Fatigue Properties and Its Prediction of Polymer Concrete for the Repair of Asphalt Pavements

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Aggregates

2.1.2. Polymer Binders

2.2. Sample Preparation

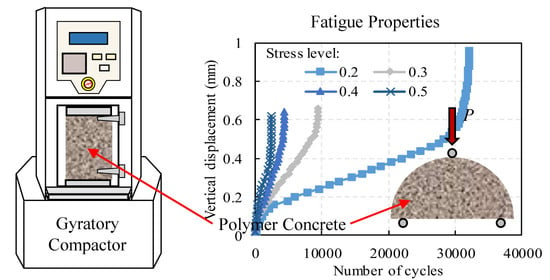

2.3. Testing Methods

2.3.1. Aggregate Feature Measurement

2.3.2. Semi-Circular Bending Test

3. Results

3.1. SCB Strength Test

3.2. Displacement Changes of SCB Fatigue Test

3.3. Attenuation of Stiffness Modulus with Loading Cycles

3.4. Evaluation and Prediction of Fatigue Life

4. Conclusions

- (1)

- Based on the SCB strength test results, it shows that the polymer content and sand ratio have significant influence on the flexural strength. The strength increases nonlinearly with the increasing polymer content, rapidly at first and then slowly. However, as the sand ratio exceeds 30%, the flexural strength of the PC decreases.

- (2)

- According to displacement changes of PC under repeated loadings, the testing process presents three stages, i.e., undamaged stage, damage development stage, and fatigue failure stage, as the number of cycles increases. Moreover, the stress level increases, and the fatigue life and final displacement tend to decrease.

- (3)

- In terms of the stiffness modulus, the fatigue damage of specimens may result in the decay of the stiffness modulus. Meanwhile, the stiffness modulus is dependent on the stress level. The average modulus of the specimens increases approximately linearly with the increasing stress.

- (4)

- A prediction model of fatigue life is established containing stress level, polymer content, tensile strength and sand ratio. The basic frame of fatigue life prediction is a power function, and the stress level plays an essential role for the predictability and accuracy.

- (5)

- The fatigue life has a strong correlation with the type of binder and the mixing gradation. Meanwhile, the optimal sand ratio of PC can be determined by the proposed empirical function. According to aggregate shape analysis, the effects of angularity and texture on fatigue life are more significant, whereas the effect of sphericity is relatively weak.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liu, C.; Lv, S.; Jin, D.; Qu, F. Laboratory investigation for the road performance of asphalt mixtures modified by rock asphalt–styrene butadiene rubber. J. Mater. Civ. Eng. 2021, 33, 04020504. [Google Scholar] [CrossRef]

- Li, J.; Wei, H.; Yao, Y.; Hu, X.; Wang, L. Contribution modeling on condition evaluation of asphalt pavement using uncertainty measurement and entropy theory. Adv. Mater. Sci. Eng. 2021, 2021, 9995926. [Google Scholar] [CrossRef]

- Transport, E.D.o.C.J.o.H.a. Review on China’s subgrade engineering research 2021. China J. Highw. Transp. 2021, 34, 1–49. [Google Scholar]

- Byzyka, J.; Rahman, M.; Chamberlain, D.A. Thermal analysis of hot mix asphalt pothole repair by finite element method. J. Transp. Eng. Part B Pavements 2020, 146, 04020029. [Google Scholar] [CrossRef] [Green Version]

- Byzyka, J.; Rahman, M.; Chamberlain, D.A. An improved interface temperature distribution in shallow hot mix asphalt patch repair using dynamic heating. Int. J. Pavement Eng. 2020, 21, 1617–1625. [Google Scholar] [CrossRef]

- Jiang, S.; Li, J.; Zhang, Z.; Wu, H.; Liu, G. Factors influencing the performance of cement emulsified asphalt mortar—A review. Constr. Build. Mater. 2021, 279, 122479. [Google Scholar] [CrossRef]

- Zhang, Z.; Sun, J.; Jia, M.; Ban, X.; Wang, L.; Chen, L.; Huang, T.; Liu, H. Effects of polyurethane thermoplastic elastomer on properties of asphalt binder and asphalt mixture. J. Mater. Civ. Eng. 2021, 33, 04020477. [Google Scholar] [CrossRef]

