et al., Pure Appl. Chem., 2000, vol. 72, p. 295.

Zhang, F., Krishnaswamy, S., and Lilley, C.M., Ultrasonics, 2006, vol. 45, p. 66.

Wu, J., Li, P., Hao, S., Yang, H., and Lan, Z., El. Chim. Acta, 2007, vol. 52, p. 5334.

Hazra, R.K., Ghosh, M., and Bhattacharyya, S.P., Chem. Phys., 2007, vol. 333, p. 18.

Kovalevskij, V. and Gulbinas, V., Acta Physica Polonica A, 2005, vol. 107, p. 351.

Lyubin, V.M., Klebanov, M., Sfez, B., and Ashkinadze, B., Mater. Lett., 2004, vol. 58, p. 1706.

Efros, A.L. and Efros, A.L., Sov. Phys. Semicond., 1982, vol. 16, p. 772.

Halperin, W.P., Rew. Mod. Phys., 1986, vol. 58, p. 533.

Alivisatos, A.P., Science, 1996, vol. 271, p. 933.

Freitas, J.C.C., Nunes, E., Passamani, E.C., et al., Acta Materialia, 2006, vol. 54, p. 5095.

Wang, X.W., Fei, G.T., Zheng, K., et al., Appl. Phys. Lett., 2006, vol. 88, p. 173114.

Nanda, K.K., Chem. Phys. Lett., 2006, vol. 419, p. 195.

Li, M. and Li, J.C., Mater. Lett., 2006, vol. 60, p. 2526.

Gleiter, H., Prog. Mater. Sci., 1989, vol. 33, p. 223.

Uyeda, R., Prog. Mater. Sci., 1991, vol. 35, p. 1.

Yatsuya, S., Kasukabe, S., and Uyeda, R., Jpn. J. Appl. Phys., 1973, vol. 12, p. 1675.

Granqvist, C.G. and Buhrman, R.A., J. Appl. Phys., 1976, vol. 47, p. 2200.

Tholen, A.R., Acta Metallurgica, 1979, vol. 27, p. 1765.

Massiot, I., Vandamme, N., Bardou, N., et al., ACS Photonics, 2014, vol. 1, no. 9, pp. 878–884.

Jackson, P., Hariskos, D., Wuerz, R., et al., Phys. Status Solidi RRL, 2015, vol. 9, pp. 28–31.

Best Research Cell Efficiencies. http://www.nrel. gov/ncpv/images/effi-ciency_chart.jpg.

Chirilă, A., Reinhard, P., Pianezzi, F., et al., Nature Mater., 2013, vol. 12, p. 1107.

Pianezzi, F., Reinhard, P., Chirilă, A., et al., Phys. Chem. Chem. Phys., 2014, vol. 16, p. 8843.

Pianezzi, F., Chirilá, A., Blösch, P., et al., Prog. Photovolt: Res. Appl., 2012, vol. 20, p. 253.

Solar Frontier HP.http://www.solarfrontier.com/eng/news/2015/C046576.html/.

Minemoto, T., Abe, Y., Anegawa, T., et al., Jpn. J. Appl. Phys., 2010, vol. 49, p. 04DP06.

Caballero, R., Kaufmann, C.A., Eisenbarth, T., et al., Photovolt: Res. Appl., 2011, vol. 19, p. 547.

Wuerz, R., Eicke, A., Kessler, F., and Pianezzi, F., Sol. Energy Mater. Sol. Cells, 2014, vol. 130, p. 107.

Wuerz, R., Eicke, A., Kessler, F., et al., Thin Solid Films, 2011, vol. 519, p. 7268.

Satoh, T., Hashimoto, Y., Shimakawa, S., et al., Sol. Energy. Sol. Cells, 2003, vol. 75, p. 65.

Yogioka, T. and Nakada, T., Appl. Phys. Express., 2009, vol. 2, p. 072201.

Herz, K., Kessler, F., Wächter, R., et al., Thin Solid Films, 2002, vol. 403–404, p. 384.

Kapur, V.K., Bansal, A., Le, P., and Asensio, O.I., Thin Solid Films, 2003, vol. 431-432, p. 53.

Ishizuka, S., Yamada, A., Matsubara, K., et al., Curr. Appl. Phys., 2010, vol. 10, p. S154.

Ishizuka, S., Hommoto, H., Kido, N., et al., Appl. Phys. Express., 2008, vol. 1, p. 092303.

Grzeta-Plenkovic, B., Popovic, S., Celustka, B., and Santic, B., J. Appl. Cryst., 1980, vol. 13, pp. 311–315.

Birkmire, R.W. and Eser, E., Ann. Rev. Mater. Sci., 1997, vol. 27, p. 625.

Sze, S.M. and Kwok, K.N., Physics of Semiconductor Devices, 3rd Ed., John Wiley & Sons, 2007.

Author information

Authors and Affiliations

Corresponding author

Additional information

The article is published in the original.

About this article

Cite this article

Mustafa, F.I., Abdsalam, Z. & Jabbar, M.A. Cigs flexible nano solar cell by inert argon gas condensation. Appl. Sol. Energy 53, 167–172 (2017). https://doi.org/10.3103/S0003701X17020116

Received:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0003701X17020116