Abstract

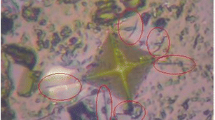

A novel method for preparing CuW composite containing micro- and nano-tungsten particles coated with SixWy phase via silicothermic coupling with aluminothermic reduction is presented in this paper. Compared with powder metallurgy, this method avoids the long sintering process at high temperatures and has the advantages of short process flow and low energy consumption. The thermodynamic equilibrium of the Al-Si-CuO-WO3 system was calculated, and CuW and slag samples were systematically analyzed. The results show that it is feasible to prepare a composite containing micro- and nano-tungsten particles coated with SixWy phase via silicothermic coupling with aluminothermic reduction, and the microstructure of CuW composites mainly composed of matrix, spherical tungsten particles wrapped with irregular SixWy phase and a small number of black inclusions. With an increase in RSi, the proportion of black inclusions decreased, tungsten-containing phases increased and the size distribution range and average diameter of tungsten-containing phases in slag showed an increasing trend.

Similar content being viewed by others

References

J. Zou, D. Song, H. Shi, and S. Liang, Mater. Res. Express 7(2), 26528 (2020).

X.J. Zhang, Z.K. Dai, and X.R. Liu, Acta Metall. Sin. 31(07), 761 (2018).

Q. Zhang, S. Liang, and L. Zhuo, Mater. Sci. Technol. 33(17), 2071 (2017).

G. He, P. Zhao, S. Guo, Y. Chen, G. Liu, and J. Li, J. Alloys Compd. 579, 71 (2013).

Y. Guo, H. Guo, B. Gao, X. Wang, Y. Hu, and Z. Shi, J. Alloys Compd. 724, 155 (2017).

C. Wang, S. Liang, F. Cao, and Q. Zhang, J. Alloys Compd. 816, 152506 (2019).

A. Ibrahim, M. Abdallah, and S.F. Mostalfa, Mater. Des. 30(4), 1398 (2009).

G.Q. Luo, L.M. Zhang, and W.S. Chen, J. Alloys Compd. 588, 49 (2014).

F.A.D. Costa, A.G.P.D. Silva, and U.U. Gomes, Powder Technol. 134(1), 123 (2003).

C. Wang, S.H. Liang, and F. Cao, J. Alloys Compd. 816(5), 152506 (2019).

Y. Li, J. Zhang, and G.Q. Luo, J. Mater. Res. Technol. 10, 121 (2021).

J.W. Wang, J.L. Fan, and H.R. Gong, J. Alloys Compd. 661, 553 (2016).

W.T. Qiu, Y. Pang, and Z. Xiao, Int. J. Refract. Met. Hard Mater. 61, 91 (2016).

V. Madhur, M. Srikanth, and A.R. Annamalai, Nanomaterials 11(2), 413 (2021).

C.S. Zhou, L.Y. Li, and J. Wang, J. Alloys Compd. 743, 383 (2018).

W.M. Daoush, J. Yao, and M. Shamma, Scr. Mater. 113(1), 246 (2016).

Q.Y. Chen, S.H. Liang, H. Zhang, and D.X. Liu, Adv. Powder Technol. Powder Technol. 32(3), 908 (2021).

Y.J. Guo, H.T. Guo, B.X. Gao, X.G. Wang, and Y.B. Hu, Adv. Powder Technol. Powder Technol. 724, 155 (2017).

T. Sarmah, N. Aomoa, and G. Bhattacharjee, J. Alloys Compd. 725, 606 (2017).

J.L. Johnson, J.J. Brezovsky, and R.M. German, Metall. Mater. Trans. A 36(10), 2807 (2005).

B.Q. Li, Z.Q. Sun, and G.L. Hou, Int. J. Refract. Met. Hard Mater. 56, 44 (2016).

L.C. Zhuo, J.L. Zhang, Q.Q. Zhang, et al., Vacuum 181, 109620 (2020).

C. Cheng, Z.W. Song, L.F. Wang, and L.S. Wang, Nanotechnol. Rev. 11(1), 760 (2022).

C. Cheng, K.X. Song, Z.W. Song, L.F. Wang, and Q.Q. Xu, JOM 74(3), 931 (2022).

C. Cheng, Z.W. Song, L.F. Wang, K.X. Song, and T. Huang, Rare Met. 41(12), 4047 (2022).

A.G. Merzhanov, J. Mater. Chem. 18, 7766 (2004).

Z.R. Tang and R.Z. Tian, Cent. South Univ. Press 51 (2009)

Acknowledgements

The authors thank the Natural Science Foundation of China (Grant No. 52204359), Chinese Postdoctoral Science Foundation (Grant No. 2022T150193), Natural Science Foundation of Henan Province (Grant No. 222300420154), Key Scientific Research Project of colleges and universities of Henan Province (Grant No. 22A450002), Foundation for Key Teacher by Henan University of Science and Technology (Grant No. 13450026), Zhongyuan Scholar Workstation Funded Project (Grant No. 224400510025) and Henan Key Research and Development Project (Grant No. 221111230600).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Cheng, C., Zhang, ME., Wang, XY. et al. Novel Synthesis of CuW Composite Containing Micro- and Nano-tungsten Particles Coated with SixWy Phase via Silicothermic Coupling with Aluminothermic Reduction. JOM (2024). https://doi.org/10.1007/s11837-024-06538-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11837-024-06538-x