- Li, M.; Min, Z.; Wang, Q.; Huang, W.; Shi, Z. Effect of epoxy resin content and conversion rate on the compatibility and component distribution of epoxy asphalt: A MD simulation study. Constr. Build. Mater. 2022, 319, 126050. [Google Scholar] [CrossRef]

- Fuseini, M.; Zaghloul, M.M.Y.; Elkady, M.F.; El-Shazly, A.H. Evaluation of synthesized polyaniline nanofibres as corrosion protection film coating on copper substrate by electrophoretic deposition. J. Mater. Sci. 2022, 57, 6085–6101. [Google Scholar] [CrossRef]

- Zaghloul, M.M.Y.M. Mechanical properties of linear low-density polyethylene fire-retarded with melamine polyphosphate. J. Appl. Polym. Sci. 2018, 135, 46770. [Google Scholar] [CrossRef]

- Fuseini, M.; Zaghloul, M.M.Y. Statistical and qualitative analysis of the kinetic models using electrophoretic deposition of polyaniline. J. Ind. Eng. Chem. 2022. [Google Scholar] [CrossRef]

- Zaghloul, M.M.Y.; Zaghloul, M.Y.M.; Zaghloul, M.M.Y. Experimental and modeling analysis of mechanical-electrical behaviors of polypropylene composites filled with graphite and MWCNT fillers. Polym. Test. 2017, 63, 467–474. [Google Scholar] [CrossRef]

- Alhazmi, H.; Shah, S.A.R.; Anwar, M.K.; Raza, A.; Ullah, M.K.; Iqbal, F. Utilization of polymer concrete composites for a circular economy: A comparative review for assessment of recycling and waste utilization. Polymers 2021, 13, 2135. [Google Scholar] [CrossRef]

- Mayhoub, O.A.; Abadel, A.A.; Alharbi, Y.R.; Nehdi, M.L.; de Azevedo, A.R.G.; Kohail, M. Effect of polymers on behavior of ultra-high-strength concrete. Polymers 2022, 14, 2585. [Google Scholar] [CrossRef]

- Cong, L.; Wang, T.; Tan, L.; Yuan, J.; Shi, J. Laboratory evaluation on performance of porous polyurethane mixtures and OGFC. Constr. Build. Mater. 2018, 169, 436–442. [Google Scholar] [CrossRef]

- Chen, J.; Yin, X.; Wang, H.; Ding, Y. Evaluation of durability and functional performance of porous polyurethane mixture in porous pavement. J. Clean. Prod. 2018, 188, 12–19. [Google Scholar] [CrossRef]

- Huang, H.; Pang, H.; Huang, J.; Zhao, H.; Liao, B. Synthesis and characterization of ground glass fiber reinforced polyurethane-based polymer concrete as a cementitious runway repair material. Constr. Build. Mater. 2020, 242, 117221. [Google Scholar] [CrossRef]

- Ma, W.; Zhao, Z.; Guo, S.; Zhao, Y.; Wu, Z.; Yang, C. Performance evaluation of the polyurethane-based composites prepared with recycled polymer concrete aggregate. Materials 2020, 13, 616. [Google Scholar] [CrossRef] [Green Version]

- Huang, H.; Pang, H.; Huang, J.; Yu, P.; Li, J.; Lu, M.; Liao, B. Influence of hard segment content and soft segment length on the microphase structure and mechanical performance of polyurethane-based polymer concrete. Constr. Build. Mater. 2021, 284, 122388. [Google Scholar] [CrossRef]

- Zaghloul, M.Y.M.; Zaghloul, M.M.Y.; Zaghloul, M.M.Y. Developments in polyester composite materials—An in-depth review on natural fibres and nano fillers. Compos. Struct. 2021, 278, 114698. [Google Scholar] [CrossRef]

- Hong, B.; Lu, G.; Li, T.; Lin, J.; Wang, D.; Liang, D.; Oeser, M. Gene-editable materials for future transportation infrastructure: A review for polyurethane-based pavement. J. Infrastruct. Preserv. Resil. 2021, 2, 27. [Google Scholar] [CrossRef]

