Harvesting Minnesota’s Wind Twice

A wind-to-ammonia pilot project shows how localized green energy applications can slash carbon intensity, empower farmer cooperatives, and keep wealth in rural communities.

The University of Minnesota West Central Research and Outreach Center (WCROC) is located in the city of Morris, in a region of the state where the winds howl across the plains of the Dakotas, bringing thunderstorms or arctic air, depending on the season. In 2003, the center received support from the Xcel Energy Renewable Development Fund to install a utility-scale wind turbine at its 1,100-acre research farm. But as the project ramped up, WCROC (where Reese works) faced a challenge—the local utility companies showed no interest in purchasing the power the turbine could produce. The center’s staff began exploring other opportunities to use and monetize the farm’s wind energy.

Producing nitrogen fertilizer, in the form of anhydrous ammonia, quickly rose to the top of the center’s list. There was an elegance to the concept. Most farmers rely on nitrogen fertilizer produced from fossil fuels to ensure their yields, but it is expensive. If those farmers could produce their own synthetic nitrogen fertilizer using wind power harvested on their land, they would gain an essential input for nourishing their crops while also benefiting the climate.

This idea laid the groundwork for WCROC’s Wind-to-Ammonia pilot project—the first venture of its kind. The research conducted through that effort has since led to an innovative partnership between WCROC, the Minnesota Farmers Union, clean energy advocates, commodity groups, and ethanol co-ops to support public investment in cooperatively owned ammonia production. Recent policies in the Inflation Reduction Act (IRA) and investments from the Department of Energy (DOE) Regional Clean Hydrogen Hubs program have improved the economic competitiveness of regionally produced “green” hydrogen.

In Minnesota, the emphasis on local ownership of these new production facilities provides an opportunity to change the dynamics in the fertilizer market, which now subjects farmers to volatile prices and frequent supply chain disruptions. Policies like the IRA that make green hydrogen economically feasible offer Minnesota’s farmer-owned cooperatives the opportunity to harness the region’s winds twice—for both energy and fertilizer—potentially building wealth in rural communities while lowering the carbon intensity of the region’s agricultural production. The pilot also shows how regional energy research and demonstration can develop uniquely local solutions that ensure the benefits of the green transition reach all corners of the country.

History of the Wind-to-Ammonia pilot

Western Minnesota has a unique history as one of the most productive agricultural landscapes in the United States, benefiting from deep prairie topsoil and plentiful water. Here, farmers raise cattle and poultry and grow corn, soybeans, sugar beets, wheat, and dry beans. As early as the 1880s, Minnesota farmers organized themselves against monopoly power through the Grange, which was founded in 1867 and became the first successful national farming organization in the United States, and the Minnesota Farmers Union (where Kagan works), which was founded in 1918. Farmers, many of them European immigrants, used cooperatives to build market power, buy inputs, and sell crops. But co-ops were also a way to build and maintain community and mobilize to counter the power of the railroad and grain monopolies. Minnesota’s agricultural cooperatives still rely on farmer members for leadership and governance to advance their goal of retaining wealth in rural communities. This long local history explains why cooperative ownership of the Wind-to-Ammonia pilot is so important to the partners involved.

Policies like the IRA that make green hydrogen economically feasible offer Minnesota’s farmer-owned cooperatives the opportunity to harness the region’s winds twice—for both energy and fertilizer.

When the pilot started, there were no synthetic nitrogen fertilizer producers in Minnesota. Even today, most of the world’s supply comes from China, Ukraine, the Middle East, India, and Russia, with some domestic production from states near the Gulf of Mexico. Fertilizer continues to be a large expenditure for farmers, with prices fluctuating widely from $400 per ton to nearly $1,600 per ton. Minnesota farmers buy around 800,000 tons of fertilizer per year—so localized renewable nitrogen production would significantly lower their overhead costs as well as their carbon footprint.

