Abstract

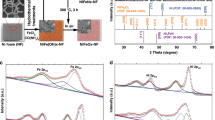

Electrochemical hydrogenation of non-fossil resources to produce value added chemicals has great potential to contribute to realization of sustainable material supply. We previously demonstrated that TiO2 catalyzed electrochemical reduction of biomass-derivable α-keto acid in the presence of NH3 or NH2OH affords amino acids. In this work, we focused on oxalic acid, which is producible by chemical degradation of agro wastes, as a starting material for the electrosynthesis of an amino acid. We examined the electrocatalytic properties of various materials, including Cu, Pt, Ti foils, calcined Al, Co, Mo, Nb, Ni, Ti, V, W, Zr foils, and some TiO2 catalysts, by conducting linear sweep voltammetry (LSV) measurements, and found that Mo and Ti foil calcined at 450 °C show favorable catalytic features for the one-step glycine electrosynthesis from oxalic acid and NH2OH. Electrochemical reduction of oxalic acid at an applied potential of − 0.7 V using calcined Ti foil resulted in formation of glycine and glyoxylic acid oxime, i.e., intermediate of the glycine formation, with moderate Faradaic efficiency of 28 and 28%, respectively.

Graphic abstract

Similar content being viewed by others

References

Kortlever R, Balemans C, Kwon Y et al (2015) Electrochemical CO2 reduction to formic acid on a Pd-based formic acid oxidation catalyst. Catal Today 244:58–62. https://doi.org/10.1016/j.cattod.2014.08.001

Kortlever R, Peters I, Koper S et al (2015) Electrochemical CO2 reduction to formic acid at low overpotential and with high Faradaic efficiency on carbon-supported bimetallic Pd-Pt nanoparticles. Acs Catal 5:3916–3923. https://doi.org/10.1021/acscatal.5b00602

Zhang S, Kang P, Ubnoske S et al (2014) Polyethylenimine-enhanced electrocatalytic reduction of CO2 to formate at nitrogen-doped carbon nanomaterials. J Am Chem Soc 136:7845–7848. https://doi.org/10.1021/ja5031529

Liu YM, Zhang YJ, Cheng K et al (2017) Selective electrochemical reduction of carbon dioxide to ethanol on a boron- and nitrogen-co-doped nanodiamond. Angew Chem Int Ed 56:15607–15611. https://doi.org/10.1002/anie.201706311

Rybchenko SI, Touhami D, Wadhawan JD et al (2016) Study of pyridine-mediated electrochemical reduction of CO2 to methanol at high CO2 pressure. Chemsuschem 9:1660–1669. https://doi.org/10.1002/cssc.201600267

Sun XF, Zhu QG, Kang XC et al (2016) Molybdenum-bismuth bimetallic chalcogenide nanosheets for highly efficient electrocatalytic reduction of Carbon Dioxide to Methanol. Angew Chem Int Ed 55:6771–6775. https://doi.org/10.1002/anie.201603034

Watanabe R, Yamauchi M, Sadakiyo M et al (2015) CO2-free electric power circulation via direct charge and discharge using the glycolic acid/oxalic acid redox couple. Energy Environ Sci 8:1456–1462. https://doi.org/10.1039/c5ee00192g

Sadakiyo M, Hata S, Fukushima T et al (2019) Electrochemical hydrogenation of non-aromatic carboxylic acid derivatives as a sustainable synthesis process: From catalyst design to device construction. Phys Chem Chem Phys 21:5882–5889. https://doi.org/10.1039/c8cp07445c

Ren D, Deng YL, Handoko AD (2015) Selective electrochemical reduction of carbon dioxide to ethylene and ethanol on copper (I) oxide catalysts. ACS Catal 5:2814–2821. https://doi.org/10.1021/cs502128q

Gattrell M, Gupta N, Co A (2006) A review of the aqueous electrochemical reduction of CO2 to hydrocarbons at copper. J Electroanal Chem 594:1–19. https://doi.org/10.1016/j.jelechem.2006.05.013

Ma S, Sadakiyo M, Heima M et al (2017) Electroreduction of carbon dioxide to hydrocarbons using bimetallic Cu-Pd catalysts with different mixing patterns. J Am Chem Soc 139:47–50. https://doi.org/10.1021/jacs.6b10740