- Naser, M.; Hawileh, R.; Abdalla, J. Fiber-reinforced polymer composites in strengthening reinforced concrete structures: A critical review. Eng. Struct. 2019, 198, 109542. [Google Scholar] [CrossRef]

- Cheng, H.T.; Lee, Y.S.; Liu, H.C.; Lee, W.J. The effect of component addition order on the properties of epoxy resin/polyurethane resin interpenetrating polymer network structure. J. Appl. Polym. Sci. 2021, 138, 49833. [Google Scholar] [CrossRef]

- Guo, T.; Xie, Y.; Weng, X. Evaluation of the bond strength of a novel concrete for rapid patch repair of pavements. Constr. Build. Mater. 2018, 186, 790–800. [Google Scholar] [CrossRef]

- Wei, H.; Li, J.; Hu, B.; Wang, F.; Zheng, J. Influence of temperature on deformation failure and acoustic emission characterisation of asphalt concrete under uniaxial compression. Int. J. Pavement Eng. 2022, 1–10. [Google Scholar] [CrossRef]

- Zhi, S.; Gun, W.W.; Hui, L.X.; Bo, T. Evaluation of fatigue crack behavior in asphalt concrete pavements with different polymer modifiers. Constr. Build. Mater. 2012, 27, 117–125. [Google Scholar] [CrossRef]

- Zaghloul, M.M.Y.; Mohamed, Y.S.; El-Gamal, H. Fatigue and tensile behaviors of fiber-reinforced thermosetting composites embedded with nanoparticles. J. Compos. Mater. 2019, 53, 709–718. [Google Scholar] [CrossRef]

- Zaghloul, M.Y.; Zaghloul, M.M.Y.; Zaghloul, M.M.Y. Influence of Stress Level and Fibre Volume Fraction on Fatigue Performance of Glass Fibre-Reinforced Polyester Composites. Polymers 2022, 14, 2662. [Google Scholar] [CrossRef]

- Yeon, K.-S.; Choi, Y.-S.; Kim, K.-K.; Yeon, J.H. Flexural fatigue life analysis of unsaturated polyester-methyl methacrylate polymer concrete. Constr. Build. Mater. 2017, 140, 336–343. [Google Scholar] [CrossRef]

- Ahn, S.; Jeon, E.-B.; Koh, H.-I.; Kim, H.-S.; Park, J. Identification of stiffness distribution of fatigue loaded polymer concrete through vibration measurements. Compos. Struct. 2016, 136, 11–15. [Google Scholar] [CrossRef]

- Gullapalli, A.; Lee, J.H.; Lopez, M.M.; Bakis, C.E. Sustained loading and temperature response of fiber-reinforced polymer–concrete bond. Transp. Res. Rec. 2009, 2131, 155–162. [Google Scholar] [CrossRef]

- Guo, Q.; Liu, Q.; Zhang, P.; Gao, Y.; Jiao, Y.; Yang, H.; Xu, A. Temperature and pressure dependent behaviors of moisture diffusion in dense asphalt mixture. Constr. Build. Mater. 2020, 246, 118500. [Google Scholar] [CrossRef]

- Zhao, Z.; Wang, S.; Ren, J.; Wang, Y.; Wang, C. Fatigue characteristics and prediction of cement-stabilized cold recycled mixture with road-milling materials considering recycled aggregate composition. Constr. Build. Mater. 2021, 301, 124122. [Google Scholar] [CrossRef]

- Chen, Q.; Wang, S.; Wang, C.; Wang, F.; Fu, H.; Yang, X. Modified waterborne epoxy as a cold pavement binder: Preparation and long-term working properties. J. Mater. Civ. Eng. 2021, 33, 04021079. [Google Scholar] [CrossRef]

- Jung, K.-C.; Roh, I.-T.; Chang, S.-H. Evaluation of mechanical properties of polymer concretes for the rapid repair of runways. Compos. Part B Eng. 2014, 58, 352–360. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, C.; Li, L.; You, Z.; Diab, A. Characterization of low temperature crack resistance of crumb rubber modified asphalt mixtures using semi-circular bending tests. J. Test. Eval. 2016, 44, 847–855. [Google Scholar] [CrossRef]

