Abstract

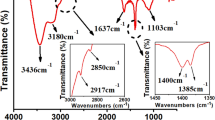

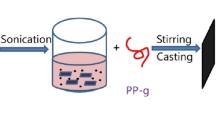

Ethylene propylene diene monomer (EPDM) possessing nonpolar groups exhibits low dielectric loss and is one of the candidates for fabricating flexible dielectric materials. Incorporation of high amount of ceramics is commonly used to improve dielectric properties of EPDM. However, the high volume fraction makes EPDM rigid and enhances the complex viscosity of composite materials during manufacturing processes. In this study, high-barrier graphene (HBG), which is highly lamellar and thin (lamellar/thickness is approximately 3300), was selected as filler. The study aims to investigate the influence of low-loading HBG on the rheological, vulcanization, dielectric, mechanical, thermal and electric properties of EPDM. In this work, the Raman spectrum shows that the grain size and layer number of HBG is 70 nm and 3–4, respectively. Rheological measurement shows that 3% HBG decreases the complex viscosity of EPDM/HBG nearly by 43%. The Fourier transform infrared (FT-IR) spectrum shows C=C on the HBG surface. Cure curves and parameters show that C=C participates in the vulcanization reaction and increases chemical cross-links of EPDM/HBG. This is an innovative approach to improve the dielectric constant (ε)-to-modulus (Y) ratio of EPDM/HBG by 77% through adjusting HBG content, which could optimize the value of ε and Y. Due to large lamellar size, the thermal conductivity of EPDM/HBG is improved by 20%. Moreover, all EPDM/HBG composites exhibit volume resistivity greater than 1 × 1010 Ω·m, which are regarded as insulated materials.

Graphical Abstract

Similar content being viewed by others

References

S. Zhu, Z. Fan, and B. Feng, Review on wearable thermoelectric generators: from devices to applications. Energy 15, 1 (2022).

C. Pang, C. Lee, and K. Suh, Recent advances in flexible sensors for wearable and implantable devices. J. Appl. Polym. Sci. 130, 1429 (2013).

W.G. Yang, Y.T. Qin, and Z. Wang, Recent advances in the development of flexible sensors: mechanisms, materials, performance optimization, and applications. J. Electron. Mater. 51, 6735 (2022).

R. Pelrine, R. Kornbluh, and Q. Pei, High-speed electrically actuated elastomers with strain greater than 100%. Science 2887, 836 (2000).

J. Su and J. Zhang, Improvement of mechanical and dielectrical properties of ethylene propylene diene monomer (EPDM)/barium titanate (BaTiO3) by layered mica and graphite flakes. Compos. B 112, 148 (2017).

Z.C. Song, L. Zhao, C.L. Chang, and A. Flexible, Highly sensitive porous PDMS tactile sensor based on the physical foaming method. J. Electron. Mater. 51, 7173 (2022).

J. Su and J. Zhang, Improvement of electrical properties and thermal conductivity of ethylene propylene diene monomer (EPDM)/barium titanate (BaTiO3) by carbon blacks and carbon fibers. J. Mater. Sci. Mater. Electron. 28, 5250 (2017).

T.D. Zhang, C.X. Dai, and C.H. Zhang, Investigations on the electrical performances of CuNPs/BN/EPDM composites. J. Electron. Mater. 51, 1349 (2022).

J. Su and J. Zhang, Remarkable enhancement of mechanical and dielectric properties of flexible ethylene propylene diene monomer (EPDM)/ barium titanate (BaTiO3) dielectric elastomer by chemical modification of particles. RSC Adv. 96, 78448 (2015).

W. Wang, J. Qian, C. Geng, M. Fan, C. Yang, L. Lingchao, and Z. Cheng, Flexible lead-free Ba0.5Sr0.5TiO3/0.4BiFeO3-0.6SrTiO3 dielectric film capacitor with high energy storage performance. Nanomaterials 11(11), 3065 (2021). https://doi.org/10.3390/nano11113065.

N. Dishovsky, F. Tantawy, and R. Dimitrov, Effect of Bi-containing superconducting ceramic on the volume resistivity of butyl rubber composites. Polym. Test. 23, 69 (2004).

V.L. Vilesh and S. Ganesanpotti, Silicone rubber- BaBiLiTeO6 composites: flexible microwave substrates for 5G applications. J. Electron. Mater. 51, 3237 (2022).

S. Wu, J. Wang, and J. Shao, Building a novel chemically modified polyaniline/thermally reduced graphene oxide hybrid through π–π interaction for fabricating acrylic resin elastomer-based composites with enhanced dielectric property. ACS Appl. Mater. Interfac. 9, 28887 (2017).

J. Su and C. Li, Effect of plasma-enhanced chemical vapor deposition (PECVD) graphene content on the properties of EPDM/graphene composites. J. Mater. Sci. Mater. Electron. 32, 9065 (2021).

B.U. Durmaz, M.G. Atılgan, and A. Aytac, A comparative study of graphene oxide or chemically reduced graphene oxide filled poly(ethylene terephthalate)/poly(butylene terephthalate)/graphene nanocomposites. Iran. Polym. J. 31, 991 (2022).

C. Lee, X. Wei, J.W. Kysar, and J. Hone, Measurement of the elastic properties and intrinsic strength of monolayer graphene. Science 321(5887), 385–388 (2008). https://doi.org/10.1126/science.1157996.

