Thin Film Composite and/or Thin Film Nanocomposite Hollow Fiber Membrane for Water Treatment, Pervaporation, and Gas/Vapor Separation

Abstract

:1. Introduction

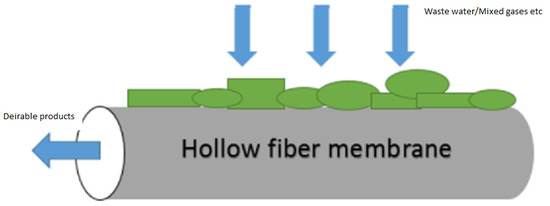

2. Method of Making Thin Film Composite (TFC) Hollow Fiber (HF)

2.1. Fabricating Hollow Fiber

- i

- Melt spinning: In this process, a melted thermoplastic polymer is extruded through a spinneret into air and is subsequently cooled.

- ii

- Dry spinning: Polymer solution in an appropriate solvent is extruded through a spinneret into air.

- iii

- Dry-jet wet spinning: Polymer solution in an appropriate solvent is extruded through a spinneret into air and a subsequent coagulant (usually water).

- iv

- Wet spinning: Polymer solution in an appropriate solvent is extruded directly into a coagulant (usually water).

- i

- Dimensions of the spinneret;

- ii

- driving force;

- iii

- temperature;

- iv

- length of air gap (for dry-jet wet spinning);

- v

- coagulant;

- vi

- composition of “dope” (polymer) and “bore” (coagulant) solutions; and

- vii

- speed at which produced fiber is collected by a motorized spool.

- i

- The diffusion of internal precipitant molecules into the concentrated hollow fiber forming polymer solution. At the same time, polymer coagulates (precipitates from solution) to form a solid phase;

- ii

- in this stage, a cross-diffusion of solvent molecules from the polymer solution into the internal nonsolvent starts and it speeds up the coagulation of the polymer and the formation of the porous structure of the fiber body; and

- iii

- during the evaporation of solvent molecules from the outer surface of the fiber into the air, the concentration of polymer on the outer surface of the fiber is increased, which is the cause of the formation of the dense (selective) polymer layer.

2.2. TFC Hollow Fiber Fabrication

- i

- Interfacial polymerisation reaction;

- ii

- dipping method;

- iii

- plasma treatment; and

- iv

- chemical reaction.

- i

- Chemical vapour deposition (CVD);

- ii

- sputtering; and

- iii

- spray pyrolysis.

2.2.1. Dip Coating

- i

- Immersion: With a constant speed, the substrate is immersed in the solution of the coating material (preferably jitter-free);

- ii

- start-up: The substrate has remained inside the solution for a while and is starting to be pulled up;

- iii

- iv

- drainage: Excess liquid will drain from the surface; and

- v

- evaporation: A thin layer is formed on the surface by evaporation of the solvent. For volatile solvents, such as alcohols, evaporation starts during the deposition and drainage steps.

2.2.2. In-Situ Polymerization

- i

- Interfacial polymerization; and

- ii

- phase inversion.

3. Water Treatment

- i

- Ultrafiltration (UF);

- ii

- reverse osmosis (RO);

- iii

- nanofiltration (NF); and

- iv

- microfiltration (MF).

3.1. RO

3.2. NF

3.3. FO

3.4. PRO

4. Pervaporation

Alcohol Dehydration

5. Gas Separation

5.1. Dip Coating Membranes

- i

- If the pores of the substrate membrane are very large, its gas flow resistance is very low. In this case, the thin layer coated on top of the substrate will govern both the flux and selectivity; or

- ii

- in the other case, the substrate membrane is considered as a solution diffusion membrane with some defective pores. The substrate governs the membrane performance. The coated layer is only to stop the gas leakage by filling the defective pores.

5.2. IP Membranes

5.3. CO2/Methane and CO2/Nitrogen Separation

5.4. SO2 Removal

5.5. O2/N2 Separation

- i

- The top selective layer was fabricated from the nucleophilic substitution copolymerization between PIM and beta-cyclodextrin (β-CD) (referred to as PIM-CD);

- ii

- polydimethylsiloxane (PDMS) was used as to make a gutter layer; and

- iii

- the material used for the substrate was polyacrylonitrile (PAN).

