Abstract

Several methods to derive accurate Timoshenko beam finite elements are presented and compared. Two application problems are examined: linear elastostatics and linearized prebuckling (LPB) stability analysis. Accurate elements can be derived for both problems using a well known technique that long preceeds the Finite Element Method: using homogeneous solutions of the governing equations as shape functions. An interesting question is: can accurate elements be derived with simpler assumptions? In particular, can linear-linear interpolation of displacements and rotations with one-point integration reproduce those elements? The answers are: no if standard variational tools based on classical functionals are used, but yes if modified functionals are introduced. The connection of modified functionals to newer methods, in particular templates, modified differential equations and Finite Increment Calculus (FIC) are examined. The results brings closure to a 50-year conumdrum centered on this particular finite element model. In addition, the discovery of modified functionals provides motivation for extending these methods to full geometrically nonlinear analysis while still using inexpensive numerical integration.

Similar content being viewed by others

References

Abramowitz M, Stegun LA (eds) (1964) Handbook of mathematical functions with formulas, graphs and mathematical tables. Applied Mathematics Series 55, Natl. Bur. Standards, U.S. Department of Commerce, Washington, D.C.. Reprinted by Wiley 1993

Absi E (1967) Equations intrinsèques d’une poutre droite à section constante. Annales de l’Institute Technique de Batiment et des Travaux Publiques. 21:151–167

Argyris JH, Kelsey S (1960) Energy theorems and structural analysis. Part I. Butterworths, London

Argyris JH (1964) Recent advances in matrix methods of structural analysis. Progress in Aeronautical Sciences, vol 4. Pergamon Press, Oxford

Argyris JH, Bronlund OE (1975) The natural factor formulation of the stiffness matrix displacement method. Comput Methods Appl Mech Eng 5:97–119

Ballarini R (2003) The Da Vinci-Bernoulli-Euler beam theory?. Mech. Eng. Magazine Online, available at http://memagazine.org/contents/current/webonly/webex418.html

Bazant ZP, Christensen M (1972) Long-wave extensional buckling of large regular frames. J ASCE Struct Div 98:2269–2288

Bazant ZP, Cedolin L (1988) Stability of structures: elastic, inelastic, fracture and damage theories, 2nd edn. World Scientific, Singapore

Belytschko T, Hughes TJR (eds) (1983) Computational methods for transient analysis. Elsevier, Amsterdam

Bergan PG, Hanssen L (1976) A new approach for deriving ‘good’ finite elements. In: Whiteman JR (ed) The mathematics of finite elements and applications II. Academic Press, London, pp 483–497

Bergan PG (1980) Finite elements based on energy-orthogonal functions. Int J Numer Methods Eng 15:1141–1555

Bergan PG, Nygård MK (1984) Finite elements with increased freedom in choosing shape functions. Int J Numer Methods Eng 20:643–664

Bergan PG, Felippa CA (1985) A triangular membrane element with rotational degrees of freedom. Comput Methods Appl Mech Eng 50:25–69

Bresse JAC (1859) Cours de mécanique appliquée – résistance des materiaux et stabilité des constructions. Gauthier-Villars, Paris

Brush DO, Almroth BO (1975) Buckling of bars, plates and shells. McGraw-Hill, New York

Clough RW, Wilson EL (1963) Stress analysis of a gravity dam by the finite element method. RILEM Bulletin No. 19:46–72. http://www.edwilson.org

Clough RW (1965) The finite element method in structural mechanics. In: Zienkiewicz OC, Hollister GS (eds) Stress analysis. Wiley, London, pp 85–119

Craig RR, Bampton MCC (1968) Coupling of substructures for dynamic analyses. AIAA J 6:1313–1319

Crandall SH (1956) Engineering analysis: a survey of numerical procedures. McGraw-Hill, New York

Cross H (1930) Analysis of continuous frames by distributing fixed-end moments, Proceedings american society of civil engineers (ASCE), pp 919–928, and Transactions ASCE (1932), 96:1–10. Reprinted. In: Grinter LE (ed) (1948) Numerical methods of analysis in engineering. MacMillan, New York, pp 1–13

Duncan WJ, Collar AR (1934) A method for the solution of oscillations problems by matrices. Phil Mag Lond Ser 7(17):865–885

Duncan WJ, Collar AR (1935) Matrices applied to the motions of damped systems. Phil Mag Lond Ser 7(19):197–214

Euler L (1744) De curvis elasticis, Appendix of Methodus inveniendis lineas curvas maximi minimeve propietate gaudentes sive solutio problematis isoparametrici lattisimo sensu accepti. (Reprinted in Caratheodory, C. (ed.) Commentaciones analyticae, Leonhardi Euleri Opera Omnia, Birkhäuser, Basel, 1952)

Euler L (1765) Theoria motus corporum solidorum seu rigidrum ex primis nostrae cognitionis principiis stabilita et ad omnis motus, qui in hujusmodi corpora cadere possunt. (Reprinted in Leonhardi Euler Opera Omnia, 3-4:3-293, Natural Science Society, Berne, 1911–1952)

Felippa CA, Bergan PG (1987) A triangular plate bending element based on an energy-orthogonal free formulation. Comput Methods Appl Mech Eng 61:129–160

Felippa CA, Militello C (1992) Membrane triangles with corner drilling freedoms: II. The ANDES element. Finite Elem Anal Des 12:189–201

Felippa CA (1994) A survey of parametrized variational principles and applications to computational mechanics. Comput Methods Appl Mech Eng 113:109–139

Felippa CA (2000) Recent advances in finite element templates. In: Topping BHV (ed) Computational mechanics for the twenty-first century. Saxe-Coburn Publications, Edinburgh, pp 71–98

Felippa CA (2001) A historical outline of matrix structural analysis: a play in three acts. Comput Struct 79:1313–1324

Felippa CA (2001) Customizing high performance elements by Fourier methods. In: Wall WA et al (eds) Trends in computational mechanics. CIMNE, Barcelona, pp 283–296

Felippa CA (2001) Customizing the mass and geometric stiffness of plane thin beam elements by Fourier methods. Eng Comput 18:286–303

Felippa CA (2003) A study of optimal membrane triangles with drilling freedoms. Comput Methods Appl Mech Eng 192:2125–2168

Felippa CA (2004) A template tutorial. In Mathisen KM, T. Kvamsdal T, Okstad KM (eds) Computational mechanics: theory and practice, CIMNE, Barcelona, pp 29–68

Felippa CA (2005) The amusing history of shear flexible beam elements. IACM Expr 17:15–19

Felippa CA (2006) Supernatural QUAD4: a template formulation, invited contribution to J.H. Argyris Memorial Issue. Comput Methods Appl Mech Eng 195:5316–5342

Felippa CA, Oñate E, (2007) Nodally exact Ritz discretizations of 1D diffusion-absorption and Helmholtz equations by variational FIC and modified equation methods. Comput Mech 39:91–111

Felippa CA, Guo Q, Park KC (2015) Mass matrix templates: general formulation and 1D examples. Arch Computat Methods Eng 22:1–66

Felippa CA, Oñate E, Idelsohn SR, Variational framework for FIC formulations in continuum mechanics: high order tensor transformations and invariants. Arch Computat Methods Eng, to appear. https://link.springer.com/article/10.1007/s11831-017-9245-0

Finlayson BA (1972) The method of weighted residuals and variational principles. Academic Press, New York (reprinted by SIAM, 2014)

Flaggs DL (1988) Symbolic analysis of the finite element method in structural mechanics. Ph. D. Dissertation, Dept of Aeronautics and Astronautics, Stanford University

Fraeijs de Veubeke BM (1965) Displacement and equilibrium models. In; Zienkiewicz OC, Hollister G (eds) Stress analysis, Wiley, London, pp 145–197 (reprinted in Int J Numer Methods Eng 52:287–342, 2001)

Frazer RA, Duncan WJ, Collar AR (1938) Elementary matrices, and some applications to dynamics and differential equations. Cambridge University Press (1st ed. 1938, 7th paperback printing 1963)

Goldberg JE, Richards RH (1963) Analysis of nonlinear structures. J ASCE Struc Div 89:333–336

Graff KF (1991) Wave motion in elastic solids. Dover, New York

Griffiths D, Sanz-Serna J (1986) On the scope of the method of modified equations. SIAM J Sci Statist Comput 7:994–1008

Hairer E, Wanner G, Lubich C (2002) Geometrical numeric integration: structure-preserving algorithms for ordinary differential equations. Springer, Berlin

Han SM, Benaroya H, Wei T (1999) Dynamics of transversally vibrating beams using four engineerings theories. J Sound Vib 225:935–988

Hartmann F (1985) The mathematical foundation of structural mechanics. Springer, Berlin

Hughes TJR (1987) The finite element method: linear static and dynamic finite element analysis. Prentice Hall, Englewood Cliffs, NJ (Dover reprint, 2000)

James BW (1935) Principal effects of axial load by moment distribution analysis of rigid structures. NACA Tech, Note No, 534

Kurrer KE (2003) The development of the deformation method. In: Becchi EA et al (eds) Essays on the history of mechanics. Birkhäuser Verlag, Basel, pp 57–88

Lancaster P, Salkaukas K (1986) Curve and surface fitting: an introduction. Academic Press, London

Levy S (1953) (1953) Structural analysis and influence coefficient for delta wings. J Aero Sci 20:449–454

Livesley RK, Chandler DB (1956) Stability functions for structural frameworks. Manchester University Press, Manchester

MacNeal RH (1978) A simple quadrilateral shell element. Comput Struct 8:175–183

MacNeal RH (1994) Finite elements: their design and performance. Marcel Dekker, New York

Malkus DS, Hughes TJR (1978) Mixed finite element methods – reduced and selective integration techniques: a unification of concepts. Comput Methods Appl Mech Eng 15:63–81