For WCROC, building the world’s first wind-to-hydrogen-to-ammonia pilot plant required overcoming multiple barriers involving costs and technology. At the time, few attempts had been made to use an intermittent source of electricity like wind to produce ammonia. Conventional production methods used hydroelectric power and natural gas—wind energy was still seen as

too expensive.

In 2005, WCROC installed a 1.65 megawatt Vestas V82 wind turbine at the research farm. The state of Minnesota and the University of Minnesota then contributed $3.3 million to construct a hydrogen plant, commissioned in 2010, followed by an ammonia plant, which went online in 2013. The entire operation includes the turbine, three small buildings, and an ammonia storage tank.

At the hydrogen plant, electricity generated by the wind turbine is used to electrolyze water (separating hydrogen from oxygen) and separate nitrogen from air. At the ammonia plant, the two pure gases—hydrogen and nitrogen—are then combined in a conventional Haber-Bosch process to produce anhydrous ammonia that is condensed and stored.

Minnesota farmers buy around 800,000 tons of fertilizer per year—so localized renewable nitrogen production would significantly lower their overhead costs as well as their carbon footprint.

The initial startup and operation of the facility was challenging, but it quickly provided critical information on operation, technical constraints, and the initial economics of small-scale green ammonia production. As soon as it was operational in 2013, the project could produce 3 kg of ammonia per hour—a small volume relative to the requirements of an average acre of corn, but the annual yield was enough to successfully produce enough fertilizer for the research farm’s needs and more. The remainder was shared with the farm’s local agriculture cooperative. With process improvements, supportive policy, and increases in electrolyzer capacity, the cost of producing ammonia at small scale soon reached a realistic range.

Collaboration with local scientists and engineers at the University of Minnesota has been key to the project’s success. Our colleagues within the university’s Department of Chemical Engineering and Materials Science have developed separation technologies that have greatly improved the overall efficiency and costs of the century-old Haber-Bosch process. They recently published a techno-economic and supply chain analysis to explore paths toward commercial deployment. Additionally, researchers from the Thomas E. Murphy Engine Research Laboratory in the Department of Mechanical Engineering developed an ammonia-fueled tractor and grain dryer, which we tested at WCROC’s research farm. We continue to find and demonstrate new ways to use ammonia, opening doors to more opportunities for commercial applications and meaningful use of clean energy.

What began as an elegant concept and a unique project on a rural agricultural experiment station in western Minnesota is now getting attention around the world. Today, the project demonstrates a vision to broaden localized production of green ammonia to reduce the carbon intensity of synthetic nitrogen fertilizer production and develop further industrial agriculture and energy applications for anhydrous ammonia. Here in Minnesota, we’re also seeing interest from other important sectors of the state’s economy, including the steel, mining, and shipping industries. It shows that the low-carbon energy transition can have meaningful benefits and real opportunities for rural communities.

Decarbonizing nitrogen fertilizer and agricultural production

The transition to green ammonia fertilizers could significantly lower the carbon intensity of farming and farm products. Traditional fossil fuel–based production of synthetic nitrogen fertilizer is responsible for roughly 2% of global greenhouse gas emissions, largely due to the massive energy requirements of the Haber-Bosch process. Using green ammonia to feed crops that are heavy fertilizer users—including corn and small grains such as oats, barley, and wheat—significantly reduces their carbon intensity without compromising productivity.

The low-carbon energy transition can have meaningful benefits and real opportunities for rural communities.

