Received 7 June 2016; accepted 27 June 2016; published 30 June 2016

1. Introduction

1.1. Purpose and Organization of the Paper

Few people in Japan are able to discuss the benefits of domestic wood. However, as long as the benefits of domestic wood are not promoted, we cannot ensure its increased production or the further penetration of domestic wood into the market.

Domestic wood represents the essence of something important to our ancestors―planting trees not for themselves but for future generations. Thus, the merit of domestic wood is to provide for future generations by creating a sustainable system in the present, which has been overlooked by consumers. Although the market share of domestic wood has declined due to price competition from imported wood, there is a worldwide trend toward local production for local consumption of wood at present. Based on this fact, the authors identify problems in Japan’s forestry industry from an economic perspective to gain a new understanding of the merits of domestic wood and propose solutions. Several intrinsic problems need to be overcome to revive forestry in Japan. In particular, the major problem is the lack of measures to increase demand, which requires concrete solutions.

This paper is organized as follows:

Chapter 2 overviews the history of Japan’s forestry industry on the basis of statistical data. Wood was deregulated in the 1960s; however, because the domestic production system could not meet the domestic demand, it was overcome by cheap foreign-made wood. This situation continues today, and forestry in Japan is in a critical situation. Even though wood shipping problems have been resolved and the supply system for wood is well organized at present, Japan’s wood industry continues to struggle due to competition from imported wood. With labor and other aspects of the production system also collapsing with the end of Japan’s period of high economic growth, Japan’s forestry industry is in a precarious situation.

Chapter 3 examines the current status of Japan’s forestry industry, including the influence of technical progress on production. We use total factor productivity to measure the technical progress of forestry in Japan. Total factor productivity expresses the extent of the contribution of factors such as technical progress (excluding capital and labor) in the growth of production volume. To deal with the specific features of forestry, we exclude the assumption of linear homogeneity of the production function and use the generalized residual method developed by Mizuno (1986) [1] . We measure total factor productivity in Japan’s forestry industry, the elasticity of substitution, and the n-th order of homogenous function under the assumption of linear homogeneity of the production function. The results confirm that with respect to production in the forestry industry, the extra economic factor of technical progress does not contribute toward improving production.

Chapter 4 measures the utility of forestry in Japan. While Chapters 2 and 3 indicate the distortions in forestry’s production structure, Chapter 4 demonstrates that the lack of stimulation for production from the demand side is the reason for such distortions. In short, relative prices remain at a high level because of the relative decline in productivity, which decreases demand, thereby causing an extreme reduction in the utility of forestry for the nation. This reduces reliance on domestic forestry so that no support from the demand side is forthcoming. We confirmed this by calculating the cardinal utility for accurately measuring the utility of forestry, using the μ homogenous CES utility function. This revealed that utility declined, and the appeal of domestic forestry diminished.

In Chapter 5, we clarify using a questionnaire survey that if opinions about domestic wood improve, then those concerned with forestry are preparing for changes that embody technical progress. This section also shows the impact of the efforts of those concerned with forestry on economic theory. From these considerations, we determine that the assessment of domestic wood must improve before we are able to see any further growth of forestry in Japan. This paper therefore concludes by advocating a feedback system that will give producers incentives that embody technical progress, thereby improving the production of domestic wood, as the key is for the government and industry to induce the demand side to ensure good quality of domestic wood.

1.2. Prior Research

First, we introduce research on capital stock and labor in Japanese forestry. Given the increase in capital stock, most studies till date have focused on the process of mechanization. Kogawa (1993) summarizes the promotion of mechanization as a replacement for the decline and aging of forestry workers. Suzuki (1999) notes that from around the mid-1980s, the use of high-function forestry vehicles, such as feller bunchers (tree-felling machines) and harvesters (felling, logging, and bucking machines), has spread rapidly. Yamaguchi (1991) [2] traces the increase in capital stock as a result of purchasing these vehicles. However, the extent to which mechanization replaced labor and contributed to the advancement of technology could not be analyzed by merely following the process of mechanization.