Weng Z, Jing JB, Wu YS (2016) Electrochemical CO2 reduction to hydrocarbons on a heterogeneous molecular Cu catalyst in aqueous solution. J Am Chem Soc 138:8076–8079. https://doi.org/10.1021/jacs.6b04746

Ikeda M, Takeno S (2013) In: Yukawa H, Inui M (eds) Corynebacterium glutamicum: biology and biotechnology. Springer, Heidelberg, Berlin, pp 107–147

Becker J, Wittmann C (2012) Systems and synthetic metabolic engineering for amino acid production - The heartbeat of industrial strain development. Curr Opin Biotechnol 23:718–726. https://doi.org/10.1016/j.copbio.2011.12.025

D'Este M, Alvarado-Morales M, Angelidaki I (2018) Amino acids production focusing on fermentation technologies: a review. Biotechnol Adv 36:14–25. https://doi.org/10.1016/j.biotechadv.2017.09.001

Strecker A (1850) Ueber die künstliche bildung der milchsäure und einen neuen, Dem glycocoll homologen körper. Justus Liebigs Ann Chem 75:27–45. https://doi.org/10.1002/jlac.18500750103

Groger H (2003) Catalytic enantioselective Strecker reactions and analogous syntheses. Chem Rev 103:2795–2827. https://doi.org/10.1021/cr020038p

Wang J, Liu XH, Feng XM (2011) Asymmetric Strecker reactions. Chem Rev 111:6947–6983. https://doi.org/10.1021/cr200057t

Harada K, Matsumot K (1967) Sterically controlled syntheses of optically active α-amino acids from α-keto acids by reductive amination. J Org Chem 32:1794–1800. https://doi.org/10.1021/jo01281a020

Kuang H, Brown ML, Davies RR et al (1996) Enantioselective reductive amination of α-keto acids to α-amino acids by a pyridoxamine cofactor in a protein cavity. J Am Chem Soc 118:10702–10706. https://doi.org/10.1021/ja954271z

Ogo S, Uehara K, Abura T et al (2004) pH-Dependent chemoselective synthesis of α-amino acids. reductive amination of α-keto acids with ammonia catalyzed by acid-stable iridium hydride complexes in water. J Am Chem Soc 126:3020–3021. https://doi.org/10.1021/ja031633r

Deng W, Wang P, Wang B et al (2018) Transformation of cellulose and related carbohydrates into lactic acid with bifunctional Al(III)-Sn(III) catalysts. Green Chem 20:735–744. https://doi.org/10.1039/c7gc02975f

Lei X, Wang FF, Liu CL et al (2014) One-pot catalytic conversion of carbohydrate biomass to lactic acid using an ErCl3 catalyst. Appl Catal A 482:78–83. https://doi.org/10.1016/j.apcata.2014.05.029

Guarin C, Gavila L, Constanti M et al (2018) Impact of cellulose treatment with hydrotalcites in hydrothermal catalytic conversion. Chem Eng Sci 179:83–91. https://doi.org/10.1016/j.ces.2018.01.014

Wang FW, Huo ZB, Wang YQ et al (2011) Hydrothermal conversion of cellulose into lactic acid with nickel catalyst. Res Chem Intermed 37:487–492. https://doi.org/10.1007/s11164-011-0274-2

Zhang J, Liu X, Sun M et al (2012) Direct conversion of cellulose to glycolic acid with a phosphomolybdic acid catalyst in a water medium. ACS Catal 2:1698–1702. https://doi.org/10.1021/cs300342k

Chen Y, Ren X, Wei Q (2017) Conversion of undaria pinnatifida residue to glycolic acid with recyclable methylamine in low temperature hydrothermal liquefaction. Bioresour Technol 228:47–55. https://doi.org/10.1016/j.biortech.2016.12.091

Sjostrom E (1991) Carbohydrate degradation products from alkaline treatment of biomass. Biomass Bioenergy 1:61–64. https://doi.org/10.1016/0961-9534(91)90053-f

Fukushima T, Yamauchi M (2019) Electrosynthesis of amino acids from biomass-derivable acids on titanium dioxide electrode. Chem Commun 55:14721–14724. https://doi.org/10.1039/c9cc07208j

Dube SK, Vasudevan P, Khandelwal BL (1982) Oxalic acid manumacture. J Chem Tech Biotechnol 32:909–919. https://doi.org/10.1002/jctb.5030320729

Mathew MD, Gopal M, Banerjee SK (1984) Preparation of oxalic acid from jute stick, an agrowasete. Agric Wastes 11:47–59. https://doi.org/10.1016/0141-4607(84)90054-4

