Abstract

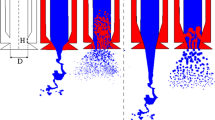

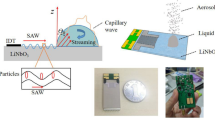

The atomizer with micro cone apertures has advantages of ultra-fine atomized droplets, low power consumption and low temperature rise. The current research of this kind of atomizer mainly focuses on the performance and its application while there is less research of the principle of the atomization. Under the analysis of the dispenser and its micro-tapered aperture’s deformation, the volume changes during the deformation and vibration of the micro-tapered aperture on the dispenser are calculated by coordinate transformation. Based on the characters of the flow resistance in a cone aperture, it is found that the dynamic cone angle results from periodical changes of the volume of the micro-tapered aperture of the atomizer and this change drives one-way flows. Besides, an experimental atomization platform is established to measure the atomization rates with different resonance frequencies of the cone aperture atomizer. The atomization performances of cone aperture and straight aperture atomizers are also measured. The experimental results show the existence of the pumping effect of the dynamic tapered angle. This effect is usually observed in industries that require low dispersion and micro- and nanoscale grain sizes, such as during production of high-pressure nozzles and inhalation therapy. Strategies to minimize the pumping effect of the dynamic cone angle or improve future designs are important concerns. This research proposes that dynamic micro-tapered angle is an important cause of atomization of the atomizer with micro cone apertures.

Similar content being viewed by others

References

CHETAN M, NEGOIAS A. New approaches to nebulizer drug delivery[C]//Advanced Topics in Electrical Engineering (ATEE); 7th International Symposium on, Bucharest, Romania, 2011: 1–4.

FDA U. Reviewer guidance for nebulizers, metered dose inhalers, spacers and actuators[EB/OL]. (2014). http://www.fda.gov/medicaldevices/deviceregulationandguidance/guidancedocuments/u cm081282.htm.

FORREST S R. The path to ubiquitous and low-cost organic electronic appliances on plastic[J]. Nature, 2004, 428(6986): 911–918.

AHMAD Z, HUANG J, THIAN E S, et al. Freeform fabrication of nano-biomaterials using 3D electrohydrodynamic print-patterning [J]. Journal of Biomedical Nanotechnology, 2008, 4(2): 185–195.

CHOI K H, ALI J, NA K-H. Fabrication of graphenenanoflake/ poly(4-vinylphenol) polymer nanocomposite thin film by electrohydrodynamic atomization and its application as flexible resistive switching device[J]. Physica B: Condensed Matter, 2015, 475: 148–155.

MEMARZADEH K, SHARILI A S, HUANG J, et al. Nanoparticulate zinc oxide as a coating material for orthopedic and dental implants[J]. Journal of Biomedical Materials Research Part A, 2015, 103(3): 981–989.

LEE S H, HENG D, NG W K, et al. Nano spray drying: a novel method for preparing protein nanoparticles for protein therapy[J]. International Journal of Pharmaceutics, 2011, 403(1–2): 192–200.

QUISPE-CONDORI S, SALDAÑA M D A, TEMELLI F. Microencapsulation of flax oil with zein using spray and freeze drying[J]. LWT-Food Science and Technology, 2011, 44(9): 1880–1887.

NANDIYANTO A B D, OKUYAMA K. Progress in developing spray-drying methods for the production of controlled morphology particles: From the nanometer to submicrometer size ranges[J]. Advanced Powder Technology, 2011, 22(1): 1–19.

CARNÉ-SÁNCHEZ A, IMAZ I, CANO-SARABIA M, et al. A spray-drying strategy for synthesis of nanoscale metal–organic frameworks and their assembly into hollow superstructures[J]. Nature Chemistry, 2013, 5(3): 203–211.

SANTANGELO P E, JACOBS B C, REN N, et al. Suppression effectiveness of water-mist sprays on accelerated wood-crib fires[J]. Fire Safety Journal, 2014, 70: 98–111.

JENFT A, COLLIN A, BOULET P, et al. Experimental and numerical study of pool fire suppression using water mist[J]. Fire Safety Journal, 2014, 67: 1–12.

ZHUO J, YINSHUI L, XUFENG Z, et al. A portable piston-type water mist fire extinguisher for spacecraft[J]. Proceedings of the Institution of Mechanical Engineers, Part E: Journal of Process Mechanical Engineering, 2015, 229(1): 52–63.

DENG Dong, ZHOU Hua, YANG Huayong. Emulational and experimental study of new water mist spray nozzle for fire suppression[J]. Chinese Journal of Mechanical Engineering, 2006, 42(12): 122–127. (in Chinese)

LU C F, FU C C, YANG J C, et al. 4A-3 traveling wave driven micro-dispenser for CPU cooling application[C]//2006 IEEE Ultrasonics Symposium, Vancouver, BC: IEEE, 2006: 54–57.

