Recycling Waste Cotton Cloths for the Isolation of Cellulose Nanocrystals: A Sustainable Approach

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sample Collection and Preparation

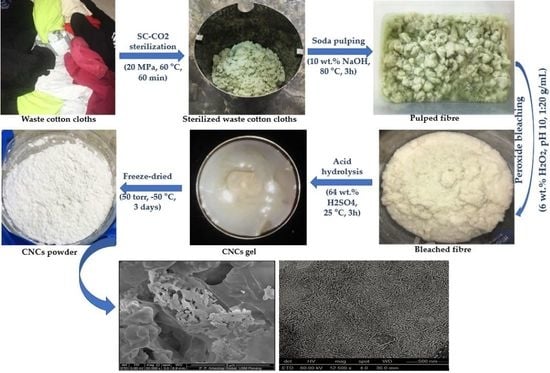

2.2. Isolation of CNCs

2.3. Morphological Analysis

2.4. ATR-FTIR Analysis

2.5. XRD Analysis

2.6. Thermal Properties Analysis

2.7. Physical Properties Analysis

2.7.1. Moisture Content

2.7.2. Cellulose Content

2.7.3. Acid Insoluble Lignin

2.7.4. Kappa Number

2.7.5. Whiteness

2.7.6. Production Cost

2.8. Zeta Potential and Dynamic Light Scattering (DLS) Using Zetasizer

3. Results and Discussion

3.1. Morphological Analysis

3.2. ATR-FTIR Analysis

3.3. Crystallinity Index Using XRD

3.4. Thermal Stability Analysis

3.5. Physical Properties Analysis

3.6. Surface Charge, Particle Size, and Size Distribution Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Niinimäki, K.; Peters, G.; Dahlbo, H.; Perry, P.; Rissanen, T.; Gwilt, A. The environmental price of fast fashion. Nat. Rev. Earth Environ. 2020, 1, 189–200. [Google Scholar] [CrossRef] [Green Version]

- Ütebay, B.; Çelik, P.; Çay, A. Effects of cotton textile waste properties on recycled fibre quality. J. Clean. Prod. 2019, 222, 29–35. [Google Scholar] [CrossRef]

- Ma, J.; Liu, Y.; Ali, O.; Wei, Y.; Zhang, S.; Zhang, Y.; Cai, T.; Liu, C.; Luo, S. Fast adsorption of heavy metal ions by waste cotton fabrics based double network hydrogel and influencing factors insight. J. Hazard. Mater. 2018, 344, 1034–1042. [Google Scholar] [CrossRef]

- Huang, S.; Tao, R.; Ismail, A.; Wang, Y. Cellulose Nanocrystals Derived from Textile Waste through Acid Hydrolysis and Oxidation as Reinforcing Agent of Soy Protein Film. Polymers 2020, 12, 958. [Google Scholar] [CrossRef] [Green Version]

- Racho, P.; Waiwong, W. Modified textile waste for heavy metals removal. Energy Rep. 2020, 6, 927–932. [Google Scholar] [CrossRef]

- Księżak, P. The CSR Challenges in the Clothing Industry. J. Corp. Responsib. Leadersh. 2017, 3, 51. [Google Scholar] [CrossRef] [Green Version]

- Johnson, S.; Echeverria, D.; Venditti, R.; Jameel, H.; Yao, Y. Supply Chain of Waste Cotton Recycling and Reuse: A Review. AATCC J. Res. 2020, 7, 19–31. [Google Scholar] [CrossRef]

- Arnold, M.G. Sustainability Transitions in Disclosures in the Fashion Industry: Comparative Insights into Social Sustainability, Circularity and Systemic Shifts. J. Text. Sci. Fash. Technol. 2020, 5, 1–11. [Google Scholar] [CrossRef]

- Wang, Z.; Yao, Z.; Zhou, J.; Zhang, Y. Reuse of waste cotton cloth for the extraction of cellulose nanocrystals. Carbohydr. Polym. 2017, 157, 945–952. [Google Scholar] [CrossRef] [PubMed]

