Abstract

In this study, we investigated a method to atomize water drops directly using an ultrasonic source equipped with a transverse vibrating plate. The atomization amount increased with the electric power to the ultrasonic source and the amount of water supplied, and when the electric power was 25 W, the full amount of water supplied (approximately 90 ml min−1) was atomized. Thus, a large amount of water could be atomized.

Export citation and abstract BibTeX RIS

Powerful ultrasonic waves have been used in various mediums, and many technologies have been developed. In solid materials, ultrasonic welding 1–6) is used to join dissimilar metals with different melting temperatures easily. In fluids, the effects of cavitation on living organisms have been investigated. 7,8) Technologies that use aerial ultrasonic energy include ultrasonic agglomeration, 9,10) ultrasonic drying, 11,12) and ultrasonic atomization. 13–18) Liquids can also be atomized by applying heat, but this method may cause physical and chemical changes in the liquid.

However, ultrasonic atomization does not involve temperature changes, avoiding these problems. Liquids can be atomized by placing an ultrasonic vibration source in the liquid, 16) but this method cannot be applied to water drops. There are two methods for water drops: the contact vibration method, which directly transmits ultrasonic vibrations to the liquid drops to atomize them; and the non-contact vibration method, which indirectly transmits high-intensity ultrasonic waves in the air to the liquid drops. Endo et al. showed that non-contact atomization can be achieved by forming a strong standing wave sound field in the air using two transverse vibrating plates. 19) However, the problem with this atomization method is that the amount of atomized water is small, and the area in which water can be dropped is narrow.

Therefore, to atomize a large amount of water drops, we considered a method of atomizing water by dropping it directly onto a transverse vibrating plate. However, atomization using this method has only been investigated using a small amount of water. 20)

In this study, the aerial ultrasonic source with a stripe-mode transverse vibrating plate and jutting driving point developed by Miura et al. 21) was used as the ultrasonic source. This ultrasonic source has the advantage of making effective use of the vibrating plate because the driving point can be placed outside the vibrating plate by having a convex end on the vibrating plate. We conducted an atomization experiment using this ultrasonic source and measured the atomization amount when the electric power to the vibration source and the amount of water supplied were varied.

