Abstract

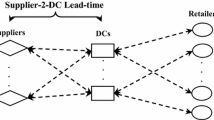

Outbound logistics network (OLN) in the downstream supply chain of a firm plays a dominant role in the success or failure of that firm. This paper proposes the design of a hybrid and flexible OLN in multi objective context. The proposed distribution network for a manufacturing supply chain consists of a set of customer zones (CZs) at known locations with known demands being served by a set of potential manufacturing plants, a set of potential central distribution centers (CDCs), and a set of potential regional distribution centers (RDCs). Three variants of a single product classified based on nature of demand are supplied to CZs through three different distribution channels. The decision variables include number of plants, CDCs, RDCs, and quantities of each variant of product delivered to CZs through a designated distribution channel. The goal is to design the network with multiple objectives so as to minimize the total cost, maximize the unit fill rates, and maximize the resource utilization of the facilities in the network. The problem is formulated as a mixed integer linear programming problem and a multiobjective genetic algorithm (MOGA) called non-dominated sorting genetic algorithm—II (NSGA-II) is employed to solve the resulting NP-hard combinatorial optimization problem. Computational experiments conducted on randomly generated data sets are presented and analyzed showing the effectiveness of the solution algorithm for the proposed network.

Similar content being viewed by others

References

Altiparamak F., Gen M., Lin L., Paksoy T. (2006) A genetic algorithm approach for multi-objective optimization of supply chain networks. Computers and Industrial Engineering 51(1): 196–215

Altiparmak F., Gen M., Lin L., Karaoglan I. (2009) A steady state genetic algorithm for multi-product supply chain network design. Computers and Industrial Engineering 56(2): 521–537

Amiri A. (2006) Designing a distribution network in a supply chain system: Formulation and efficient solution procedure. European Journal of Operational Research 171(2): 567–576

Amodeo L., Chen H., El Hadji A. (2008) Supply chain inventory optimization with multiple objectives: An industrial case study. Studies in Computational Intelligence 144: 211–230

Bachlaus M., Pandey M. K., Mahajan C., Shankar R., Tiwari M.K. (2008) Designing an integrated multi-echelon agile supply chain network: A hybrid taguchi-particle swarm optimization approach. Journal of Intelligent Manufacturing 19(6): 747–761

Bhattacharya R., Bandyopadhyay S. (2010) Solving conflicting bi-objective facility location problem by NSGA II evolutionary algorithm. International Journal of Advanced Manufacturing Technology 51(1–4): 397–414

Bilgen B., Günther H. O. (2010) Integrated production and distribution planning in the fast moving consumer goods industry: A block planning application. OR Spectrum 32: 927–955

Chandra C., Grabis J. (2009) Configurable supply chain: Framework, methodology and application. International Journal of Manufacturing Technology and Management 17(1–2): 5–22

Chandra C., Kamrani A. K. (2003) Knowledge management for consumer-focused product design. Journal of Intelligent Manufacturing 14: 557–580

Cheng F., Ye F. (2011) A two objective optimisation model for order splitting among parallel suppliers. International Journal of Production Research 49(10): 2759–2769

Cheng F., Ye F., Yang J. (2009) Multi-objective optimization of collaborative manufacturing chain with time-sequence constraints. International Journal of Advanced Manufacturing Technology 40: 1024–1032

Chopra S., Meindl P., Kalra D.V. (2008) Supply chain management (2nd ed). Dorling Kindersley (India) Pvt. Ltd. (Licensee of Pearson Education), New Delhi

Cintron A., Ravindran A. R., Ventura J. A. (2010) Multi-criteria mathematical model for designing the distribution network of a consumer goods company. Computers and Industrial Engineering 58(4): 584–593

Coello C. C. A. (1999) A comprehensive survey of evolutionary-based multi-objective optimization techniques. Knowledge and Information Systems: An International Journal 1(3): 269–308

Deb K. (2001) Multi-objective optimization using evolutionary algorithms. Wiley, Chichester

Deb K., Pratap A., Agarwal S., Meyarivan T. (2002) A fast and elitist multi-objective genetic algorithm: NSGA-II. IEEE Transactions on Evolutionary Computation 6(2): 182–197

Ding H., Benyoucef L., Xie X. (2006) A simulation-based multi-objective genetic algorithm approach for networked enterprises optimization. Engineering Applications of Artificial Intelligence 19(6): 609–623

Dogan K., Goetschalckx M. (1999) A primal decomposition method for the integrated design of production-distribution systems. IIE Transactions (Institute of Industrial Engineers) 31(11): 1027–1036

ElMaraghy H.A., Majety R. (2008) Integrated supply chain design using multi-criteria optimization. International Journal of Advanced Manufacturing Technology 37: 371–399

Farahani R. Z., Elahipanah M. (2008) A genetic algorithm to optimize the total cost and service level for just-in-time distribution in a supply chain. International Journal of Production Economics 111(2): 229–243

Gebennini E., Gamberini R., Manzini R. (2009) An integrated production-distribution model for the dynamic location and allocation problem with safety stock optimization. International Journal of Production Economics 122(1): 286–304

Gen M., Altiparmak F., Lin L. (2006) A genetic algorithm for two-stage transportation problem using priority-based encoding. OR Spectrum 28(3): 337–354

Goetschalckx, M. (2008). Distribution system design. In G. Don Taylor (Ed.), Logistics engineering handbook. Florida: Taylor and Francis Group (CRC Press).

