1. Introduction

Nowadays, assessing structural health conditions is necessary because of the numerous issues and failures of some structures. Reference [

1] developed a method for detecting and localizing single and multiple damages on bridges by analyzing the vibration characteristics using a mode shape component-specific damage index. Another previous study is reported by [

2] and describes a strategy for detecting, identifying, and quantifying damage in order to categorize diverse categories into broad non-parametric and parametric classifications. The authors of [

3] described a method that utilized MEMS-based sensors in conjunction with an enhanced autoregressive model for structural monitoring that was especially applicable to towers. Among the parameters that contribute to the deterioration of the components of a structure are various defects on concrete, such as surface cracks, delamination, and spalling [

4]. The authors provide background information on delamination in concrete, which is frequently produced by a high air content that becomes trapped behind a tight power-troweled finish on the surface, while spalling is caused by a variety of factors, including poor concrete quality, insufficient curing, and poor finishing processes, to mention a few [

4,

5]. The individual discussion of these parameters is presented in the related works section. In the past, the evaluation and investigation of the health condition of structures were conducted manually with human intervention. However, when humans provide the assessment, subjective instinct is used to perform tasks such as crack analysis, and the results are frequently time-consuming and more prone to error.

Despite the existing protocols on detailed visual examinations for manual assessments of concrete, humans still use psychophysical measurements in evaluating image quality, which is based on the human perception of visual information [

6]. Given these human constraints inherent in manual inspections, the results may be inefficient and cause serious problems that contribute to the continuous deterioration of structures.

The implementation of computer vision can overcome the said drawbacks and can automatically recognize and classify different types of defects on concrete. Computer-based assessments provide superior advantages, especially in terms of recognition and classification. The following studies employed computer-vision-based systems for classification applications. In addition, these research works utilized convolutional neural network (CNN) models to immediately preserve and secure the structural stability of buildings or structures. Reference [

7] used a surface crack detection approach, which included convolution and pooling layers for a concrete image dataset applied to image processing and deep learning techniques. Another study [

8] implemented a concrete crack detection and monitoring scheme founded on a deep-learning-based multiresolution analysis to impose an automatic crack type recognition based on CNN. Moreover, other research [

9] implemented a CNN-based automated pavement crack identification model to distinguish between defective and non-crack concrete.

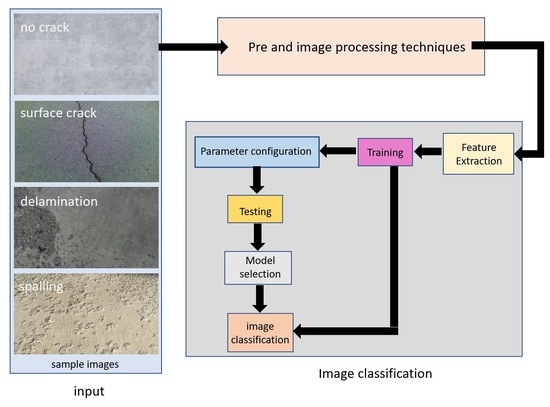

The main objective of this study is to improve the existing research. The proposed scheme in this paper is the development of an automated image-based concrete condition recognition technique that can be used, not only to categorize non-defective concrete into defective concrete, but also to recognize multivariant defects such as surface cracks, delamination, and spalling. The proposed multivariant defect detection neural network architecture is based on a convolutional model capable of recognizing various types of defects in concrete. In addition, the suggested system aims to aid the development of different fault detection and identification techniques and expedite the assessment of the state of existing structural components.

The remainder of this study is structured as follows.

Section 2 discusses the literature related to the proposed method.

Section 3 details the methodology of the proposed algorithm.

Section 4 includes experiments and discussions of the results. Finally,

Section 5 concludes this study.

4. Discussion of Results

Different parameters were employed, including accuracy, precision, sensitivity, and F1-Score, to demonstrate the significance and performance of this paper’s proposed model. The following shows the description of each parameter as shown in

Figure 12.

The following equations of the parameters used in this study are based on the confusion matrix interpretation.

Figure 13 shows the confusion matrix for the training set using the proposed model with a classification accuracy of 98.8%. Meanwhile,

Figure 14 shows the confusion matrix for the testing set using the proposed model with a classification accuracy of 98.9%.

The experimental setup for this study compared ResNet50, VGG16, and MobiNetV2 with the proposed model. As shown in

Table 4, the training and testing accuracy results of the proposed model are much higher than those of the other CNN models.

Normally, hyperparameters are particularly sensitive when training using convolutional neural networks; this study employs 5000 epochs with a learning rate of 0.0001 to assess the trained model. To ensure the experimental model performed optimally, we monitored the validation loss every epoch and modified the weight variables accordingly when the validation loss reduced during the training process.