- Huang, S.; Liu, X.; Chang, C.; Wang, Y. Recent developments and prospective food-related applications of cellulose nanocrystals: A review. Cellulose 2020, 27, 2991–3011. [Google Scholar] [CrossRef]

- Xiong, R.; Zhang, X.; Tian, D.; Zhou, Z.; Lu, C. Comparing microcrystalline with spherical nanocrystalline cellulose from waste cotton fabrics. Cellulose 2012, 19, 1189–1198. [Google Scholar] [CrossRef]

- Grishkewich, N.; Mohammed, N.; Tang, J.; Tam, K.C. Recent advances in the application of cellulose nanocrystals. Curr. Opin. Colloid Interface Sci. 2017, 29, 32–45. [Google Scholar] [CrossRef]

- Lamaming, J.; Hashim, R.; Leh, C.P.; Sulaiman, O.; Sugimoto, T.; Nasir, M. Isolation and characterization of cellulose nanocrystals from parenchyma and vascular bundle of oil palm trunk (Elaeis guineensis). Carbohydr. Polym. 2015, 134, 534–540. [Google Scholar] [CrossRef] [PubMed]

- Rasheed, M.; Jawaid, M.; Parveez, B.; Zuriyati, A.; Khan, A. Morphological, chemical and thermal analysis of cellulose nanocrystals extracted from bamboo fibre. Int. J. Biol. Macromol. 2020, 160, 183–191. [Google Scholar] [CrossRef]

- Jiang, Q.; Xing, X.; Jing, Y.; Han, Y. Preparation of cellulose nanocrystals based on waste paper via different systems. Int. J. Biol. Macromol. 2020, 149, 1318–1322. [Google Scholar] [CrossRef]

- Shamskar, K.R.; Heidari, H.; Rashidi, A. Preparation and evaluation of nanocrystalline cellulose aerogels from raw cotton and cotton stalk. Ind. Crop. Prod. 2016, 93, 203–211. [Google Scholar] [CrossRef]

- El Achaby, M.; Kassab, Z.; Aboulkas, A.; Gaillard, C.; Barakat, A. Reuse of red algae waste for the production of cellulose nanocrystals and its application in polymer nanocomposites. Int. J. Biol. Macromol. 2018, 106, 681–691. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Salari, M.; Khiabani, M.S.; Mokarram, R.R.; Ghanbarzadeh, B.; Kafil, H.S. Preparation and characterization of cellulose nanocrystals from bacterial cellulose produced in sugar beet molasses and cheese whey media. Int. J. Biol. Macromol. 2019, 122, 280–288. [Google Scholar] [CrossRef] [PubMed]

- Shi, S.; Zhang, M.; Ling, C.; Hou, W.; Yan, Z. Extraction and characterization of microcrystalline cellulose from waste cotton fabrics via hydrothermal method. Waste Manag. 2018, 82, 139–146. [Google Scholar] [CrossRef] [PubMed]

- Zhong, T.; Dhandapani, R.; Liang, D.; Wang, J.; Wolcott, M.P.; Van Fossen, D.; Liu, H. Nanocellulose from recycled indigo-dyed denim fabric and its application in composite films. Carbohydr. Polym. 2020, 240, 116283. [Google Scholar] [CrossRef]

- Maciel, M.M.; Ávila, D.; Benini, K.C.C.D.C.; Voorwald, H.J.C.; Cioffi, M.O.H. Obtainment and characterization of nanocellulose from an unwoven industrial textile cotton waste: Effect of acid hydrolysis conditions. Int. J. Biol. Macromol. 2019, 126, 496–506. [Google Scholar] [CrossRef]

- Abdul Fatah, I.Y.; Abdul Khalil, H.P.S.; Hossain, M.S.; Aziz, A.A.; Davoudpour, Y.; Dungani, R.; Bhat, A. Exploration of a chemo-mechanical technique for the isolation of nanofibrillated cellulosic fiber from oil palm empty fruit bunch as a reinforcing agent in composites materials. Polymers 2014, 6, 2611–2624. [Google Scholar] [CrossRef] [Green Version]

