Abstract

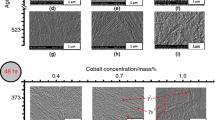

In order to develop the main applications of Cu-based shape memory alloys (SMAs), the effect of annealing time and temperature on the microstructure, mechanical properties, and shape memory characteristics of Cu-Al-Ni-xCo SMAs (x is 0.38, 0.6, and 1.2 wt.%) were studied. A distinct consideration is lent to the microstructural changes, phase transformation, and mechanical properties, which might take place in accordance with the changes in the alloying element/composition and/or heat treatment implementation. Because of this, the microstructural changes were portrayed using a variable-pressure scanning electron microscope, energy-dispersive spectrometer, and x-ray diffraction. The strength and hardness were determined using a universal Instron testing machine and Vickers hardness testing machine, respectively. The shape memory test was carried out using specially designed with an insulated system. The results indicated that the phase transformation of Cu-Al-Ni-xCo SMAs can be changed by varying the annealing temperature and time, and subsequent annealing can cause an effective impact on the shape memory effect. Moreover, it was also realized that the annealing treatment is involved in controlling the presence of γ 2 phase precipitate, thereby, improving the mechanical properties. The highest fracture stress and strain of 860.94 MPa and 9.43%, respectively, were determined in the Cu-Al-Ni-0.6 wt.% Co SMAs after being annealed at 500 °C for 3 h. In particular, the Cu-Al-Ni-1.2 wt.% Co SMAs obtained 84.08% recovery, which is the highest strain recovery after being annealed at 500 °C for 3 h.

Similar content being viewed by others

References

H. Funakubo, Shape Memory Alloys (CRC Press LLC, Boca Raton, 1987)

M. Kumar, R. Gupta, Introduction to Shape Memory Alloys (Springer, Berlin, 2008)

D.C. Lagoudas, Shape Memory Alloys: Modeling and Engineering Applications (Springer, Berlin, 2008)

S. Saud et al., Thermal aging behavior in Cu–Al–Ni–xCo shape memory alloys. J. Therm. Anal. Calorim. 119(2), 1273–1284 (2015)

M.I.A.E. Aal, Influence of the pre-homogenization treatment on the microstructure evolution and the mechanical properties of Al–Cu alloys processed by ECAP. Mater. Sci. Eng. A 528(22–23), 6946–6957 (2011)

M.A. Morris, S. Gunter, Effect of heat treatment and thermal cycling on transformation temperatures of ductile Cu-Al-Ni-Mn-B alloys. Scr. Metall. Mater. 26(11), 1663–1668 (1992)

S. Saud et al., Structure-property relationship of Cu-Al-Ni-Fe shape memory alloys in different quenching media. J. Mater. Eng. Perform. 23(1), 255–261 (2014)

A. Melzer, D. Stockel, Using shape-memory alloys. Med. Device Technol. 6(4), 16–20, 22–3 (1995)

R. Dasgupta, A look into Cu-based shape memory alloys: present scenario and future prospects. J. Mater. Res. 29(16), 1681–1698 (2014)

S. Miyazaki et al., The fracture of Cu–Al–Ni shape memory alloy. Trans. Jpn. Inst. Met. 22(4), 244–252 (1981)

Y. Sutou et al., Effects of grain size and texture on damping properties of Cu–Al–Mn-based shape memory alloys. Mater. Sci. Eng. A 438, 743–746 (2006)

J. Fernández et al., Thermal stability of the martensitic transformation of Cu–Al–Ni–Mn–Ti. Mater. Sci. Eng. A 438–440, 723–725 (2006)

S. Saud et al., Influence of Ti additions on the martensitic phase transformation and mechanical properties of Cu–Al–Ni shape memory alloys. J. Therm. Anal. Calorim. 118, 1–12 (2014)

R.D. Dar, H. Yan, Y. Chen, Grain boundary engineering of Co–Ni–Al, Cu–Zn–Al, and Cu–Al–Ni shape memory alloys by intergranular precipitation of a ductile solid solution phase. Scr. Mater. 115, 113–117 (2016)

S. Montecinos et al., Grain size evolution in Cu-based shape memory alloys. J. Mater. Sci. 50(11), 3994–4002 (2015)

E. Mazzer et al., Thermodynamic analysis of the effect of annealing on the thermal stability of a Cu–Al–Ni–Mn shape memory alloy. Thermochim. Acta 608, 1–6 (2015)

C.A. Canbay, Z. Karagoz, Effects of annealing temperature on thermomechanical properties of Cu–Al–Ni shape memory alloys. Int. J. Thermophys. 34(7), 1325–1335 (2013)

M. Fremond, S. Miyazaki, Shape Memory Alloys, vol. 351 (Springer, Berlin, 2014)

K. Yildiz, M. Kok, Study of martensite transformation and microstructural evolution of Cu–Al–Ni–Fe shape memory alloys. J. Therm. Anal. Calorim. 115(2), 1509–1514 (2014)

S.N. Saud et al., Effect of Ta additions on the microstructure, damping, and shape memory behaviour of prealloyed Cu-Al-Ni shape memory alloys. Scanning 2017, 1–13 (2017)

U. Sarı, İ. Aksoy, Electron microscopy study of 2H and 18R martensites in Cu–11.92 wt% Al–3.78 wt% Ni shape memory alloy. J. Alloy. Compd. 417(1–2), 138–142 (2006)

U. Sari, Influences of 2.5wt% Mn addition on the microstructure and mechanical properties of Cu-Al-Ni shape memory alloys. Int. J. Miner. Metall. Mater. 17(2), 192–198 (2010)

S.H. Chang, Influence of chemical composition on the damping characteristics of Cu–Al–Ni shape memory alloys. Mater. Chem. Phys. 125(3), 358–363 (2011)

E. Patoor et al., Shape memory alloys, part I: general properties and modeling of single crystals. Mech. Mater. 38(5), 391–429 (2006)

S.N. Saud et al., Effect of quarterly element addition of cobalt on phase transformation characteristics of Cu-Al-Ni shape memory alloys. Metall. Mater. Trans. A 46(8), 3528–3542 (2015)

F. Sun et al., Investigation of early stage deformation mechanisms in a metastable β titanium alloy showing combined twinning-induced plasticity and transformation-induced plasticity effects. Acta Mater. 61(17), 6406–6417 (2013)

Acknowledgments

The author(s) would like to thank the Universiti Teknologi, Malaysia, for providing the financial support and facilities for this research.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ainul Haidar, M., Saud, S.N. & Hamzah, E. Microstructure, Mechanical Properties, and Shape Memory Effect of Annealed Cu-Al-Ni-xCo Shape Memory Alloys. Metallogr. Microstruct. Anal. 7, 57–64 (2018). https://doi.org/10.1007/s13632-017-0413-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13632-017-0413-2