Abstract

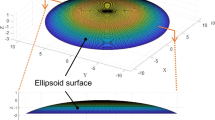

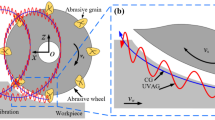

High-efficiency precision grinding can shorten the machining cycle of aspheric optical elements by a factor of 2–10. To achieve this objective, ultrasonic vibration (UV)–assisted grinding (UVG) has been increasingly applied to manufacture aspheric optics. However, the mechanisms of material removal and surface formation in UV-assisted aspheric grinding of glass ceramics have rarely been studied. Herein, rotary UV-assisted vertical grinding (RUVG) was used to explore the machining mechanism of coaxial curved surfaces. First, RUV-assisted scratch experiments were conducted on aspheric surface of glass ceramics, which exhibited multiple benefits over conventional scratching. These include a reduction in the scratch force by 37.83–44.55% for tangential component and 3.87–28.15% for normal component, an increase in plastic removal length by 43.75%, and an increase in material removal rate by almost a factor of 2. Moreover, grinding marks on the aspheric surface in RUVG were accurately simulated and optimized by adjusting grinding parameters. RUVG experiments were performed to verify the accuracy of grinding texture simulations and investigate the UV effect. The results demonstrate that UV can improve the surface quality of aspheric grinding when compared with conventional vertical grinding. In particular, the total height of the profile of form accuracy and its root mean square were significantly improved by a factor of 3.38–4.54 and 7.15–10.82, respectively, and the surface roughness reduced by 10.03–12.10%. This study provides deeper insight into material removal and surface generation mechanisms for RUVG of aspheric surfaces, and it is thus envisaged that these results will be useful in engineering applications.

Similar content being viewed by others

References

Zhang SH, Guo XG, Yuan S, Jin ZJ, Tang WC (2022) Insight on the structural changes of glass-ceramics during nanoindentation derived from reactive force-field-based molecular dynamic simulations. Appl Surf Sci 571:151375. https://doi.org/10.1016/j.apsusc.2021.151375

Yang X, Qiu ZJ, Wang YG (2019) Investigation of material flow behaviour and chip formation mechanism during grinding of glass-ceramics by nanoscratch. Ceram Int 45:15954–15963. https://doi.org/10.1016/j.ceramint.2019.05.104

Cao Y, Ding W, Zhao B, Wen X, Li S, Wang J (2022) Effect of intermittent cutting behavior on the ultrasonic vibration-assisted grinding performance of Inconel718 nickel-based superalloy. Precis Eng 78:248–260. https://doi.org/10.1016/j.precisioneng.2022.08.006

Yang ZC, Zhu LD, Zhang GX, Ni CB, Lin B (2020) Review of ultrasonic vibration-assisted machining in advanced materials. Int J Mach Tools Manuf 156:103594. https://doi.org/10.1016/j.ijmachtools.2020.103594

Chen Y, Su H, Qian N, He J, Gu J, Xu J, Ding K (2021) Ultrasonic vibration-assisted grinding of silicon carbide ceramics based on actual amplitude measurement: Grinding force and surface quality. Ceram Int 47:15433–15441. https://doi.org/10.1016/j.ceramint.2021.02.109

Gao T, Zhang X, Lia CH, Zhang Y, Yang M, Jia D, Ji H, Zhao Y, Li R, Yao P, Zhu L (2020) Surface morphology evaluation of multi-angle 2D ultrasonic vibration integrated with nanofluid minimum quantity lubrication grinding. J Manuf Process 51:44–61. https://doi.org/10.1016/j.jmapro.2020.01.024

Cao JG, Wu YB, Lu D (2014) Fundamental machining characteristics of ultrasonic assisted internal grinding of SiC ceramics. Mater Manuf Process 29:557–563. https://doi.org/10.1080/10426914.2014.892615

Li H, Chen T, Duan Z, Zhang Y, Li H (2022) A grinding force model in two-dimensional ultrasonic-assisted grinding of silicon carbide. J Mater Process Technol 304:117568. https://doi.org/10.1016/j.jmatprotec.2022.117568

Lv DX, Huang YH, Wang HX, Tang YJ, Wu XC (2013) Improvement effects of vibration on cutting force in rotary ultrasonic machining of BK7 glass. J Mater Process Technol 213:1548–1557. https://doi.org/10.1016/j.jmatprotec.2013.04.001

Huang C, Zhou M, Zhang HJ (2021) A cutting force prediction model in axial ultrasonic vibration end grinding for BK7 optical glass considering protrusion height of abrasive grits. Measurement 180:109512. https://doi.org/10.1016/j.measurement.2021.109512