Next, we examine prior studies on economic theory. Here, we primarily focus on the system-wide approach developed by Theil (1980a, 1980b) [3] [4] . Mizuno (1992, 1998) [5] [6] conducts analyses utilizing these features. However, although the system-wide approach has not been utilized for industries in Japan, we have judiciously applied it to forestry.

Kuroda (1981) [7] discusses the measurement theory for total factor productivity, which expresses the rate of technical progress. This was the first serious attempt at researching total factor productivity in Japan. However, the analysis focuses on linear homogeneity without taking full advantage of the utility of the translog function, which is less restrictive.

Currently, active discussions concerning total factor productivity are held in Japan. Sakuragawa (2005) [8] demonstrates the measurement of total factor productivity that generalizes the degree of return and the competitive position of the market. Miyagawa (2006) [9] summarizes the discussions and research conducted till date regarding total factor productivity. Here, the focus was on the task of eliminating bias in measurement and the associated data management.

However, neither of these studies has analyzed forestry in Japan. This paper builds on these prior studies by conducting a more in-depth analysis.

2. The Current Status of Domestic Wood

We first consider the basic data pertaining to forestry. Figure 1 illustrates the amount of production output (Gross output of forestry), capital stock, and labor in forestry.1

Figure 1 indicates that the Japanese Gross output of forestry has certainly decreased. Gross output of forestry, which was ¥907.6 billion in 1980 (2005 real prices. The following is the same), and then declined to ¥448.1 billion by 2009. This is because, with almost no tariff barriers, the domestic wood industry has been suppressed by wood from abroad.

Second, while the number of forestry workers has also decreased following the decline in forestry gross output of forestry capital stock has surprisingly seen a significant increase. Capital stock was ¥3.4342 trillion in 1980 but about three times to ¥9.0356 trillion by 2009. The decrease in the number of workers can be considered to be offset by the increase in capital stock, but capital stock is now approximately 20 times the gross output of forestry.

Gross output of forestry, capital stock, and labor usually increase and decrease together, but this is completely irregular. In forestry, gross output of forestry and labor are decreasing and only capital stock is increasing. This demonstrates the distorted nature of forestry in Japan.

Here, we present the reasons for the decline in gross output of forestry, the decline in labor, and the increase in capital stock.

![]()

Figure 1. Output, Capital stock, and Labor of foresty.

First, we focus on the significant decline in gross output of forestry.2

In 1961, the Cabinet enacted emergency measures to stabilize wood prices to curb price increases caused by rising demand for wood to build wooden houses resulting from the government’s income doubling policy in 1960. This Cabinet decision led to further deregulation of imported wood, causing a severe blow to the domestic wood industry, which had to contend with curtailed operations and a series of bankruptcies. It was, therefore, not possible to establish a system for increasing the gross output of forestry.

The second reason is that the exchange rate moved toward a stronger yen. The exchange rate is one of the factors influencing demand for domestic wood. When the yen appreciates, domestic industries choose to use cheaper, imported wood instead of domestic wood, leading to lower demand for domestic wood. Since the mid- 1980s, the yen has become stronger and wood imports have continued to expand, resulting in a further shrinking of the domestic wood market.

The third reason is that, apart from its high price, domestic wood also faces instability of supply. Because forests are considered to be a source of wood supply only during the period between planting and felling, supply volumes vary depending on the time of planting and felling. In contrast, such seasonality is not a problem in the case of imported wood. Overseas markets were able to provide a stable flow of wood in large lots. Due to these factors, the domestic forestry and wood industry was forced to neglect the almost 10 million hectares of artificial forests established after World War II. The devastation of domestic forests advanced further, and wood production decreased.

