Abstract

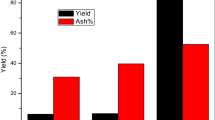

The focus of present research is to see the effectiveness of Pilot scale Batac jig for beneficiation of coarse (− 13 + 1 mm) low volatile coking coal from Jharia through a series experimentation wherein appropriate diverse process parameters were exploited for definitive study. The feed coal properties were measured in terms of proximate and ultimate analysis. The gross calorific value was observed as 5784 kcal/kg. The performance of jigging process observed layer wise, evidenced that the stroke length and air pressure of the process parameters were impressively provoking generation in potency of the process. The jigging experiments revealed that 24.6% ash content of concentrate was achieved with 76% yield from the feed ash content of 32.5% in top layers under optimum process conditions, whereas bottom layer contained 57.4% ash as the final reject. The jig product is promising and practicable for assured usage as blendable coking coal for making metallurgical coke.

Similar content being viewed by others

References

Geological Survey of India, Report, inventory of Indian coal resources, Government of India, New Delhi (2019).

Charan TG, Chattopadhyay US, Sinha KMK, Singh KMP & Singh PK, Beneficiation and utilization of low volatile coking coal and non-linked washery Indian coking coals for metallurgical purposes, J Mines, Metals and Fuels, 66 (2018) 365-369.

Chattopadhyay US & Charan TG, Utilization of high ash, low volatile coking coals of Jharia coalfield, India for coke making, Coke and Chemistry, 64 (2021) 12–17. https://doi.org/10.3103/S1068364X21010026.

Bhattacharya S, Coking coal preparation in India: problems and prospects. The South African Coal Processing Society, Int Coal Conference, Gauteng, South Africa, 1–18 (2009).

Andavarapu MR, Vidyadhar A & Prasad Ranjit, Beneficiation of difficult-to-wash Indian low volatile coking coal fines by Falcon concentrator, Intl J Coal Preparation and Utilization, in press (2021). https://doi.org/10.1080/19392699.2021.1984902.

Meyer EJ & Craig LK, Dynamic modelling for dense medium separation in coal beneficiation, 13th Symposium on Automation in Mining, Mineral and Metal Processing, Cape Town, South Africa 38–43 (2010).

Ambrós WM, Jigging: A review of fundamentals and future directions, Minerals, 10 (2020)1-31. https://doi.org/10.3390/min10110998.

Charan TG, Chattopadhyay US, Singh KMP, Kabiraj S & Haldar DD, Pilot-scale Baum jig washing for beneficiation of a high-ash Indian non-coking coal, Int J Coal Preparation and Utilization, 29 (2009) 130-139. https://doi.org/10.1080/19392690902936396.

Sanders GJ, Ziaja D & Kottmann J, Cost-efficient beneficiation of coal by ROMJIGs and BATAC jigs, Coal Preparation, 22 (2002) 181-197. https://doi.org/10.1080/07349340215010.

Tripathy A, Panda L, Sahoo AK, Biswal SK …. & Sahu AK, Statistical optimization study of jigging process on beneficiation of fine size high ash Indian non-coking coal. Advanced Powder Technology, 27 (2016) 1219–1224. https://doi.org/10.1016/j.apt.2016.04.006

Surowiak A, Evaluation of the results of coal jigging process, E3S Web of Conferences, 18 (2017) 1–6.https://doi.org/10.1051/e3sconf/20171801030.

Mishra BK & Adhikari B, Analysis of fluid motion during jigging, Minerals Engineering, 12 (1999) 1469-1477. https://doi.org/10.1016/50892-6875(99)00135-1.

Kowol D & Matusiak P, Use of a jig beneficiation process for obtaining mineral raw materials, Materials Science and Engineering, 545 (2019) 1-11. https://doi.org/10.1088/1757-899X/545/1/012006.

Mahmoud M. Ahmed, Optimization of a jigging process using statistical technique. Int J Coal Preparation and Utilization, 31 (2011) 112-123. https://doi.org/10.1080/19392699.2010.549383.

Will BA & Napier Munn T, Mineral Processing Technology: An Introduction to the Practical Aspects of Ore Treatment and Mineral, 7th Edition, Elsevier Science and Technology Books, October 2006, 444 pp, ISBN: 0750644508.

Acknowledgements

The authors acknowledge Dr. T. Gouri Charan, retired Chief Scientist, CSIR-CIMFR, Dhanbad for providing the LVC coal samples.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Andavarapu, M.R., Vidyadhar, A., Prasad, R. et al. Efficacy of Pilot Scale Batac Jig on LVC Coal Utilization for Coke Making. Trans Indian Inst Met 76, 1553–1561 (2023). https://doi.org/10.1007/s12666-023-02875-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-023-02875-8