- Hossain, M.S.; Ab Rahman, N.N.N.; Balakrishnan, V.; Alkarkhi, A.F.M.; Ahmad Rajion, Z.; Abd. Kadir, M.O. Optimizing supercritical carbon dioxide in the inactivation of bacteria in clinical solid waste by using response surface methodology. Waste Manag. 2015, 38, 462–473. [Google Scholar] [CrossRef]

- García-García, D.; Balart, R.; Lopez-Martinez, J.; Ek, M.; Moriana, R. Optimizing the yield and physico-chemical properties of pine cone cellulose nanocrystals by different hydrolysis time. Cellulose 2018, 25, 2925–2938. [Google Scholar] [CrossRef] [Green Version]

- Ding, M.; Li, C.; Chen, F. Isolation and characterization of cellulose nanocrystals from cloth hairs and evaluation of their compatibility with PLLA. Cellulose 2017, 24, 4785–4792. [Google Scholar] [CrossRef]

- Przybysz, K.; Małachowska, E.; Martyniak, D.; Boruszewski, P.; Iłowska, J.; Kalinowska, H.; Przybysz, P. Yield of Pulp, Dimensional Properties of Fibers, and Properties of Paper Produced from Fast Growing Trees and Grasses. BioResources 2017, 13, 1372–1387. [Google Scholar] [CrossRef]

- Segal, L.; Creely, J.J.; Martin, A.E., Jr.; Conrad, C.M. An empirical method for estimating the degree of crystallinity of native cellulose using the X-ray diffractometer. Text. Res. J. 1959, 29, 786–794. [Google Scholar] [CrossRef]

- TAPPI, J. Preparation of wood for chemical analysis T 264 cm-97. TAPPI J. 1997, 1–3. Available online: https://www.scribd.com/document/340758480/Tappi-T264-Cm-97 (accessed on 1 November 2020).

- Wise, L.E.; Murphy, M.; Daddieco, A.A. Chlorite holocellulose, its fractionation and bearing on summative wood analysis and on studies on the hemicellulose. Tech. Assoc. Pap. 1946, 29, 210–218. [Google Scholar]

- Park, C.-W.; Han, S.-Y.; Choi, S.-K.; Lee, S.-H. Preparation and Properties of Holocellulose Nanofibrils with Different Hemicellulose Content. BioResources 2017, 12, 6298–6308. [Google Scholar] [CrossRef] [Green Version]

- Tye, Y.Y.; Leh, C.P.; Lee, K.T.; Abdullah, W.N.W. Non-wood Lignocellulosic Biomass for Cellulosic Ethanol Production: Effects of Pretreatment on Chemical Composition in Relation to Total Glucose Yield. J. Jpn. Inst. Energy 2017, 96, 503–508. [Google Scholar] [CrossRef] [Green Version]

- Ang, L.S.; Leh, C.P.; Lee, C.C. Effects of alkaline pre-impregnation and pulping on Malaysia cultivated kenaf (Hibiscus cannabinus). BioResources 2010, 5, 1446–1462. [Google Scholar]

- TAPPI, J. Acid-insoluble lignin in wood and pulp T 222 om-02. TAPPI J. 2002, 1, 1–5. [Google Scholar]

- TAPPI, J. Kappa number of pulp T 236 om-99. J. TAPPI 1999, 1–4. [Google Scholar]

- TAPPI, J. Brightness of pulp, paper and paperboard (directional reflectance at 457 nm) T 452 om-98. TAPPI J. 1998, 1–9. [Google Scholar]

- Srasri, K.; Thongroj, M.; Chaijiraaree, P.; Thiangtham, S.; Manuspiya, H.; Pisitsak, P.; Ummartyotin, S. Recovery potential of cellulose fiber from newspaper waste: An approach on magnetic cellulose aerogel for dye adsorption material. Int. J. Biol. Macromol. 2018, 119, 662–668. [Google Scholar] [CrossRef] [PubMed]

- Allafi, F.A.S.; Hossain, S.; Ab Kadir, M.O.; Shaah, M.A.H.; Lalung, J.; Ahmad, M.I. Waterless processing of sheep wool fiber in textile industry with supercritical CO2: Potential and challenges. J. Clean. Prod. 2021, 285, 124819. [Google Scholar] [CrossRef]