Next, we consider the reasons for the significant growth of capital stock in spite of the huge decline in gross output of forestry.3

First, it is likely that the capital stock purchased with subsidies was not properly utilized for increasing production. This is related to the problem of the labor force and mechanization, as discussed in the next paragraph, but it could also be due to the inability of aging workers to make good use of this capital stock.

Second, machines were introduced for controlling disasters, such as sediment discharge, caused by insufficient maintenance of forests. As of 1995, approximately 80% of the artificial forests in Japan were in need of forest management measures such as cutting and thinning. The situation was such that if thinning was not performed, it would lead not only to degradation of the artificial forest resources but also to a rapid increase in forests that are likely to experience many disasters. The capital stock for preventing such disasters increased, but this was not directly linked to an increase in the amount of domestic production.

Although it overlaps with the second reason, the third reason is the introduction of mechanization for environmental improvement to prevent global warming caused by forest management. Forest management is the most urgent challenge with respect to environmental conservation, and capital stock probably increased due to investment in resources for environmental improvement.

Finally, we discuss the reasons for the decrease in labor.4

First, because labor productivity in Japanese forestry is low, the profit obtained per hour of labor is less; therefore, wages are low. Low wages mean that the situation is not conducive to attracting workers, possibly resulting in a shortage of workers.

Second, as the number of forestry workers became inadequate, the number of available workers further decreased in spite of the growth in newcomers resulting from the “green jobs” initiative started in Japan in fiscal 2006. The reduction in the number of forestry workers means that the production system is by no means stable.

The third reason can be the aging of workers. According to the Forestry Agency’s “2013 Annual Report on Trends in Forests and Forestry”, the average age of forestry workers in 2010 was 52.1, higher than the average of 45.8 for workers across all industries.

3. Production Side: Measurement of Total Factor Productivity

Let’s explore the reasons for distortions in the production side of the forestry industry. Here, we hypothesize that production issues are related to factors external to the economic system. In short, even though technical progress is advancing rapidly in society as a whole, technological innovations in Japanese forestry did not occur in tandem with this progress. In other words, we verify the hypothesis that forestry in Japan could not embody the advancing technical progress.

3.1. Theories Employed―Generalized Residual Method and CES Production Function

1) Why CES is appropriate

In the case of forestry, it is not the case that structural instability increases with the variability of scale elasticity. Rather, the trend is stable. In short, it can be considered as “being in stable decline”. Therefore, CES, which assumes homogeneity, is deemed to be appropriate for the production function rather than the unstable yet workable translog model.

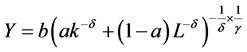

The CES production function can be expressed as follows:

(2.1)

(2.1)

Here, Y denotes the quantity of production, k denotes the quantity of capital stock, and L denotes the number of labor. The rest are parameters.

The data used in the estimation are from Figure 1: The quantity of production and the forestry capital stock are the real value (at the 2005 price).The estimation period is 1981-2009.

2) Estimation of the CES production function

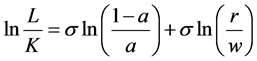

Under optimal conditions, a company’s ratio of labor to capital, ratio of its nominal price of capital to its nominal price of labor, and σ can be given as follows:

(2.2)

(2.2)

(2.3)

(2.3)

Here, r denotes the nominal price of capital and w denotes the nominal price of labor.5

This equation is used to estimate the CES production function. If the natural logarithm for both sides is taken, the equation is as follows:

(2.4)

(2.4)

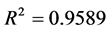

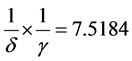

In this equation, σ will be obtained using the method of least squares to perform a regression analysis, giving elasticity of substitution .

.

Revised

Elasticity of substitution is

Interpretation of the elasticity of substitution.

In the case of forestry, the elasticity of substitution is 0.1511. If the comparative price of capital stock and labor changes by 1%, the ratio of capital stock to labor changes by approximately 0.15%. This shows that both labor and capital do not respond much to changes in other prices. In the case of forestry in Japan, even if any one element becomes cheaper, it does not mean that it will replace other factors of production.

