中国组织工程研究 ›› 2021, Vol. 25 ›› Issue (4): 521-525.doi: 10.3969/j.issn.2095-4344.2362

• 组织工程口腔材料 tissue-engineered oral materials • 上一篇 下一篇

激光选区熔化钴铬烤瓷合金金瓷结合界面的特性

孙 启1,周亚男1,董 鑫1,李 宁1,颜家振1,石浩江1,许 胜2,张 幖3

- 1四川大学机械工程学院,四川省成都市 610065;2广西医科大学口腔医学院,广西壮族自治区南宁市 530021;3成都科宁达材料有限公司,四川省成都市 610042

Metal-ceramic interface characteristics of Co-Cr alloy fabricated by selective laser melting

Sun Qi1, Zhou Yanan1, Dong Xin1, Li Ning1, Yan Jiazhen1, Shi Haojiang1, Xu Sheng2, Zhang Biao3

- 1School of Mechanical Engineering, Sichuan University, Chengdu 610065, Sichuan Province, China; 2School of Stomatology, Guangxi Medical University, Nanning 530021, Guangxi Zhuang Autonomous Region, China; 3Chengdu KeNingDa Materials Co., Ltd., Chengdu 610042, Sichuan Province, China

摘要:

文题释义:

激光选区熔化:该技术是一种新型的金属3D打印技术,其以三维CAD切片模型为基础,在惰性气体的保护下,高能量的激光束按照模型规划好的路径逐层扫描合金粉末,扫描过的粉末熔化和凝固后结合在一起,最终形成一个致密的金属零件。

烤瓷合金金瓷结合:在修复口腔缺损牙部位时,为了满足美学的需要和与牙周组织良好的生物相容性,通常采用金属冠或桥作为基底,在基底上覆盖与天然牙外观上相似的瓷粉,经过烤瓷烧结而成的烤瓷修复体。这种金瓷修复体具有天然牙外观和金属基底良好的理化性能。在临床应用中如果金属与修饰瓷之间的结合力较低,会发生崩瓷和裂瓷等现象,影响烤瓷修复体的临床使用寿命。而金瓷之间结合力的大小通常与金瓷结合界面的特性有关。

背景:激光选区熔化技术制作的钴铬烤瓷合金正被广泛应用于牙科修复领域,但目前该工艺对钴铬烤瓷合金金瓷结合性能的影响存在争议。

目的:观察牙科用激光选区熔化钴铬烤瓷合金金瓷结合界面的特性。

方法:分别采用精密铸造法与激光选区熔化法制备钴铬烤瓷合金试件,烤瓷后利用万能试验机、扫描电镜、能谱仪、金相显微镜等方法观察其金瓷结合强度、显微组织、结合界面特性及断裂行为。

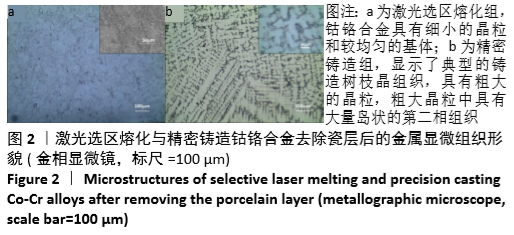

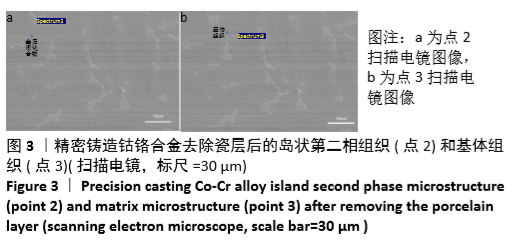

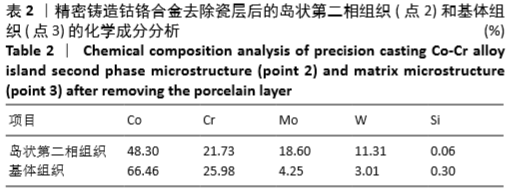

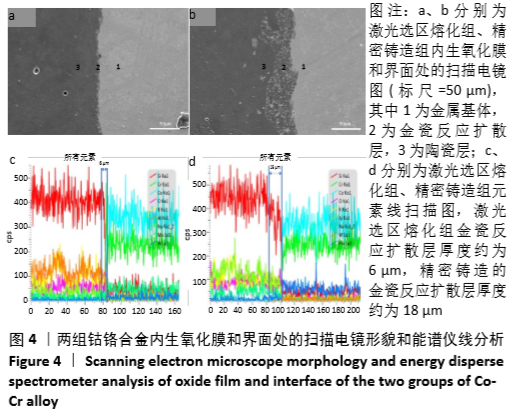

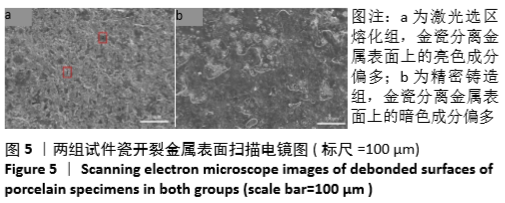

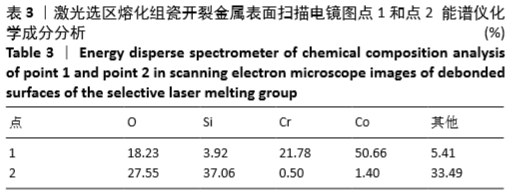

结果与结论:①精密铸造钴铬合金的金瓷结合强度大于激光选区熔化钴铬合金(P < 0.05);②金相显微镜显示,激光选区熔化钴铬合金具有细小的晶粒和较均匀的基体,精密铸造钴铬合金显示了典型的铸造树枝晶组织,具有粗大的晶粒,粗大的晶粒中具有大量岛状的第二相组织;③扫描电镜显示,精密铸造钴铬合金的金瓷反应扩散层厚于激光选区熔化钴铬合金;④扫描电镜显示,精密铸造钴铬合金烤瓷件偏向于内聚断裂,激光选区熔化钴铬合金烤瓷件偏向于黏附断裂;⑤结果表明,激光选区熔化钴铬烤瓷合金的金瓷结合强度虽低于精密铸造钴铬合金,但仍能满足标准YY0621.1-2016的金瓷结合强度要求。

https://orcid.org/0000-0002-5704-9011 (孙启)

中国组织工程研究杂志出版内容重点:生物材料;骨生物材料; 口腔生物材料; 纳米材料; 缓释材料; 材料相容性;组织工程

中图分类号: