Abstract

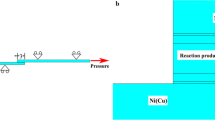

Interfacial reaction and shear behavior of the joints between the Au–29Sn (at.%) solder and the Ni–xCo (x = 20, 40, 60, and 80 at%) alloys soldered at 350 °C for various durations were investigated in this study. The results show that Ni3Sn2 is the common reaction product at the solder/substrate interfaces after soldering regardless of the Co content, but the morphology and growth kinetics of Ni3Sn2 are closely related to the Co content of Ni–Co substrates. With increasing of Co content in Ni–Co substrates, the growth rate of Ni3Sn2 decreases, and the needle-like shaped Ni3Sn2 grain changes to lath-shaped type. In addition, the thickness of the Ni3Sn2 layer maintains at about 7 μm even after long duration due to depletion of Sn in the solder matrix. The shear strength of Au–Sn/Ni–xCo joints is sensitive to the thickness of Ni3Sn2 layer. It can achieve about 45 MPa and maintain above 40 MPa if adequate thickness of Ni3Sn2 layer, typically 2–5 μm, is obtained at the interface.

Similar content being viewed by others

References

H.-K. Cheng, Y.-J. Lin, C.-M. Chen, K.-C. Liu, Y.-L. Wang, T.-F. Liu, Metall. Mater. Trans. A 47, 3971–3980 (2016)

S.F. Choudhury, L. Ladani, J. Alloys Compds. 680, 665–676 (2016)

J. Koo, C. Lee, S.J. Hong, K.-S. Kim, H.M. Lee, J. Alloys Compds. 650, 106–115 (2015)

W. Liu, Y. Wang, Y. Ma, Q. Yu, Y. Huang, Mater. Sci. Eng. A 651, 626–635 (2016)

X. Zhu, R. Wang, C. Peng, X. Wei, J. Peng, J. Mater. Sci. Mater. Electr. 25, 742–748 (2013)

Z.X. Zhu, C.C. Li, L.L. Liao, C.K. Liu, C.R. Kao, J. Alloys Compds. 671, 340–345 (2016)

J.-W. Yoon, H.-S. Chun, B.-I. Noh, J.-M. Koo, J.-W. Kim, H.-J. Lee, S.-B. Jung, Microelectron. Reliab. 48, 1857–1863 (2008)

X.F. Wei, Y.K. Zhang, R.C. Wang, Y. Feng, Microelectron. Reliab. 5, 748–754 (2013)

H.Q. Dong, V. Vuorinen, X.W. Liu, T. Laurila, J. Li, M. Paulasto-Kröckel, J. Electron. Mater. 45, 566–575 (2015)

P. Yao, P. Liu, J. Liu, Microelectron. Eng. 86, 1969–1974 (2009)

T. Maeshima, H. Ikehata, K. Terui, Y. Sakamoto, Mater. Des. 103, 106–113 (2016)

A. Wierzbicka-Miernik, K. Miernik, J. Wojewoda-Budka, K. Szyszkiewicz, R. Filipek, L. Litynska-Dobrzynska, A. Kodentsov, P. Zieba, Mater. Chem. Phys. 142, 682–685 (2013)

K.C. Huang, F.S. Shieu, T.S. Huang, C.T. Lu, C.W. Chen, H.W. Tseng, S.L. Cheng, C.Y. Liu, J. Electr. Mater. 39, 2403–2411 (2010)

H.F. Lin, Y.C. Chang, C.C. Chen, J. Electr. Mater. 43, 3333–3340 (2014)

C.C. Chen, Y.T. Chan, Y.T. Chen, J. Mater. Res. 25, 1321–1328 (2011)

C.C. Chen, Y.T. Chen, J. Alloys Compds. 545, 28–31 (2012)

W. Zhu, J. Wang, H. Liu, Z. Jin, W. Gong, Mater. Sci. Eng. A 456, 109–113 (2007)

H. Liu, H. Wang, W. Zhu, X. Tao, Z. Jin, J. Mater. Res. 22, 1502–1511 (2011)

H.Q. Dong, S. Jin, L.G. Zhang, J.S. Wang, X.M. Tao, H.S. Liu, Z.P. Jin, J. Electr. Mater. 38, 2158–2169 (2009)

H.Q. Dong, V. Vuorinen, T. Laurila, M. Paulasto-Kröckel, CALPHAD 43,61–70 (2013)

J. Wang, L.B. Liu, H.S. Liu, Z.P. Jin, CALPHAD 31, 249–255 (2007)

Y. Liu, D. Liang, Y. Du, L. Zhang, D. Yu, CALPHAD 33, 695–703 (2009)

Y.H. Chao, S.W. Chen, C.H. Chang, C.C. Chen, Metall. Mater. Trans. A 39, 477–489 (2008)

Acknowledgements

This work was financially supported by Ministry of Science and Technology of China (JPPT-125-GH-039).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Peng, J., Wang, R.C., Wang, M. et al. Microstructure evolution and shear behavior of Au–Sn/Ni–xCo (x = 20, 40, 60, and 80 at.%) joints soldered at 350 °C. J Mater Sci: Mater Electron 28, 7286–7291 (2017). https://doi.org/10.1007/s10854-017-6413-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-017-6413-9