Abstract

In this study, within the framework of the unified viscoplastic cyclic constitutive theory, a cyclic constitutive model is developed based on the modified Chaboche nonlinear kinematic hardening rule. The proposed model improves the prediction of stress relaxation and relaxation stress decay behavior of P92 steel with cycling through the flow rule of hyperbolic sine and static recovery term coupled with accumulative plastic strain and introduces the plastic strain range memory effect to better describe the cyclic softening characteristics of P92 steel. The proposed model is written into the user subroutine of finite element software ABAQUS. Strain-controlled low-cycle fatigue (LCF) and creep–fatigue interaction behavior simulations are performed for the ferritic–martensitic stainless steel P92 at different temperatures and different mechanical strain ranges, respectively. Moreover, a preliminary prediction of the LCF behavior of P92 steel under non-isothermal conditions is provided. By comparing with the experimental results, it can be found that the proposed modified model can provide positive simulation results.

Graphical abstract

Similar content being viewed by others

Data availability

All the data generated or analyzed during this study are included in this article.

Code availability

Not applicable.

References

Zhang SL, Xuan FZ (2017) Interaction of cyclic softening and stress relaxation of 9–12% Cr steel under strain-controlled fatigue-creep condition: experimental and modeling. Int J Plast 98:4–64. https://doi.org/10.1016/j.ijplas.2017.06.007

Wang XW, Zhang TY, Zhang W (2021) An improved unified viscoplastic model for modelling low cycle fatigue and creep fatigue interaction loadings of 9–12%Cr steel. Eur J Mech A Solids 85:104123. https://doi.org/10.1016/j.euromechsol.2020.104123

Zhang Z, Hu ZF, Schmauder S (2016) Low-cycle fatigue properties of P92 ferritic-martensitic steel at elevated temperature. J Mater Eng Perform 25:1650–1662. https://doi.org/10.1007/s11665-016-1977-8

Jürgens M, Olbricht J, Fedelich B et al (2019) Low cycle fatigue and relaxation performance of ferritic–martensitic grade P92 steel. Metals 9(1):99. https://doi.org/10.3390/met9010099

Jürgens M (2020) Verhalten des hochwarmfesten Stahles P92 unter zyklischen thermo-mechanischen Bedingungen in lastflexiblen Dampfkraftwerken. Dissertation, Technische Universität Berlin. https://depositonce.tu-berlin.de/handle/11303/11653.

Chaboche JL (1989) Constitutive equations for cyclic plasticity and cyclic viscoplasticity. Int J Plast 5:247–302. https://doi.org/10.1016/0749-6419(89)90015-6

Bari S, Hassan T (2002) An advancement in cyclic plasticity modeling for multiaxial ratcheting simulation. Int J Plast 18(7):873–894. https://doi.org/10.1016/S0749-6419(01)00012-2

Abdel-Karim M, Ohno N (2000) Kinematic hardening model suitable for ratchetting with steady-state. Int J Plast 16:225–240. https://doi.org/10.1016/S0749-6419(99)00052-2

Kang G, Ohno N, Nebu A (2003) Constitutive modeling of strain range dependent cyclic hardening. Int J Plast 19(10):1801–1819. https://doi.org/10.1016/S0749-6419(03)00016-0

Chen X, Jiao R (2004) Modified kinematic hardening rule for multiaxial ratcheting prediction. Int J Plast 20:871–898. https://doi.org/10.1016/j.ijplas.2003.05.005

da Costa-Mattos H, Pacheco PMCL (2009) Non-isothermal low-cycle fatigue analysis of elasto-viscoplastic materials. Mech Res Commun 36(4):428–436. https://doi.org/10.1016/j.mechrescom.2008.12.003

Del Vecchio FJC, Reis JML, da Costa Mattos HS (2014) Elasto-viscoplastic behaviour of polyester polymer mortars under monotonic and cyclic compression. Polym Test 35:62–72. https://doi.org/10.1016/j.polymertesting.2014.02.007

da Costa Mattos HS, Reis JML, De Medeiros LGMO et al (2017) Analysis of the cyclic tensile behaviour of an elasto-viscoplastic polyamide. Polym Test 58:40–47. https://doi.org/10.1016/j.polymertesting.2016.12.009

Motta EP, Reis JML, da Costa Mattos HS (2018) Analysis of the cyclic tensile behaviour of an elasto-viscoplastic polyvinylidene fluoride (PVDF). Polym Test 67:503–512. https://doi.org/10.1016/j.polymertesting.2018.03.012

Metzger M, Seifert T (2013) On the exploitation of Armstrong–Frederik type nonlinear kinematic hardening in the numerical integration and finite-element implementation of pressure dependent plasticity models. Comput Mech 52:515–524. https://doi.org/10.1007/s00466-003-0454-z

Chaboche JL (2008) A review of some plasticity and viscoplasticity constitutive theories. Int J Plast 24:1642–1693. https://doi.org/10.1016/j.ijplas.2008.03.009