- Yao, Y.; Li, J.; Ni, J.; Liang, C.; Zhang, A. Effects of gravel content and shape on shear behaviour of soil-rock mixture: Experiment and DEM modelling. Comput. Geotech. 2022, 141, 104476. [Google Scholar] [CrossRef]

- Jiang, J.; Ni, F.; Dong, Q.; Wu, F.; Dai, Y. Research on the fatigue equation of asphalt mixtures based on actual stress ratio using semi-circular bending test. Constr. Build. Mater. 2018, 158, 996–1002. [Google Scholar] [CrossRef]

- Elseifi, M.A.; Mohammad, L.N.; Ying, H.; Cooper III, S. Modeling and evaluation of the cracking resistance of asphalt mixtures using the semi-circular bending test at intermediate temperatures. Road Mater. Pavement Des. 2012, 13, 124–139. [Google Scholar] [CrossRef]

- Shiri, S.; Yazdani, M.; Pourgol-Mohammad, M. A fatigue damage accumulation model based on stiffness degradation of composite materials. Mater. Des. 2015, 88, 1290–1295. [Google Scholar] [CrossRef]

- Li, J.; Zhang, J.; Qian, G.; Zheng, J.; Zhang, Y. Three-dimensional simulation of aggregate and asphalt mixture using parameterized shape and size gradation. J. Mater. Civ. Eng. 2019, 31. [Google Scholar] [CrossRef] [Green Version]

- Yao, Y.; Li, J.; Liang, C.; Hu, X. Effect of coarse recycled aggregate on failure strength for asphalt mixture using experimental and DEM method. Coatings 2021, 11, 1234. [Google Scholar] [CrossRef]

| Items | Units | Results | Requirements | |

| 5–10 mm | 10–16 mm | |||

| Apparent density | g/cm3 | 2.718 | 2.735 | ≥2.65 |

| Crushing value | % | 16.7 | 17.4 | ≤22 |

| Water absorption | % | 0.43 | 0.41 | ≤1.5 |

| Los Angeles attrition loss | % | 16.0 | 16.7 | ≤22.0 |

| Mud content | % | 0.45 | 0.3 | ≤0.8 |

| Items | Units | Epoxy Resin | Polyurethane |

|---|---|---|---|

| Density | g/cm3 | 1.317 | 1.117 |

| PH | — | 7.5 | 8.1 |

| Melting point | °C | 252 | 175 |

| Thermal expansion | μm/mK | 54 | 160 |

| Viscosity | MPa·s, 25 °C | 2734 | 1233 |

| Tensile strength | MPa | 2.7 | 1.9 |

| Elongation at break | % | 200 | 550 |

| Curing time | h | 12 | ≤12 |

| Particle Size (mm) | Value | Percentage of Flat- elongated Particles (%) | Texture | Gradient Angularity | Sphericity |