Goetschalckx M., Vidal C.J., Dogan K. (2002) Modeling and design of global logistics systems: A review of integrated strategic and tactical models and design algorithms. European Journal of Operational Research 143(1): 1–18

Goldberg D. E. (1989) Genetic algorithms in search, optimization and machine learning. Addison-Wesley, New York

Ioannou G. (2005) Streamlining the supply chain of the Hellenic sugar industry. Journal of Food Engineering 70(3): 323–332

Jawahar N., Balaji A. N. (2009) A genetic algorithm for the two-stage supply chain distribution problem associated with a fixed charge. European Journal of Operational Research 194(2): 496–537

Jayaraman V., Ross A. (2003) A simulated annealing methodology to distribution network design and management. European Journal of Operational Research 144(3): 629–645

Jiao J., Simpson T. W., Siddique Z. (2007) Product family design and platform-based product development: A state-of-the-art review. Journal of Intelligent Manufacturing 18: 5–29

Kauder S., Meyr H. (2009) Strategic network planning for an international automotive manufacturer-balancing flexibility and economical efficiency. OR Spectrum 31: 507–532

Kazemi A., Fazel Zarandi M. H., Moattar Husseini S. M. (2009) A multi-agent system to solve the production-distribution planning problem for a supply chain: A genetic algorithm approach. International Journal of Advanced Manufacturing Technology 44(1–2): 180–193

Kim J., Moon I. (2008) Strategic design of hydrogen infrastructure considering cost and safety using multiobjective optimization. International Journal of Hydrogen Energy 33(21): 5887–5896

Konak A., Coit D. W., Smith A. E. (2006) Multi-objective optimization using genetic algorithms: A tutorial. Reliability Engineering and System Safety 91: 992–1007

Koo L. Y., Adhitya A., Srinivasan R., Karimi I. A. (2008) Decision support for integrated refinery supply chains. Part 2: Design and operation. Computers and Chemical Engineering 32(11): 2787–2800

Liao S., Hsieh C., Lin Y. (2011) A multi-objective evolutionary optimization approach for an integrated location-inventory distribution network problem under vendor-managed inventory system. Annals of Operations Research 186(1): 213–229

Lim S. J., Jeong S. J., Kim K. S., Park M. W. (2006) Hybrid approach to distribution planning reflecting a stochastic supply chain. International Journal of Advanced Manufacturing Technology 28: 618–625

Lin L., Mitsuo G., Xiaoguang W. (2009) Integrated multistage logistics network design by using hybrid evolutionary algorithm. Computers and Industrial Engineering 56: 854–873

Luh G. C., Chueh C. H., Liu W. W. (2003) MOIA: Multi-objective immune algorithm. Engineering Optimization 35(2): 143–164

Manzini R., Bindi F. (2009) Strategic design and operational management optimization of a multi stage physical distribution system. Transportation Research Part E: Logistics and Transportation Review 45(6): 915–936

Manzini R., Gebennini E. (2008) Optimization models for the dynamic facility location and allocation problem. International Journal of Production Research 46(8): 2061–2086

Manzini R., Gamberi M., Gebennini E., Regattieri A. (2008) An integrated approach to the design and management of a supply chain system. International Journal of Advanced Manufacturing Technology 37: 625–640

Melo M. T., Nickel S., Saldanha-da-Gama F. (2009) Facility location and supply chain management—A review. European Journal of Operational Research 196(2): 401–412

Paksoy T., Cavlak E. B. (2011) Development and optimization of a new linear programming model for production/distribution network of an edible vegetable oil manufacturer. Journal of Logistics Systems and Management 9(1): 1–21

Pishvaee M. S., Farahani R. Z., Dullaert W. (2010) A memetic algorithm for bi-objective integrated forward/reverse logistics network design. Computers and Operations Research 37(6): 1100–1112

Rabbani M., Tavakkoli-Moghaddam R., Parsa H. (2008) A new mathematical model for a distribution network problem in a multi-product supply chain system: A real case study. International Journal of Manufacturing Technology and Management 15(1): 1–11

Sarkar D., Modak J. M. (2005) Pareto-optimal solutions for multi-objective optimization of fed-batch bioreactors using nondominated sorting genetic algorithm. Chemical Engineering Science 60: 481–492

Sarmiento A. M., Nagi R. (1999) A review of integrated analysis of production-distribution systems. IIE Transactions (Institute of Industrial Engineers) 31(11): 1061–1074

Serrano V., Alvarado M., Coello C. A. (2007) Optimization to manage supply chain disruptions using the NSGA-II. Advances in Soft Computing 42: 476–485

Shen Z.-J. Max, Daskin M. S. (2005) Trade-offs between customer service and cost in integrated supply chain design. Manufacturing and Services Operations Management 7(3): 188–207

Srinivas N., Deb K. (1995) Multi-objective function optimisation using non-dominated sorting in genetic algorithms. Evolutionary Computations 2(3): 221–248

Syarif A., Gen M. (2003) Hybrid genetic algorithm for production/distribution system in supply chain. International Journal of Smart Engineering System Design 5(4): 289–298

Syarif A., Yun Y., Gen M. (2002) Study on multi-stage logistic chain network: A spanning tree-based genetic algorithm approach. Computers and Industrial Engineering 43(1–2): 299–314

Thanh P. N., Bostel N., Peton O. (2008) A dynamic model for facility location in the design of complex supply chains. International Journal of Production Economics 113(2): 678–693

Tiwari M. K., Raghavendra N., Agrawal S., Goyal S.K. (2010) A hybrid Taguchi-immune approach to optimize an integrated supply chain design problem with multiple shipping. European Journal of Operational Research 203(1): 95–106

Vidal C., Goetschalckx M. (1997) Strategic production–distribution models: A critical review with emphasis on global supply chain models. European Journal of Operational Research 98: 1–18

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hiremath, N.C., Sahu, S. & Tiwari, M.K. Multi objective outbound logistics network design for a manufacturing supply chain. J Intell Manuf 24, 1071–1084 (2013). https://doi.org/10.1007/s10845-012-0635-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10845-012-0635-8