The tables below provide the precision, recall, and F1-Score results of the experiments. The experimental findings indicate that the suggested model attained an accuracy of 98.9% for the testing dataset, which is the highest rate of damage recognition among the experimental models.

Likewise, each condition/variant of the concrete images was tested to determine the results of the different parameters used. Similarly, the proposed model was compared with the other CNN models, as shown in

Table 5,

Table 6,

Table 7 and

Table 8.

Figure 15 and

Figure 16 show the training accuracy and training loss, respectively, of the proposed model. They show that the proposed model provided better detection accuracy results and minimal loss.

The following is a comparative analysis of this study to the other existing relative approaches. Reference [

44] uses the concept for crack detection, which is accomplished by the use of a deep fully convolutional network. The VGG16 neural network was chosen as the backbone of the FCN encoder for crack image categorization. The network makes use of an encoder to analyze an input image and extract the features required for semantic segmentation. The model that was utilized has an average accuracy of around 90%. As a remark in a normal scenario, if an image contains crack-like features/characteristics, image enhancement or filtering is required to minimize some of the extraneous images. The application is confine to one type of defect, the surface crack. The research can enhance the approach for use with other concrete defects.

As presented in [

45], the application uses a deep learning framework addressing the efficient training and deployment of an automatic defect detection system and uses ResNet as the classifier, achieving an accuracy of detection at 87.5%; however, the datasets used are just limited to a total of 603 raw images. Moreover, the description of the selected concrete defects as well as the breakdown of each kind are not been discussed in any details in this paper; the efficiency of performance can be increased if the dataset is augmented.

The study in reference [

46] utilizes deep neural networks to detect surface defects of concrete bridges. Additionally, the acquired dataset used a light detection and ranging scanner. Although this scheme achieved an accuracy of 90% rate, the acquisition of the presented dataset was not clearly discussed and the concept can be improved by providing details of the technical specification of the set-up.

The previous study on [

47] uses machine learning to assist in determining the presence and location of cracks in concrete using surface images. The method provides a crack candidate region to categorize cracks and non-cracks. However, the accuracy detection method was not specified in order to validate the suggested model, and the dataset specifications were not supplied in a clear manner. Additionally, the annotation was not explained in detail.

The given study in [

13] that employs a wavelet-based multiresolution analysis of ultrasonic signals in conjunction with the automated identification through artificial neural networks (ANNs) based on CNN has a result of an accuracy around 98%. However, the presented approach was used only on surface cracks; therefore, the performance cannot be sustained when applied to the other structural defects.

From the study in [

48], the approach that employs a Mask R-CNN to localize cracks on concrete surfaces obtained an accuracy of around 93.94% in the detection of cracks on concrete surfaces; however, in order to determine other concrete defects types, the suggested network can be retrained on a broader and more diversified dataset that includes additional variants of defects.

The approach in [

49] examines a variety of pre-trained CNN models for crack identification purposes, including MobileNetV2, ResNet101, VGG16, and InceptionV2 CNN models, but focuses on the MobileNet model, which achieves a 99.59% performance; however, despite the fact that the presented study includes images of walls, sidewalks, and a bridge, the concentration of the application is focused solely on surface cracks.

Lastly, the proposed scheme focuses on multivariant concrete defects such as surface cracks, delamination, and spalling. The proposed CNN model uses an integrated pooling module to minimize the loss of some of the significant information in the dataset, while the attention-based method improves some of the features of input data, but not all of it. The network pays more attention to the small but significant region of the data. The accuracy of defect detection achieves a rating of 98.8%.

5. Conclusions

Human intervention limits the accuracy of image evaluation. Typically, the resulting image quality evaluation is subjective rather than objective. Subjective image quality evaluations are a technique that is based on how humans perceive and evaluate image quality. Structure evaluation is vital, as human perception is not always dependable. The purpose of this study is to develop an objective structural monitoring system that will help prevent future occurrences that might cause damage to the structure as well as human injury. To address this drawback, the proposed scheme of this study aims to develop an automated image-based concrete condition identification technique capable of categorizing non-defective concrete into defective concrete and recognizing multivariant defects such as surface cracks, delamination, and spalling.

The proposed multivariant defect detection neural network architecture is based on a convolutional model capable of detecting various types of defects in concrete. Additionally, the system aims to aid in the development of different fault detection and identification techniques and speed up the assessment of the conditions of existing structural components. Experiments with various images show that the method presented is effective. The proposed model showed a classification accuracy of 98.8% for the training set and 98.9% for the testing set. Overall, it provided results on different metrics of performance.

In the future, we intend to incorporate the concept of spatial resolution into our method, which will enable us to detect microcracks in low-light conditions or to deal with a variety of external factors such as varying lighting conditions and variations in the concrete surface. Furthermore, other forms of damaged concrete, such as rebars and blistering, may be incorporated into this model in order to broaden the scope of the characteristics of the suggested neural network/model.