Abstract

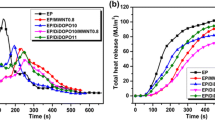

In this study, the aromatic carbon content of epoxy resin (EP) increased via carbon tar pitch (CTP) modification, and the CTP occurred self-polymerization reaction. The carboxyl and hydroxyl groups of CTP and the hydroxyl and carboxyl groups of EP occurred chemical cross-linking reaction. CTP and graphitization treatment promoted EP CF carbon crystal growth. The graphitization degree of pure EP CF and 40 wt% CTP modified EP CF are 8.42% and 44.21%, respectively. With the increase CTP content, the cell size, ligament junction and density of graphitization modified EP CF gradually increased, while the number of pores and cells gradually decreased. The cell size, ligament junction size and density of 40 wt% CTP modified graphitization EP CF increased to 1200 μm, 280 μm and 0.5033 g/cm3, respectively. EP CF exhibits entangling carbon ribbon and isotropic amorphous carbon. The 40 wt% CTP modified EP CF is composed of evenly distributed amorphous resin carbon and graphite domain CTP carbon. The graphitization modified EP CF improved electrical conductivity, and the electrical conductivity of 40 wt% CTP modified EP CF is 126.6 S/m. The compressive strength can be decided by EP carbon strength and its char yield, and graphitization 40 wt% CTP modified EP CF reached 4.9 MPa. This study provides some basis for preparation and application of CTP modified EP CF.

Similar content being viewed by others

Data availability

The data availability is provided by a reasonable way.

References

Xiao BH, Lin RT, Xiao K, Liu ZQ (2022) A highly compressible, nitrogen doped carbon foam based all pseudo-capacitance asymmetric supercapacitors. J Power Sources 530:231307

Ma XD, Jia C, Liu YK, Yu XY, Xiong XH (2022) Oxygen-rich graphene vertically grown on 3D N-doped carbon foam for high-performance sodium ion batteries. J Power Sources 530:231292

Zhang LY, Liu M, Roy S, Chu EK, See KY, Hu X (2016) Phthalonitrile-based carbon foam with high specific mechanical strength and superior electromagnetic interference shielding performance. ACS Appl Mater Inter 8(11):7422–7430

Zhi MY, Liu QY, Chen H, Chen XT, Feng SH, He YH (2019) Thermal stability and flame retardancy properties of epoxy resin modified with functionalized graphene oxide containing phosphorus and silicon elements. ACS Omega 4(6):10975–10984

Choudhary HK, Kumar R, Pawar SP, Sahoo B (2021) Role of graphitization-controlled conductivity in enhancing absorption dominated EMI shielding behavior of pyrolysis-derived Fe3C@C-PVDF nanocomposites. Mater Chem Phys 263:124429

Yang N, Lu K (2021) Effects of transition metals on the evolution of polymer-derived SiOC ceramics. Carbon 171:88–95

Konno H, Shiba K, Kaburagi Y, Hishiyama Y, Inagaki M (2001) Carbonization and graphitization of Kapton-type polyimide film having boron-bearing functional groups. Carbon 39(11):1731–1740

Yum SH, Kim SH, Lee W, Kim H (2015) Improvement of ablation resistance of phenolic composites reinforced with low concentrations of carbon nanotubes. Compos Sci Technol 121:16–24

Kim SG, Heo SJ, Kim S, Kim J, Kim SO, Lee D, Lee S, Kim J, You NH, Kim M, Kim HC, Chae HG, Ku BC (2022) Ultrahigh strength and modulus of polyimide-carbon nanotube-based carbon and graphitic fibers with superior electrical and thermal conductivities for advanced composite applications. Compos B Eng 247:110342

Makomaski G, Ciesinska W, Zielinski J (2012) Thermal properties of pitch-polymer compositions and derived activated carbons. J Therm Anal Calorim 109(2):767–772

Yang XX, Zhao S, Zhang ZZ, Chi Y, Yang CM, Wang CT, Zhen YZ, Wang DJ, Fu F, Chi R (2022) Pore structure regulation of hierarchical porous carbon derived from coal tar pitch via pre-oxidation strategy for high-performance supercapacitor. J Colloid Interf Sci 614:298–309