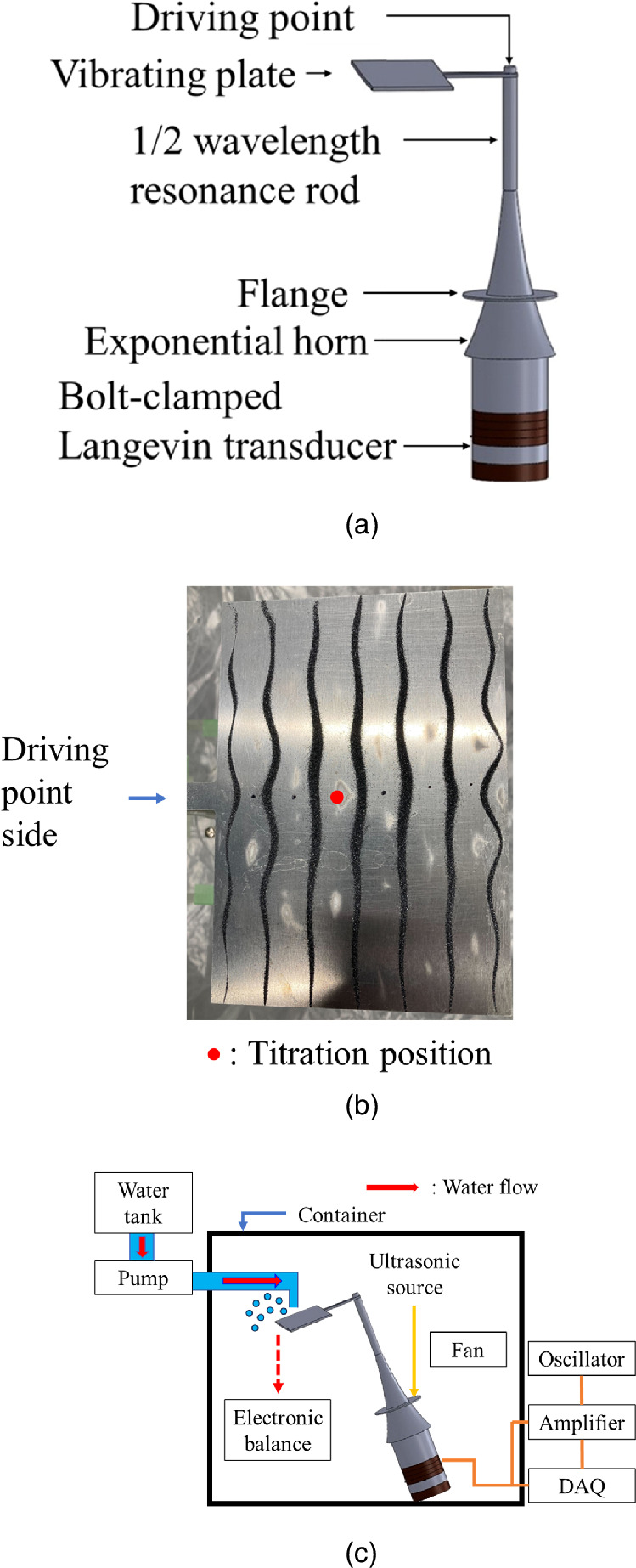

Figure 1(a) shows the ultrasonic source with a transverse vibrating plate and jutting driving point, which consists of a 20 kHz bolt-clamped Langevin longitudinal transducer (D45520) and a flanged (diameter 60 mm, thickness 2 mm) exponential horn (wide end diameter 55 mm, narrow end diameter 12 mm, length 141 mm) attached with screws, a transmission rod (length 97 mm, diameter 12 mm) attached to the tip, and a convex-end transverse vibrating plate attached to the tip. 20,21) The longitudinal vibration obtained from the transducer, horn, and rod is used to generate transverse vibration on the vibrating plate using the driving point. The transverse vibration vibrates has a striped mode (a half wavelength of the transverse vibration is 18.9 mm). In this paper, the vibrating plate size is 3 mm thick, the convex end is 64 mm long and 12 mm wide, and the vibrating plate is 123 mm long (6.5 times of the half wavelength of the transverse vibration) and 174 mm wide (approximately 9 times of the same). All the parts are duralumin.

Fig. 1. Experimental equipment. (a) Ultrasonic source, (b) transverse vibrating plate, and (c) experimental atomization equipment.

Download figure:

Standard image High-resolution imageFigure 1(b) shows a Chladni figure on the vibrating plate. In the figure, the black wavy lines are where sand has accumulated, indicating a striped mode transverse vibration where the vibration nodes are on the line. The admittance characteristics of this ultrasonic source were measured using an impedance analyzer (NF, ZGA5920). The resonant frequency was 19.9 kHz, the conductance value was 22 mS, and the sharpness Q was 585. The resonance frequency of the longitudinal vibration and the transverse vibration were matched by adjusting the length of the transmission rod.

Water was dropped directly onto the vibrating plate, and the load changed depending on whether there was water on the plate, which affected the driving of the sound source. Therefore, we controlled the electric power and the resonance frequency using the following method. The effective voltage and current values and their phase differences were measured and converted to digital format using Data AcQuisition system (DAQ). Then, using the system development software (Labview), adjustments were made to a constant set power and resonant frequency.

Figure 1(c) shows an overview of the experimental equipment. The ultrasonic source, electronic balance, and electric fan were placed inside the container to minimize external factors during the experiment. Additionally, a metering pump for dropping water onto the vibrating plate, an oscillator, an amplifier, and DAQ to drive the ultrasonic source were installed outside the container. The ultrasonic source was tilted by 20° to allow the water drops to flow easily. The experiment was conducted for 240 s with the pump turned on and the time the water began falling was 0 s. To examine the effect in a steady state with a stable supply of water, the ultrasonic waves were applied for 3 min from 30 to 210 s, when the water supply was sufficiently stable. The droplet position was set at the antinode of the vibration indicated by the red circle in Fig. 1(b). This position was chosen because the water drops spread on the plate surface, so the effect of load fluctuations was minimized, and the water was atomized immediately.

Figure 2 shows a photograph of atomization. The pump hose was placed above the vibrating plate, and the transverse vibration generated an atomized water mist over a wide area (left of Fig. 2). In addition, a fan was used to blow away the atomized water to prevent it from adhering to the vibrating plate again. The atomization amount was determined from the difference between the amount of water supplied and the amount of water that fell from the vibrating plate without being atomized. The amount of water that was not atomized was measured by an electronic balance installed under the vibrating plate.

Fig. 2. Photograph of atomization.

Download figure:

Standard image High-resolution imageTo clarify the characteristics of the direct atomization of water dropped onto the vibrating plate, we investigated the atomization amount under various conditions while varying the electric power of the ultrasonic source and the amount of water supplied. The electric power was varied from 5 to 25 W in 5 W increments. The amount of water supplied was in the range of 10–90 ml min−1.