A. Balandin, S. Ghosh, and W. Bao, Superior thermal conductivity of single-layer graphene. Nano Lett. 8, 902 (2008).

A. Tarhini, M. Alchamaa, and M. Khraiche, The effect of temperature on the electrical and thermal conductivity of graphene-based polymer composite films. J. Appl. Polym. Sci. 139, 51896 (2021).

M. Kumar and S. Kirupavathy, Investigations on the capacitive behaviour of hydrothermally synthesised cadmium meta niobate incorporated reduced graphene oxide hybrid nanocomposite electrode material. J. Mater. Sci. Mater. Electron. 33, 2428 (2022).

H. Wu, W. Zhou, and Q. Liu, High pressure homogenization of graphene and carbon nanotube for thermal conductive polyethylene composite with a low filler content. J. Appl. Polym. Sci. 139, 51838 (2022).

A. Ghorbankhan, M. Nakhaei, and G. Naderi, Prediction and optimization of mechanical properties of PA6/NBR/graphene nanocomposites fabricated by friction stir processing. J. Elast. Plast. 54, 67 (2022).

T. Wu, Y. Yang, and W. Sun, Unfolding graphene nanosheets towards high barrier performance of epoxy/graphene nanocomposite coating. Compos. A Appl. Sci. Manuf. 153, 106732 (2022).

Y. Shen, H. Chen, and S. Chen, Graphene as a diffusion barrier at the interface of liquid-state low-melting Sn–58Bi alloy and copper foil. Appl. Surf. Sci. 578, 152108 (2022).

J. Su, S. Chen, and J. Zhang, Effect of hot air aging on properties of EPDM/SmBO3/EVA and EPDM/ATO/EVA composites. J. Appl. Polym. Sci. 122, 3277 (2011).

J. Su, S. Chen, and J. Zhang, Effect of hot-air aging on properties of EPDM/SmBO3/EAA and EPDM/ATO/EAA composites. J. Compos. Mater. 46, 589 (2012).

Y. Zhu, S. Murali, and W. Cai, Graphene and graphene oxide: synthesis, properties, and applications. Adv. Mater. 22, 3906 (2010).

A. Ferrari, J. Meyer, and V. Scardaci, Raman spectrum of graphene and graphene layers. Phys. Rev. Lett. 97, 187401 (2006).

A. Ferrari, Raman spectroscopy of graphene and graphite: Disorder, electron phonon coupling, doping and nonadiabatic effects. Solid State Commun. 143, 47 (2007).

V. Popov, and P. Lambin, Theoretical Raman intensity of the G and 2D bands of strained graphene. Carbon 54, 86 (2013).

J. Park, A. Reina, and R. Saito, G′ band Raman spectra of single, double and triple layer graphene. Carbon 47, 1303 (2009).

X. Xiang, Y. Zhu, and M. Yin, Study of microwave reduction of graphene oxide suspension: structure and functional groups. J. Mater. Sci. 57, 3280 (2022).

J. Su, and J. Zhang, Effect of treated mica on rheological, cure, mechanical, and dielectric properties of ethylene propylene diene monomer (EPDM)/barium titanate (BaTiO3)/mica. J. Appl. Polym. Sci. 134, 44833 (2017).

S. Pongdhorn, S. Chakrit, and T. Uthai, Comparison of reinforcing efficiency between Si-69 and Si-264 in a conventional vulcanization system. Polym. Test. 23, 871 (2004).

M. Alam, V. Kumar, and P. Potiyaraj, Synergistic activities of binary accelerators in presence of magnesium oxide as a cure activator in the vulcanization of natural rubber. J. Elast. Plast. 54, 123 (2022).

Y. Zhao, X.D. Jia, and L. Li, Effects of surface modified graphene oxide on the cure kinetics of warm-mixed epoxy-asphalt. Polym. Sci. Ser. B 64, 229 (2022).

C. Nakason, P. Wannavilai, and A. Kaesaman, Effect of vulcanization system on properties of thermoplastic vulcanizates based on epoxidized natural rubber/polypropylene blends. Polym. Test. 25, 34 (2006).

J. Heerden, and R. Swanepoel, XRD analysis of ZnO thin films prepared by spray pyrolysis. Thin Solid Films 299, 72 (1997).

X. Liu, X. Hong, and B. Liang, Preparation of mechanically stripped functionalized multilayer graphene and its effect on thermal conductivity of polyethylene composites. J. Polym. Res. 29, 146 (2022).

G. Yin, Y. Yang, and F. Song, Dielectric elastomer generator with improved energy density and conversion efficiency based on polyurethane composites. ACS Appl. Mater. Interface 9, 5237 (2017).

V. Sarangapani, and D. Rajamanickam, Effect of gamma irradiation on titanium dioxide-filled polymer composites in cable insulation applications Iran. Polym. J. 31, 809 (2022).

Acknowledgments

The study was funded by the Scientific Research Foundation for the introduction of talent (YK19-01-02), from Nanjing Vocational University of Industry Technology.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There are no conflicts to declare.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Su, J. Improvement of Relative Ratio of Dielectric Constant to Young’s Modulus of Ethylene Propylene Diene Monomer (EPDM)/High-Barrier Graphene (HBG) for Dielectric Elastomer Application. J. Electron. Mater. 52, 6089–6097 (2023). https://doi.org/10.1007/s11664-023-10541-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-023-10541-4