|---|---|---|---|---|---|

| 5–10 | Mean | 8.34 | 343.6 | 3283 | 0.67 |

| Standard deviation | — | 93.5 | 802.5 | 0.08 | |

| 10–16 | Mean | 7.98 | 422.9 | 2961 | 0.69 |

| Standard deviation | — | 124.2 | 671.8 | 0.09 |

| Sand Ratio (%) | Polymer Content (%) | ER–PC | PU–PC | ||

|---|---|---|---|---|---|

| SCB Strength (MPa) | CV(%) | SCB Strength (MPa) | CV(%) | ||

| 25 | 5 | 2.29 | 5.80 | 1.28 | 4.17 |

| 10 | 9.88 | 5.40 | 7.34 | 4.29 | |

| 15 | 14.05 | 5.31 | 11.97 | 5.09 | |

| 20 | 16.68 | 5.91 | 13.51 | 4.22 | |

| 30 | 5 | 2.98 | 4.92 | 1.76 | 4.47 |

| 10 | 12.02 | 5.76 | 5.94 | 4.15 | |

| 15 | 16.27 | 4.30 | 13.19 | 4.43 | |

| 20 | 18.82 | 6.09 | 15.24 | 5.10 | |

| 35 | 5 | 2.71 | 4.55 | 1.49 | 4.62 |

| 10 | 10.63 | 5.81 | 4.91 | 4.19 | |

| 15 | 15.11 | 5.19 | 11.27 | 4.82 | |

| 20 | 17.83 | 6.44 | 14.45 | 4.83 | |

| Sand Ratio (%) | Polymer Content (%) | ER–PC | PU–PC | ||||

|---|---|---|---|---|---|---|---|

| K1 | K2 | R2 (%) | K1 | K2 | R2 (%) | ||

| 25 | 5 | 110.910 | 3.033 | 99.42 | 81.855 | 3.005 | 99.05 |

| 10 | 152.310 | 3.082 | 99.77 | 97.822 | 3.134 | 99.58 | |

| 15 | 235.350 | 2.824 | 99.95 | 150.340 | 2.883 | 99.77 | |

| 20 | 343.560 | 2.618 | 99.99 | 200.460 | 2.758 | 99.91 | |

| 30 | 5 | 157.050 | 2.972 | 99.8 | 122.080 | 3.079 | 99.62 |

| 10 | 176.190 | 3.141 | 99.98 | 170.620 | 3.114 | 99.86 | |

| 15 | 289.830 | 2.872 | 99.95 | 265.170 | 2.887 | 99.94 | |

| 20 | 431.950 | 2.643 | 99.85 | 398.970 | 2.657 | 99.93 | |

| 35 | 5 | 119.320 | 3.109 | 99.4 | 88.262 | 3.083 | 99.6 |

| 10 | 172.020 | 3.074 | 99.85 | 112.890 | 3.171 | 99.95 | |

| 15 | 296.260 | 2.763 | 99.99 | 189.090 | 2.879 | 99.95 | |

| 20 | 415.400 | 2.593 | 99.99 | 265.690 | 2.691 | 99.98 | |

| Materials | Sand Ratio (%) | a | b | R2 (%) |

|---|---|---|---|---|

| ER–PC | 25 | 0.8959 | 3.8454 | 1 |

| 30 | 1.4134 | −1.1837 | 99.97 | |

| 35 | 1.1071 | 7.3932 | 99.54 | |

| PU–PC | 25 | 0.3479 | 2.9345 | 99.49 |

| 30 | 1.1604 | 3.5212 | 99.99 | |

| 35 | 0.6810 | 3.0317 | 99.67 |

| Polymer Matrix | Tensile Strength (MPa) | Sand Ratio (%) | Aggregate Morphology | K1 | K2 | ||

|---|---|---|---|---|---|---|---|

| Texture | Angularity | Sphericity | |||||

| ER | 2.7 | 25 | 368.2 | 3056 | 0.69 | 110.91 | 3.033 |

| 2.7 | 30 | 359.2 | 2991 | 0.69 | 157.05 | 2.972 | |

| 2.7 | 35 | 368.5 | 3263 | 0.68 | 119.32 | 3.109 | |

| PU | 1.9 | 25 | 365.6 | 2967 | 0.67 | 81.855 | 3.006 |

| 1.9 | 30 | 368.4 | 3197 | 0.68 | 122.08 | 3.079 | |

| 1.9 | 35 | 372.2 | 3270 | 0.68 | 88.262 | 3.083 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ren, S.; Hu, X. Fatigue Properties and Its Prediction of Polymer Concrete for the Repair of Asphalt Pavements. Polymers 2022, 14, 2941. https://doi.org/10.3390/polym14142941

Ren S, Hu X. Fatigue Properties and Its Prediction of Polymer Concrete for the Repair of Asphalt Pavements. Polymers. 2022; 14(14):2941. https://doi.org/10.3390/polym14142941

Chicago/Turabian StyleRen, Senzhi, and Xin Hu. 2022. "Fatigue Properties and Its Prediction of Polymer Concrete for the Repair of Asphalt Pavements" Polymers 14, no. 14: 2941. https://doi.org/10.3390/polym14142941