HOU Y, TAO Y, HUAI X. The effects of micro-structured surfaces on multi-nozzle spray cooling[J]. Applied Thermal Engineering, 2014, 62(2): 613–621.

NEGEED E-S R, HIDAKA S, KOHNO M, et al. Effect of the surface roughness and oxidation layer on the dynamic behavior of micrometric single water droplets impacting onto heated surfaces[J]. International Journal of Thermal Sciences, 2013, 70: 65–82.

PANÃO M R O, MOREIRA A L N, DURÃO D F G. Thermal-fluid assessment of multijet atomization for spray cooling applications[J]. Energy, 2011, 36(4): 2302–2311.

HEIJ B de, SCHOOT B van der, ROOIJ N F de, et al. Modelling and optimisation of A vaporiser for inhalation drug therapy[C]//Technical Proceedings of the 1999 International Conference on Modeling and Simulation of Microsystems, Puerto Rico, USA: NSTI, 1999: 542–545.

DE HEIJ B, VAN DER SCHOOT B, BO H, et al. Characterisation of a fL droplet generator for inhalation drug therapy[J]. Sensors and Actuators A: Physical, 2000, 85(1–3): 430–434.

PAN C T, SHIEA J, SHEN S C. Fabrication of an integrated piezo-electric micro-nebulizer for biochemical sample analysis[J]. Journal of Micromechanics and Microengineering, 2007, 17(3): 659–669.

MAEHARA N, UEHA S, MORI E. Influence of the vibrating system of a multipinhole-plate ultrasonic nebulizer on its performance[J]. Review of Scientific Instruments, 1986, 57(11): 2870.

MAEHARA N, UEHA S, MORI E. Optimum design procedure for multi-pinhole-plate ultrasonic atomizer[J]. Japanese Journal of Applied Physics, 1987, 26(S1): 215–217.

SHEN S-C, WANG Y-J, CHEN Y-Y. Design and fabrication of medical micro-nebulizer[J]. Sensors and Actuators A: Physical, 2008, 144(1): 135–143.

SHEN S C. A new cymbal-shaped high power microactuator for nebulizer application[J]. Microelectronic Engineering, 2010, 87(2): 89–97.

LU C, YANG J, FU C. No back-pressure effect micro-dispenser suction pump[C]//2006 International Microsystems, Package, Assembly Conference Taiwan. Taipei: IEEE, 2006: 1–4.

WHITE F M. Fluid mechanics[M]. New York: McGraw-Hill, 2003.

OLSSON A, STEMME G, STEMME E. Numerical and experimental studies of flat-walled diffuser elements for valve-less micropumps[J]. Sensors and Actuators A: Physical, 2000, 84(1–2): 165–175.

ZHANG Jianhui, XIA Qixiao, ZHEN Hong, et al. Flow direction of piezoelectric pump with nozzle/diffuser-elements[J]. Chinese Journal of Mechanical Engineering, 2004, 17(1): 107–109.

Author information

Authors and Affiliations

Corresponding author

Additional information

Supported by National Natural Science Foundation of China (Grant Nos. 51375227, 91223201)

CAI Yufei, born in 1984, is currently a PhD candidate at College of Aerospace Engineering, Nanjing University of Aeronautics and Astronautics, China. His research interests include air vehicle environment control and atomization.

ZHANG Jianhui, born in 1963, is currently a professor and a PhD candidate supervisor at School of Electro-Mechanical Engineering, Guangzhou University, China. His research area is mechanical design and its theory, piezoelectric driving.

ZHU Chunling, born in 1968, is currently a professor and a PhD candidate supervisor at College of Aerospace Engineering, Nanjing University of Aeronautics and Astronautics, China. Her research area is air vehicle environment control and aircraft de-icing/anti-icing calculation and design.

HUANG Jun, born in 1981, is currently a PhD at Research Center of Fluid Machinery Engineering and Technology, China. His research area is piezoelectric driving, fluid solid coupling analysis and multi-field simulations.

JIANG Feng is a master graduate from State Key Laboratory of Mechanics and Control of Mechanical Structures, Nanjing University of Aeronautics and Astronautics, China. His research area is mechanical design and its theory, piezoelectric driving.

Rights and permissions

About this article

Cite this article

Cai, Y., Zhang, J., Zhu, C. et al. Theoretical calculations and experimental verification for the pumping effect caused by the dynamic micro-tapered angle. Chin. J. Mech. Eng. 29, 615–623 (2016). https://doi.org/10.3901/CJME.2016.0324.037

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3901/CJME.2016.0324.037