Martin HC (1966) On the derivation of stiffness matrices for the analysis of large deflection and stability problems. In: Bader R, et al. (eds.), Proceedings 1st conference on matrix methods in structural mechanics, AFFDL-TR-66-80, Air Force Institute of Technology, pp 697–716

Melosh RJ (1962) Development of the stiffness method to define bounds on the elastic behavior of structures. Ph. D. Dissertation, University of Washington, Seattle

Melosh RJ (1963) Bases for the derivation of matrices for the direct stiffness method. AIAA J 1:1631–1637

Militello C, Felippa CA (1991) The first ANDES elements: 9-DOF plate bending triangles. Comput Methods Appl Mech Eng 93:217–246

Oñate E, (1998) Derivation of the stabilization equations for advective-diffusive fluid transport and fluid flow problems. Comput Methods Appl Mech Eng 151:233–267

Oñate E, Taylor RL, Zienkiewicz, OC, Rojek J, (2003) A residual correction method based on finite calculus. Eng Comput 20:629–638

Oñate E, (2004) Possibilities of finite calculus in computational mechanics. Int J Numer Methods Eng 60:255–281

Oñate E, Rojek J, Taylor RL, and Zienkiewicz OC, (2004) Finite calculus formulation for incompressible solids using linear triangles and tetrahedra. Int J Numer Methods Eng 59:1473–1500

Oñate E, Miquel J, Hauke G, (2006) A stabilized finite element method for the one-dimensional advection diffusion-absorption equation using finite calculus. Comput Methods Appl Mech Eng 195:3926–3946

Oñate E, Zárate F, Idelsohn S, (2006) Finite element formulation for the convective-diffusive problem with sharp gradients using finite calculus. Comput Methods Appl Mech Eng 195:1793–1825

Oñate E, Valls A, and Garcia J, (2007) Modeling incompressible flows at low and high Reynolds numbers via a finite calculus-finite element approach. J Comput Phys 224:332–351

Oñate E, Idelsohn SR, Celigueta M, Rossi R, (2008) Advances in the Particle Finite Element Method for the analysis of fluid-multibody interaction problems and bed erosion in free surface flows. Comput Methods Appl Mech Eng 197:1777–1800

Oñate E, Idelsohn SR, Felippa CA, (2011) Consistent pressure Laplacian stabilization for incompressible continua via higher-order finite calculus. Int J Numer Methods Eng 87:171–195

Oñate E, Nadukandi, P., Idelsohn SR, Felippa CA, (2011) A family of residual-based stabilized finite element methods for Stokes flow. Int J Numer Methods Eng 65:106–134

Oñate E, (2013) Structural analysis with the finite element method: linear statics — Vol. 2, beams, plates and shells. CIMNE Barcelona, Springer

Oñate E, Franci A, Carbonell, J, (2014) Lagrangian formulation for finite element analysis of quasi-incompressible fluids with reduced mass losses. Int J Numer Methods Fluids 74:699–731

Oñate E (2016) Finite Increment Calculus (FIC): a framework for deriving enhanced computational methods in mechanics. Adv Model Simul Eng Sci 3:1–18

Ostenfeld A (1926) Die deformationsmethode. Springer, Berlin

Park KC (1984) Symbolic Fourier analysis procedures for \(C^0\) finite elements. In: Liu WK, Belytschko T, Park KC (eds) Innovative methods for nonlinear problems. Pineridge Press, Swansea, pp 269–293

Park KC, Flaggs DL (1984) An operational procedure for the symbolic analysis of the finite element method. Comput Methods Appl Mech Eng 42:37–46

Park KC, Flaggs DL (1984) A Fourier analysis of spurious modes and element locking in the finite element method. Comput Methods Appl Mech Eng 46:65–81

Park KC, Stanley GM (1986) A curved \(C^0\) shell element based on assumed natural-coordinate strains. J Appl Mech 53:278–290

Pestel EC, Leckie FA (1963) Matrix methods in elastomechanics. McGraw-Hill, New York

Pilkey WD, Wunderlich W (1993) Mechanics of structures: variational and computational methods. CRC Press, Boca Raton, FL

Pilkey WD (2002) Analysis and design of elastic beams. Wiley, New York

Popov EP (1991) Engineering mechanics of solids, 2nd edn. Prentice Hall, Englewood Cliffs, NJ

Przemieniecki, JS (1968) Theory of matrix structural analysis. McGraw-Hill, New York (Dover edition 1986)

Strang G, Fix G (1973) An analysis of the finite element method. Prentice-Hall, Englewood Cliffs, NJ

Timoshenko SP (1921) On the correction for shear of the differential equation for transverse vibration of prismatic bars, Phil. Mag., XLI, pp 744–46. (Reprinted in The Collected Papers of Stephen P. Timoshenko, McGraw-Hill, London, 1953. See also pp 329–331 of [89])

Timoshenko SP, Goodier JN (1951) Theory of elasticity. McGraw-Hill, New York

Timoshenko SP (1953) History of strength of materials. McGraw-Hill, New York

Timoshenko SP, Young DN (1955) Vibration problems in engineering. Van Nostrand, Princeton, NJ

Timoshenko SP, Woinowsky-Krieger S (1959) Theory of plates and shells. McGraw-Hill, New York

Timoshenko SP, Gere, JM (1961) Theory of elastic stability. McGraw-Hill, New York (Expanded 2nd ed reprinted by Dover, New York, 2009. First edition published by McGraw-Hill, 1936)

Tong P (1969) Exact solution of certain problems by the Finite Element Method. AIAA J 7:179–180

Turing AM (1948) Rounding errors in matrix processes. Quart J Math 1:287–308

Turner MJ, Clough RW, Martin HC, Topp LJ (1956) Stiffness and deflection analysis of complex structures. J Aero Sci 23:805–824

Turner MJ (1959) The direct stiffness method of structural analysis. Structural and Materials Panel Paper, AGARD Meeting, Aachen, Germany

Turner MJ, Martin HC, Weikel, BC (1964) Further developments and applications of the stiffness method. In: Fraeijs de Veubeke BM (ed) Matrix methods of structural analysis. AGARDograph 72, Pergamon Press, Oxford, pp 203–266

von Mises R, Ratzersdorfer J (1926) Die Knicksicherheit von Rahmentragwerken. Z Angew Math Mech 6:181–198

von Neumann J, Goldstine H (1947) Numerical inverting of matrices of high order. Bull Amer Math Soc 11:1021–1099

Waltz JE, Fulton RE, Cyrus NJ (1968) Accuracy and convergence of finite element approximations. In: Berke L et al (eds) Proceedings 2nd conference on matrix methods in structural mechanics, AFFDL-TR-68-150. Air Force Institute of Technology, Dayton, Ohio, pp 995–1028

Wang CM, Reddy JN, Lee KH (2000) Shear deformable beam and plates: relationships with classical solutions. Elsevier, Amsterdam

Wang CM, Wang CY (2004) Exact solutions for buckling of structural members. CRC Press, Boca Raton, FL

Warming RF, Hyett BJ (1974) The modified equation approach to the stability and accuracy analysis of finite difference methods. J Comput Phys 14:159–179

Wilkinson JH (1963) Rounding errors in algebraic processes. Prentice Hall, Englewood Cliffs, NJ

Wilson EL (1963) Finite element analysis of two-dimensional structures, Ph. D. Dissertation, Department of Civil Engineering, University of California at Berkeley, CA. Also published as SESM Report 63–2 (1963) University of California at Berkeley, CA

Wilson EL (1978) The static condensation algorithm. Int J Numer Methods Eng 8:198–203

Zhang F (ed) (2005) The Schur complement and its applications. Springer, New York

Zienkiewicz OC, Cheung YK (1965) Finite elements in the solution of field problems. The Engineer 220:507–510

Acknowledgements

The initial work of the first author on the FIC method was performed in 2004–2008 while he was a visitor at CIMNE (Centro Internacional de Métodos Numéricos en Ingenieria) in Barcelona, Spain. The visits were partly supported by fellowships awarded by the Spanish Ministerio de Educación y Cultura during May-June of those years, and partly by the National Science Foundation under grant High-Fidelity Simulations for Heterogeneous Civil and Mechanical Systems, CMS-0219422.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix 1: Abbreviations and Nomenclature

This Appendix contains tables pertaining to abbreviations and symbols used in paper (Tables 3, 4, 5, 6, 7).

Appendix 2: Legendre Polynomials

In this Appendix, which focuses on individual elements, superscript e is omitted to reduce clutter.

1.1 2.1 Legendre Polynomial Basis

If the nonlinear effect of the axial force is ignored, the homogeneous solutions of the equilibrium equations listed in Sect. 2.4 are standard cubic polynomials. These have been extensively used in the HODES method since the early 1920s; cf. Appendix Sect. 8.2. These functions and their derivatives possess limited element-integrated orthogonality properties. As pointed out in [30, 31] those properties can be improved by passing to the Legendre polynomial basis (Legendre, 1785).

The first four Legendre polynomials, expressed in the natural isoparametric coordinate \(\xi =2x/\ell \), are used in this and the next Appendix, except that the cubic one is modified by introducing a free parameter \(\chi \) in its linear term. (This modification helps to derive optimal geometric stiffness matrices.) In this basis the transverse displacement assumption over the element is written

in which \(\xi \) is the isoparametric coordinate, \(\mathbf {c}=\left[ \begin{array}{cccc}c_{0}&c_{1}&c_{2}&c_{3}\end{array}\right] ^T\) and \(\mathbf {P}=\left[ \begin{array}{cccc}P_{0}&P_{1}&P_{2}&P_{(\chi )}\end{array}\right] \), with

This will be called the parametrized Legendre basis. \(P_{(\chi )}\) becomes the conventional Legendre cubic polynomial \(P_3={\textstyle {1\over 2}}(5\xi ^3-3\xi )\) if \(\chi =3\). Figure 8a illustrates the classical \(P_{0}\) through \(P_{3}\); note that \(P_{n}(1)=1\), \(P_{n}(-1)=(-1)^n\) for \(n=0,1\ldots \). Figure 8b shows \(P_{(\chi )}\) for various values of \(\chi \).