Tsai CC, Tseng CH (2006) The effect of friction reduction in the presence of in-plan vibrations. Arch Appl Mech 75:164–176. https://doi.org/10.1007/s00419-005-0427-0

Wang YH, Liang ZQ, Zhao WX, Wang XB, Wang H (2020) Effect of ultrasonic elliptical vibration assistance on the surface layer defect of M-plane sapphire in microcutting. Mater Des 192:108755. https://doi.org/10.1016/j.matdes.2020.108755

Zhao P, Zhang L, Liu X (2021) Crack forms sensitivity-based prediction on subsurface cracks depth in ultrasonic-vibration assisted grinding of optical glasses. Appl Sci 11:7553. https://doi.org/10.3390/app11167553

Brehl DE, Dow TA (2008) Review of vibration-assisted machining. Precis Eng 32:153–172. https://doi.org/10.1016/j.precisioneng.2007.08.003

Feucht F, Ketelaer J, Wolff A, Mori M, Fujishima M (2014) Latest machining technologies of hard-to-cut materials by ultrasonic machine tool. Procedia CIRP 14:148–152. https://doi.org/10.1016/j.procir.2014.03.040

Shen J, Wang J, Jiang B, Xu X (2015) Study on wear of diamond wheel in ultrasonic vibration-assisted grinding ceramic. Wear 332–333:788–793. https://doi.org/10.1016/j.wear.2015.02.047

Sun GY, Zhao LL, Zhen M, Zhao QL (2018) Force prediction model considering material removal mechanism for axial ultrasonic vibration-assisted peripheral grinding of Zerodur. Int J Adv Manuf Technol 98:2775–2789. https://doi.org/10.1007/s00170-018-2457-0

Liang Z, Wang X, Wu Y, Xie L, Jiao L, Zhao W (2013) Experimental study on brittle–ductile transition in elliptical ultrasonic assisted grinding (EUAG) of monocrystal sapphire using single diamond abrasive grain. Int J Mach Tools Manuf 71:41–51. https://doi.org/10.1016/j.ijmachtools.2013.04.004

Yang ZC, Zhu LD, Lin B, Zhang GX, Ni CB, Sui TY (2019) The grinding force modeling and experimental study of ZrO2 ceramic materials in ultrasonic vibration assisted grinding. Ceram Int 45:8873–8889. https://doi.org/10.1016/j.ceramint.2019.01.216

Zhou WH, Tang JY, Shao W, Wen J (2022) Towards understanding the ploughing friction mechanism in ultrasonic assisted grinding with single grain. Int J Mech Sci 222:107248. https://doi.org/10.1016/j.ijmecsci.2022.107248

Wu B, Zhao B, Ding W, Su H (2021) Investigation of the wear characteristics of microcrystal alumina abrasive wheels during the ultrasonic vibration-assisted grinding of PTMCs. Wear 477:203844. https://doi.org/10.1016/j.wear.2021.203844

Cao Y, Zhao B, Ding W, Liu Y, Wang L (2021) On the tool wear behavior during ultrasonic vibration-assisted form grinding with alumina wheels. Ceram Int 47:26456–26474. https://doi.org/10.1016/j.ceramint.2021.06.059

Sun GY, Shi F, Zhao QL, Ma Z (2020) Material removal behaviour in axial ultrasonic assisted scratching of Zerodur and ULE with a Vickers indenter. Ceram Int 46:14613–14624. https://doi.org/10.1016/j.ceramint.2020.02.262

Huang W, Yu D, Zhang X, Zhang M, Chen D (2018) Ductile-regime machining model for ultrasonic elliptical vibration cutting of brittle materials. J Manuf Process 36:68–76. https://doi.org/10.1016/j.jmapro.2018.09.029

Zhao B, Chang BQ, Wang XB, Bie WB (2019) System design and experimental research on ultrasonic assisted elliptical vibration grinding of nano-ZrO2 ceramics. Ceram Int 45:24865–24877. https://doi.org/10.1016/j.ceramint.2019.08.273

Wang J, Zhang J, Feng P, Guo P (2018) Damage formation and suppression in rotary ultrasonic machining of hard and brittle materials: a critical review. Ceram Int 44:1227–1239. https://doi.org/10.1016/j.ceramint.2017.10.050

Xiao XZ, Li G, Li ZH (2021) Prediction of the surface roughness in ultrasonic vibration-assisted grinding of dental zirconia ceramics based on a single-diamond grit model. Micromachines 12:543. https://doi.org/10.3390/mi12050543