5.6. Water Vapor Transport

6. Summary

- (1)

- Among various methods to coat the thin selective layer on the porous sublayer, dip coating and IP are the most popular for practical applications;

- (2)

- the thin selective layer is developed mostly on the lumen side of the HF;

- (3)

- as for gas/vapor separation, coating of the thin surface layer is done mostly by dip coating. There are only a few examples of IP;

- (4)

- as for water treatment, applications of TFC HFs in FO and PRO are newly investigated for desalination purposes;

- (5)

- in pervaporation, applications of TFC HFs are most encouraging for alcohol dehydration; and

- (6)

- high-performance multiple-layer PIM composite hollow fiber membranes for gas separation open a new avenue for researchers.

Funding

Conflicts of Interest

Abbreviations

| ABn-NH | functionalized acid-activated bentonite clay |

| BDT | 1,3 benzenedithiol |

| BTT | 1,3,5-benzenetrithol |

| CMCNa | sodium carboxymethyl cellulose |

| 3,5-DABA | 3,5-diaminobenzoic acid |

| DCo | Dip coating |

| DI | deionized |

| DMS | Dimethylsiloxane |

| FS | functional selective |

| GOTMS | 3-glycidyloxypropyltrimethoxy-silane |

| HFM | Hollow fiber membrane |

| HPEI | hyper branched polyethyleneimine |

| IP | interfacial polymerization |

| IPC | isophthaloyl chloride |

| MPD | m-phenylenediamine |

| MWCO | molecular weight cut off |

| NF | Nanofiltration |

| NPTs | Nanoparticles |

| PAN | Polyacrylonitrile |

| PAI | polyamide-imide |

| PDA | Polydopamine |

| PDMS | Polydimethylsiloxane |

| PEBAX | poly(ether block amide) |

| PES | Polyethersulfone |

| PIMs | polymers of intrinsic microporosity |

| PIP | Piperazine |

| PK | Polyketone |

| PP | Polypropylene |

| PPSU | Polyphenylenesulfone |

| PQ-10 | polyquaternium-10 |

| PRO | Pressure retarded osmosis |

| PSF | Polysulfone |

| PTMSP | poly[1-(trimethylsilyl)-1-propyne |

| PVA | polyvinyl alcohol |

| PVDF | Polyvinylene fluoride |

| PVP | poly (4-vinyl pyridine) |

| PWF | pure water flux |

| RO | reverse osmosis |

| SIR | Silicon rubber |

| TDS | total dissolved solids |

| TEOS | tetraethylorthosilicate |

| TEPA | Tetraethylenepentamine) |

| TETA | Triethylenetetramine |

| TFC | thin film composite |

| TFM | thin film membrane |

| TFN | thin film nanocomposite |

| Ti(OBu)4 | Titanium butoxide |

| TMC | trimesoyl chloride |

| TOC | total organic carbon |

References

- Encyclopedia of Life Support Systems (Eolss): Volume 1: Desalination and Water Resources (Desware): Membrane Processes; EOLSS Publishers Co Ltd.: Oxford, UK, 2010; ISBN 978-1-84826-877-7.

- Van der Meer, W.G.J.; van Dijk, J.C. Theoretical optimization of spiral-wound and capillary nanofiltration modules. Desalination 1997, 113, 129–146. [Google Scholar] [CrossRef]

- Petersen, R.J.; Cadotte, J.E. Thin Film Composite Reverse Osmosis Membranes. In Handbook of Industrial Membrane Technology; Noyes Press: Park Ridge, NJ, USA, 1990; Chapter 5; p. 308. [Google Scholar]

- Cadotte, J.E. Interfacially Synthesized Reverse Osmosis Membrane. U.S. Patent 4,277,344, 7 July 1981. [Google Scholar]

- Vinogradov, N.E.; Kagramanov, G.G. The development of polymer membranes and modules for air separation. J. Phys. Conf. Ser. 2016, 751, 012038. [Google Scholar] [CrossRef]

- Luo, L.; Wang, P.; Zhang, S.; Han, G.; Chung, T.S. Novel thin-film composite tri-bore hollow fiber membrane fabrication for forward osmosis. J. Membr. Sci. 2014, 461, 28–38. [Google Scholar] [CrossRef]

