Abstract

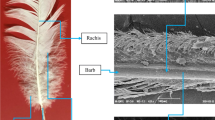

In this work, thermal properties of composites from chicken feather fiber (CFF) and polylactic acid (PLA) were investigated. CFF/PLA green composites were manufactured by extrusion and injection molding. Short and long fibers (3 and 20 mm) were used at different contents (2, 5 and 10 mass%). The effects of fiber concentration and fiber length on thermal properties of CFF/PLA composites were studied. Thermal properties of CFF/PLA composites were examined through differential scanning calorimetry (DSC), thermogravimetric analysis (TG) and dynamic mechanical analysis (DMA). From the experiments, it was found that addition of CFF was effective to improve the thermal properties of PLA. The DSC results showed that heat flow increased with the increase in CFF content on the glass transition, on the crystallization temperature and on melting temperature. The TG results revealed that addition of CFF to PLA had positive effect on the thermal stability. In addition, the results of DMA experiments showed that the tan δ decreased with the increasing CFF content, indicating less damping and more elastic behavior in the composites. The results obtained from this study provide important information on the temperature-dependent properties of CFF/PLA and lead to new product development based on natural resources.

Similar content being viewed by others

References

La Mantia FP, Morreale M. Green composites: a brief review. Compos A. 2011;42:579–88.

Zini E, Scandola M. Green composites: an overview. Polym Compos. 2011;32:1905–14.

Vink ETH, Rabago KR, Glassner DA, Gruber PR. Applications of life cycle assessment to NatureWorks polylactide(PLA) production. Polym Degrad Stab. 2003;80:403–19.

Oksman K, Skrifvars M, Selin JF. Natural fibres as reinforcement in polylactic acid (PLA) composites. Compos Sci Technol. 2003;63:1317–24.

Bax B, Müssig J. Impact and tensile properties of PLA/Cordenka and PLA/flax composites. Compos Sci Technol. 2008;68:1601–7.

Kannan TG, Wu CM, Cheng KB. Effect of different knitted structure on the mechanical properties and damage behaviour of Flax/PLA (Poly Lactic acid) double covered uncommingled yarn. Compos B. 2012;43:2836–42.

Suardana NPG, Ku MS, Lim JK. Effects of diammonium phosphate on the flammability and mechanical properties of bio-composites. Mater Des. 2011;32:1990–9.

Baghei B, Skrifvars M, Berglin L. Manufacture and characterization of thermoplastic composites made from PLA/hemp co-wrapped hybrid yarn prepregs. Compos A. 2013;50:93–101.

Tokoro R, Vu DM, Okubo K, Tanaka T, Fujii T, Fujiura T. How to improve mechanical properties of polylactic acid with bamboo fibers. J Mater Sci. 2008;43(2):775–87.

Nishino T, Hirao K, Kotera M, Nakamae K, Inagaki H. Kenaf reinforced biodegradable composite. Compos Sci Technol. 2003;63:1281–6.

Huda MS, Drzal LT, Mohanty AK, Misra M. Effect of fiber surface-treatments on the properties of laminated biocomposites from poly(lactic acid) (PLA) and kenaf fibers. Compos Sci Technol. 2008;68:424–32.

Bledzki AK, Jaszkiewicz A, Scherzer D. Mechanical properties of PLA composites with man-made cellulose and abaca fibres. Compos A. 2009;40:404–12.

Ho MP, Lau KT, Wang H, Bhattacharyya D. Characteristics of a silk fibre reinforced biodegradable plastic. Compos B. 2011;42:117–22.

Cheung HY, Lau KT, Tao XM, Hui D. A potential material for tissue engineering Silkworm silk/PLA biocomposite. Compos B. 2008;39:1026–33.

Altman GH, Diaz F, Jakuba C, Calabro T, Horan RL, Chen J, et al. Silk-based biomaterials. Biomaterials. 2003;24:401–16.

Reddy N, Yang Y. Structure and properties of chicken feather barbs as natural protein fibers. J Polym Environ. 2007;15:81–7.

Barone JR, Schmidt WF, Liebner CFR. Compounding and molding of polyethylene composites reinforced with keratin feather fiber. Compos Sci Technol. 2005;65:683–92.

Barone JR, Schmidt WF. Polyethylene reinforced with keratin fibers obtained from chicken feathers. Compos Sci Technol. 2005;65:173–81.