3) Measurement of economies of scale

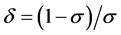

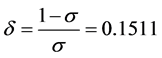

Taking the logarithm of the CES production function in Equation (2.1) yields the following equation:

(2.5)

(2.5)

represents the economies of scale and corresponds to the degree in the case of the n-th order homogeneous function. With respect to this equation, first δ and then

represents the economies of scale and corresponds to the degree in the case of the n-th order homogeneous function. With respect to this equation, first δ and then  are obtained by conducting a regression analysis using the method of least squares.

are obtained by conducting a regression analysis using the method of least squares.

Revised

We get the following value:

![]()

Regarding the degree of homogeneity.

The degree of the homogeneous function ![]() is 1.136. With respect to the scale of domestic wood, Japanese

is 1.136. With respect to the scale of domestic wood, Japanese

forestry exhibits increasing returns to scale. Specifically, if investment in capital K and labor L is doubled, then production volume increases 2.1977 times.

In theory, this means that when capital stock is increased, production volume does not increase, so the supply of domestic wood can be increased by investing in more workers. Japanese forestry is characterized by such increasing returns to scale.

3.2. Generalized Residual Method for Measuring Total Factor Productivity

1) Theory

The generalized residual method is a theory developed by Mizuno (1986) [1] and popularized by Sakuragawa (2005) [7] . Previous theories of measuring total factor productivity were premised on a linear homogeneous function; however, because total factor productivity includes the rate of technical progress, a linear homogeneous function is an inappropriate assumption when there is the possibility that either capital or labor will be working strongly.

The total factor productivity of the generalized residual method is given in the following equation:

![]() (2.6)

(2.6)

Here, ![]() are given as the following factor shares:

are given as the following factor shares:

![]()

![]()

Unlike the CES distribution parameter, the factor share is variable and can be calculated from the data. Denote the growth rates of Y, K, and L, respectively. Total factor productivity can be obtained by calculating equation (2.6).

2) Interpretation of the results of calculating total factor productivity

Figure 2 presents the results of measuring total factor productivity.

Because Figure 2 has been enlarged, the variability seems to be great, but the actual numerical changes were extremely small such that total factor productivity was almost zero. This shows that factors external to the economic system, such as technical progress, did not contribute at all to the growth of forestry.

The reasons for this low level of total productivity may be the following:

First, technical progress is not embodied in the labor force, and we do not see any successors to the current labor force. The lack of technological continuity is usually cited as the reason for unsuccessful technology transfer. However, in the case of forestry, the situation is more critical. In fact, there are literally few young successors to replace the aging labor force. The majority of those who engage in forestry are the elderly although there are some who have quit their jobs and are engaging in forestry for the first time. This is why it is difficult to pass on the basics of technology.

A second reason is the peculiarity of the forestry industry. Unlike other industries, in forestry, the time from planting to harvesting (felling) takes more than 40 years. There can be no harvesting until the forest is mature. Therefore, compared to other industries, the embodiment of technical progress is lagging. In addition, forestry is just a task of planting and felling trees. Even if one can think of ways to do forestry work more efficiently, it is difficult to link it to groundbreaking technical progress.

Third, another supply-side problem is that capital stock increases are utilized not only to increase the production volume but also for forest maintenance, including environmental conservation. It is, therefore, difficult to directly link an increase in capital stock to an increase in the production volume.

In the forestry industry, lower productivity can also be interpreted as being caused by a lack of motivation to increase production efficiency. Perhaps, the demand side did not provide the incentives to the supply side.

We will, therefore, examine whether there was any stimulation (or lack of it) from the demand side that could have caused sluggishness on the supply side.

4. Calculating the Utility of Japanese Forestry

If domestic wood has low productivity, it will be difficult to overcome the competition posed by imported wood as long as prices remain at a high level, so demand will fall and the utility of domestic wood will decline. Such a situation will not provide any stimulus to the production side. This chapter examines this structure.