Li Z, Zheng K, Liao W, Xiao X (2018) Surface characterization of zirconia ceramics in ultrasonic vibration-assisted grinding. J Braz Soc Mech Sci Eng 40:379. https://doi.org/10.1007/s40430-018-1296-0

Wang QY, Liang ZQ, Wang XB, Bai SW, Yeo SH, Jia S (2020) Modelling and analysis of generation mechanism of micro-surface topography during elliptical ultrasonic assisted grinding. J Mater Process Technol 279:116585. https://doi.org/10.1016/j.jmatprotec.2019.116585

Yang ZC, Zhu LD, Ni CB, Ning JS (2019) Investigation of surface topography formation mechanism based on abrasive-workpiece contact rate model in tangential ultrasonic vibration-assisted CBN grinding of ZrO2 ceramics. Int J Mech Sci 155:66–82. https://doi.org/10.1016/j.ijmecsci.2019.02.031

Zhou WH, Tang JY, Chen HF, Shao W (2019) A comprehensive investigation of surface generation and material removal characteristics in ultrasonic vibration assisted grinding. Int J Mech Sci 156:14–30. https://doi.org/10.1016/j.ijmecsci.2019.03.026

Zhang XF, Yang L, Wang Y, Lin B, Dong YH, Shi C (2020) Mechanism study on ultrasonic vibration assisted face grinding of hard and brittle materials. J Manuf Process 50:520–527. https://doi.org/10.1016/j.jmapro.2020.01.003

Zhou WH, Tang JY, Shao W (2020) Modelling of surface texture and parameters matching considering the interaction of multiple rotation cycles in ultrasonic assisted grinding. Int J Mech Sci 166:105246. https://doi.org/10.1016/j.ijmecsci.2019.105246

Jiang J, Sun S, Wang D, Yang Y, Liu X (2020) Surface texture formation mechanism based on the ultrasonic vibration-assisted grinding process. Int J Mach Tools Manuf 156:103595. https://doi.org/10.1016/j.ijmachtools.2020.103595

Chen B, Luo L, Jiao H, Li S, Li S, Deng Z, Yao H (2021) Affecting factors, optimization, and suppression of grinding marks: a review. Int J Adv Manuf Technol 115:1–29. https://doi.org/10.1007/s00170-021-07116-0

Chen B, Li S, Deng Z, Guo B, Zhao Q (2017) Grinding marks on ultra-precision grinding spherical and aspheric surfaces. Int J Precis Eng Manuf Green Technol 4(4):419–429. https://doi.org/10.1007/s40684-017-0047-5

Pan Y, Zhao Q, Guo B, Chen B, Wang J, Wu X (2020) An investigation of the surface waviness features of ground surface in parallel grinding process. Int J Mech Sci 170:105351. https://doi.org/10.1016/j.ijmecsci.2019.105351

Qiao JP, Feng M, Li Y, Li SS, Zeng J, Wu YB (2021) A study on tangential ultrasonic-assisted mirror grinding of zirconia ceramic curved surfaces. Int J Adv Manuf Technol 112:2837–2851. https://doi.org/10.1007/s00170-020-06512-2

Chen MJ, Zhao QL, Dong S, Li D (2005) The critical conditions of brittle–ductile transition and the factors influencing the surface quality of brittle materials in ultra-precision grinding. J Mater Process Technol 168:75–82. https://doi.org/10.1016/j.jmatprotec.2004.11.002

Funding

This work was supported by the National Natural Science Foundation of China (NSFC) (grant number 52105493), the Natural Science Basic Research Plan in Shaanxi Province of China (grant number 2023-JC-QN-0713), the Hunan Provincial Natural Science Foundation of China (grant number 2023JJ40670), the Youth Innovation Promotion Association CAS (grant number 2023423), and the China Postdoctoral Science Foundation (grant number 4139ZRY4).

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Guoyan Sun: conceptualization, writing—original draft preparation. Sheng Wang: writing—original draft preparation; experiments, image processing. Qingliang Zhao: writing—review and editing. Xiabin Ji: data curation. Jiaoteng Ding: measurement and data analysis.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sun, G., Wang, S., Zhao, Q. et al. Material removal and surface generation mechanisms in rotary ultrasonic vibration–assisted aspheric grinding of glass ceramics. Int J Adv Manuf Technol 130, 3721–3740 (2024). https://doi.org/10.1007/s00170-023-12904-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-12904-x