Bullions TA, Hoffman D, Gillespie RA, Price-O’Brien J, Loos AC. Contributions of feather fibers and various cellulose fibers to the mechanical properties of polypropylene matrix composites. Compos Sci Technol. 2006;66:102–14.

Reddy N, Yang Y. Light-mass polypropylene composites reinforced with whole chicken feathers. J Appl Polym Sci. 2010;116:3668–75.

Huda S, Yang Y. Composites from ground chicken quill and polypropylene. Compos Sci Technol. 2008;68:790–8.

Flores-Hernandez CG, Colin-Cruz A, Velasco-Santos C, Castano VM, Rivera-Armenta JL, Almendarez-Camarillo A, Garcia-Casillas PE, Martinez-Hernandez AL. All green composites from fully renewable biopolymers: chitosan–starch reinforced with keratin from feathers. Polymers. 2014;6:686–705.

Martinez-Hernandez AL, Velasco-Santos C, De-Icaza M, Castano VM. Dynamical–mechanical and thermal analysis of polymeric composites reinforced with keratin biofibers from chicken feathers. Compos B. 2007;38:405–10.

Cheng S, Lau KT, Liu T, Zhao Y, Lam PM, Yin Y. Mechanical and thermal properties of chicken feather fiber/PLA green composites. Compos B. 2009;40:650–4.

Finkenstadt VL, Liu L. Evaluation of poly(lactic acid) and sugar beet pulp green composites. J Polym Environ. 2007;15:1–6.

De Rosa IM, Iannoni A, Kenny JM, Puglia D, Santulli C, Sarasini F, Terenzi A. Poly(lactic acid)/Phormium tenax composites: morphology and thermo-mechanical behavior. Polym Compos. 2011;32:1362–8.

Huda MS, Drzal LT, Mohanty AK, Misra M. Chopped glass and recycled newspaper as reinforcement fibers in injection molded poly(lactic acid) (PLA) composites: a comparative study. Compos Sci Technol. 2006;66:1813–24.

Kaiser MR, Anuar HB, Samat NB, Abdul Razak SB. Effect of processing routes on the mechanical, thermal and morphological properties of PLA-based hybrid biocomposite. Iran Polym J. 2013;22:123–31.

Gregorova A, Hrabalova M, Wimmer R, Saake B, Altaner C. Poly(lactide acid) composites reinforced with fibers obtained from different tissue types of Picea sitchensis. J Appl Polym Sci. 2009;114:2616–23.

Pilla S, Gong S, O’Neill E, Rowell RM, Krzysik AM. Polylactide-pine wood flour composites. Polym Eng Sci. 2008;48:578–87.

Moshiul AKM, Mina MF, Beg MDH, Mamun AA, Bledzki AK, Shubhra QTH. Thermo-mechanical and morphological properties of short natural fiber reinforced poly(lactic acid) biocomposite: effect of fiber treatment. Fibers Polym. 2014;15(6):1303–9.

Luo H, Xiong G, Ma C, Chang P, Yao F, Zhu Y, Zhang C, Wan Y. Mechanical and thermo-mechanical behaviors of sizing-treated corn fiber/polylactide composites. Polym Test. 2014;39:45–52.

Baba BO, Özmen U. Preparation and mechanical characterization of chicken feather/PLA composites. Polym Compos. 2015;1–9. doi:10.1002/pc.23644.

Porras A, Maranon A, Ashcroft IA. Thermo-mechanical characterization of Manicaria Saccifera natural fabric reinforced poly-lactic acid composite lamina. Compos A. 2016;81:105–10.

Masirek R, Kulinski Z, Chionna D, Piorkowska E, Pracella M. Composites of poly(l-lactide) with hemp fibers: morphology and thermal and mechanical properties. J Appl Polym Sci. 2007;105:255–68.

Goriparthi BK, Suman KNS, Rao NM. Effect of fiber surface treatments on mechanical and abrasive wear performance of polylactide/jute composites. Compos A. 2012;43:1800–8.

Acknowledgements

This research was funded by the Celal Bayar University Research Funds (Number: 2013/35).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Özmen, U., Baba, B.O. Thermal characterization of chicken feather/PLA biocomposites. J Therm Anal Calorim 129, 347–355 (2017). https://doi.org/10.1007/s10973-017-6188-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-017-6188-5