- Pandey, P.; Chauhan, R.S. Membranes for gas separation. Prog. Polym. Sci. 2001, 26, 853–893. [Google Scholar] [CrossRef]

- Li, Z.Y.; Maeda, H.; Kusakabe, R.; Morooka, S.; Anzai, H.; Akiyama, S. Preparation of palladium-silver alloy membranes for hydrogen separation by the spray pyrolysis method. J. Membr. Sci. 1993, 78, 247–254. [Google Scholar] [CrossRef]

- Rahaman, M.N. Ceramic Processing; CRC Press: Boca Raton, FL, USA, 2007; pp. 242–244. ISBN 0-8493-7285-2. [Google Scholar]

- Quéré, D. Fluid coating on a fiber. Annu. Rev. Fluid Mech. 1999, 31, 347–384. [Google Scholar] [CrossRef]

- De Ryck, A.; Quéré, D. Fluid Coating from a Polymer Solution. Langmuir 1998, 14, 1911–1914. [Google Scholar] [CrossRef]

- Urper, G.M.; Reyhan, S.T.; Turker, T.; Esra, A.G.; Volodmyr, T.; Ismail, K. Hollow fiber nanofiltration membranes: A comparative review of interfacial polymerization and phase inversion fabrication methods. Sep. Sci. Technol. 2017, 52, 2120–2136. [Google Scholar] [CrossRef]

- Perry, R.H.; Green, D.W. (Eds.) Perry’s Chemical Engineer’s Hand Book, 7th ed.; McGraw Hill: New York, NY, USA, 1997. [Google Scholar]

- Tadros, S.E.; Trehu, Y.M. Coating Process for Composite Reverse Osmosis Membranes. U.S. Patent 4,980,061, 25 December 1990. [Google Scholar]

- Veríssimo, S.; Peinemann, K.V.; Bordado, J. Thin-film composite hollow fiber membranes: An optimized manufacturing method. J. Membr. Sci. 2005, 264, 48–55. [Google Scholar] [CrossRef]

- Ni, L.; Wang, J.; Zhang, Y.; Meng, J.; Jhang, Y. The performance improvement of hollow fiber composite reverse osmosis membranes by post-treatments. Desalin. Water Treat. 2011, 34, 32–36. [Google Scholar] [CrossRef]

- Kim, E.S.; Deng, B. Effect of NH3 plasma on thin-film composite membrane: Relationship of membrane and plasma properties. Membr. Water Treat. 2013, 4, 109–126. [Google Scholar] [CrossRef]

- Sun, S.P.; Hatton, T.A.; Chan, S.Y.; Chung, T.S. Novel thin-film composite nanofiltration hollow fiber membranes with double repulsion for effective removal of emerging organic matters from water. J. Membr. Sci. 2012, 401–402, 152–162. [Google Scholar] [CrossRef]

- Liu, T.Y.; Bian, L.X.; Yuan, H.G.; Pang, B.; Lin, Y.K.; Tong, Y.T.; der Bruggen, B.V.; Wang, X.L. Fabrication of a high-flux thin film composite hollow fiber nanofiltration membrane for wastewater treatment. J. Membr. Sci. 2015, 478, 25–36. [Google Scholar] [CrossRef]

- Zheng, Y.; Yao, G.; Cheng, Q.; Yu, S.; Liu, M.; Gao, C. Positively charged thin-film composite hollow fiber nanofiltration membrane for the removal of cationic dyes through submerged filtration. Desalination 2013, 328, 42–50. [Google Scholar] [CrossRef]

- Maurya, S.K.; Parashuram, K.; Singh, P.S.; Ray, P.; Reddy, A.V.R. Preparation of polysulfone-polyamide thin film composite hollow fiber nanofiltration membranes and their performance in the treatment of aqueous dye solutions. Desalination 2012, 304, 11–19. [Google Scholar] [CrossRef]

- Yu, S.; Chen, Z.; Cheng, Q.; Lu, Z.; Liu, M.; Gao, C. Application of thin film composite hollow fiber membrane to submerged nanofiltration of anionic dye aqueous solutions. Sep. Purif. Technol. 2012, 88, 121–129. [Google Scholar] [CrossRef]