4.1. Declining Productivity

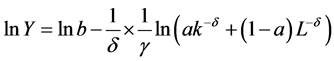

Capital productivity and labor productivity can be calculated from the data as follows (Figure 3).6

One can observe the decline in productivity at both companies from the descending lines to the right, thus, the price of wood tends to remain at a high level.

With regard to wood, it is difficult to differentiate the quality of domestic and imported wood. In fact, imported wood is considered to be of good quality because of its degree of dryness. Indeed, the product that is cheaper is considered to be better. Because of this, as shown in Figure 4, the decline in demand is expected to continue and the price of domestic wood is expected to remain at a high level.

![]()

Figure 3. Labor productivity and capital productivity.

![]()

Figure 4. Wood prices. Source: report on wood supply and demand from annual statistics on raw materials prices.

4.2. Declining Utility

When demand falls, utility declines. If utility declines, incentives to produce wood decrease and there is no motivation to adopt new technology. This hypothesis of a vicious circle has come true. Let’s now calculate the actual cardinal utility of forestry in Japan.

1) The CES utility function

Here, we calculate utility using the CES utility function.

![]()

Here, the reason for utilizing the μ homogenous utility function is to measure the cardinal utility at which the degree of motivation can be accurately calculated.

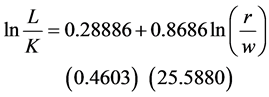

The CES utility function can be estimated as follows. First, the demand function is given in the following equation:

![]() (3.1)

(3.1)

Here, q1 denotes the actual amount of wood production (at the 2010 price), q2 denotes the actual amount of mushroom production volume (at the 2010 price), p1 denotes the wood deflator, and p2 denotes the mushroom deflator (substituted by the shiitake deflator). Here, we use data for 1981-2013. Taking the logarithm of demand function from Equation (3.1), we get the following:

![]() (3.2)

(3.2)

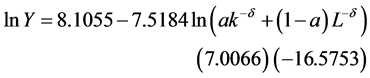

The solution of this equation is as follows:

![]()

![]()

Therefore, ![]() ,

,![]() . And we can calculate the parameters of (3.1) as follows.

. And we can calculate the parameters of (3.1) as follows.

![]()

![]()

![]()

2) Measuring scale elasticity

Theil’s (1980) [3] [4] system-wide approach shows the development solution of the utility maximization problem using the differential demand equation. This theory is used to measure the scale elasticity. This is also useful in calculating the cardinal utility to measure utility accurately. The derivative demand equation of the relative price equation is expressed as follows:

![]() (3.3)

(3.3)

![]() (3.4)

(3.4)

There are the following conditions.

![]()

Note that ![]() is the Frish price index,

is the Frish price index, ![]() is the Divisia quantity index7, and φ is the income flexibility.8 wi (i = 1, 2) is the budget share of the good in the total expenditure. The marginal share θi (i = 1, 2) is the additional amount spent on the good when the income increases. θij (i = 1, 2, j = 1, 2) are the substitution parameters. The actual estimation is conducted using the absolute price form given below. This is the same value as the relative price equation:

is the Divisia quantity index7, and φ is the income flexibility.8 wi (i = 1, 2) is the budget share of the good in the total expenditure. The marginal share θi (i = 1, 2) is the additional amount spent on the good when the income increases. θij (i = 1, 2, j = 1, 2) are the substitution parameters. The actual estimation is conducted using the absolute price form given below. This is the same value as the relative price equation:

![]() (3.5)

(3.5)

According to the parameter conditions, the Equation (3.5) is equal to the following equation:

![]() (3.6)

(3.6)

Here, πij (i = 1, 2, j = 1, 2) are the substitution parameters. Also, ![]() is the Divisia quantity index and is given by the following equation:

is the Divisia quantity index and is given by the following equation:

![]()

Here is the result of estimating the absolute price form using the method of least squares9:

![]()

![]()

Therefore, ![]() and

and ![]() .

.