- Martins, M.A.; Teixeira, E.M.; Corrêa, A.C.; Ferreira, M.; Mattoso, L.H.C. Extraction and characterization of cellulose whiskers from commercial cotton fibers. J. Mater. Sci. 2011, 46, 7858–7864. [Google Scholar] [CrossRef]

- Satyamurthy, P.; Jain, P.; Balasubramanya, R.H.; Vigneshwaran, N. Preparation and characterization of cellulose nanowhiskers from cotton fibres by controlled microbial hydrolysis. Carbohydr. Polym. 2011, 83, 122–129. [Google Scholar] [CrossRef]

- Yue, Y.; Zhou, C.; French, A.D.; Xia, G.; Han, G.; Wang, Q.; Wu, Q. Comparative properties of cellulose nano-crystals from native and mercerized cotton fibers. Cellulose 2012, 19, 1173–1187. [Google Scholar] [CrossRef]

- Morais, J.P.S.; Rosa, M.D.F.; Filho, M.D.S.M.D.S.; Nascimento, L.D.; Nascimento, D.M.D.; Cassales, A.R. Extraction and characterization of nanocellulose structures from raw cotton linter. Carbohydr. Polym. 2013, 91, 229–235. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hou, W.; Ling, C.; Shi, S.; Yan, Z. Preparation and characterization of microcrystalline cellulose from waste cotton fabrics by using phosphotungstic acid. Int. J. Biol. Macromol. 2019, 123, 363–368. [Google Scholar] [CrossRef]

- Zhao, G.; Du, J.; Chen, W.; Pan, M.; Chen, D. Preparation and thermostability of cellulose nanocrystals and nanofibrils from two sources of biomass: Rice straw and poplar wood. Cellulose 2019, 26, 8625–8643. [Google Scholar] [CrossRef]

- Weerasooriya, P.R.D.; Malaysia, M.U.S.; Jamal, S.N.A.; Haafiz, M.K.M.; Khalil, H.P.S.A.; Kaus, N.H.M.; Amalini, A.N.; Hiziroglu, S. The Role of Montmorillonite Loading on the Physicochemical Properties of Regenerated Cellulose Nanocomposite Films Obtained from Microcrystalline Cellulose. J. Phys. Sci. 2020, 31, 85–103. [Google Scholar] [CrossRef]

- Sun, X.; Wu, Q.; Zhang, X.; Ren, S.; Lei, T.; Li, W.; Xu, G.; Zhang, Q. Nanocellulose films with combined cellulose nanofibers and nanocrystals: Tailored thermal, optical and mechanical properties. Cellulose 2017, 25, 1103–1115. [Google Scholar] [CrossRef]

- Johar, N.; Ahmad, I.; Dufresne, A. Extraction, preparation and characterization of cellulose fibres and nanocrystals from rice husk. Ind. Crop. Prod. 2012, 37, 93–99. [Google Scholar] [CrossRef]

- Hosseinidoust, Z.; Sim, G.; Alam, N.; Tufenkji, N.; Van De Ven, T.G.M. Cellulose nanocrystals with tunable surface charge for nanomedicine. Nanoscale 2015, 7, 16647–16657. [Google Scholar] [CrossRef] [Green Version]

- Morantes, D.; Muñoz, E.; Kam, D.; Shoseyov, O. Highly Charged Cellulose Nanocrystals Applied as A Water Treatment Flocculant. Nanomaterials 2019, 9, 272. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Raw Materials | Length (nm) | Diameter (nm) | Yield CNC (%) | Methods | References |