Ortego EV, Agulló JAM, Monge JA, Amorós DC, Solano AL (2008) Comparative study of the micropore development on physical activation of carbon fibers from coal tar and petroleum pitches. Micropor Mesopor Mater 112(1–3):125–132

Xu HT, Guo JG, Li WL, Li XK (2008) The effect of the molecular structure of naphthalene-based mesophase pitch on the properties of carbon fibers derived from it. New Carbon Mater 112(1–3):125–132

Im US, Kim J, Lee BR, Peck DH, Jung DH (2019) Mechanical and electrical properties of MCMB/chopped carbon fiber composite with different bead size. Sci Rep 9(1):7065

Kim JH, Jo AY, Choi YJ, Lee KB, Im JS, Bai BC (2020) Improving the mechanical strength of carbon-carbon composites by oxidative stabilization. J Mater Res Technol 9(6):16513–16521

Hong J, Wu T, Wang X, Lu ZW, Zhang JL, Zeng BR, Yuan CH, Dai LZ (2022) Copper-catalyzed pyrolysis of halloysites@polyphosphazene for efficient carbonization and smoke suppression. Compos Part B Eng 230:109547

Dang AL, Li H, Li TH, Zhao TK, Xiong CY, Zhuang Q, Shang YD, Chen XD, Ji XL (2016) Preparation and pyrolysis behavior of modified coal tar pitch as C/C composites matrix precursor. J Anal Appl Pyrol 119:18–23

Yumitori SJ (1996) Effect of anodic oxidation of coal tar pitch-based carbon fiber on adhesion in epoxy matrix: part 1. Comparison between H2SO4 and NaOH solutions. Compos A Appl 27(11):1051–1058

Wen H, Zhang XX, Xia R, Yang ZL, Wu YJ (2019) Thermal decomposition properties of epoxy resin in SF6/N2 mixture. Materials 12(1):75

Duan ZY, Fiquet O, Ablitzer C, Cassayre L, Vergnes H, Floquet P, Joulia X (2021) Application of pyrolysis to remove hydrogen from an organic nuclear waste. J Hazard Mater 401:123367

Liu HG, Li TH, Wang XL, Zhang WJ, Zhao TK (2014) Preparation and characterization of carbon foams with high mechanical strength using modified coal tar pitches. J Anal Appl Pyrol 110:442–447

Yu M, Zhong CZ, Zhang YH, Chen QL, Ao XQ, Lei XY, Li CQ (2018) Pyrolysis behavior and chemical composition of the precursors influence on structure and properties of coal-tar-pitch-based carbon foams. J Anal Appl Pyrol 134:293–300

Liu CQ, Zhang LY, Yuan XX, Li X, Wu YT, Wang XF (2019) Effect of ZrC formation on graphitization of carbon Phase in polymer derived ZrC–C ceramics. Materials 12(24):4153

Kumari K, Rani S, Kumar P, Prakash S, Dhakate SR, Kumari S (2023) Study of mesophase pitch based carbon fibers: Structural changes as a function of anisotropic content. J Anal Appl Pyrol 171:105961

Huang XY, Yan M, Lu HL, Zhong YD, Luo H, Tian CC, Yang P, Ni YY, Zhou XF (2022) A novel method to synthesize high-strength elastic gel and carbonized aerogel. Appl Surf Sci 580:152240

Acknowledgements

This research was funded by the National Natural Science Foundation of China (52072302, 51872235 and 51802267), the Key Industrial Chain Project Shaanxi Province (2020ZDLGY11-04), the Fundamental Research Funds for the Central Universities (3102021TS0405).

Author information

Authors and Affiliations

Contributions

PJY: conceptualization, methodology, data curation, investigation, formal analysis, writing-original draft. THL: conceptualization, funding acquisition, supervision. HL: conceptualization, supervision. ALD: investigation, supervision.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yang, P.J., Li, T.H., Li, H. et al. Microstructure, electrical conductivity and mechanical properties of graphitization carbon foam derived from epoxy resin modified with coal tar pitch. Carbon Lett. 34, 1065–1073 (2024). https://doi.org/10.1007/s42823-023-00642-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42823-023-00642-9