For beam elements, each function in (68) has clear physical meaning in the spirit of natural modes (also called deformation patterns) advocated by Argyris since the early 1960s [4, 5]:

-

\(P_{0}\) and \(P_{1}\) represent translational and rotational rigid motions, respectively.

-

\(P_{2}\) is a constant-curvature bending mode, which is symmetric about \(\xi =0\). For the BE model it represents pure bending with zero shear.

-

\(P_{(\chi )}\) is a linear-curvature bending mode, which is antisymmetric about \(\xi =0\). For the Timoshenko model it represents a linearly varying moment with constant mean shear strain.

For a deeper study of mathematical properties of Legendre polynomials, as well as their generation by recurrent relations, see [1, Ch. 22]. An important application in numerical analysis is the construction of 1D Gauss integration rules: the abscissas of the n-point rule are the zeros of \(P_{n}(\xi )\).

1.2 2.2 Orthogonality Properties and Covariance Matrices

Orthogonality properties of (67) can be exhibited by introducing the row matrix derivatives

where primes denote derivatives with respect to x. Since the parameter \(\chi \) affects only the linear \(\xi \) term in \(P_{(\chi )}\), \( \mathbf {P}''\) and \( \mathbf {P}'''\) are independent of \(\chi \). Four covariance matrices, denoted by \(\mathbf {V}\) here, are obtained by taking dyadic product integrals over the element length \(\ell \):

Recalling that \(dx={\textstyle {1\over 2}}\ell d\xi \), evaluation of (70) gives

It can be observed that

-

\(\mathbf {V}_2\) and \(\mathbf {V}_3\) are diagonal and independent of \(\chi \), hence displaying full orthogonality of entries of \(\mathbf {P}''\) and \(\mathbf {P}'''\) (the last one being trivial)

-

Setting \(\chi =3\) (whence \(P_{(\chi )}\) becomes the classical Legendre cubic polynomial \(P_3\)) diagonalizes \(\mathbf {V}_0=\ell \mathbf{diag }[ 1, 1/3, 1/5, 1/7]\).

-

Setting \(\chi =5\) diagonalizes \(\mathbf {V}_1= (4/\ell ) \mathbf{diag }[ 0, 1, 3, 5]\).

-

No value of \(\chi \) makes all four covariant matrices diagonal.

For future use, \(\mathbf {V}_2\) is split as \(\mathbf {V}_2=\mathbf {V}_{2b}+\mathbf {V}_{2h}\), where

The subscripts b and h in (72) denote “basic” and “higher order,” respectively, in accordance with the terminology of Bergan’s Free Formulation [10, 11]. Note that \(\mathbf {V}_{2b}\) and \(\mathbf {V}_{2h}\) are associated with the symmetric and antisymmetric Legendre bending modes, respectively. All of the foregoing results are independent of \(\Phi \). Consequently, they are applicable to both Timoshenko and BE models.

1.3 2.3 Material Stiffness Matrix

The material stiffness matrix will be derived in two steps: first as a natural stiffness in terms of natural coordinates (the Legendre polynomial coefficients), and then transformed to physical coordinates (the node displacements). This staged process allows extra flexibility in several derivations, notably those in Appendix Sect. 2.6. It is extended to templates in Appendix 3.

1.3.1 2.3.1 Natural Material Stiffness

A beam material stiffness matrix expressed in terms of the Legendre coefficients \(c_i\) defined in (67) will be called a natural material stiffness, and denoted by \(\mathbf {S}_M\). [The term “natural” is explained in Appendix Sect. 2.1.] Since \(\mathbf {S}_M\) depends only on \(\mathbf {V}''\) and \(\mathbf {V}'''\), it is independent of \(\chi \).

Matrix \(\mathbf {S}_M\) is the Hessian of the natural strain energy denoted by \(\Upsilon =\Upsilon _f+\Upsilon _s\), where \(\Upsilon _f\) comes from flexure (bending) and \(\Upsilon _s\) from shear. The former is further split as \(\Upsilon _f=\Upsilon _b+\Upsilon _h\), due to symmetric bending \(v''_b=\mathbf {V}''_b \mathbf {c}\), (basic bending mode) and antisymmetric bending \(v''_h=\mathbf {V}''_h \mathbf {c}\) (higher order bending mode). Denote by \(R_{b}\), \(R_{h}\) and \(R_{s}\) the rigidities pertaining to \(\Upsilon _b\), \(\Upsilon _h\), and \(\Upsilon _s\), respectively, which are assumed constant along the element. Then

The natural material stiffness matrix accordingly splits as

The components of \(\mathbf {S}_M\) are obtained by taking the Hessians

All these matrices are diagonal, independent of \(\chi \), and have rank at most one. Normally \(R_b=R_h=EI\) but sometimes it is useful to adjust these values, as done to construct hinge-equipped elements later. \(R_s\) is a shear rigidity coefficient defined as

\(R_s\) vanishes for the BE model.

1.3.2 2.3.2 Physical Material Stiffness

The physical and natural DOF are linked by \(\mathbf {u}=\mathbf {G}\mathbf {c}\) and \(\mathbf {c}=\mathbf {G}^{-1} \mathbf {u}=\mathbf {H}\mathbf {u}\), where \(\mathbf {u}=\left[ \begin{array}{cccc}v_1&\theta _1&v_2&\theta _2\end{array}\right] ^T\) and \(\mathbf {c}=\left[ \begin{array}{cccc}c_0&c_1&c_2&c_3\end{array}\right] ^T\). Both \(\mathbf {G}\) and \(\mathbf {H}\) are \(4\times 4\) matrices. For the Timoshenko model the total section rotation is \(\theta =v'-\gamma =v'+EI/(GA_s) v'''=v'+\Phi \ell ^2 v'''/12\). Evaluating at nodes and inverting gives

where \(G_{14}=( \chi -5 )/2\), \(G_{34}=-G_{14}\), \(G_{24}=G_{44}=(15-\chi +10\Phi )/\ell \), \(H_{21}= -30+5(\chi -5)/(1+\Phi )\), \(H_{23}=-H_{21}\), \(H_{22}=H_{24}=3\ell (\chi -5)/(2(1+\Phi ))\), \(H_{41}=6/(1+\Phi )\), \(H_{43}=-H_{41}\), and \(H_{42}=H_{44}=3\ell /(1+\Phi )\). For the BE model set \(\Phi =0\).

The physical material matrix is obtained by applying the \(\mathbf {H}\) transformation matrix (77) to (74). We assume that all rigidities are constant along the element. Thus

all of which are independent of \(\chi \). It is instructive to express each component as a rank-one matrix in dyadic (spectral) form. Define the basic (symmetric) and higher-order (antisymmetric) eigenvectors

(These can be normalized to unit length by dividing through by \(\sqrt{2}\) and \(\sqrt{2}\sqrt{4+\ell ^2}/\ell \), respectively.) Then

For a prismatic element \(R_b=R_h=EI\). If so \(C_b=2EI/\ell \), \(C_h= 3 EI (4+\ell ^2)/(\ell (1+\Phi )^2)\), and \(C_s=C_h \Phi \). Adding these matrices: \(\mathbf {K}_M=C_b \mathbf {v}_b \mathbf {v}_b^T+C_h (1+\Phi ) \mathbf {v}_h\mathbf {v}_h^T\) yields the optimal, nodally-exact, material stiffness (29). Since the eigenvectors (79) are orthogonal, they survive in \(\mathbf {K}_M\), which has rank 2, with two nonzero eigenvalues: \(C_b\) and \(C_h (1+\Phi )\).

The template interpretation is: \(\mathbf {K}_{Mb} \) is the basic stiffness, whereas \(\mathbf {K}_{Mh}+\mathbf {K}_{Ms}=\mathbf {K}_{Mh} (1+\Phi )\) is the higher order stiffness. This was first noted in [27] for the BE model, in which \(\mathbf {K}_{Ms}\) vanishes. Further development of templates is done in Appendix 3.

1.4 2.4 Geometric Stiffness Matrix

The geometric stiffness matrix can be derived from the \(W^e_v\) work functional given in (14)– (15), where it is also called the geometric energy functional. By analogy with the natural strain energy notation in (73), evaluation of this term in the parametrized Legendre basis (68) will be denoted by \(\Upsilon _F\). We have

The natural geometric stiffness is the Hessian of \(\Upsilon _F\) with respect to \(\mathbf {c}\):

Transformation to physical coordinates gives \(\mathbf {K}_{Gv}= \mathbf {H}^T \mathbf {S}_{G} \mathbf {H}\), which is independent of \(\chi \). This matrix agrees with the consistent geometric stiffness displayed in (36), derived using the shape functions of Sect. 2.7. Setting \(\Phi =0 \) yields the BE version (38). The latter can be traced back to [58]. It was noted in Sect. 4.1 that those matrices are NOT optimal. Reaching that goal requires more advanced mathematical machinery, which is deployed in Appendix 3.

1.5 2.5 Hinged Timoshenko Beam Elements

This section derives stiffness matrices for Timoshenko beam elements with an internal hinge. Some of the following results have been used in graduate courses since 1989 but not published.

1.6 2.6 Midhinged Beam Element

The Timoshenko beam element shown in Fig. 9a has a mechanical hinge at midspan (\(\xi =0\)). Cross sections on both hinge sides can freely rotate respect to each other. Figure 9b sketches in 3D view a fabrication method sometimes used in short-span pedestrian bridges: gaps on either side of the hinged section cuts are filled with a bituminous material that permits small relative rotations.

This configuration can be treated with two ordinary elements of length \(\ell /2\) with a special 3-DOF node at the hinge, where lateral displacements are identical but rotations are not. This can introduce complications in programming. Those can be avoided by developing a single two-noded hinged element, which may be useful for articulated members that appear in robotics, as well as modeling midspan damage in reinforced concrete beams.

