Abstract

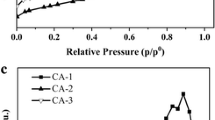

Micro-nano hollow materials have become a research hotspot due to their unique structure and properties. Blast furnace gas is one of the main pollutants discharged from steelmaking, and the COS chemical property in blast furnace gas is stable, which is difficult to be effectively removed. Nano-hollow sphere composite has the advantages of large specific surface area, adjustable material size, and stable performance. It has become one of the most promising hydrolysis catalytic materials due to its good catalytic performance. In this study, the template of carbon spheres was synthesized by the glucose hydrothermal method, and activated aluminum nitrate was loaded on carbon sphere templates by the method of equal volume impregnation. Urea was used as precipitant to prepare uniform Al2O3 hollow sphere hydrolysis catalyst, and its application and removal performance in COS removal of blast furnace gas was explored. The results showed that (1) When the ratio of water to alcohol was 30 mL:90 mL and the calcination temperature was 950 ℃, the particle size of the prepared γ-Al2O3 hollow sphere hydrolysis catalyst was between 100 and 150 nm, the average pore size was 6.785 nm, the total pore volume was 0.259 cm3·g−1 and the specific surface area was 154.665 m2·g−1. (2) When the roasting temperature is 950 ℃ and the addition amount is 40 mmol, the hydrolysis catalytic efficiency of COS is the highest. After the reaction for 70 min, the hydrolysis catalytic efficiency is maintained at about 68%, and the conversion amount is 120 mg·m−3.

Similar content being viewed by others

References

Kong L, Luo S, Zhang G et al (2022) Interfacial polarization dominant CNTs/PyC hollow microspheres as a lightweight electromagnetic wave absorbing material[J]. Carbon 193:216–229

Lei Z, Yao Y, Yusu W et al (2022) Study on denitration performance of MnO2@CeO2 core-shell catalyst supported on nickel foam[J]. Appl Phys A Mater Sci Process 128(3):1–8

Xingxin D, Jie S, Linze Lv et al (2022) Yolk-shell Sb2S3@C hollow microspheres with controllable interiors for high space utilization and structural stability of Na-storage[J]. Chem Nano Mat 8(3):e202100515

Wang H, Wang J, Bo G et al (2020) Degradation of pollutants in polluted river water using Ti/IrO2-Ta2O5 coating electrode and evaluation of electrode characteristics[J]. J Clean Prod 273:123019

Ren Y, Zhang G, Huo J et al (2022) Flower-like TiO2 hollow microspheres with mixed-phases for high-pseudocapacitive lithium storage[J]. J Alloys Compd 902:163730

Wang J, Yang Z, Wang H et al (2021) Decomposition process of cefotaxime sodium from antibiotic wastewater by up-flow blanket filter (UBF) reactor: reactor performance, sludge characteristics and microbial community structure analysis[J]. Sci Total Environ 758:143670

Li X, Wang X, Wang L et al (2022) Efficient removal of carbonyl sulfur and hydrogen sulfide from blast furnace gas by one-step catalytic process with modified activated carbon[J]. Appl Surf Sci 579:152189

Lei Z, Xi L, Lingbo Q et al (2021) Application of a blast furnace slag carrier catalyst in flue gas denitration and sulfur resistance[J]. RSC Adv 11:15036–15043

Cao R, Ning P, Wang X et al (2022) Low-temperature hydrolysis of carbonyl sulfide in blast furnace gas using Al2O3-based catalysts with high oxidation resistance[J]. Fuel 310:122295

Wang H, Zhang L, Tian Y et al (2021) Performance of nitrobenzene and its intermediate aniline removal by constructed wetlands coupled with the micro-electric field[J]. Chemosphere 264:128456

Zhao S, Junpeng L, Zhiqiang S (2020) Synergistic decarbonization and desulfurization of blast furnace gas via a novel magnesium-molybdenum looping process[J]. Fuel 279:118418

Song Q, Bao J, Xue S et al (2021) Collaborative disposal of multisource solid waste: Influence of an admixture on the properties, pore structure and durability of foam concrete[J]. J Market Res 14:1778–1790

Na L, Ping N, Xin S et al (2021) Simultaneous catalytic hydrolysis of HCN, COS and CS2 over metal-modified microwave coal-based activated carbon[J]. Sep Purif Technol 259:118205