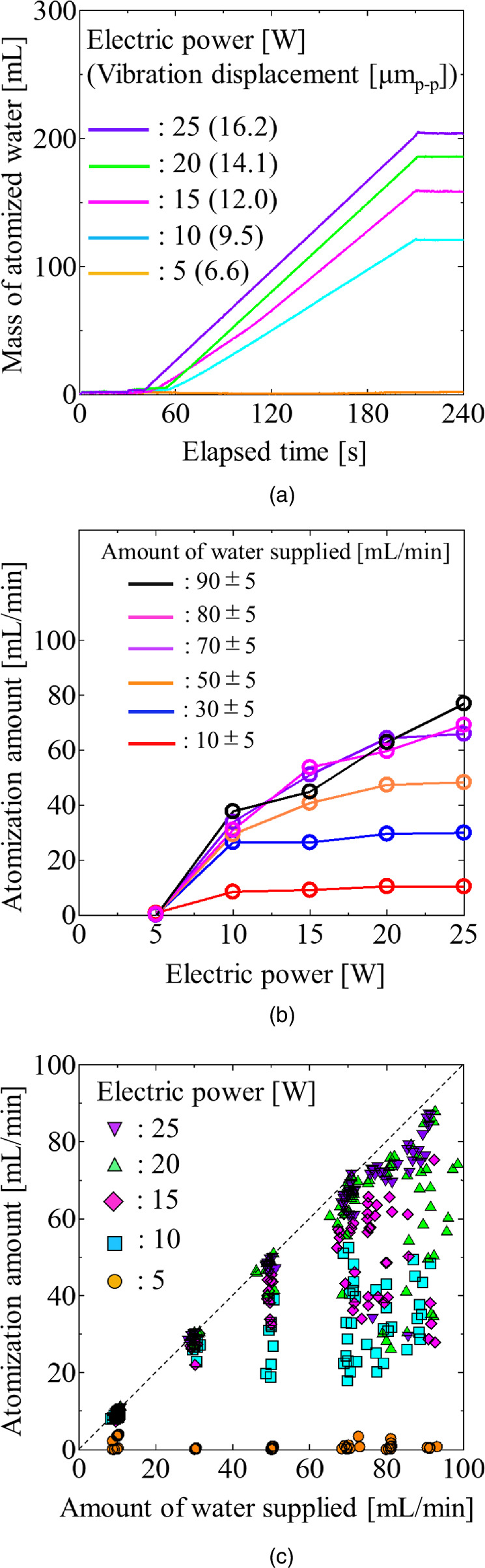

Figure 3 shows the results of an atomization experiment. Figure 3(a) shows an example of the results for an amount of water supplied of 70 ± 5 ml min−1 (expressed with a range because the pump performance did not allow a constant value). The vertical axis of the figure is the mass of atomized water, the horizontal axis is the elapsed time, and the parameter is the electric power. The values shown in parentheses are the transverse vibration displacement amplitude (p–p value) at the water droplet position [the red circle in Fig. 1(b)] during each electric power. The mass of atomized water increased from 30 s when ultrasonic irradiation started to 210 s when irradiation stopped when the electric power was 10 W or more, indicating that atomization occurred during ultrasonic irradiation. In contrast, when the electric power was 5 W (the vibration displacement was 6.6 μmp–p), there was almost no atomization. In addition, the mass of atomized water increased with the electric power, indicating that more atomization occurred.

Fig. 3. Results of atomization experiment. Relationship between the (a) mass of atomized water and elapsed time, (b) atomization amount and electric power, and (c) atomization amount and the amount of water supplied.

Download figure:

Standard image High-resolution imageFigure 3(b) shows the average amount of atomization with respect to the electric power for the experiment performed seven times or more under each set of conditions. In the figure, the vertical axis is the atomization amount, the horizontal axis is the electric power, and the parameter is the amount of water supplied. The atomization amount increased with the electric power and the amount of water supplied.

Figure 3(c) shows the atomization amount for each amount of water supplied for the same experiment. In the figure, the vertical axis is the atomization amount, the horizontal axis is the amount of water supplied, and the parameter is the electric power. The broken line shows the case where all the water supplied was atomized. As in Fig. 3(b), the atomization amount increased with the amount of water supplied, except when the electric power was 5 W. When the electric power was 25 W, almost all the water supplied during ultrasonic irradiation was atomized. In addition, the atomization amount approached the broken line as the electric power increased, indicating that atomization became more stable as the power increased.

In this study, we investigated the atomization amount possible by directly supplying water to the transverse vibrating plate. Our results were as follows.

- (1)As the electric power increased, atomization became more stable.

- (2)When the electric power was 25 W, that almost all the water supplied was atomized within the measurement range, and up to 90 ml min−1 could be atomized.

These results revealed that a large amount of dropped water can be atomized by direct atomization with a vibrating plate.