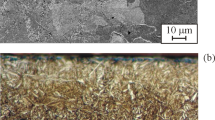

In this study, the structure and properties of multilayer coatings consisting of alternating CrN/TiN layers on C11000 copper and aged C 17200 alloy are analyzed. Coatings with a total thickness of about 4 μm have been obtained by the method of cathode-arc deposition using two targets made of chromium and titanium. The microhardness of the applied coatings reached 14 GPa. The adhesive strength is investigated by scratch testing in which the destruction of coatings on copper and copper-beryllium alloy substrates occurs at loads up to 10 and 20 N, respectively. The behavior of the multilayer coatings during tribological tests with boundary lubrication is studied with simultaneous registration of acoustic emission (AE) signals. The results obtained indicate that the friction coefficients decrease from 0.11 to 0.07 with a load increase from 5 to 10 N and behave the same for coatings on copper and beryllium bronze substrates.

Similar content being viewed by others

References

Z. M. Zhong, M. H. Leong, and X. D. Liu, Mater. Des., 32 (2), 643–648 (2011).

M. F. Yan, Y. D. Zhu, C. S. Zhang, et al., Mater. Des., 84, 10–17 (2015).

L. Liu, H. H. Shen, X. Z. Liu, et al., Appl. Surf. Sci., 388, 103–108 (2016).

Y. Zhu, Z. Li, H. Bi, et al., Materials, 15 (22), 8002 (2022).

L. Yang, F. Y. Zhang, M. F. Yan, and M. L. Zhang, Appl. Surf. Sci., 292, 225–230 (2014).

A. Bloyce, Trans. Inst. Met. Finish., 72 (2), 58–62 (1994).

A. Markov, E. Yakovlev, D. Shepel’, and M. Bestetti, Results Phys., 12, 1915–1924 (2019).

L. Liu, H. H. Shen, X. Z. Liu, et al., Appl. Surf. Sci., 388, 103–108 (2016).

H. Ma, Q. Miao, G. Zhang, et al., Ceram. Int., 47 (9), 12583–12591 (2021).

S. N. Rabadzhiyska, L. P. Kolaklieva, T. M. Cholakova, et al., Bulg. Chem. Commun., 50, Special Issue G, 172–180 (2018).

J. Kacprzyńska-Gołacka, J. Smolik, A. Mazurkiewicz, et al., Solid State Phenom., 237, 27–33 (2015).

P. Feng, P. Borghesani, W. A. Smith, et al., Appl. Mech. Rev., 72 (2), 020801 (2020).

L. M. Babici, A. Tudor, and J. Romeu, Appl. Sci., 12 (19), 9527 (2022).

J. Hanchi and B. E. Klamecki, Wear, 145 (1), 1–27 (1991).

Z. Geng, D. Puhan, and T. Reddyhoff, Tribol. Int., 134, 394–407 (2019); https://doi.org/10.1016/j.triboint.2019.02.014.

A. Hase, Y. Sato, K. Shinohara, and K. Arai, Coatings, 11 (6), 737 (2021); https://doi.org/10.3390/coatings11060737.

A. Filippov, A. Vorontsov, N. Shamarin, et al., Metals, 12 (12), 2046 (2022).

H. Okamoto, M. E. Schlesinger, and E. M. Mueller, Eds., Alloy Phase Diagrams, Vol. 3, ASM International (2016).

Y.-Y. Chang, H. Chang, L.-J. Jhao, and C.-C. Chuang, Surf. Coat. Technol., 350, 1071–1079 (2018).

C. Zhao, Y. Zhu, Z. Yuan, and J. Li, Surf. Coat. Technol., 403, 126399 (2020).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Semenchuk, N.V., Kolubaev, A.V., Sizova, O.V. et al. Structure and Properties of Multilayer CrN/TiN Coatings Obtained by Vacuum-Arc Plasma-Assisted Deposition on Copper and Beryllium Bronze. Russ Phys J 66, 1077–1086 (2023). https://doi.org/10.1007/s11182-023-03045-5

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11182-023-03045-5