Lei Z, Hao S, Yusu W et al (2022) Study on dry desulfurization performance of MnOx hydrothermally loaded halloysite desulfurizer[J]. Environ Technol Innov 26:102308

Argonul A, Er OO, Kayahan U et al (2020) Syngas cleaning for coal to methanol demo plant–H2S and COS removal[J]. Chem Eng Commun 208(7):950–964

Wang H, Quan B, Bo G et al (2020) Advanced oxidation treatment of dissolved organic matter from wastewater treatment plant secondary effluent using scattering electrical reactor[J]. J Clean Prod 267:122258

Jia-nan Gu, Liang J, Songjie Hu et al (2022) Enhanced removal of COS from blast furnace gas via catalytic hydrolysis over Al2O3-based catalysts: insight into the role of alkali metal hydroxide[J]. Sep Purif Technol 295:121356

Song Q, Zhao HongYu, Jia JinWei et al (2020) Effects of demineralization on the surface morphology, microcrystalline and thermal transformation characteristics of coal[J]. J Anal Appl Pyrol 145:104716

Lanzerstorfer C, Preitschopf W, Neuhold R et al (2019) Emissions and removal of gaseous pollutants from the top-gas of a blast furnace[J]. ISIJ Int 59(3):590–595

Lei Z, Yang J, Weiwei X et al (2022) Application and removal mechanism of ZnO/Bentonite desulfurizer in the dry desulfurization[J]. Appl Phys Mater Sci Process 128:146

Xiang L, Xueqian W, Langlang W (2022) Efficient removal of carbonyl sulfur and hydrogen sulfide from blast furnace gas by one-step catalytic process with modified activated carbon. Appl Surf Sci 579:152189

Song Q, Zhao H, Chang S et al (2020) Study on the catalytic pyrolysis of coal volatiles over hematite for the production of light tar[J]. J Anal Appl Pyrol 151:104927

Chen Z, Li J, Zhang Z et al (2021) Controllable architecture of mesoporous double-nanoshell SiO2/TiO2 hollow tube based on layer by layer method[J]. J Nanomater 2021:1–9

Hongyu Z, Yuhuan Li, Qiang S et al (2021) Catalytic reforming of volatiles from co-pyrolysis of lignite blended with corn straw over three iron ores: effect of iron ore types on the product distribution, carbon-deposited iron ore reactivity and its mechanism[J]. Fuel 286:119398

Chen Y, Zhang W, He B et al (2017) Preparation and characterization of Co modified [email protected]2 core-shell structure nano catalytic material for carbon monoxide oxidation at low temperature[J]. Gongneng Cailiao/J Funct Mater 48(6):06158–06164

Qiang S, Hongyu Z, Jinwei J et al (2020) Pyrolysis of municipal solid waste with iron-based additives: a study on the kinetic, product distribution and catalytic mechanisms [J]. J Clean Prod 258:120682

Li K, Veith GM, Lamm ME et al (2022) Hermetically sealed porous-wall hollow microspheres enabled by monolithic glass coatings: potential for thermal insulation applications[J]. Vacuum 195:110667

Hongyu Z, Qiang S, Shucheng L et al (2018) Study on catalytic co-pyrolysis of physical mixture/staged pyrolysis characteristics of lignite and straw over an catalytic beds of char and its mechanism[J]. Energy Convers Manage 161:13–26

Zhao H, Chen Y, Duan X (2020) Study on the factors affecting the deep reduction of coal gangue containing high contents of iron and sulfur[J]. Fuel 288:119571

Xinyu M, Xue Q, Shengyang H et al (2021) Hollow spherical LiNi0.5Mn1.5O4 synthesized by a glucose-assisted hydrothermal method[J]. Mater Lett 289:129417

Funding

This work was supported by the Key Research and Development Program of Shaanxi (Program No.2021SF-445), Shaanxi Key Laboratory of Geological Support for Coal Green Exploitation (DZBZ2021Z-01), Natural Science Basic Research Program of Shaanxi (2019JL-01) and Key Research and Development Program of Shaanxi (2019ZDLSF05-05–01).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhang, L., Yang, X., Zhang, L. et al. Preparation of nano-hollow sphere hydrolytic catalyst and study on its COS removal performance. J Nanopart Res 24, 268 (2022). https://doi.org/10.1007/s11051-022-05641-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11051-022-05641-x