- Wei, X.; Kong, X.; Wang, S.; Xiang, H.; Wang, J.; Chen, J. Removal of heavy metals from electroplating wastewater by thin-film composite nano filtration hollowfiber membranes. Ind. Eng. Chem. Res. 2013, 52, 17583–17590. [Google Scholar] [CrossRef]

- Liu, J.Q.; Xu, Z.L.; Li, X.H.; Zhang, Y.; Zhou, Y.; Wang, Z.X.; Wang, X.J. An improved process to prepare high separation performance PA/PVDF hollow fiber composite nanofiltration membranes. Sep. Purif. Technol. 2007, 58, 53–60. [Google Scholar] [CrossRef]

- Plisko, T.V.; Liubimova, A.S.; Bildyukevich, A.V.; Penkova, A.V.; Dmitrenko, M.E.; Mikhailovskii, V.Y.; Melnikova, G.B.; Semenov, K.N.; Doroshkevich, N.V.; Kuzminova, A.I. Fabrication and characterization of polyamide-fullerenol thin film nanocomposite hollow fiber membranes with enhanced antifouling performance. J. Membr. Sci. 2018, 51, 20. [Google Scholar] [CrossRef]

- Abolfazli, Z.; Rahimpour, A. Fabrication and modification of Thin-film composite hollow fiber NF Membranes. J. Membr. Sci. Res. 2017, 3, 42–49. [Google Scholar]

- Fang, W.; Shi, L.; Wang, R. Interfacially polymerized composite nanofiltration hollow fiber membranes for low-pressure water softening. J. Membr. Sci. 2013, 430, 129–139. [Google Scholar] [CrossRef]

- Sukitpaneenit, P.; Chung, T.S. High performance thin-film composite forward osmosis hollow fiber membranes with macrovoid-free and highly porous structure for sustainable water production. Environ. Sci. Technol. 2012, 46, 7358–7365. [Google Scholar] [CrossRef] [PubMed]

- Zhong, P.; Weber, n.M.; Maletzko, C. Development of Thin-Film Composite forward Osmosis Hollow Fiber Membranes Using Direct Sulfonated Polyphenylenesulfone (SPPSU) as Membrane Substrates. Environ. Sci. Technol. 2013, 47, 7430–7436. [Google Scholar] [CrossRef] [PubMed]

- Gang, H.; Cheng, Z.L.; Chung, T.S. Thin-film composite (TFC) hollow fiber membrane with double-polyamide active layers for internal concentration polarization and fouling mitigation in osmotic processes. J. Membr. Sci. 2016, 523, 497–504. [Google Scholar]

- Chou, S.; Shi, L.; Wang, R.; Tang, C.Y.; Qiu, C.; Fane, A.G. Characteristics and potential applications of a novel forward osmosis hollow fiber membrane. Desalination 2010, 261, 36–372. [Google Scholar] [CrossRef]

- Chou, S. Preparation, Characterization and Optimization of Thin-Film Composite Hollow Fiber Membranes for Osmotically Driven Membrane Processes. Ph.D. Thesis, School of Civil and Environmental Engineering, Singapore Membrane Technology Center, Singapore, 2013. [Google Scholar]

- Fang, X.X. Fabrication of thin Film Composite Forward Osmosis Hollow Fiber Membranes. 2018. Available online: https://www.researchgate.net/publication/43945729_Fabrication_of_thin film_composite_forward_osmosis_hollow_fiber_membranes (accessed on 10 January 2018).

- Shibuya, M.; Yasukawa, M.; Mishima, S.; Tanaka, Y.; Takahashi, T.; Matsuyama, H. A thin-film composite-hollow fiber forward osmosis membrane with a polyketone hollow fiber membrane as a support. Desalination 2017, 402, 33–41. [Google Scholar] [CrossRef]

- Ren, J.; McCutcheon, J.R. Making Thin Film Composite Hollow Fiber Forward Osmosis Membranes at the Module Scale Using Commercial Ultrafiltration Membranes. Ind. Eng. Chem. Res. 2017, 56, 4074–4082. [Google Scholar] [CrossRef]

- Loeb, S.; Norman, R.S. Osmotic power plants. Science 1975, 189, 654–655. [Google Scholar] [CrossRef] [PubMed]