As we have the constraint conditions about the parameters of the system-wide approach, we need not estimate the parameters of the second Equation (3.4).10 Estimating the respective parameters, we get the following, as shown in Table 1.

According to this, the scale elasticity μ, which corresponds to n of the n-th order homogeneous function of the CES utility function, is obtained.11 The solution is as follows:

![]()

Regarding utility, the solution was the increasing return.

4.3. Calculating Cardinal Utility

Cardinal utility was calculated using the above parameters of the CES utility function. The results are shown in Figure 5.

Cardinal utility accurately expresses the psychological state of the consumer as a numeric value. The results of the utility calculation indicate that utility decreases as the production volume of and demand for wood decline. Differentiation from imported wood is not possible. In contrast, in terms of distribution and customary degree of processing, imported wood is considered to be good, so domestic wood could be of inferior quality. Thus, the result of calculating the utility of domestic wood is that it actually cannot successfully compete in terms of price or quality.

This implies that the consumer cannot see the meaning or importance of using Japan’s domestic wood. The result is a negative spiral situation in which a decline in utility decreases incentives for technical progress on the supply side.12

![]()

Table 1. Estimation value of the parameters of the system-wide approach.

5. Opinions about Domestic Wood and the Need for Technical Progress

5.1. Questionnaire Survey

A simple questionnaire survey was conducted using the opportunity method, targeting 42 people, including forestry workers and those concerned with the forestry industry from the Hokkaido region, with the aim of measuring whether an increase in utility actually impacts technical progress.13 On the basis of this, we illustrate the structure and solutions for the forestry industry.

Table 2 presents the results of an interview questionnaire targeting those concerned with the forestry industry regarding questions on “whether an increase in the users’ evaluation of domestic wood leads to efforts to embody technical progress” (implemented in October-November 2015).

Among the 42 survey participants, 22 responded that they were “making efforts”, 8 answered that they were “not making efforts”, and 12 responded “don’t know”.

Those who responded that they were “making efforts” constituted 52 % of the total surveyed participants, more than half of the respondents. Higher opinions of domestic wood can lead to increasing demand over the long term; therefore, more than half of the forestry organization is sensitive to the changes in the market and responded that they “proactively embody technical progress”.

Those who responded that they were “not making efforts” constituted 19% of the total surveyed participants. However, this includes those who responded that they “make consistent efforts and will not alter their volume of effort even if the reputation of domestic wood improves” and those who answered that “the forestry organization is acting carefully and evaluating whether the improved reputation of domestic wood is temporary; therefore, embodiment is not easily achieved”.

Those who responded with “don’t know” constituted 29% of the total surveyed participants. Behind this response lies the answer, “it’s hard to say”, triggered by the complex situation surrounding the forestry industry in recent years.

The results of this survey indicate that more than half of the forestry organization embodies technical progress. One can say that the reason why the forestry organization has not embodied technical progress is the problem of the reputation of domestic wood. Even if the production volume increases temporarily, with its current reputation, there is no way to anticipate future demand. Therefore, the forestry industry has curtailed efforts toward the embodiment of technical progress.

5.2. Theoretical Basis

Next, we present the underlying theoretical basis and formula by looking at Figure 6. The first quadrant indicates the relation between the cardinal utility of domestic wood and its quantity when mushrooms are a constant. As the utility function estimated above is the function of increasing return. The fourth quadrant is the production function of increasing returns to scale represented by the production volume of domestic wood and the amount of labor when capital is a constant. Even though the right side of the dotted line of production function 1 is theoretically possible, from Japan’s perspective, it suggests that production is impossible. First, even if we assume the existence of a labor force, the steep mountain slopes in Japan make production difficult. Second, successor workers with expertise have not been nurtured, making production impossible. Originally, if the production function has increasing returns to scale, the higher the production, the greater the profit would be, but in the case of forestry in Japan, production has hit a ceiling for the above reasons.