|---|---|---|---|---|---|

| Commercial cotton balls | 150 ± 50 | 14 ± 5 | 60 | H2SO4 hydrolysis | [38] |

| Cotton | 450 | 25 | 77 | H2SO4 hydrolysis | [16] |

| Cotton | 287.24 ± 79.75 | 29.69 ± 5.07 | 51 | H2SO4 hydrolysis | [39] |

| Cotton | 120.27 ± 36.25 | 40.74 ± 7.59 | 22 | Enzymatic hydrolysis | [39] |

| Cotton fabrics | 76–159 | 14.2–15 | 30–35 | H2SO4 hydrolysis | [40] |

| Cotton linters | 161–193 | 10–13 | 74–80 | H2SO4 hydrolysis | [41] |

| Degreasing cotton | 17–230 | 2–25 | 52.4 ± 1.5 | Mixed H2SO4 and HCl hydrolysis | [9] |

| Old sheet bed | 28–470 | 3–35 | 46.7 ± 1.8 | Mixed H2SO4 and HCl hydrolysis | [9] |

| Textile waste from factory | 97.25 ± 25.18 | 5.69 ± 2.08 | 60.41 | Oxidation | [4] |

| Waste cotton fabrics | 5–100 | 10–65 | 21.5 | H2SO4 hydrolysis and ultrasonication | [11] |

| Waste cloths from landfill | 10–30 | 2–6 | 65.40 ± 2.1 | H2SO4 hydrolysis and ultrasonication | Present study |

| Properties | Waste Cotton Cloths | Pulped Fiber | Bleached Fiber | CNCs |

|---|---|---|---|---|

| Yield (%) | - | 80.39 ± 1.0 | 86.02 ± 1.4 | 65.40 ± 1.3 |

| Moisture content (%) | 7.4 ± 0.03 | 7.3 ± 0.17 | 7.2 ± 0.13 | 6.5 ± 0.13 |

| Cellulose yield (%) | 81.38 ± 0.60 | 87.38 ± 0.62 | 88.13 ± 0.50 | 97.87 ± 0.19 |

| α-cellulose (%) | 80.39 ± 0.13 | 86.02 ± 0.24 | 86.66 ± 0.25 | 96.82 ± 0.05 |

| β-cellulose (%) | 0.99 ± 0.14 | 1.36 ± 0.14 | 1.47 ± 0.12 | 1.05 ± 0.06 |

| Hemicellulose (γcellulose) (%) | 14.29 ± 0.33 | 6.83 ± 0.24 | 4.33 ± 0.13 | 2.10 ± 0.08 |

| Klason lignin (%) | 8.00 ± 0.52 | 5.79 ± 0.63 | 2.83 ± 0.74 | ND |

| Kappa number | 16.81 ± 0.97 | 14.88 ± 0.96 | 13.92 ± 0.96 | ND |

| Ash content (%) | 9.12 ± 0.87 | 7.71 ± 0.92 | 7.17 ± 0.86 | 3.94 ± 0.97 |

| Whiteness (%) | 56 ± 2 | 62 ± 3 | 86 ± 2 | 82 ± 4 |

| Production cost (USD/g) | - | - | - | 0.19 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mohamed, S.H.; Hossain, M.S.; Mohamad Kassim, M.H.; Ahmad, M.I.; Omar, F.M.; Balakrishnan, V.; Zulkifli, M.; Yahaya, A.N.A. Recycling Waste Cotton Cloths for the Isolation of Cellulose Nanocrystals: A Sustainable Approach. Polymers 2021, 13, 626. https://doi.org/10.3390/polym13040626

Mohamed SH, Hossain MS, Mohamad Kassim MH, Ahmad MI, Omar FM, Balakrishnan V, Zulkifli M, Yahaya ANA. Recycling Waste Cotton Cloths for the Isolation of Cellulose Nanocrystals: A Sustainable Approach. Polymers. 2021; 13(4):626. https://doi.org/10.3390/polym13040626

Chicago/Turabian StyleMohamed, Siti Hajar, Md. Sohrab Hossain, Mohamad Haafiz Mohamad Kassim, Mardiana Idayu Ahmad, Fatehah Mohd Omar, Venugopal Balakrishnan, Muzafar Zulkifli, and Ahmad Naim Ahmad Yahaya. 2021. "Recycling Waste Cotton Cloths for the Isolation of Cellulose Nanocrystals: A Sustainable Approach" Polymers 13, no. 4: 626. https://doi.org/10.3390/polym13040626