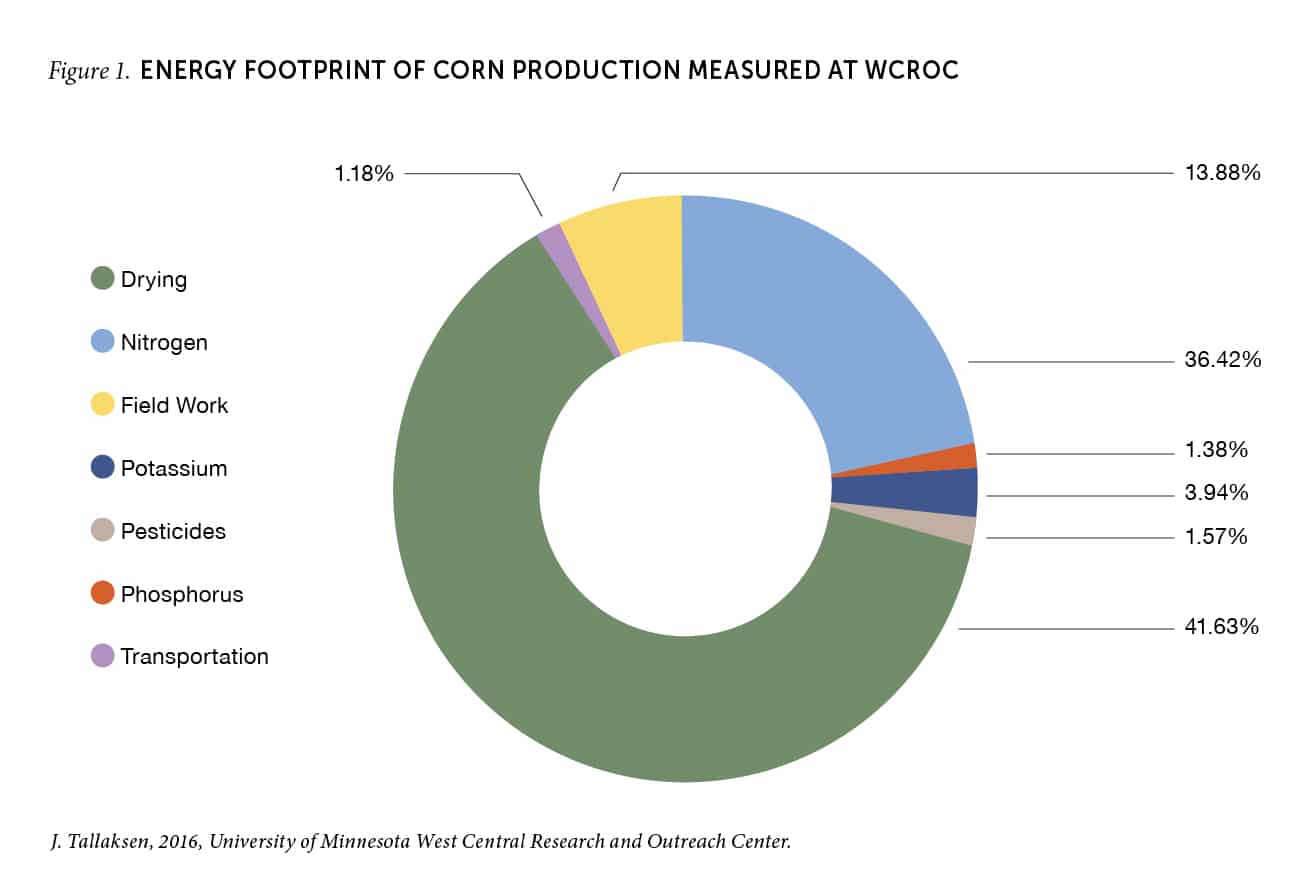

Likewise, using green ammonia as a fuel for grain dryers—the large burners and fans that reduce moisture in stored grains—also shows promise. Nitrogen fertilizer is responsible for 36.42% of the fossil energy of corn produced on WCROC’s land, while grain drying is responsible for 41.63%. When green ammonia is used for both fertilizer and dryer fuel, the fossil energy footprint is reduced by over 78%.

Transitioning to green ammonia could also create opportunities for regional production facilities to produce essential products locally. In recent years, the biofuel industry has shown interest in reducing the carbon intensity of ethanol production. Building green ammonia plants near ethanol plants could reduce net emissions if biogenic carbon dioxide from ethanol production was used to produce urea fertilizer. Farmers tend to prefer urea to ammonia because the granular fertilizer is safer, easier to store, and can be applied to fields more quickly and easily.