Both the curvature \(\kappa =v''\) and the bending moment \(M=EI \kappa \) must vanish at midspan. But in a element built via cubic interpolation of v(x), \(\kappa \) must vary linearly in both \(\xi \) and x. Consequently the mean curvature, which is controlled by the Legendre polynomial \(P_{2}\) (that shown in blue in Fig. 8) must be zero. That constraint can be enforced by setting the symmetric (basic) bending rigidity \(R_{b}\) to zero whereas the antisymmetric bending rigidity is the normal one: \(R_{h}=EI\). Plugging into (78) yields the nodally-exact material stiffness matrix

Plainly \(\mathbf {K}_{MH}^e\) has rank one; its nonzero eigenvalue is \( 6 EI (4+\ell ^2) (1+\Phi )/\ell ^3\). The result may be gotten by more advanced methods, such as mixed variational principles (assuming transverse displacements and bending moments), but the above derivation uses only undergraduate mathematics.

Two generalizations of the element of Fig. 9. a spring-midhinged element; b hinge moved to an arbitrary location \(\xi =\xi _H\) within element

1.7 2.7 Spring-MidHinged Beam Element

A generalization of the previous element is shown in Fig. 10a: the midpoint hinge is restrained by a torsional (a.k.a. rotational) spring and an extensional spring with spring constants \(k_T^{}=\mu EI/\ell \) and \(k_E^{}=\delta EI/\ell ^3\), respectively. The rigidity parameters \(\mu \) and \(\delta \) are dimensionless.

The stiffness derivation is more involved. The transverse displacement is piecewise split into \(v^-(\xi )\) going from \(\xi =-1\) to \(\xi =0\) (left halfspan), and \(v^+(\xi )\) going from \(\xi =0\) to \(\xi =1\) (right halfspan). See Fig. 11 for visualization of this kinematic split. Both portions are expressed in terms of Legendre polynomials, giving 8 natural coefficients. Eight symbolic equations are then established for kinematic and static matching at node 1 (\(\xi =-1\)), node 2 (\(\xi =1\)) and the hinge node (\(\xi =0\)). Solving these equations via Mathematica links the natural and physical coordinates.

The resulting material stiffness matrix can be presented as a sum of two contributions:

where \(\mathbf {K}_{MH}\) is (83) for the free hinge while \(\mathbf {K}_{Mk}\) brings in the effect of the springs:

in which

This matrix simplifies if one spring is missing. For example, if \(\delta =0\) so \(k_E=0\), it reduces to

which is independent of \(\Phi \). \(\mathbf {K}_{Mk}\) has rank equal to the number of springs present. The rank of \(\mathbf {K}_{MHk}\) is then 3 or 2. One rigid body mode: rigid rotation about the hinge, always remains.

Some limits can be checked to verify the above results: \( \delta =0, \mu \rightarrow \infty \): the hinge disappears, the factor in (87) \(\rightarrow EI/\ell \), and \(\mathbf {K}_{MHk}\) becomes (29).

\( \mu =0, \delta \rightarrow \infty \): \(\mathbf {K}_{MHk}\) splits into two uncoupled \(2\times 2\) blocks, accounting for the rigid support.

Visualization of the piecewise-split deflection \(v(\xi )\) and rotation \(\theta (\xi )\) for the spring-midhinged element of Fig. 10a. Data: \(EI=1\), \(\ell =1\), \(k_T=k_E=0\); nodal data and function expressions shown in figure. Dashed portions are extensions of \(v^-(\xi )\) and \(\theta ^-(\xi )\) into the right halfspan, and of \(v^+(\xi )\) and \(\theta ^+(\xi )\) into the left halfspan

1.8 2.8 Geometric Stiffness Matrix Reduction

The derivation of the geometric stiffness for the element of Fig. 10a triggers a challenge: how to eliminate (reduce) its three hinge freedoms. Since this operation is not covered in the FEM literature, a brief description of two model reduction methods is given.

Static Condensation. Let \(\mathbf {K}_{Mu}\) and \(\lambda \mathbf {K}_{Gu}\) denote the unreduced \(7\times 7\) material and geometric stiffness matrices, respectively, that include the 3 hinge freedoms. Note that the coefficient \(\lambda \) is explicitly taken out as dimensionless load factor. This can be done by writing \(F=\lambda F_{ref}\), where \(F_{ref}\) is a reference force, and then putting F back in the reduced equations.

The tangent stiffness combination \(\mathbf {K}_{Tu}=\mathbf {K}_{Mu}+\lambda \mathbf {K}_{Gu}\) is treated by the well known static condensation procedure [80, 105] to eliminate the hinge freedoms. This yields a reduced tangent matrix \(\mathbf {K}_{Tr}\) with rational entries in \(\lambda \), which makes subsequent buckling analysis through a linear eigenproblem impossible. To recover that capability, that matrix is expanded in Taylor series in \(\lambda \) up to linear terms:

Higher order terms in (88) are discarded. Then \(\mathbf {K}_{M}\) and \(\mathbf {K}_{G}\) are taken as the reduced material and geometric stiffness matrices, respectively, and renamed \(\mathbf {K}_{MHk}\) and \(\mathbf {K}_{GHk}\) for the present element. This \(\mathbf {K}_{MHk} \) does reproduce (84) but \(\mathbf {K}_{GHk}\) is new. This procedure uses explicit linearization.

Kinematic Reduction. The optimal material stiffness (29) is assembled over the two beam portions and the spring stiffnesses directly added to the hinged freedoms. Partial condensation of this \(7\times 7\) unreduced material matrix provides a \(7\times 4\) transformation \(\mathbf {T}_r\) matrix that connects the 3 hinge freedoms to the 4 retained ones. Let \(\mathbf {u}=\left[ \begin{array}{cccc}v_1&\theta _1&v_2&\theta _2\end{array}\right] ^T\) and \(\mathbf {u}_H=\left[ \begin{array}{cccc}v_0&\theta ^{-}_0&\theta ^{+}_0\end{array}\right] ^T\). The transformation can be presented in partitioned form:

Here \(\mathbf {I}_4\) is the \(4\times 4\) identity matrix whereas

in which

The reduced geometric stiffness is obtained by a congruential transformation:

The similarity to the well known Craig-Bampton mass reduction scheme [18] is plain. It can be shown that kinematic reduction produces the same geometric stiffness as static condensation followed by \(\lambda \)-linearization. Therefore (92) may be viewed as implicit linearization. The proof involves straightforward matrix algebra using the Schur complement [106] and is omitted.

1.9 2.9 Geometric Stiffness For Spring-MidHinged Beam

The kinematic reduction method is simpler to implement, and is the one used here. It was applied using the assembled quasi-optimal geometric stiffness (126) to built the \(7 \times 7\) matrix \(\mathbf {K}_{GH}\) . The result of the reduction (92) can be presented as a two-matrix combination:

Here \(\mathbf {K}_{GH}\) is the geometric stiffness for a free hinge:

in which \(K_{GH11}= 4 (97+180 \Phi +80 \Phi ^2)\), \(K_{GH12}=2 \ell (17+20 \Phi )\ell \), \(K_{GH22}= (97+ 180 \Phi +80 \Phi ^2) \ell ^2\), and \(K_{GH24}= -(63+140 \Phi +80 \Phi ^2) \ell ^2\). The second matrix brings the effect of the springs:

in which

This matrix simplifies considerably if the extensional spring is missing. Setting \(\delta =0\) gives

Buckling problems solved with a single spring-midhinged element in Example 3. BE model used for both cases

Example 3

Two buckling problems involving a spring-midhinged Euler column are solved with the element developed in Appendix Sect. 2.7– Appendix Sect. 2.9. The BE model (\(\Phi =0\)) is assumed for both. Only one hinged element is used to discretize the member. Two discretizations are considered:

-

Unreduced Model. The hinge DOF are retained in the LPB eigenproblem. This involves \(7 \times 7\) stiffness matrices, which become to \(5\times 5\) upon applying BC. Five critical loads are obtained, ordered \(\lambda _{cr1}\le \ldots \lambda _{cr5}\).

-

Reduced Model. The hinge DOF are eliminated from the geometric stiffness by kinematic reduction—as stated in Appendix Sect. 2.9, this gives identical results to static condensation followed by linearization. The \(4 \times 4\) matrices are cut to \(2\times 2\) upon applying BC, giving two critical loads: \(\lambda _{cr1}\le \lambda _{cr2}\).

The first problem, shown in Fig. 12a, involves a pinned-pinned beam member of length L and constant bending rigidity EI, which is subjected to a compressive axial load \(P=\lambda ^2 EI/L^2\). The member has a midspan hinge stabilized with a torsional spring of rigidity \(k_T=\mu EI/L\), \(\mu \ge 0\). The quasi-optimal geometric stiffness (126) is paired with the optimal BE material stiffness (30).

Results for the lowest critical load \(P_{cr}=\lambda _{cr1}^2 EI/L^2\) are shown in Fig. 13a, where \(\lambda _{cr1}^2\) is plotted as function of \(\mu \) over [0, 1000]. They are compared with the exact solution with the buckling-exact element derived in Appendix 5. The exact characteristic equation is

This agrees with [101, Sec. 2.5.2]. It gives symmetric buckling modes, starting with \(\lambda _{cr1}\), which depend on \(\mu \), as well as antisymmetric mode solutions \(\lambda _{cr}=2 n \pi \), \(n=1,2,\ldots \) for which the hinge is a node and the spring has no effect. As \(\mu \rightarrow \infty \), (98) approaches \(\sin \lambda =0\), which gives the classical Euler solutions. The unreduced model gives at least 3 correct places for all \(\mu \) so no difference can be seen in the plots. The reduced model, however, loses accuracy as \(\mu \) increases. The results for the second mode are way off and not shown.

