Abstract

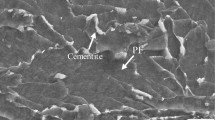

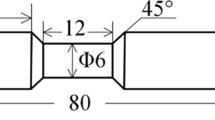

The microstructure and toughness of coarse grain zone (CGZ) and mixed grain zone (MGZ) for laser welded 960 MPa grade high strength steel joints were investigated by thermal simulation with a Gleeble-3500 thermal simulator. The results show that microstructure of the stimulated CGZ mainly consists of uniform interweaved lath martensite, and grain growth is not severe upon increasing the cooling time (t 8/5). Microstructure of the stimulated MGZ presents strip-like in low peak temperature, and small block martensite is formed on the grain boundary. However, in high peak temperature, the strip-like microstructure disappears and small block martensite presents net-like structure. The lath character for MGZ and CGZ is very obvious under TEM observation, and the average lath thickness of BM, MGZ, and CGZ is 100, 150 and 200 nm, respectively. The impact energy and microhardness of CGZ are higher than MGZ and reduce with increasing the cooling time. The fracture toughness deteriorating drastically for MGZ may be related with the formation of the mixture microstructure, in which the small block martensite is distributed in the shape of a network.

Similar content being viewed by others

References

X.H. Xue, Y.Y. Shan, L. Zheng, and S.N. Lou, Microstructural Characteristic of Low Carbon Microalloyed Steels Produced by Thermo-Mechanical Controlled Process, Mater. Sci. Eng. A, 2006, 438, p 285–287

H.J. Aval, S. Serajzadeh, and A.H. Kokabi, Prediction of Grain Growth Behavior in HAZ During Gas Tungsten Arc Welding of 304 Stainless Steel, J. Mater. Eng. Perform., 2009, 18, p 1193–1200

H.F. Dong, D.Y. Cai, Z.Z. Zhao, Z.Y. Wang, Y.H. Wang, Q.X. Yang, and B. Liao, Investigation on Static Softening Behaviors of a Low Carbon Steel Under Ferritic Rolling Condition, J. Mater. Eng. Perform., 2010, 19, p 151–154

S.K. Panda, M.L. Kuntz, and Y. Zhou, Finite Element Analysis of Effects of Soft Zones on Formability of Laser Welded Advanced High Strength Steels, Sci. Technol. Weld. Join., 2009, 14, p 52–61

H.J.C. Voorwald, I.M. Miguel, M.P. Peres, and M.O.H. Cioffi, Effects of Electroplated Zinc-Nickel Alloy Coatings on the Fatigue Strength of AISI, 4340 High-Strength Steel, J. Mater. Eng. Perform., 2005, 14, p 249–257

M. Shome, Effect of Heat-Input on Austenite Grain Size in the Heat-Affected Zone of HSLA-100 Steel, Mater. Sci. Eng. A, 2007, 44, p 6454–6460

G.S. Panos, R.W. Fonda, and R.A. Vandermeer, Microstructural Changes in HSLA-100 Steel Thermally Cycled to Simulate the Heat-Affected Zone During Welding, Metallurg. Mater. Trans., 1995, 26, p 3277–3293

W. Meng, Z.G. Li, J. Huang, Y.X. Wu, and S. Katayama, Microstructure and Softening of Laser Welded 960 MPa Grade High Strength Steel Joints, J. Mater. Eng. Perform., 2014, 23, p 538–544

P. Bilmes, C. Llorente, and J. Perez Ipin, Toughness and Microstructure of 13Cr4NiMo High Strength Steel Welds, J. Mater. Eng. Perform., 2000, 9, p 609–615

T. Mohandas, G. Madhusudan, B. Reddy, and K. Satish, Heat-Affected Zone Softening in High Strength Low Alloy Steels, J. Mater. Process. Technol., 1999, 88, p 284–294

B.E. Peddle and C.A. Pickles, Carbide and Hardness Development in the Heat-Affected Zone of Tempered and Post weld Heat-Treated 2.25Cr-1Mo Steel Weldments, J. Mater. Eng. Perform., 2000, 9, p 477–488

N.M. Abd-Allah, M.S. El-Fadaly, M.M. Megahed, and A.M. Eleiche, Fracture Toughness Properties of High-Strength Martensitic Steel within a Wide Hardness Range, J. Mater. Eng. Perform., 2001, 10, p 576–585

Y.W. Shi and Z.X. Han, Effect of Weld Thermal Cycle on Microstructure and Fracture Toughness of Simulated Heat-Affected Zone for a 800 MPa Grade High Strength Low Alloy Steel, J. Mater. Process. Technol., 2008, 207, p 30–39

L.Y. Lan, C.L. Qiu, D.W. Zhao, X.H. Gao, and L.X. Du, Microstructural Characteristics and Toughness of the Simulated Coarse Grained Heat Affected Zone of High Strength Low Carbon Bainitic Steel, Mater. Sci. Eng. A, 2011, 529, p 192–200

H.T. Kuo, R.C. Wei, W.F. Wu, and J.R. Yang, Simulated Heat Affected Zone in ASTM A533-B Steel Plates Under Low Heat Inputs, Mater. Chem. Phys., 2009, 117, p 471–477

C. Lee, J.B. Lee, D.H. Park, and S.J. Na, Effect of Weld HAZ Softening on Tensile Strength of Welded Joint with Weld HAZ Softening, Mater. Sci. Forum, 2008, 580-582, p 589–592

Y.Z. Zhu, D.M. Liang, J.C. Li, J.P. Xu, and Z.L. Xue, Effects of Thermo-Mechanical Treatment and Microalloying with Cr, Nb and Ti on Phase Transformation in C-Mn Steel Strips Produced by Compact Strip Production Process, Mater. Sci. Eng. A, 2011, 528, p 8365–8373

J. Moon and C. Lee, Behavior of (Ti, Nb)(C, N) Complex Particle During Thermomechanical Cycling in the Weld CGHAZ of a Microalloyed Steel, Acta Mater., 2009, 57, p 2311–2320

W.W. Xu, Q.F. Wang, T. Pan, H. Su, and C.F. Yang, Effect of Welding Heat Input on Simulated HAZ Microstructure and Toughness of a V-N Microalloyed Steel, J. Iron Steel Res. Int., 2007, 14, p 234–239

N. Eliaz, A. Shachar, B. Tal, and D. Eliezer, Characteristics of Hydrogen Embrittlement, Stress Corrosion Cracking and Tempered Martensite Embrittlement in High-Strength Steels, Eng. Fail. Anal., 2002, 9, p 167–184

Acknowledgment

This work was supported by the National Natural Science Foundation of China (Grant No. 51035004)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Meng, W., Li, Z., Jiang, X. et al. Microstructure and Toughness of Simulated Heat-Affected Zone of Laser Welded Joint for 960 MPa Grade High Strength Steel. J. of Materi Eng and Perform 23, 3640–3648 (2014). https://doi.org/10.1007/s11665-014-1137-y

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-014-1137-y