Abstract

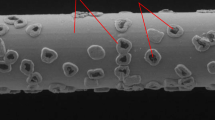

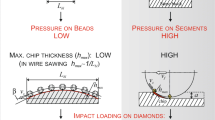

Great attention has been paid on fabricating diamond wire by using the brazing diamond because of its strong chemical bonding strength and controllability of grits distribution. Although several serving performances of brazed diamond wire have been reported, seldom do these studies refer to its process characteristics. Sawing performances of a brazed diamond wire are investigated and compared with those of a sintered diamond wire on a wire saw machine. The surface topographies of beads selected from the two wires are micro observed before sawing. The sawing tests are carried out in constant feed rate feeding(CFF) and constant normal force feeding(CNFF). In CFF test, sawing force, power, and the cut depths of positions on contact curve are measured. Then, coupled with the observations of beads topographies, sawing force and its ratio, relations of power against material removal rate, and contact curve linearity are compared and discussed. In CNFF test, the sawing rates of the two wires are investigated. The results indicate that the brazed wire performs with lower sawing force(less 16% of tangential force and 28% of normal force), more energy efficiency(nearly one-fifth of sawing power is saved), at a higher sawing rate (the rate is doubled) and with better contact curve linearity as compared with the sintered wire. This proposed research experimentally evaluates the sawing performances of brazed diamond wire from the aspect of process parameters, which can provide a basis for popularizing the brazed diamond wire.

Similar content being viewed by others

References

DAVIS P R. The future of diamond abrasives in stone processing[J]. Industrial Diamond Review, 2001, 61(3): 159–167.

WRIGHT D N, ENGELS J A. The environment and cost benefits of using diamond wire for quarrying and processing of natural stone[J]. Industrial Diamond Review, 2003, 63(4): 165–24.

MOLFINO R M, ZOPPI M. A robotic system for underwater eco-sustainable wire-cutting[J]. Automation in Construction, 2012, 24(3): 213–223.

HUANG Guoqin, XU Xipeng. Analysis of the breakage of diamond wire saws in sawing of stone[J]. Key Engineering Materials, 2006, 304–305: 123–126.

HUANG Hui, XU Xipeng. Study on the wear of diamond beads in wire sawing[J]. Materials Science Forum, 2006, 532–533: 436–439.

ÖZÇELIK Y, BAYRAM F. Optical investigations of bead wear in diamond wire cutting[J]. Industrial Diamond Review, 2004, 64(3): 60–65.

ÖZÇELIK Y, KULAKSIZ S, CETIN M C. Assessment of the wearing on diamond beads in the cutting of different rock types by the ridge regression[J]. Journal of Materials Processing Technology, 2002, 127(3): 392–400.

TÖNSHOFF H K, ASCHE J. Wear of metal-bond diamond tools in the machining of stone[J]. Industrial Diamond Review, 1997, 57(1): 7–13.

HUANG Guoqin, HUANG Hui, GUO Hua, et al. Influences of sawing parameters on forces and energy in wire sawing of granite[J]. Journal of Mechanical Engineering, 2009, 43(3): 234–239. (Chinese)

OLIVEIRA L J, BOBROVNITCHII G S, FILGUEIRA M. Processing and characterization of impregnated diamond cutting tools using a ferrous metal matrix[J]. International Journal of Refractory Metals & Hard Materials, 2007, 25(4): 328–335.

RISSO L, VICENZI B, BERNIERI S. Improved cutting performance of diamond beads by means of innovative shape [C] // Proceedings of the Second International Industrial Diamond Conference, Rome, Italy, April 19–20, 2007: B.1.1.

ÖZÇELIK, Y. Optimum working conditions of diamond wire cutting machines in the marble industry[J]. Industrial Diamond Review, 2005, 1(5): 58–64.

ÖZÇELIK, Y. Development of a single diamond bead test machine for marble cutting[J]. Industrial Diamond Review, 2008, 68(1): 56–62.

CHATTOPADHYAY A K, CHOLLET L, HINTERMANN H E. Experimental investigation on induction brazing of diamond with Ni-Cr hardfacing alloy under argon atmosphere[J]. Journal of Materials Science, 1991, 26(18): 5 093–5 100.

SUNG J C, SUNG M. The brazing of diamond[J]. International Journal of Refractory Metals and Hard Materials, 2009, 27(2): 382–393.

SUNG C M. Brazed diamond grid: a revolutionary design for diamond saws[J]. Diamond and Related Materials, 1999, (8): 1 540–1 543.

XIAO Bing, FU Yucan, SU Honghua, et al. Machining performance of brazed diamond wire saw with optimum grain distribution[J]. Key Engineering Materials, 2005, 304–305: 43–47.

LIU B C, ZHANG Z P, SUN Y H. Sawing trajectory and mechanism of diamond wire saw[J]. Key Engineering Materials, 2004, 259–260: 395–400.

NAKAGAWA H B, NAKAZWA H D, NISHIMURA N K, et al. High-speed and high-accuracy slabbing of marble using diamond wire saw[J]. Journal of Japanese Social Abrasive Technology, 2004, 48(6): 329–334 (in Japanese).

MALKIN S. Grinding technology: theory and applications of machining with abrasives[M]. New York: American Society of Civil Engineers, 1989.

Author information

Authors and Affiliations

Corresponding author

Additional information

This project is supported by National Natural Science Foundation of China(Grant Nos. 51235004, 51105148, 51175194), and Program for Changjiang Scholars and Innovative Research Team in University of China(Grant No. IRT1063)

HUANG Guoqin, born in 1981, is currently a lecturer at Huaqiao University, China. From there he received his PhD degree in 2010. His research interests include the fabrication of super-abrasive tools, high efficiency cutting, modelling, and the optimization of abrasive machining.

XU Xipeng, born in 1964, is currently a professor and a PhD candidate supervisor at Huaqiao University, China. He received his PhD degree at Nanjing University of Aeronautics and Astronautics, China, in 1992. He worked as a visiting researcher at the Grinding Research Laboratory, University of Massachusetts, United States of American, from 1998 to 1999. His research interests include machining and grinding processes for hard and brittle materials, tribology issues in machining with abrasives, and the fabrication of super-abrasive tools.

Rights and permissions

About this article

Cite this article

Huang, G., Xu, X. Sawing performance comparison of brazed and sintered diamond wires. Chin. J. Mech. Eng. 26, 393–399 (2013). https://doi.org/10.3901/CJME.2013.02.393

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3901/CJME.2013.02.393