Abstract

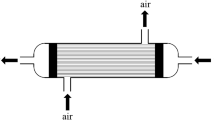

In this study, a flow analysis and a fluid-solid interaction analysis were performed on a hollow fiber membrane module used for dehumidification of a pneumatic system. To ensure the reliability of the flow analysis results, we performed the dehumidification experiment at a temperature of 30 °C and a relative humidity(RH) of 30% on a module with a similar to that of the analyses. shape only the part containing hollow fiber membranes was considered. Results of the dehumidification experiments were compared with the results of the flow analysis. The results of dehumidification experiments and the flow analysis had a difference of approximately 5%, and although the five models had different grid numbers, the results of flow analysis showed a difference of about 1% in the dehumidification efficiency ensuring the accuracy. A one-way fluid-solid interaction analysis with various materials was performed. From the result, we found that the baffle having the largest shape deformation was the one made of polyethylene material, which was then subjected to a 2-way fluid-solid interaction at 0.53 bar, 1 bar, 5 bar, and 10 bar. The fluid flow and the dehumidification characteristics were determined for different shapes of the deformed baffle. Finally, the effects of three types of flow paths based on the positions of the inlet and the outlet on the baffle deformation and the dehumidification efficiency were studied. We found that dehumidification efficiency was highest when inlet and outlet were positioned in a straight line.

Similar content being viewed by others

References

C. Ma et al., Separation Purification Tech. 209, 707 (2019).

J. Wang, X. Gao and G. Ji, Separation Purification Tech. 213, 1 (2019).

DEWETRON (DEWE-800), DEWETRON Korea.

G. Zhang et al., Appl. Thermal Engin. 146, 701 (2019).

Solidworks 2015, Dassault System.

M. Ho Song and K. Y. Kim, Trans. Korean Hydrogen New Energy Soc. 27, 29 (2016).

S. Saneinejad et al., J. Wind Eng. Ind. Aerodyn. 104–106, 455 (2014).

B. J. Julian et al., Chem. Engin. J. 142, 87 (2015).

X. Han, X. Zhang, L. Wang and R. Niu, Energy Build. 57, 14 (2013)

ANSYS FLUENT v14.5, ANSYS, Korea.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jeong, EA., Khan, H.A., Yun, SN. et al. Fluid-Solid Interaction Analysis for Improvement in the Dehumidification Characteristics of a Hollow Fiber Membrane Module for Use in a Pneumatic Power Unit. J. Korean Phys. Soc. 75, 791–800 (2019). https://doi.org/10.3938/jkps.75.791

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3938/jkps.75.791