- Chou, S.; Wang, R.; Shi, L.; She, Q.; Tang, C.; Fane, A.G. Thin-film composite hollow fiber membranes for pressure retarded osmosis (PRO) process with high power density. J. Membr. Sci. 2012, 389, 25–33. [Google Scholar] [CrossRef]

- Ingole, P.G.; Choi, W.; Kim, K.H.; Park, C.H.; Choi, W.K.; Lee, H.K. Synthesis, characterization and surface modification of PES hollow fiber membrane support with polydopamine and thin film composite for energy generation. Chem. Eng. J. 2014, 243, 137–146. [Google Scholar] [CrossRef]

- Wan, C.F.; Yang, T.; Gai, W.; Lee, Y.D.; Chung, T.S. Thin-film composite hollow fiber membrane with inorganic salt additives for high mechanical strength and high power density for pressure-retarded osmosis. J. Membr. Sci. 2018, 555, 388–397. [Google Scholar] [CrossRef]

- Zuo, J.; Wang, Y.; Chung, T.S. Novel organic–inorganic thin film composite membranes with separation performance surpassing ceramic membranes for isopropanol dehydration. J. Membr. Sci. 2013, 433, 60–71. [Google Scholar] [CrossRef]

- Zuo, J.; Wang, Y.; Sun, S.P.; Chung, T.S. Molecular design of thin film composite (TFC) hollow fiber membranes for isopropanol dehydration via pervaporation. J. Membr. Sci. 2012, 405, 123–133. [Google Scholar] [CrossRef]

- Sukitpaneenit, P.; Chung, T.S. Fabrication and use of hollow fiber thin film composite membranes for ethanol dehydration. J. Membr. Sci. 2014, 450, 124–137. [Google Scholar] [CrossRef]

- Tsai, H.A.; Chung, L.H.; Lee, K.R.; Lai, J.Y. The preparation of polyamide/polyacrylonitrile composite hollow fiber membranes for pervaporation. Appl. Mech. Mater. 2013, 377, 246–249. [Google Scholar] [CrossRef]

- Hua, D.; Ong, Y.K.; Wang, P.; Chung, T.S. Thin-film composite tri-bore hollow fiber (TFC TbHF) membranes for isopropanol dehydration by pervaporation. J. Membr. Sci. 2014, 471, 155–167. [Google Scholar] [CrossRef]

- Hua, D.; Chung, T.S.; Shi, G.M.; Fang, C. Teflon AF2400/Ultem composite hollow fiber membranes for alcohol dehydration by high-temperature vapor permeation. AIChE J. 2016, 62, 1747–1757. [Google Scholar] [CrossRef]

- Henis, J.M.S.; Tripodi, M.K. A novel approach to gas separations using composite hollow fiber membranes. Sep. Sci. Technol. 1980, 15, 1059–1068. [Google Scholar] [CrossRef]

- Henis, J.M.S.; Tripodi, M.K. Composite hollow fiber membranes for gas permeation: The resistance model approach. J. Membr. Sci. 1981, 8, 233–246. [Google Scholar] [CrossRef]

- Henis, J.M.S.; Tripodi, M.K. Multicomponent Membranes for Gas Separations. U.S. Patent 4,230,463, 28 October 1977. [Google Scholar]

- Lonsdale, H.K. The growth of membrane technology. J. Membr. Sci. 1982, 10, 81–181. [Google Scholar] [CrossRef] [Green Version]

- Baker, R.W. Membrane Separation System; Noyes Data Corporation: Park Ridge, NJ, USA, 1991. [Google Scholar]

- Baker, R.W. Future directions of membrane gas separation technology. Ind. Eng. Chem. Res. 2002, 41, 1393–1411. [Google Scholar] [CrossRef]

- Liang, C.Z.; Yong, W.F.; Chung, T.S. High-performance composite hollow fiber membrane for flue gas and air separations. J. Membr. Sci. 2017, 541, 367–377. [Google Scholar] [CrossRef]

- Liu, L.; Chakma, A.; Feng, X. CO2/N2 separation by poly(ether block amide) thin film hollow fiber composite membranes. Ind. Eng. Chem. Res. 2015, 44, 6874–6882. [Google Scholar] [CrossRef]

- Fam, W.; Mansouri, J.; Li, H.; Chen, V. Improving CO2 separation performance of thin film composite hollow fiber with Pebax®1657/ionic liquid gel membranes. J. Membr. Sci. 2017, 537, 54–68. [Google Scholar] [CrossRef]