Results from problems of Example 3. left: pinned-pinned beam-column with rotationally constraint midhinge; right: pinned-pinned beam-column with extensionally restrained midhinge. s-mode and a-mode are appreviations for symmetric and antisymmetric buckling mode, respectively. Values of \(\delta \) that maximize critical load in left figure are marked by crossed circles

The variation pictured in Fig. 12b has an extensional spring of rigidity \(k_E=\delta EI/L^3\), \(\delta \ge 0\). This configuration features eigenvalue crossings, with the attendant possibility of choosing \(\delta \) to maximize the lowest critical load. The exact characteristic equation is

There is a single symmetric mode with \(\lambda _{cr}^2=\delta /4\), for which the submembers remain straight, taking no bending energy. It depends only on \(\delta \) and gives the lowest critical load for \(\delta \le 16\pi ^2\). The \(\sin (\lambda /2)\) factor provides the antisymmetric mode solutions \(\lambda _{cr}=2n\pi \), \(n=1,2,...\) with a node at the hinge, which do not depend on \(\delta \). The symmetric and first antisymmetric mode cross at \(\delta _{\times }=16\pi ^2\approx 157.91\).

The FEM results for the first two modes are shown in Fig. 13b, along with the exact solution. The unreduced model captures the symmetric mode exactly, whereas for the second mode gives \(\lambda _{cr}^2=48\) instead of \(4\pi ^2\). Crossing occurs at \(\delta _{\times }=192\). The reduced model overshoots the symmetric critical load over most of the range, gives a second critical load at \(\lambda _{cr}^2=960/17\approx 56.47\), and predicts a crossing at \(\delta _{\times }\approx 226\).

These simple but thoughtworthy examples underscore the quirky nature of model reduction. Condensation of the material stiffness has no side effects: equilibrium and nodal exactness are preserved. But reduction at the geometric stiffness level may cause significant accuracy loss. The underlying reason, explained in Appendix Sect. 2.8, is linearization—whether explicit or implicit—that discards higher order terms in the load factor. Thus errors can be expected to grow as the factor increases.

1.10 2.10 Off-Center Hinged Beam Element

Another generalization of the element in Fig. 9a is shown in Fig. 10b. The free hinge is now located at arbitrary isoparametric coordinate \(-1\le \xi _H\le 1\). The derivation requires adjusting two Legendre polynomial bases over variable lengths and is omitted. The resulting material stiffness is the rank-one matrix

This reduces to (83) for \(\xi _H=0\). The limit cases \(\xi _H=\pm 1\) are not excluded. If springs are attached to the hinge, the matrices derived in previous subsections must be adjusted for a variable \(\xi _H\). The entries become exceedingly complicated and are not given here.

Example 4

The material stiffness (100) for an arbitrarily placed hinge is applied to a simple design optimization problem that can be entirely done by hand in closed form. This is pictured in Fig. 14a. A Bernoulli–Euler (BE) fixed-fixed prismatic beam AB of total span L is loaded by a point force P (positive upward) at its center C. Two hinges are symmetrically placed at distances \({\textstyle {1\over 2}}\alpha L\) from the end supports. Because of the symmetry about C, it is possible to model the problem with just one hinged beam element, say the left half-span, as illustrated in Fig. 14b. The displacement support conditions are: \(v_1=\theta _1=\theta _2=0\). This leaves only one unknown DOF: the midspan deflection \(v_2=v_C\) under \({\textstyle {1\over 2}}P\). Question: for which hinge configuration, defined by \(\alpha \) as design variable, is \(v_C\) minimized in magnitude?

Mathematically this is a constrained optimization problem:

Does such a minimum exist? For both \(\alpha =0\) (a simply supported beam) and \(\alpha =1\) (a doubly hinged cantilever), textbooks give \(v_C=PL^3/(48EI)\), which provides checks on the computations by setting \(\xi _H=\pm 1\). For \(\alpha \) in between, \(|v_C|\) gets smaller, so there is in fact an optimal value, which is readily computable by hand.

The element stiffness matrix (100), upon setting \(\xi _H\rightarrow 2\alpha -1\), \(\ell \rightarrow L/2\) and \(\Phi =0\), is used as master stiffness. Applying the BCs \(v_1=\theta _1=\theta _2=0\) leaves only one equation: \(12 EI/(\ell ^3 (1+3\xi _H^2)) v_2= P/2\), which solved for \(v_2\) gives

By inspection \(|v_C|\) is minimized for \(\xi _H=0\), or \(\alpha =1/2\). That is, the hinges should be placed at the quarterspans. If this is done, the center deflection is \(PL^3/(192EI)\) as compared to \(PL^3/(48EI)\) when \(\xi _H=\pm 1\). That is a gain of 4 in deflection stiffness under the center point load. If shear flexibility is considered: \(\Phi >0\), the optimal \(\xi _H\) moves closer to the supports.

Note: \(PL^3/(192EI)\) is the same as the center defection of a centrally-point-loaded, fixed-fixed beam without hinges. The advantages of placing hinges are: (1) the absolute maximum moment is minimized, as can be easily verified, and (2) thermal expansion effects can be abated with appropriate sliding devices at the hinges.

Appendix 3: Templates and Modified Equations

This Appendix presents two mathematical techniques for deriving optimal elements: templates and modified differential equations. While the combination can be used on a variety of problems, they are better exhibited in the context of specific applications. In accordance with the main subject of the paper, we construct optimal elements for the Timoshenko plane beam model, with BE as special case. The rationale is plain: if the combination does not work for beams there is little hope for plates and shells, which carry more complicated forms of rotational DOF. References for more general applications are provided in Appendix 8 along with a brief historical summary.

The element superscript e is again omitted for brevity.

1.1 3.1 Templates: Concept and Examples

A finite element template, or template for short, is a set of FEM equations that contains symbolic free parameters. Their numerical values are picked to improve performance, and in some cases to achieve optimality in a defined sense. As an example, take a two-node linear elastostatics plane beam element with the standard 4 degrees of freedom. The generic material stiffness equations are

where the only pre-assumption is matrix symmetry. The values of the 10 independent stiffness entries: \(K_{M11}\) through \(K_{M44}\) may be viewed as parameters. This is called a universal template, since it include all possible symmetric stiffness forms for a linear model. But for optimality studies this is far too general. The number of free parameters may be cut down by applying behavioral and fabrication constraints. Two examples for the above element:

-

Applying the rigid body motion \(\mathbf {v}^e=\left[ \begin{array}{cccc}1&0&1&0\end{array}\right] \) must give a zero force vector. Consequence: the third column (row) must be the negated first column (row): \(K_{M13}=K_{M31}=-K_{M11}\), etc.

-

If the element is prismatic (constant contitutive and fabrication properties), symmetry requires \(K_{M33}=K_{M11}\), etc.

Instead of going over individual constraints a more systematic procedure is to use natural modes. For beam elements, this is done in Appendix 2 using Legendre polynomials with a minor tweak in the cubic term. For both the Timoshenko and BE models of prismatic (uniform) elements it gives the material stiffness template

This form, presented in [27], has one free parameter: the scalar \(\beta \). Plainly it is easier to deal with one parameter than with ten.

Some notation: \(\mathbf {K}_b\) and \(\mathbf {K}_h\) are the basic and higher order stiffness matrices, respectively, a terminology originated as described in Appendix Sect. 8.5 Their sum \(\mathbf {K}_M\) has the correct rank of 2 and is positive semidefinite if \(\beta >0\). Parameter \(\beta \) scales only the higher order stiffness \(\mathbf {K}_h^e\).

1.2 3.2 Geometric Stiffness Templates

Templates for the geometric element stiffness necessarily contain more parameters. Their generic configuration is

where \(\mathbf {S}_{G}\) is a natural stiffness matrix endowed with \(n_\beta \) free parameters, which are denoted \(\beta _i\), \(i=1,2,\ldots n_\beta \), and \(\mathbf {H}\) is the transformation matrix given in (77) that maps natural coordinates to node displacements.

Matrix \(\mathbf {S}_{G}\) is set up by including free parameters in the \(\mathbf {V}_1\) covariant matrices derived in Appendix Sect. 2.2. For arbitrary values of \(\chi \), only four independent entries of \(\mathbf {V}_1\) are nonzero. It is convenient to parametrize those as

which will be called the natural geometric stiffness template. A simple computation shows that the factor \(4F/\ell \) forces \(\beta _1=1\), leaving four free parameters: \(\beta _2,\beta _3,\beta _4,\chi \) for the optimal \(\mathbf {K}_G\) search. Results are reported in Appendix Sect. 3.5 and following sections.

Flowchart of the modified differential equation (MoDE) method applied to FEM. Adapted from [36], which addressed the convection-diffusion problem. Step 4 may be a difficult one requiring human decisions; for instance Taylor series in an patch dimension parameter and truncation. Steps 1–3 are automatic but symbolic processing normally requires a computer algebra program

1.3 3.3 Optimal BE Beam Material Stiffness

How do we pick the best \(\beta \) in (104)? As announced, the modified differential equation method will be used. This is based on knowledge at the Mechanics of Materials level: the governing ODE for computing deflections (called strong form in the literature) for a prismatic BE beam is (9) with \(\Phi =0\):

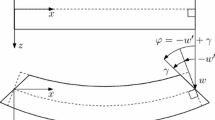

where v(x) is the lateral deflection and q(x) the applied distributed load—see Fig. 2—and primes denote derivatives respect to x. Task: find the optimal \(\beta \), with only (104) and (107) as given. By “optimal” is meant achieving a “best fit” in the sense explained below. No variational or weak forms are considered. Although both (104) and (107) are undergraduate level material, the fitting task is far from trivial.

The key idea is to construct an ODE that is satisfied exactly by the discrete system at the nodes. This is called the modified differential equation or MoDE. Typically it has infinite order, in which case it is labeled IOMoDE. If an instance of \(\beta \) in (104) is found that

-

Reduces the IOMoDE to a finite-order modified differential equation, called FOMoDE, and

-

The FOMoDE matches (107),

the FEM model is nodally exact and it is happy hour. But often an exact match is impossible. If so the goal is to get the best fit possible in low powers of the element length \(\ell \). This is done by expanding the IOMoDE in Taylor series in \(\ell \) about \(\ell =0\), and truncating the expansion after the first nonzero term.

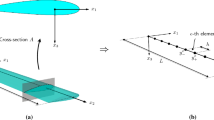

The procedure is flowcharted in Fig. 15. The process begins from a two-element patch extracted from an infinite regular lattice pictured in Fig. 16.

Since computations are necessarily symbolic and error prone if done by hand, they are better carried out with the assistance of a computer algebra system. An algorithmic description is given in Appendix 4 along with a supporting Mathematica implementation. Running the steps of Fig. 15 as detailed in that Appendix gives the infinite order modified differential equation (IOMoDE)

The optimal choice is clear: setting \(\beta =1\) makes (108) a FOMoDE identical to (107). Replacing into (104) gives the well known result (30), Since we have exactly matched (107), the element endowed with this matrix is nodally exact (NE). There are two additional points:

-

Nodal exactness is preserved if EI and \(\ell \) vary from element to element. This requires more elaborate symbolic computations.

-

The high order derivatives in (108) must be interpreted in a formal sense; see [46, Ch. X].

1.4 3.4 Timoshenko Beam Material Stiffness

Next, try the template (104) on a Timoshenko beam element. The governing ODE for the no-axial-load case is (9), reproduced here for convenience:

Going through the steps of Fig. 15, we get the IOMoDE

Setting \(\beta =1+\Phi \) matches (109). Inserting in (104) gives (29), which is nodally exact.

1.5 3.5 Optimal BE Geometric Stiffness

We consider first the BE model under LPB (Linearized Prebuckling) assumptions. Assume that the beam element is under a uniform axial force \(F=-P\) (P is positive compression), which produces a state of initial axial stress. The governing ODE in terms of deflections becomes \(EI v''''(x)+F v''(x)=q(x)\). For the following analysis the lateral load q(x) is irrelevant and is set to zero so the target ODE is

The search for optimal \(\mathbf {K}_G\) starts with the natural geometric stiffness 4-parameter template \(\mathbf {S}_G\) in (106). The physical geometric stiffness is \(\mathbf {K}_G=\mathbf {H}^T \mathbf {S}_G \mathbf {H}\), where the matrix \(\mathbf {H}\) given in (77) brings one more parameter: \(\chi \), from the parametrized Legendre basis; see (68). The five parameters can be reduced to four by setting \(\beta _1=1\), which follows automatically from the \(\mathbf {S}_G\) scaling factor. The modified equation analysis produces the IOMode

where the “higher order terms” are \(O(\ell ^8)\) and higher. The \(C_i\)’s are dimensionless functions of the template parameters. Two coefficients that can be zeroed by proper choice of parameters are

Solving \(C_2=C_4=0\) for \(\beta _2\) and \(\beta _3\), both of which appear linearly there, gives

Upon choosing \(\beta _2\) and \(\beta _3\) as per (114), the \(\ell ^6\) coefficient in (112) becomes

Examination of \(C_6\) shows that it does not vanish for any real \(\beta _4\) and \(\chi \). Thus optimality reduces to finding minima of \(C_6\) as function of \(\beta _4\) and \(\chi \). Solving \(\partial C_6/\partial \chi =0\) for \(\beta _4\) yields four roots, two of which are real. For convenience define

The two real roots are

Replacing either root into (115) gives

This minimum is independent of \(\chi \) so one cannot do better than this. The optimum—within the template assumption (112)—has been reached but we are free to pick \(\chi \), which produces two \(\beta _4\) as per (117). Inserting these into (114) gives

The two parameter sets: \([\beta _2,\beta _{3|1},\beta _{4|1},\chi ]\), and \([\beta _2,\beta _{3|2},\beta _{4|2},\chi ]\), can be used to form two optimal geometric stiffness matrices called \(\mathbf {K}_{Gop1}\) and \(\mathbf {K}_{Gop2}\), respectively. Their expressions are:

where \(c_{op}=F/(12 \sqrt{15} \ell )\), \(a_1=24 \sqrt{15}-36\), \(a_2=12 \sqrt{15}-18-6 \root 4 \of {135}\), \(a_3=11 \sqrt{15}-12-6 \root 4 \of {135}\), \(a_4=7 \sqrt{15}-6-6 \root 4 \of {135}\), \(a_5=6 (2 \sqrt{15}+\root 4 \of {135}-3)\), \(a_6=11 \sqrt{15}-12+6 \root 4 \of {135}\), and \(a_7=7 \sqrt{15}-6+6 \root 4 \of {135}\). Both \(\mathbf {K}_{Gop1}\) and \(\mathbf {K}_{Gop2}\) are independent of \(\chi \) (which cancels out in the \(\mathbf {H}^T \mathbf {S}_G \mathbf {H}\) transformation), so for convenience one may preset \(\chi =0\) in (119). In the example below both versions gave exactly the same results; it is not known if this holds for other problems. In any case \(\mathbf {K}_{Gop1}\) has the better condition number and is the recommended one.

These optimal matrices do not seem to appear in the literature.

1.6 3.6 Quasi-Optimal BE Geometric Stiffness

The optimal matrices (120) have complicated coefficients, which leads to unwieldy expressions when extending to the Timoshenko model. It is possible to find “quasi-optimal” forms that keep \(C_2=C_4=0\) with a slightly larger \(C_6\), but have parameter values that are simple integers. Two instances are

Both choices produce the same physical geometric stiffness:

The modified equation analysis gives \(C_6=-1/37800\), which is about 20% bigger than for the optimal. This matrix will be labeled quasi-optimal. It was derived for an advanced FEM course in 1998 but never published.

Example 5

Table 8 collects results for the buckling analysis of a prismatic cantilever beam-column using the BE model. See Fig. 17. The number of elements \(N_e\) varies from 1 to 16. All elements have the same length \(\ell =L/N_e\). The material matrix is the nodally-exact one (29). Several geometric stiffness matrices are compared: the two optimal forms (120) — (both versions give identical results), quasi-optimal (122); consistent (38); and “bar” (123). The latter is obtained by setting \(\beta _1=1\), \(\beta _2=\beta _3=\beta _4=0\) and \(\chi =5\) in (112), which produces

This instance has historic importance as being the first geometric stiffness published in the open literature by Turner et. al. [94] and Argyris [4]. It was derived for the bar element—using linear shape functions–but applied to beams. [The term “stringer” was used instead of “bar” in the older literature.] Note that both “consistent” and “bar” instances converge from above; the former as \(O(\ell ^4)\) and the latter as \(O(\ell ^2)\). Both “optimal” and “quasi-optimal” converge as \(O(\ell ^6)\) but not monotonically.

The computed accuracy for the first two critical loads is graphically summarized in the log-log plots of Fig. 18 as correct digits in \(\lambda _{cr}\) versus number of elements. The impressive accuracy delivered by the optimal and quasi-optimal instances should be noted. For example both optimal versions give the first critical load to nearly 4 places with one element! Differences between optimal and quasi-optimal results are practically meaningless.

Log-log plots of BE-modeled buckling prediction accuracy of cantilever beam-column member, for modes 1 and 2 in a and b, respectively. This summarizes results collected in Table 8. Horizontal axis: number of elements along member (1 through 16) in 2-log spacing. Vertical axis: number of correct digits of predicted \(\lambda _{cr}\), obtained by taking the negated decimal log of the computed value absolute error

1.7 3.7 Quasi-Optimal Timoshenko Geometric Stiffness

For the Timoshenko model, the governing ODE to be matched (again ignoring the lateral load) is \((EI(1+F/GA_s) v''''(x)+ Fv''=0\), which may be rearranged to the canonical form

As noted in Appendix Sect. 3.6, when passing to the Timoshenko beam model it is convenient to generalize the quasi-optimal BE geometric stiffness (122), which has simpler entries. The MoDE analysis shows that only the \(\beta _3\) coefficient needs to be adjusted:

Both choices produce the same matrix:

where \(b_1=12(7+5 \Phi (3+\Phi ))\), \(b_2=6(2+5\Phi )\), \(b_3=11+5\Phi (5+\Phi )\), and \(b_4=1+5(1-\Phi )\Phi \). This reduces to (122) if \(\Phi =0\).

Log-log plots of Timo-modeled buckling prediction accuracy of cantilever beam-column member, for modes 1 and 2 in a and b, respectively. See legend of Fig. 18 for details

Arch frame optimization problem for Example 7. a structure; b finite element idealization

Example 6

Table 8 show results for the benchmark of Fig. 17, but now for a Timoshenko model with \(\Phi _0=12EI/(GA_s L^2)=1/2\), which represents a high shear flexibility. Again 1 through 16 elements are used along the span. The element-level shear flexibility \(\Phi \) need to be adjusted as per element length; thus

where \(N_e\) is the number of elements. This coefficient grows rapidly as \(N_e\) increases; e.g., \(\Phi =128\) for \(N_e=16\) and \(\Phi _0=1/2\). This has a significant degradation effect on the convergence rate, as shown below.

Results are shown in Table 9 for two geometric stiffnesses: quasi-optimal (126) and consistent (36). Accuracy results are graphically summarized as log-log plots in Fig. 19, which is displayed in the same vertical scale as Fig. 18, A glance plainly shows that both accuracy and convergence rate are significantly degraded. This can be explained by observing that the first nonzero \(C_i\) coefficient in the IOMoDE are

so both grow as \(O(\Phi )\) as \(\Phi \rightarrow \infty \). From (127) note that a nonzero \(\Phi \) grows as \(1/\ell ^2\) as \(\ell \rightarrow 0\). That cuts the convergence of the consistent version from \(O(\ell ^4)\) to \(O(\ell ^2)\) and that of the quasi-optimal one from \(O(\ell ^6)\) to \(O(\ell ^4)\). For the bar version (results not shown) it cuts \(O(\ell ^2)\) to O(1), whence it does not converge for the Timoshenko model.