Mane JD, Modak HM, Ramaiah NA et al (1988) Utilization of sugarcane trash and other cellulosic wastes for production of oxalic acid. Biol Wastes 25:171–176. https://doi.org/10.1016/0269-7483(88)90077-8

Guru M, Bilgesu AY, Pamuk V (2001) Production of oxalic acid from sugar beet molasses by formed nitrogen oxides. Bioresour Technol 77:81–86. https://doi.org/10.1016/s0960-8524(00)00122-x

Ventura M, Williamson D, Lobefaro F et al (2018) Sustainable synthesis of oxalic and succinic acid through aerobic oxidation of C6 polyols under mild conditions. Chemsuschem 11:1073–1081. https://doi.org/10.1002/cssc.201702347

Krasowski JA, Marton J (1983) The formation of oxalic acid during bleaching of kraft pulp. J Wood Chem Technol 3:445–458. https://doi.org/10.1080/02773818308085175

Liu YY, Ge SJ, Li YM et al (2018) Oxalate formation during hydrogen peroxide-reinforced oxygen delignification. J Ind Eng Chem 58:45–50. https://doi.org/10.1016/j.jiec.2017.09.005

Asada T, Furujo A, Kawasaki Y (2010) Oxalic acid and the manufacturing methods therefor. JP pat 2010–059082

Fischer J, Lehmann T, Heitz E (1981) The production of oxalic acid from CO2 and H2O. JAppl Electrochem 11:743–750. https://doi.org/10.1007/bf00615179

Ikeda S, Takagi T, Ito K (1987) Selective formation of formic acid, oxalic acid, and carbon monoxide by electrochemical reduction of carbon dioxide. Bull Chem Soc Jp 60:2517–2522. https://doi.org/10.1246/bcsj.60.2517

Kushi Y, Nagao H, Nishioka T (1994) Oxalate formation in electrochemical CO2 reduction catalyzed by rhodium-sulfur cluster. Chem Lett 1:2. https://doi.org/10.1246/cl.1994.2175

Angamuthu R, Byers P, Lutz M et al (2010) Electrochemical CO2 conversion to oxalic acid by copper complex. Science 327:313–315. https://doi.org/10.1126/science.1177981

Kumar RS, Kumar SS, Kulandainathan MA (2012) Highly selective electrochemical reduction of carbon dioxide using Cu based metal organic framework as an electrocatalyst. Electrochem Commun 25:70–73. https://doi.org/10.1016/j.elecom.2012.09.018

Paris AR, Bocarsly AB (2019) High-efficiency conversion of CO2 to oxalate in water is possible using a Cr-Ga oxide electrocatalyst. ACS Catal 9:2324–2333. https://doi.org/10.1021/acscatal.8b04327

Subramanian S, Athira KR, Kulandainathan MA et al (2020) New insights into the electrochemical conversion of CO2 to oxalate at stainless steel 304 L cathode. J CO2 Util 36:105–115. https://doi.org/10.1016/j.jcou.2019.10.011

Yamauchi M, Ozawa N, Kubo M (2016) Experimental and quantum chemical approaches to develop highly selective nanocatalysts for CO2‐free Power circulation. Chem Rec 16:2249–2259. https://doi.org/10.1002/tcr.201600047

Sadakiyo M, Hata S, Cui X et al (2017) Electrochemical production of glycolic acid from oxalic acid using a polymer electrolyte alcohol electrosynthesis cell containing a porous TiO2 catalyst. Sci Rep 7:17032. https://doi.org/10.1016/j.jcou.2019.10.011

Fukushima T, Kitano S, Hata S et al (2018) Carbon-neutral energy cycles using alcohols. Sci Technol Adv Mater 19:142–152. https://doi.org/10.1080/14686996.2018.1426340

Fukushima T, Higashi M, Kitano S et al (2019) Multiscale design for high-performance glycolic acid electro-synthesis cell: Preparation of nanoscale-IrO2-applied Ti anode and optimization of cell assembling. Catal Today. https://doi.org/10.1016/j.cattod.2019.03.071

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Fukushima, T., Yamauchi, M. Electrosynthesis of glycine from bio-derivable oxalic acid. J Appl Electrochem 51, 99–106 (2021). https://doi.org/10.1007/s10800-020-01428-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10800-020-01428-x