- Lasseuguette, E.; Rouch, J.C.; Remigy, J.C. Hollow-fiber coating: Application to preparation of composite hollow-fiber membrane for gas separation. Ind. Eng. Chem. Res. 2013, 52, 13146–13158. [Google Scholar] [CrossRef] [Green Version]

- Borisov, L.; Ovcharova, A.; Bakhtin, D.; Bazhenov, S.; Volkov, A.; Ibragimov, R.; Gallyamov, R.; Bondarenko, G.; Mozhchil, R.; Bildyukevich, A.; et al. Development of polysulfone hollow fiber porous supports for high flux composite membranes: Air plasma and piranha etching. Fibers 2017, 5, 6. [Google Scholar] [CrossRef]

- Fachrurrazi, A.K.Z.Z.G.; Ismail, M.N.I.a.A.F. Asymmetric hollow fiber membrane coated with polydimethylsiloxane-metal organic framework hybrid layer for gas separation. Sep. Purif. Technol. 2015, 146, 85–93. [Google Scholar]

- Kim, K.H.; Ingole, P.G.; Kim, J.H.; Lee, H.K. Separation performance of PEBAX/PEI hollow fiber composite membrane for SO2/CO2/N2 mixed gas. Chem. Eng. J. 2013, 233, 242–250. [Google Scholar] [CrossRef]

- Kim, K.; Hong, S.U.; Kim, J.H.; Lee, H.K. Preparation and performance evaluation of composite hollow fiber membrane for SO2 separation. AIChE J. 2014, 60, 2298–2306. [Google Scholar] [CrossRef]

- Chong, K.C.; Lai, S.O.; Lau, W.J.; Thiam, H.S.; Ismail, A.F.; Roslan, R.A. Preparation, characterization, and performance evaluation of polysulfone hollow fiber membrane with PEBAX or PDMS coating for oxygen enhancement process. Polymers 2018, 10, 126. [Google Scholar] [CrossRef]

- Meng, B.; Yang, N.T.; Tan, X.Y.; Zhang, B.Y. Preparation of polyvinylidene fluoride/polyvinyl dimethylsiloxane composite hollow fiber membranes and their separation properties. Chin. J. Polym. Sci. 2005, 23, 75–82. [Google Scholar] [CrossRef]

- Liang, C.Z.; Chung, T.S. Robust thin film composite PDMS/PAN hollow fiber membranes for water vapor removal from humid air and gases. Sep. Purif. Technol. 2018, 202, 345–356. [Google Scholar] [CrossRef]

- Liang, C.Z.; Liu, J.T.; Lai, J.Y.; Chung, T.S. High-performance multiple-layer PIM composite hollow fiber membranes for gas separation. J. Membr. Sci. 2018, 541, 93–196. [Google Scholar] [CrossRef]

- Pian, C.; Shen, J.; Liu, G. Ceramic hollow fiber-supported PDMS composite membranes for oxygen enrichment from air. Asia-Pac. J. Chem. Eng. 2016. [Google Scholar] [CrossRef]

- Ingole, P.G.; Choi, W.K.; Baek, I.H.; Lee, H.K. Highly selective thin film composite hollow fiber membranes for mixed vapor/gas separation. RSC Adv. 2015, 5, 78950–78957. [Google Scholar] [CrossRef]

- Ingole, P.G.; Sohail, M.; Abou-Elanwar, A.M.; Baig, M.I.; DeokJeon, J.D.; Choi, W.K.; Kim, H.; Lee, H.K. Water vapor separation from flue gas using MOF incorporated thin film nanocomposite hollow fiber membranes. Chem. Eng. J. 2018, 334, 2450–2458. [Google Scholar] [CrossRef]

- Sohail, M.; Yun, Y.N.; Lee, E.; Kim, S.K.; Cho, K.; Kim, J.-N.; Kim, T.W.; Moon, J.-H.; Kim, H. Synthesis of highly crystalline NH2-MIL-125 (Ti) with S-shaped water isotherms for adsorption heat transformation. Cryst. Growth Des. 2017, 17, 1208–1213. [Google Scholar] [CrossRef]

