Abstract

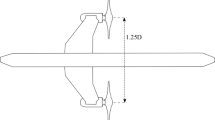

The Issue of mixing efficiency in agitated tanks has drawn serious concern in many industrial processes. The turbulence model is very critical to predicting mixing process in agitated tanks. On the basis of computational fluid dynamics(CFD) software package Fluent 6.2, the mixing characteristics in a tank agitated by dual six-blade-Rushton-turbines(6-DT) are predicted using the detached eddy simulation(DES) method. A sliding mesh(SM) approach is adopted to solve the rotation of the impeller. The simulated flow patterns and liquid velocities in the agitated tank are verified by experimental data in the literature. The simulation results indicate that the DES method can obtain more flow details than Reynolds-averaged Navier-Stokes(RANS) model. Local and global mixing time in the agitated tank is predicted by solving a tracer concentration scalar transport equation. The simulated results show that feeding points have great influence on mixing process and mixing time. Mixing efficiency is the highest for the feeding point at location of midway of the two impellers. Two methods are used to determine global mixing time and get close result. Dimensionless global mixing time remains unchanged with increasing of impeller speed. Parallel, merging and diverging flow pattern form in the agitated tank, respectively, by changing the impeller spacing and clearance of lower impeller from the bottom of the tank. The global mixing time is the shortest for the merging flow, followed by diverging flow, and the longest for parallel flow. The research presents helpful references for design, optimization and scale-up of agitated tanks with multi-impeller.

Similar content being viewed by others

References

BIGGS R D. Mixing rates in stirred tanks[J]. AIChE J. 1963, 9(5): 636–640.

RAGHAV RAO K S M S, JOSHI J B. Liquid phase mixing in mechanically agitated vessels[J]. Chemical Engineering Communications, 1988, 74(1): 1–25.

ZHAO D, GAO Z, MULLER-STEINHAGEN H, et al. Liquidphase mixing times in sparged and boiling agitated reactors with high gas loading[J]. Industrial & Engineering Chemistry Research, 2001, 40(6): 1482–1487.

REWATKAR V B, JOSHI J B. Effect of impeller design on liquid phase mixing in mechanically agitated reactors[J]. Chemical Engineering Communications, 1991, 102(1): 1–33.

XU S A, FENG L F, GU X P, et al. Mixing time in stirred tank of three phase gas-liquid-floating particle systems[J]. Journal of Chemical Engineering of Chinese Universities, 2000, 14(4): 328–333. (in Chinese)

CABARET F, BONNOT S, FRADETTE L. Mixing time analysis using colorimetric method and image processing[J]. Industrial & Engineering Chemistry Research, 2007, 46(14): 5032–5042.

LEE K C, YIANNESKIS M. A liquid crystal thermographic technique for the measurement of mixing characteristics in stirred vessel[J]. Chemical Engineering Research & Design, 1997, 75(A8): 746–754.

OSMAN J J, VARLEY J. The use of compuational fluid dynamic (CFD) to estimate mixing times in a stirred tank[J]. IChemE, Symposium Series, 1999,146.

JAWORSKI Z, BUJALSKI W, OTOMO N, et al. CFD study of homogenization with dual Rushton turbines-comparison with experimental results. Part 1: initial studies[J]. Transactions of the institution of Chemical Engineers Research and Design, 2000, 78(3): 327–333.

REVSTEDT J, FUCHS L, TRAGARDH C. Large eddy simulation of the turbulent flow in a stirred reactor[J]. Chemical Engineering Science, 1998, 53(24): 4041–4053.

MIN J, GAO Z M. Large eddy simulation of mixing time in a stirred tank[J]. Chinese Journal Chemical Engineerig, 2006, 14(1): 1–7.

HARTMANN H, DERKSEN J J, HEA VAN DEN AKKER. Mixing times in a turbulent stirred tank by means of LES[J]. AIChE J., 2006, 52(11): 3696–3706.

ZADGHAFFARI R, MOGHADDAS J S, REVSTEDT J. A mixing study in a double-Rushton stirred tank[J]. Computers and Chemical Engineering, 2009, 33(7): 1240–1246.

YEOH S L, PAPADAKIS G, YIANNESKIS M. Determination of mixing time and degree of homogeneity in stirred vessels with large eddy simulation[J]. Chemical Engineering Science, 2005, 60(8–9): 2293–2302.