Szmytka F, Rémy L, Maitournam H et al (2010) New flow rules in elasto-viscoplastic constitutive models for spheroidal graphite cast-iron. Int J Plast 26(6):905–924. https://doi.org/10.1016/j.ijplas.2009.11.007

Lemaitre J, Chaboche JL (1994) Mechanic of solid materials. Cambridge University Press, Cambridge

Bartošák M, Španiel M, Doubrava K (2020) Unified viscoplasticity modelling for a SiMo 4.06 cast iron under isothermal low-cycle fatigue-creep and thermo-mechanical fatigue loading conditions. Int J Fatigue 136:105566. https://doi.org/10.1016/j.ijfatigue.2020.105566

Cao WY, Yang JJ, Zhang HL (2021) Unified constitutive modeling of Haynes 230 including cyclic hardening/softening and dynamic strain aging under isothermal low-cycle fatigue and fatigue-creep loads. Int J Plast 112:102922. https://doi.org/10.1016/j.ijplas.2020.102922

Ahmed R, Hassan T (2017) Constitutive modeling for thermo-mechanical low-cycle fatigue-creep stress–strain responses of Haynes 230. Int J Solids Struct 126:122–139. https://doi.org/10.1016/j.ijsolstr.2017.07.031

Wu Z, Chen X, Fan Z (2022) Study of high-temperature low-cycle fatigue behavior and a unified viscoplastic-damage model for heat-resistant cast iron. J Materi Eng Perform 31:8136–8147. https://doi.org/10.1007/s11665-022-06803-7

Chaboche JL, Rousselier G (1983) On the plastic and viscoplastic constitutive equations—part II: application of internal variable concepts to the 316 stainless steel. J Press Vess Technol 105:159–164. https://doi.org/10.1115/1.3264258

Ohno N, Kachi Y (1986) A constitutive model of cyclic plasticity for nonlinear hardening materials. J Appl Mech Trans ASME doi 10(1115/1):3171771

Zhang T, Wang X, Zhou D (2022) A universal constitutive model for hybrid stress-strain controlled creep-fatigue deformation. Int J Mech Sci 225:107369. https://doi.org/10.1016/j.ijmecsci.2022.107369

Barrett PR, Hassan T (2020) A unified constitutive model in simulating creep strains in addition to fatigue responses of Haynes 230. Int J Solids Struct 185:394–409. https://doi.org/10.1016/j.ijsolstr.2019.09.001

Kan Q, Zhao J, Xu X (2022) Temperature-dependent cyclic plastic deormation of U75VG rail steel: experiments and simulations. Eng Fail Anal 140:106527. https://doi.org/10.1016/j.engfailanal.2022.106527

Krovvidi SK, Goyal S, Veerababu J (2022) Viscoplastic constitutive parameters for inconel alloy-625 at 843 K. In: Jonnalagadda K, Alankar A, Balila NJ, Bhandakkar T (eds) Advances in structural integrity: structural integrity over multiple length scales. Springer, Berlin, pp 27–39. https://doi.org/10.1007/978-981-16-8724-2_3

Nouailhas D, Cailletaud G, Policella H et al (1985) On the description of cyclic hardening and initial cold working. Eng Fract Mech 21:887–895. https://doi.org/10.1016/0013-7944(85)90095-5

Zhang Z, Delagnes D, Bernhart G (2002) Anisothermal cyclic plasticity modelling of martensitic steels. Int J Fatig 24:635–648. https://doi.org/10.1016/S0142-1123(01)00182-7

Zheng WJ, Zhu JJ, Yuan WH (2023) Tempering stress relaxation behavior and microstructure evolution of 300 M steel. Mater Charact. https://doi.org/10.1016/j.matchar.2023.112688

Chen HS, Du LH, Khan MS et al (2022) A unified model to predict the hot stamping and subsequent stress-relaxation process of a Ti-6Al-4V alloy. J Mater Sci Eng. https://doi.org/10.1088/1757-899X/1270/1/012098

Dattoma V, Marta DG, Nobile R (2022) An experimental study on residual stress relaxation in low-cycle fatigue of Inconel 718Plus. Fatigue Fract Eng M. https://doi.org/10.1111/FFE.13864

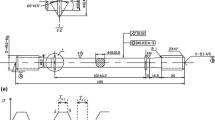

ISO 12106 (2017) Metallic materials. Fatigue test. Uniaxial test using strain control method, International Organization for Standardization. https://www.iso.org/standard/64687.html

Wang Y (2014) Experimental and numerical evaluations of viscoplastic material behaviour and multiaxial ratchetting for austenitic and ferritic materials. PhD thesis, Universität Stuttgart, Institut für Materialprüfung, Werkstoffkunde und Festigkeitslehre

Chaboche JL, Nouailhas D (1989) Constitutive modeling of ratchetting effects—part II: possibilities of some additional kinematic rules. ASME J Eng Mater Technol 111(4):384–392. https://doi.org/10.1115/1.3226488

Saad AA, Hyde TH, Sun WH et al (2013) Characterization of viscoplasticity behaviour of P91 and P92 power plant steels. Int J Pres Ves Pip 111:246–252. https://doi.org/10.1016/j.ijpvp.2013.08.001

Borrego LP, Abreu LM, Costa JM et al (2004) Analysis of low cycle fatigue in AlMgSi aluminium alloys. Eng Fail Anal 11:715–725. https://doi.org/10.1016/j.engfailanal.2003.09.003

Acknowledgements

This work is partly supported by the Natural Science Foundation of Hebei Province, China (No. E2021501011), and Central University Basic Scientific Research Business Expenses (No. N2123028).

Funding

This study was funded by the Natural Science Foundation of Hebei Province, China (No. E2021501011), and Central University Basic Scientific Research Business Expenses (No. N2123028).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

No conflict of interest has been declared by the author(s).

Additional information

Technical Editor: João Marciano Laredo dos Reis.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix 1

Appendix 1.1: Numerical discretization

Since the experiments were performed under isothermal conditions, the temperature rate and temperature strain rate were zero. First, the backward Euler method was used to discretize the constitutive equations, and the following expressions were obtained for the time interval from the \(n{\text{th}}\) to the \(n + 1{\text{th}}\) step (\(\Delta t_{n + 1} = t_{n + 1} - t_{n}\)):

The yield surface is discretized as Eq. (36)

Next, the isotropic hardening is discretized as follows:

where \(k = \frac{1}{{1 + D\Delta p_{n + 1} }}\).

The mean stress evolution tensor \(Y_{n + 1}^{(i)}\) is discretized to obtain:

Simplifying Eq. (38), the following is given:

where \(\varphi^{(i)} = \frac{1}{{1 + \alpha_{b}^{(i)} J\left( {{{\varvec{\upalpha}}}_{n + 1}^{(i)} } \right)^{{m^{(i)} }} \Delta t}}\), \(\rho^{(i)} = \alpha_{b}^{(i)} Y_{st}^{(i)} J\left( {{{\varvec{\upalpha}}}_{n + 1}^{(i)} } \right)^{{m^{(i)} - 1}} \Delta t\).

The back stress evolution equation is expressed as Eq. (40):

where \(w^{(i)} = \frac{1}{{1 + \gamma^{(i)} \delta^{\prime}\Delta p_{n + 1} + \gamma^{(i)} \varphi^{(i)} \rho^{(i)} \Delta p_{n + 1} + b^{(i)} J\left( {{{\varvec{\upalpha}}}_{n + 1}^{(i)} } \right)^{{m^{(i)} - 1}} \Delta t}}\).

Appendix 1.2: Implicit stress integration method

The implicit integration method, also known as the radial regression method, is used in this paper. In this method, the stress return mapping uses an elastic prediction-inelastic correction process. Thus, the stress tensor can be written as Eq. (41):

where G is the shear. The test stress of von Mises is indicated as follows:

According to the von Mises test stress, the effect force such as von Mises can be obtained:

Then, the stress normal can be rewritten as a function of the trial quantities::

The viscoplastic flow rule is in hyperbolic sinusoidal form, and then the expression for \(\dot{p}_{n + 1}\) is as follows:

Newton–Raphson iteration method is used to solve for \(\Delta p\):

where

And we substitute Eqs. (48)–(50) into Eq. (47) to simplify the formula about \(\Delta p\):

Appendix 1.3: Consistent material tangent operator

During the finite element implementation, the user needs to provide subroutines containing the constitutive equations and the consistent tangent stiffness matrix to maintain the quadratic convergence of the global Newtonian method. The formulation of the consistent tangent stiffness matrix depends on the chosen integration format and the constitutive equation.

Differentiating the discrete constitutive equations:

The above formula is expressed by the deviation stress tensor:

The partial stress tensor can be written as follows using the stress tensor and the strain tensor:

The test deviation stress tensor can be expressed by the strain tensor:

where K indicates the bulk modulus and I shows the identity matrix.

The stress normals are expressed as:

Rearranging the above equation:

Substituting Eqs. (57) and (61) into Eq. (56), we obtain:

Differentiating the effective viscoplastic strain increment, we obtain:

where

Substituting Eqs. (63), (64) and (35) into Eq. (62) and simplifying gives:

where

Substituting \(\delta \Delta p\),\(\delta \sigma_{e}\) and \(\delta \sigma_{e}^{{{\text{tr}}}}\) into Eq. (61) to obtain consistent tangent stiffness (CTS), the definition of the terms in the CTS is described in Eq. (69):

From the above equation, the Jacobian matrix is finally obtained as (Table

4):

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhu, L., Chen, X., Lang, L. et al. Study of high-temperature uniaxial low cyclic fatigue and creep–fatigue behavior of P92 steel using a unified viscoplastic constitutive model. J Braz. Soc. Mech. Sci. Eng. 46, 50 (2024). https://doi.org/10.1007/s40430-023-04610-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-023-04610-2