- Baig, M.I.; Ingole, P.G.; Choi, W.K.; Park, S.R.; Kang, E.C.; Lee, H.K. Development of carboxylated TiO2 incorporated thin film nanocomposite hollow fiber membranes for flue gas dehydration. J. Membr. Sci. 2016, 514, 622–635. [Google Scholar] [CrossRef]

- Ingole, P.G.; Choi, W.K.; Lee, G.B.; Lee, H.K. Thin-film-composite hollow-fiber membranes for water vapor separation. Desalination 2017, 403, 12–23. [Google Scholar] [CrossRef]

- Yun, S.H.; Ingole, P.G.; Kim, K.H.; Choi, W.K.; Lee, H.K. Synthesis of cross-linked amides and esters as thin film composite membrane materials yields permeable and selective material for water vapor/gas separation. J. Mater. Chem. A 2015, 3, 7888–7899. [Google Scholar] [CrossRef]

- Ingole, P.G.; Baig, I.M.; Pawar, R.R.; Jeon, J.D.; Lee, H.K. Thin film nanocomposite (TFN) hollow fiber membranes incorporated with functionalized acid-activated bentonite (ABn-NH) clay: Towards enhancement of water vapor permeance and selectivity. J. Mater. Chem. A 2017, 5, 20947–20958. [Google Scholar] [CrossRef]

| TFC HF Membrane | Use | Results | Ref. |

|---|---|---|---|

| Reverse Osmosis | |||

| PDA-PES | Desalination | High flux, excellent power density performance, and good stability. Can be used in all engineered osmosis applications, including PRO. | [15] |

| PA-PSF, post treated with NaOCl And PVA solution | Desalination | Salt rejection of 96.3% and pure water flux of 10.9 L·m−2·h−1. | [16] |

| Low-pressure NH3 plasma treatment (six commercial TFC membranes (3 NF, 3 RO) | Water treatment | CA of NH3 plasma treated membranes were decreased with increasing plasma treatment time. Surface hydrophilicity increased. | [17] |

| Nano filtration | |||

| Polypiperazine amide-PES/PVDF (NF) | Waste water treatment | High-flux and outstanding selectivity of TOC/TDS. | [19] |

| HPEI-Torlon® PAI (NF) | Removal of organic matters from water | Water permeability 4.9 L m−2 bar−1 h−1. | [18] |

| PVA + PQ-10–PP (NF) | Desalination | Salt rejection order CaCl2 > MgCl2 > NaCl > MgSO4 > Na2SO4. Cationic dye removal (submerged filtration). | [20] |

| PA-PSF (NF) | Removal of dye etc. Water treatment | MWCO 490 to 730 g/mole. Rejections: Reactive black-5 and rhodamine-B 60–97%, water flux of 10–35 mL m−2 h−1 at 25 psi. | [21] |

| CMCNa/PP (NF) | Water treatment | MWCO 700 Da. Remove anionic dyes. The dye retention 99.8%, water permeability 7.0 L m−2 h−1 bar, salt rejection 99.8%. | [22] |

| PIP + TMC-PSF + PES (NF) | Heavy metal removal | Pure water flux of approximately 152 L m−2 h−1 at 0.1 MPa. Rejection rates for chromium, copper, and nickel ions were 95.76%, 95.33%, and 94.99%, respectively. | [23] |

| PA (TMC + PIP)-PVDF | Desalination | Rejections Na2SO4, MgCl2, KCl, NaCl, PEG600 and PEG1000—92.3%, 7.0%, 9.5%, 14.2%, 88.4%, and 89.3% respectively. | [24] |

| Si NPTs + TETA-PSF | Desalination | Rejection increased from 15.17% to 25.44% with increasing the TETA concentration from 0.5% to 10% (w/v). Concentration of additives affects the structure and performance. | [26] |

| Fullerene C60(OH)22–24 + PA-PSF (UF) | Water treatment | Superior antifouling properties. Decrease of pure water flux and a slight increase of rejection of lysozyme and PVP K-15. Superior antifouling properties. Correlation between surface properties and fouling behavior. | [25] |

| PA-PEI | PWP about 17 L m−2 h−1 bar−1. Rejections for Mg2+ and Ca2+ ions around 90%. Water flux 20 L m−2 h−1 at 2 bar pressure. Suitable for water softening applications. | [27] | |