GIMBUN J, RIELLY C D, NAGY Z K, et al. Detached eddy simulation on the turbulent flow in a stirred tank[J]. AIChE J., 2012, 58(10): 3224–3241.

YANG F L. Detached eddy simulation and PIV study of the maroinstability in eccentrically stirred tanks[D] Jinan: Shandong University, 2010.

YANG F L, ZHOU S J, ZHANG C X. Turbulent flow and mixing performance of a novel six-blade grid disc impeller[J]. Korean Journal of Chemical Engineering, 2015, 32(5): 816–825.

SUN H, XIAO R F, WANG F J, et al. Analysis of the pump-turbine S characteristics using the detached eddy simulation method[J]. Chinese Journal of Mechanical Engineering, 2015, 28(1): 115–122.

WU D H, YUAN S Q, REN Y, et al. CFD investigation of the influence of volute geometrical variations on hydrodynamic characteristics of circulator pump[J]. Chinese Journal of Mechanical Engineering, 2016, 29(2): 315–324.

SPALART P R, ALLMARAS S R. A one-equation turbulence model for Aerodynamic flows[J]. AIAA Paper, 1992, 92–0439.

SHUR M, SPALART P R, STRELETS M, et al. Detached-eddy simulation of an Airfoil at high angle of attack[C]//4th Int. Symposium on Eng. Turb. Modeling and Experiments, Corsica, France, May, 1999.

KASAT G R, KHOPKAR A R, RANADE V V, et al. CFD simulation of liquid-phase mixing in solid-liquid stirred reactor[J]. Chemical Engineering Science, 2008, 63(15): 3877–3885.

FAKHERI F, MOGHADDAS J. Compartment mixing model in a stirred tank equipped dual Rushton Turbine[J]. Iranian Journal of Chemical Engineering, 2012, 9(3): 14–21.

RUTHERFORD K, LEE K C, MAHMOUDI S M S, et al. Hydrodynamic characteristics of dual Rushton impeller stirred vessels[J]. AIChE J., 1996, 42(2): 332–346.

MICALE G, BRUCATO A, GRISAFI F. Prediction of flow fields in a dual-impeller stirred vessel[J]. AIChE J., 1999, 45(2): 445–464.

WENG Z X, HUANG Z M, LI Y M. The influence of multi-impeller spacing on mixing characteristics in turbulent stirred tanks[J]. Chemical Engineering(China), 1983, 6: 1–7. (in Chinese)

WANG K, FENG L F. Mixing equipment design[M] Beijing: China Machine Press, 2000. (in Chinese)

MAO D M. Fundamental research on flow and mixing in multi-impeller vessel[D] Hangzhou: Zhejiang University, 1998. (in Chinese)

QI N N, WU G Y, WANG H, et al. CFD simulation of mixing characteristics in stirred tank by Smith turbine[J]. Journal of Chemical industry and Engineering(China), 2010, 61(9): 2305–2313. (in Chinese)

MONTANTE A, LEE K C, BRUCATO A. An experimental study of double-to-single-loop transition in stirred vessels[J]. Canadian Journal of Chemical Engineering, 1999; 77(4): 649–659.

OCHIENG A, ONYANGO M S, KUMAR A, et al. Mixing in a tank stirred by a Rushton turbine at a low clearance[J]. Chemical Engineering and Processing, 2008, 47(5): 842–851.

Author information

Authors and Affiliations

Corresponding author

Additional information

Supported by Key Scientific Research Project of Sichuan Provincial Education Department (Grant No. 15ZA0107), and Doctor Foundation of Southwest University of Science and Technology(Grant No. 11zx7162)

LI Liangchao, born in 1976, is currently a teacher at Southwest University of Science and Technolgy, China. He received his PhD degree from Zhejiang University, China, in 2010. His research interests include fluid mixing technology, mechachonics engineering, fluid power transmission and control.

XU Bin, born in 1975, is currently an associate professor at Southwest University of Science and Technology. He received his PhD degree from Dalian University of Technology, China, in 2010. His research interests include mechachonics engineering, Rheology, fluid mixing technology.

Rights and permissions

About this article

Cite this article

Li, L., Xu, B. CFD simulation of local and global mixing time in an agitated tank. Chin. J. Mech. Eng. 30, 118–126 (2017). https://doi.org/10.3901/CJME.2016.1107.129

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3901/CJME.2016.1107.129