Results for arch frame buckling optimization problem for selected values of \(\rho \) and \(\Phi \). Here \(\lambda _1\) is associated with a symmetric buckling mode in which node 2 displaces vertically without rotation. On the other hand, \(\lambda _2\) and \(\lambda _3\) are lateral modes in which node 2 rotates and displaces horizontally. Note that the vertical scale of the rightmost two plots is different

Example 7

This example illustrates the application of an accurate Timoshenko geometric stiffness to a buckling optimization problem. The arch frame shown in Fig. 20 consists of two identical beam-column members clamped at their supports, and loaded by a vertical load \(f_y=\lambda P_ref\) at the crown, where \(\lambda >0\) if the load goes downward. Material and fabrication properties are indicated in the figure. The FEM idealization is shown in Fig. 20b. Each member is modeled by one Timoshenko beam-column element. The optimal material stiffness (29) and the quasi-optimal geometric stiffness (126) are used for the FEM model. The \(6\times 6\) beam-column element stiffness matrices incorporate the effect of axial deformations and are appropriately rotated to the global positions through appropriate kinematic transformations.

The optimization question is: which rise angle \(\varphi \) maximizes the critical buckling load? Note that since L is taken as unity—see (129) below—the member fabrication cost is the same for any rise angle.

It is convenient to reduce all equations to dimensionless form since the optimum angle \(\varphi \) is also a dimensionless variable. This is done as follows:

Here \(\rho \) plays the role of radius of gyration of the cross section. The shear coefficient \(\Phi =12 EI/(GA_s L^2)=12\gamma ^2/(GA_s)\) is kept as a variable that indirectly defines \(GA_s=12\gamma ^2/\Phi \). Three dimensionless variables are left: \(\varphi \), \(\gamma \), and \(\Phi \). The load \(f_Y\) is made dimensionless by taking \(P_{ref}=-1\). The master stiffness matrices are \(9\times 9\), but reduce to \(3\times 3\) upon deleting all equations associated with nodes 1 and 3. Denoting \(c=\cos \varphi \), \(s=\sin \varphi \) and \(c_2=\cos ^2\varphi \), the reduced material and geometric stiffness matrices are

where for the geometric stiffness (126):

The determinant d of \(K_M+\lambda K_G\) is taken. d is a cubic polynomial in \(\lambda \), with coefficients that depend on \(\varphi \), \(\rho \) and \(\Phi \). On giving numeric values to \(\rho \) and \(\Phi \), \(d=0\) provides three critical load factors \(\lambda _1\), \(\lambda _2\) and \(\lambda _3\) as functions of \(\varphi \). These are plotted in Fig. 21 over \(\varphi \in [30^\circ ,90^\circ ]\) for \(\rho =1/5, 1/10,1/20\) combined with \(\Phi =0,1/3\). (Shallow arches with \(\varphi <30^\circ \) are omitted since they are subject to another type of instability: snap-through, which is not covered by the LPB model.) The optimal \(\varphi \) is marked on the plots; it is the max distance from the \(\lambda =0\) axis to the lowest plot. It may occur at a crossover, or at a local maximum. As can be expected, the influence of \(\rho \) is important. The reduction in buckling strength from \(\Phi =0\) to \(\Phi =1/3\) is significant because that value implies a high shear flexibility; however, the optimum locations angles do not change significantly.

Rerunning the \(\Phi =0\) case with the optimal BE geometric stiffness hardly changes the plots.

Appendix 4: MoDE Implementation Example

This Appendix provides computational details on the modified differential equation method (MoDE) flowcharted in Fig. 15. The first section goes over the analysis for a material stiffness template, in equation-by-equation detail. The second section presents the actual Mathematica implementation.

1.1 4.1 MoDE Analysis Example

The MoDE analyis details are presented here for the material stiffness of the BE beam model. Consider the lattice shown in Fig. 16a, from which a generic two-element patch is extracted as indicated in Fig. 16b. The identical elements are labeled as (1) and (2), respectively. The lateral load q(x) is not necessarily periodic (this is NOT Fourier analysis). The FEM patch equations at node j are

Here \(\mathbf {v}_p= \left[ \begin{array}{cccccc}v_i&\theta _i&v_j&\theta _j&v_k&\theta _k\end{array}\right] ^T\) is the 6-vector collecting the patch DOF, while \(f_j\) and \(m_j\) are consistent nodal loads to be computed as function of the lateral load q(x) and its derivatives at \(x_j\) as shown below. Expand v(x), \(\theta (x)\) and q(x) in Taylor series about \(x=x_j\), truncating at \(n+1\) terms for v and \(\theta \), and \(m+1\) terms for q. (Typically \(m=n-4\) when doing a material stiffness but \(m=0\) for a geometric stiffness.) Using \(\zeta =(x-x_j)/\ell \) as dimensionless coordinate going from i to k, the series are

Here \(v_j^{[n]}\), etc., is an abbreviation for \(d^n v(x_j)/dx^n\). [Note: Brackets are used instead of parentheses to avoid confusion with element superscripts. If derivatives are indexed by primes or roman numerals, brackets are omitted.] Evaluate the v(x) and \(\theta (x)\) series at i and k by setting \(\zeta =\pm 1\), and insert in (132). To compute \(f_j\) and \(m_j\) use the q(x) series evaluated over elements (1) and (2). Denote by \(\xi ^{(1)}\) and \(\xi ^{(2)}\) the isoparametric coordinates over elements (1) and (2), respectively, linked to \(\zeta \) by \(\zeta ^{(1)}=-{\textstyle {1\over 2}}(1-\xi ^{(1)})\) and \(\zeta ^{(2)}={\textstyle {1\over 2}}(1+\xi ^{(2)})\). The lateral loads over (1) and (2) are \(q^{(1)}=q(\zeta ^{(1)})\), and \(q^{(2)}=q(\zeta ^{(2)})\), respectively. Then

Here

are the BE Hermitian shape functions associated with the j node trial function. (For the Timoshenko beam model those functions must be adjusted; see Sect. 2.7). To show the resulting system in matrix form it is convenient to collect values and derivatives at node j into column vectors:

Both \(\mathbf {v}_j\) and \(\varvec{\theta }_j\) have length \(n+1\) whereas \(\mathbf {q}_j\) has length \(m+1\). The resulting differential system can be compactly written in matrix form:

Here \(\mathbf {R}_{vv}\), \(\mathbf {R}_{v\theta }\), \(\mathbf {R}_{\theta v}\) and \(\mathbf {R}_{\theta \theta }\) are upper triangular Toeplitz matrices of order \((n{+}1)\times (n{+}1)\) whereas \(\mathbf {L}_v\) and \(\mathbf {L}_\theta \) are generally rectangular matrices of order \((n{+}1)\times (m{+}1)\). Here are these matrices for \(n=6\), \(m=2\):

In the \(\mathbf {R}_{\theta \theta }\) expression, \(\phi =3\beta -1\). Elimination by static condensation of \(\varvec{\theta }_j\) gives the system

For the matrices (138) we get

Postmultiplication by \(\mathbf {v}_j\) and \(\mathbf {q}_j\) yields

in which x-derivatives of order 5 or higher are denoted with bracketed Roman numeral superscripts. The nontrivial equations in \(\mathbf {R}\mathbf {v}_j = \mathbf {L}\mathbf {q}_j\) are \(EI \,\, v''''(x)=q(x)-(1-\beta ) \ell ^4 q''''(x)/(720 \beta )\) and \(EI v^v=q'(x)\). Solving for \(v''''(x)\), which is uncoupled, gives the finite order ODE

If n and m are increased in steps of 2 so that \(m=n-4\), additional terms appear. For example:

The infinite order ODE (IOMoDE) that emerges as \(n\rightarrow \infty \) is (108). As noted in Appendix Sect. 3.3, this reduces to the exact governing ODE (107) if \(\beta =1\), thus validating (30) as the nodally exact stiffness.

1.2 4.2 MoDE Implementation in Mathematica

The Mathematica coding of the MoDE analysis flowcharted in Fig. 15 is presented here. It can do material and geometric stiffness matrices that cover both Timoshenko and BE models.

Implementation assumption: the two elements in the patch of Fig. 16b must be identical, with same EI, \(\ell \) and \(\Phi \). Relaxing this constraint, which is sufficient for our purposes, would need changes to the logic of modules PatchNodeForces and BeamFOMoDE.

Five primitive (= self-contained) modules are group-listed in Fig. 22. (Actually one: TaylorSeries, is technically an inline function.) They are invoked as follows:

This function returns the Taylor series of f[x] about x=0 with increment h, up to and including the \(n^{th}\) derivative, where \(n\ge 0\). For example, fseries = TaylorSeries[f,x,h,3] returns f[x]+h * f[x]+h2 * f[x]/2+h3 * f[x])/6 in fseries.

Module BeamGMatrix returns the \(\mathbf {G}\) matrix defined in (77) that maps physical to natural DOF whereas module BeamHMatrix returns its inverse \(\mathbf {H}=\mathbf {G}^{-1}\) thap maps natural to physical DOF. Both are \(4\times 4\) matrices. The arguments are the element length Le (called \(\ell \) in the text), the shear flexibility coefficient \(\Phi \) and the adjusted Legendre cubic polynomial parameter \(\chi \).

This module forms the natural geometric stiffness template \(\mathbf {S}_G\). The first argument, tag, is a character string. Legal tags are “KG4” or “KG6”. If “KG4”, it builds the template matrix (106). using the element length Le, the axial force F and the four \(\beta \) parameters supplied in the list argument \(\beta \)pars. If tag is “KG6” it fills the bottom \(3\times 3\) principal minor of that matrix with two additional parameters: \(\beta _5\) and \(\beta _6\)—this particular template is not used in the present work. Argument \(\Phi \) is not used in the listed implementation; it is provided for possible extensions. The module returns \(\mathbf {S}_G\) as a \(4\times 4\) matrix. If tag is illegal it returns Null.

