Abstract

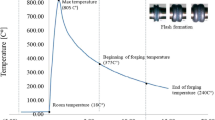

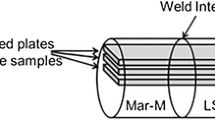

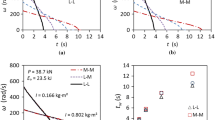

It has been widely assumed, but never proven, that the efficiency of the inertia friction welding (IFW) process is independent of process parameters and is relatively high, i.e., ~70 to 95 pct. In the present work, the effect of IFW parameters on process efficiency was established. For this purpose, a series of IFW trials was conducted for the solid-state joining of two dissimilar nickel-base superalloys (LSHR and Mar-M247) using various combinations of initial kinetic energy (i.e., the total weld energy, E o), initial flywheel angular velocity (ω o), flywheel moment of inertia (I), and axial compression force (P). The kinetics of the conversion of the welding energy to heating of the faying sample surfaces (i.e., the sample energy) vs parasitic losses to the welding machine itself were determined by measuring the friction torque on the sample surfaces (M S) and in the machine bearings (M M). It was found that the rotating parts of the welding machine can consume a significant fraction of the total energy. Specifically, the parasitic losses ranged from 28 to 80 pct of the total weld energy. The losses increased (and the corresponding IFW process efficiency decreased) as P increased (at constant I and E o), I decreased (at constant P and E o), and E o (or ω o) increased (at constant P and I). The results of this work thus provide guidelines for selecting process parameters which minimize energy losses and increase process efficiency during IFW.

Similar content being viewed by others

Abbreviations

- I :

-

Flywheel moment of inertia

- E o, E(t):

-

Initial (total) and instantaneous kinetic energy of flywheel

- P :

-

Axial compression force

- ω o and ω :

-

Initial and instantaneous angular velocity of the flywheel

- t and t w :

-

Current and total welding time (t = 0 at the moment when the joined samples are brought together under the axial force P)

- M :

-

Total torque of the flywheel

- M S :

-

Sample friction torque

- \( M_{\text{S}}^{\hbox{min} } \) :

-

Minimum value of the sample friction torque

- M M :

-

Friction torque of the welding machine

- a and M M0 :

-

Coefficients of the linear dependence of M M on ω (Eq. [5])

- E S :

-

Energy dissipated at the weld interface during IFW (sample energy)

- \( E_{\text{S}}^{\text{cr}} \) :

-

Critical (minimum) amount of sample energy required to produce a sound weld at a given P

- E M :

-

Energy dissipated by the welding machine during IFW (parasitic energy)

- η = E S/E o :

-

Efficiency of the IFW process

References

A. Chamanfar, M. Jahazi, and J. Cormier: Metall. Mater. Trans. A, 2015, vol. 46A, pp. 1639–69.

E.D. Nicholas: Weld. World, 2003, vol. 47, pp. 2–9.

M.M. Attallah and M. Preuss: in Welding and Joining of Aerospace Materials, M.C. Chaturvedi, ed., Woodhead Publishing, Oxford, 2012.

Recommended Practices for Friction Welding (AWS Standard), American Welding Society, Miami, FL, 1989.

R.J. Reagan: Heat Measurements in Inertia Welding of Aluminum to Steel, DoE Report DE86012463, Oak Ridge National Laboratory, Oak Ridge, TN, 1986.

M. Maalekian: Sci. Technol. Weld. Join., 2007, vol. 12, pp. 738–59.

W. Liu, F. Wang, X. Yang, and W. Li: Adv. Mater. Sci. Eng., 2013, vol. 2013, pp. 196382(1)–(9).

F.F. Wang, W.Y. Li, J.L. Li, and A. Vairis: Int. J. Adv. Manuf. Technol., 2014, vol. 71, pp. 1909–18.

C.J. Bennett, M.M. Attallah, M. Preuss, P.H. Shipway, T.H. Hyde, and S. Bray: Metall. Mater. Trans. A, 2013, vol. 44A, pp. 5054–64.

C. Bennett: J. Manuf. Process., 2015, vol. 18, pp. 84–91.

D.W. Mahaffey, O.N. Senkov, R. Shivpuri, and S.L. Semiatin: Metall. Mater. Trans. A, 2016, vol. 47, pp. 3981–4000.

D.F. Wilcock and E.R. Booser: Bearing Design and Application, McGraw-Hill, New York, 1957.

B.S. Herbage: in Sixth Turbomachinery Symposium, M.P. Boyce, ed., Texas A&M University Press, College Station, TX, 1977, pp. 33–38.

F. Kreith and D.Y. Goswami: The CRC Handbook of Mechanical Engineering, 2nd ed., CRC Press, Boca Raton, FL, 2005.

M.B. Mohammed, T.H. Hyde, C.J. Bennett, and E.J. Williams: in 2009 ASME Turbo Expo, June 8, 2009–June 12, 2009, American Society of Mechanical Engineers, Orlando, FL, 2009, pp. 829–37.

O.N. Senkov, D.W. Mahaffey, S.L. Semiatin, and C. Woodward: Metall. Mater. Trans. A, 2014, vol. 45, pp. 5545–61.

O.N. Senkov, D.W. Mahaffey, S.L. Semiatin, and C. Woodward: J. Mater. Eng. Perform., 2015, vol. 24, pp. 1173–84.

Acknowledgments

Inertia friction welding experiments were conducted at EWI, Inc., Columbus, Ohio. The assistance of David Workman (EWI), Mark Ruddell (UDRI), Phillip Blosser (UDRI), and Andy Rosenberger (AFRL) in conducting the experiments is much appreciated. We also thank Rajiv Shivpuri (OSU) for valuable discussions. ONS acknowledges financial support through US Air Force On-site Contract FA8650-10-D-5226 managed by UES, Inc., Dayton, OH. DJT and WZ acknowledge the financial support of AFRL through the NSF I/UCRC Manufacturing and Materials Joining Innovation Center.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted 13 December 2016.

Rights and permissions

About this article

Cite this article

Senkov, O.N., Mahaffey, D.W., Tung, D.J. et al. Efficiency of the Inertia Friction Welding Process and Its Dependence on Process Parameters. Metall Mater Trans A 48, 3328–3342 (2017). https://doi.org/10.1007/s11661-017-4115-9

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-017-4115-9