Beyond agricultural uses, green anhydrous ammonia has been promoted as a potential hydrogen carrier and energy storage option because it is significantly cheaper to store and transport above ground than hydrogen gas. In 2016, the DOE established the REFUEL program to pursue promising hydrogen carriers, and most of the research and development efforts have focused on the production of low carbon intensity anhydrous ammonia.

Still, green ammonia requires further research to reach its full potential. Today, considerable water usage is required for green ammonia production, and there are concerns about controlling nitrous oxide emissions (also a potent greenhouse gas) that necessitate further investment in research and testing. Although green ammonia may become a revolutionary fuel for shipping, mining, and other applications, today there is a clear benefit to small-scale, distributed, localized production models that are easily monitored and adapted to local constraints.

Who owns the green transition?

Until recently, commercializing wind-to-ammonia production faced significant hurdles, despite its benefits. Heavy up-front building costs coupled with the volatile conventional nitrogen fertilizer market simply didn’t pencil out. That fundamental calculation changed with the IRA’s 45V Clean Hydrogen Production Tax Credit, which provides up to $3 per kilogram of clean hydrogen produced, depending on the lifecycle greenhouse gas emissions rate. Additionally, the 2021 Bipartisan Infrastructure Law authorized the DOE’s Regional Clean Hydrogen Hubs program, which is investing $7 billion to grow the hydrogen economy across the United States. The Heartland Hydrogen Hub in North Dakota, South Dakota, and Minnesota will be developing the infrastructure needed to create and commercialize green ammonia and clean hydrogen in the region.

This influx of investment and development comes at a time when the domestic fertilizer industry is highly concentrated. With just four companies controlling 75% of the US market, consolidation leads to higher prices and fewer choices for farmers. For example, when Russia invaded Ukraine, fertilizer prices more than doubled. With few alternatives, farmers were forced to absorb the cost to ensure sufficient crop yields.

When Russia invaded Ukraine, fertilizer prices more than doubled. With few alternatives, farmers were forced to absorb the cost to ensure sufficient crop yields.

We see a huge opportunity to build this new clean hydrogen and green ammonia sector with farmer ownership at the center. During the 2023 state legislative session, a coalition of partners, including the Minnesota Farmers Union, WCROC, commodity groups, ethanol co-ops, and agricultural retailers, helped advance a pilot grant program for farmer cooperatives to buy equity shares in green fertilizer production facilities. The $7 million grant program, administered by the Minnesota Department of Agriculture, is the first of its kind in the nation to incentivize farmer ownership of green ammonia. State policymakers are enthusiastic about building a new sector in Minnesota that uses homegrown resources for a high-value market. Agricultural retail cooperatives that sell seeds, fertilizer, chemicals, and equipment are exploring the possibility of carrying green fertilizer products, while clean fuel markets—including sustainable aviation fuel—are driving biofuel companies to look at green hydrogen as a key part of their decarbonization strategy.

From a co-op perspective, having a locally produced, fixed-price fertilizer to offer members is a valuable addition to a business plan. For farmers, using a low-carbon fertilizer can open new markets to reduce carbon emissions across the supply chain. And for fertilizer developers, having a relationship with farmer cooperatives means a guaranteed market that isn’t dependent on global market dynamics. We see green nitrogen fertilizer as the first rung on the green hydrogen development ladder, with possible high-value applications across industrial sectors such as steel and low-carbon fuels. The state’s pilot grant program for green fertilizer is one way to ensure that the benefits of these green investments stay rooted with farm families and the communities where they live.

Of equal importance is the role that green hydrogen can play in reducing the state’s greenhouse gas emissions. Climate resilience is a priority for Minnesota farmers on the front lines of the changing climate—as is finding new ways to manage their land and operations in the face of increased storms, droughts, and heat waves. Partnerships between farmers and energy and agriculture researchers, coupled with favorable federal and state policies, are creating new opportunities to reshape who benefits from the green transition.