This module returns polynomial shape functions for beam lateral displacements, as listed in Sect. 2.7. It is used to compute consistent loads as per (134) when doing a material stiffness template. Argument model is a character string: either “BE” or “Timo”. Arguments Le and \(\Phi \) are as described above. Argument \(\xi \) is the isoparametric natural coordinate; this is normally a symbol.

If model is “BE” it returns the four classical Hermitian shape functions, in which case \(\Phi \) is not used. If model is “Timo” it returns the 4 cubic shape functions listed in (20). The module returns a 4-item list. If model is illegal it returns a list of four Null values.

Two modules that construct a beam element stiffness matrix and assemble the stiffness of a two-element patch are listed in Fig. 23. They are invoked as follows.

This module forms the stiffness of a beam element. The first argument, tag, is a character string that can be either “KM” to form the material stiffness matrix, or “KG4” to form the geometric stiffness matrix with the 4-parameter template \(\mathbf {S}_G\) of (106) and the \(\chi \)-parametrized matrix \(\mathbf {H}\) of (77).

The other arguments are: the bending rigidity EI (constant over element), the element length Le, the shear flexibility coefficient \(\Phi \), the axial force F, positive if tension (used only for a geometric stiffness matrix), the template parameter list \(\beta \)pars, and the Legendre basis parameter \(\chi \).

If tag is “KM”, only one parameter is needed, so \(\beta \)pars is simply \(\beta \) , and \(\chi \) is not used since \(\mathbf {K}_M\) is formed directly. If tag is “KG4” the module calls BeamSGMatrix and BeamHMatrix to get \(\mathbf {K}_G\) as \(\mathbf {H}^T\mathbf {S}_G\mathbf {H}\). The second to last arguments may be symbolic or numeric. The module returns a \(4\times 4\) stiffness matrix. If tag is illegal an error message is printed, and the module returns Null.

This module assembles the patch stiffness equations of a patch of two adjacent elements, as pictured in Fig. 16. The inputs are their \(4\times 4\) stiffness matrices computed via BeamStiffMatrix. In the present work the two elements are assumed identical, so Ke1=Ke2.

The assembled patch stiffness matrix is \(6\times 6\) as it involves three nodes with two DOF each, cf. Fig. 16. But rows pertaining to i and k are not needed in the ensuing analysis because their DOF are eliminated via the series (133). Thus the first two and the last two rows can be removed. The module actually returns a \(2 \times 6\) matrix Kp, such as the one shown in the left hand side of (132).

Module PatchNodeForces, listed in Figs. 24, 25, constructs the matrices \(\mathbf {L}_f\), \(\mathbf {L}_m\) and vector \(\mathbf {q}_f\) defined in (155) and (156), which are used for the matrix computation of the patch consistent node forces \(f_j\) and \(m_j\) of (151). These are used only for material stiffness analysis. The module is invoked as

Here model is either “BE” or “Timo”, q is a symbol for the lateral load q(x), Le, \(\Phi \) and \(\xi \) are as defined before, and x is the symbol for the axial coordinate used in the Taylor series expansion of q(x). Finally, integers n and m specify the highest derivative order used in the Taylor expansions of v(x), \(\theta (x)\), and q(x) as indicated in (136).

The module returns the list Lf,Lm,qj. Here the matrices Lf and Lm are defined in (137) whereas vector qj is defined in (136). In geometric stiffness template analysis it is usual to set q to 0, in which case null matrices are returned and the consistent force computation skipped.

Module BeamFOMoDE, listed in Fig. 28, carries out the computation of the Finite Order Modified ODE. The module is invoked as

Several arguments have been defined before: model, EI, \(\Phi \), Le, F, \(\xi \), x, n, m, and q. Additional ones are

- MorG:

-

A letter string: “M” for material stiffness analysis, “G” for geometric stiffness analysis.

- Kp:

-

The \(2\times 6\) patch stiffness matrix returned by TwoElemPatchStiff.

- nh:

-

In geometric stiffness analysis of Timo model, highest power of h=Le in a series expansion of the \(k^2\) term of (124). Normally set to 6. See RHS below.

- simp:

-

A logical flag. If True, additional simplifications are done internally.

- inv:

-

A logical flag. If True, the Inverse function is used in the condensation process (139). If False, the LinearSolve function is used.

The module returns a 3-item list: FOMoDE.RHS,err:

- FOMoDE :

-

The computed FOMoDE, represented as the value of \(v''''(x)\). More precisely, its series expansion in even powers of h=Le up to order O(nh).

- RHS :

-

The right hand side of the canonical governing equation. For material stiffness analysis it is the RHS of (109). For geometric stiffness analysis it is the series expansion of the coefficient \(k^2\) in (124) in even powers of h=Le, up to order O(nh). Note that if \(\Phi =0\) (the BE model), \(k^2\) is simply F/EI and no expansion is needed.

- err :

-

The difference FOMoDE-RHS. If zero, the correct matching is achieved. If nonzero, further analysis is done by examining its Taylor series in the element length.

Module containing the inlined results for the IOMoDE errror coefficients \(C_2\), \(C_4\) and \(C_6\), as output by the script of Fig. 27

1.3 4.3 MoDEAnalysis Examples

The script of Fig. 26 does the MoDE analysis of the one-parameter material stiffness matrix (104). It uses \(n=10\) and \(m=6\). The printed results (not shown) corroborate the result (108).

The script of Fig. 27 is the first step in finding an optimal geometric stiffness for the BE model. It uses the “KG4” template with \(\beta _1\) preset to 1, three free \(\beta \) parameters: \(\beta _2\), \(\beta _3\) and \(\beta _4\), plus the Legendre basis parameter \(\chi \).

The primary result of the MoDE analysis are the error coefficients \(C_2\), \(C_4\), and \(C_6\), which are complicated functions of the four parameters. These are printed in InputForm format and inlined to flesh out the TruncBECoeffs module listed in Fig. ??. The subsequent parameter-optimization analysis is done with ad-hoc scripts (not shown) that call this module to retrieve the coefficients and perform the algebraic manipulations described in Appendix Sect. 3.5.

Appendix 5: Buckling Exact Stiffness

This Appendix develops exact stiffness equations for buckling analysis with plane Timoshenko beam elements. This is possible when exact homogeneous solutions of the governing stability equations are known. The case treated below is that of a prismatic element subjected to constant compressive axial force, under linearized prebuckling (LPB) assumptions. The resulting stiffness matrix will be labeled buckling exact (BuE) and tagged with an asterisk: \(()^*\).

The homogeneous solutions of the equilibrium equation (11) are trigonometric functions (sine and cosine) if \(k^2\) is real positive and constant over the element, and so is the dimensionless parameter \(\lambda =k\ell \). The solutions are nonlinear in \(\lambda \), and so are the resulting stiffness matrix entries. These complicated expressions have limited practical use as explained in Appendix Sect. 5.3, but serve to corroborate previous results when expanded in Taylor or Padé series.

The beam-column element studied here is pictured in Fig. 2. Of the six degrees of freedom (DOF) shown there only four are used in the BuE stiffness equations derived below:

The axial displacements \(u_1\) and \(u_2\), which uncouple at the individual element level, may be included later to complete a beam-column element, able to transform to global coordinates for assembly.

As in previous Appendices, the element supercript: \(()^e\) is omitted for brevity.

1.1 5.1 Buckling Exact Physical Stiffness

The axial force is denoted \(P=-F\), which is positive if compressive. Under the LPB assumptions, the stiffness entries depend nonlinearly on P whereas the generic \(4\times 4\) matrix form (103) still holds. The template method is used to construct \(\mathbf {K}^*\). The first step is to introduce dimensionless free parameters \(C_{ij}\):

This is called a universal template, since it include all possible elements with a symmetric stiffness. For a prismatic beam element, additional symmetries require \(C_{11}=C_{33}\), \(C_{22}=C_{44}\), etc. Let \(\mathbf {v}_{T}=\left[ \begin{array}{cccc} 1&0&1&0\end{array}\right] \) be the translational rigid body mode. Then \(\mathbf {K}^* \mathbf {v}_T=\mathbf {0}\), the zero force 4-vector. Imposing these constraints the number of free parameters is reduced to four, renamed \(c_1\) through \(c_4\):

Next consider the rigid “element tilt” \(\mathbf {v}_{R}=\left[ \begin{array}{cccc} -\ell /2&1&\ell /2&1\end{array}\right] \). Now \(\mathbf {K}^* \mathbf {v}_R=\left[ \begin{array}{cccc}-P&0&P&0\end{array}\right] \), which is consistent with the LPB assumptions. This supplies two additional constraints:

where the dimensionless axial force parameter \(\lambda \) is defined as in (124), except that L becomes \(\ell \):

As noted above, we assume that \(k^2\ge 0\), so the \(+\) square root is taken. Solving (155) for \(c_3\) and \(c_4\) gives

whence the number of independent template parameters is cut to two: \(c_1\) and \(c_2\). Matching the homogeneous solutions given above to the nodal DOF leads to two trascendental nonlinear equations, which are solved with Mathematica, The solution can be presented as

in which all Greek symbols identify dimensionless variables. If the node displacements are precluded: \(v_1=v_2=0\), removal of rows and columns 1 and 3 reduces (154) to the moment-rotation stiffness matrix:

As noted by Bazant and Cedolin [8, Sec. 2.1]. for the BE model (\(\Phi =0\)) these equations appeared in a 1935 NACA note [50], where it was used for the moment-distribution, hand-computation method of Hardy Cross [20]. Inversion provides the moment-rotation flexibility matrix.

The entries of this matrix are known as stability functions in the older literature. For the BE model these can be traced back to von Mises [97]; see also Timoshenko and Gere [91, Ch. 1]. Additional references are [43, 54]. Stability functions for the Timoshenko model were first derived by Absi [2], and are further developed in [7, 81, 82, 100, 101].