![]()

Table 2. Results of the survey on the embodiment of technical progress.

![]()

Figure 6. Utility function and production function.

Currently, let’s assume that in regard to production function 1, the amount of labor L1 and cardinal utility u1 are realized. Even if the cardinal utility changes, the production function Y1 will increase and decrease, but production will stop at the dotted line.

We propose to change the situation from one of no embodiment of technical progress to one in which technical progress is embodied and the production function is shifted upward, as in Y2. The survey results indicate that this is possible. In the first quadrant, as the users’ opinion of domestic wood improves, cardinal utility increases from ![]() to

to![]() . Due to this, the amount of domestic wood increases from

. Due to this, the amount of domestic wood increases from ![]() to

to![]() . Then, the original production function Y1 enters the dotted line, and the volume cannot be attained. However, as demonstrated by the questionnaire survey results, if the reputation of domestic wood improves, the forestry industry will make efforts to embody technical progress, shifting the production function to Y2, and then the production volume can be attained.

. Then, the original production function Y1 enters the dotted line, and the volume cannot be attained. However, as demonstrated by the questionnaire survey results, if the reputation of domestic wood improves, the forestry industry will make efforts to embody technical progress, shifting the production function to Y2, and then the production volume can be attained.

6. Conclusions

This paper shows that advanced technical progress is not being embodied in Japan’s forestry industry at present. The industry is in decline due to price competition from imported wood. However, it shows that embodiment itself can be a powerful means of succeeding in price competition and also identifies the factors required to bring about this embodiment based on a theoretical foundation and a survey of actual conditions. In short, this paper indicates that an improvement in users’ opinions of domestic wood is essential.

Importantly, those concerned with the forestry industry and the government must promote the merits of domestic wood. It is first important to convey to users the essence of what our forebears hold dear and second to convey the fact that the care taken until a tree reaches maturity as a bearing tree is valuable and that the grain of Japanese wood is excellent in terms of balance and design. Unlike other materials, domestic wood is a reflection of the work done by our forebears who live many decades ago. Innumerable people have worked hard and nurtured trees from the planting stage to the present. It is erroneous to think of wood resources in the same way as such mineral resources as coal or petroleum. People plant trees and take care of these trees for many years, after which the trees finally become a resource. This aspect of wood in Japan―this commitment and pride over generations―makes domestic wood very different than imported wood.

As long as the Japanese are not aware of this, in other words, as long as they are not able to differentiate between domestic wood and imported wood, the futile price competition will continue. Communicating the appeal of domestic wood from the demand side to the supply side would provide an opportunity to overhaul the production structure. If the demand side can show the value of domestic wood, utility will increase and stimulate the production side.

NOTES

![]()

1Missing data about number of employees in forestry was calculated by assuming an equal increase and decrease in the existing data gap.

![]()

2See K. Yamagishi (2001) [10] pp.19-29, p. 161.

3See K. Yamagishi (2001) [10] pp.19-29.

4See T. Aikawa (2010) [11] pp. 32-37, M. Yoneda, Japan is a Forest Nation (2011) [12] , pp. 18, 21.

![]()

5The long-term interest rate was actualized using the inflation rate, and the nominal wage was actualized using the consumer price index.

![]()

6The production volume was calculated by dividing the amount of capital stock and labor stock.

![]()

7See K. Mizuno (1998) [7] pp. 36-37.

8We regard the income flexibility as −0.5. as we did so in Mizuno, K. 1998 [7] p. 151.

9w1, w2 used here were calculated using the average of the two periods.

![]()

10See K. Mizuno (1992) [6] pp. 140-146.

11See K. Mizuno (1992) [6] p. 145.

12Recently, the yen has been depreciating, and the market share of domestic wood is making a comeback.

![]()

13The opportunity method uses those who are close to the topic as survey target. One of this paper’s authors is an employee of the Forestry Agency and lives in Hokkaido, so the survey was conducted targeting those involved with forestry throughout Hokkaido.