| Forward Osmosis, Pressure Retarded Osmosis | |||

| Functional selective PA layer-PES (FO, PRO) | Desalination application | Relatively high water fluxes FO 32–34 L m−2 h−1. PRO 57–65 L m−2 h−1 (PRO) for pure water feed and 2 M NaCl as the draw solution. Model seawater solution as the feed, water flux up to 15–18 L m−2 h−1. | [28] |

| PA-PPSU | Desalination in FO process | FO and PRO. Higher water flux. | [29] |

| PA-PES (dTFC-PES) (FO, PRO) | Waste water treatment | High feed recovery of 80% in the FO mode. Stable performance was observed in the PRO mode. | [30] |

| PA-PES (FO) | Water treatment, desalination | Water flux 12.4 L m−2 h−1 for 3.5 wt % NaCl feed solution and 2 M NaCl draw solution. | [31] |

| PA-PES (FO) | Water treatment, desalination | Excellent intrinsic separation properties. Water flux of 42.6 L m−2 h−1 using 0.5 M NaCl as the draw solution. | [32] |

| PA-Matrimid® (Tri-bore-composite) (PRO, FO) | Saline water treatment | High water fluxes of 50.5 L m−2 h−1 and 11.8 L m−2 h−1 with salt leakages as low as 3.5 and 2.5 g m−2 h−1, in PRO and FO modes, when using 2 M NaCl as the draw solution and pure water as the feed. | [6] |

| PA-polyketone (IP shell side) | Saline water treatment | HF with smaller diameter -higher FO flux and better mechanical properties than those larger diameter HF. | [34] |

| PA-PES | Desalination | Under optimized conditions, water flux—42.6 L h−1 m−2 using 0.5 M NaCl as draw solution. Superior performance as FO HF. | [33] |

| PA-PES (PRO) | Water treatment | Could be used in PRO process. Water permeability—9.22 × 10−12 ms−1 Pa−1. Salt permeability—3.86 × 10−8 m s−1. Structural parameter—4.6 × 10−4 m. | [37] |

| PDA-PES (PRO) | Water treatment | Very high flux, excellent power density performance, and good stability. Can be used in all engineered osmosis applications, including PRO. | [38] |

| PA-CaCl2 + PES | Saline water treatment | Highest pure water permeability. Very low salt permeability. | [39] |

| Membrane | Use | Result | Ref |

|---|---|---|---|

| Pervaporation | |||

| PA (4 different MPD and 3 different HPEI)-PA + imide | Isopropanol dehydration | Separation factor of 624, flux 1282 g m−2 h−1, permeate 99.1 wt % water. | [41] |

| GOTMS + PA-Poly ether imide (Ultem®) | Isopropanol dehydration | Separation performance surpassing ceramic membranes. | [40] |

| PA-PES (dual layer), Surface modified polydopamine or silicone rubber | Ethanol dehydration | Water separation factors 51 and 60, high fluxes 6.6 and 7.5 kg m−2 h−1. Good selectivity/separation factors. | [42] |

| PA-PAN + SiO2 (dual layer, triple orifice spinneret) | Separation of 90 wt.% aqueous isopropanol solution | 419 g m−2 h−1 of permeation flux and 96.6 wt % of water content in permeate. | [43] |

| Poly (ether imide) Ultem® 1010 (tri-bore hollow fiber) | Isopropanol dehydration | Flux 2.65 kg m−2 h−1 with a separation factor of 246 for water/IPA separation at 50 °C using 85/15 wt % IPA/water as the feed. | [44] |

| Teflon AF2400 layer on the outer surface of Ultem HFs (dip coating) | Isopropanol dehydration | Flux 4265 g m−2 h−1, separation factor 383 for 95% isopropanol dehydration at 125 °C. | [45] |

| Membrane | Use | Result | Ref. |

|---|---|---|---|

| CO2/methane and CO2/nitrogen separation | |||

| PEBA-PEI | CO2/N2 | Permeate stream containing 62 mol % CO2 was obtained at a CO2 recovery of 20%. 99.4 mol %. N2 in the residue with a nitrogen recovery of 36%. | [54] |

| Four kinds of TFC composite HFM | Gas separation | High CO2 and N2 permeability. CO2/N2 selectivity’s 3.4–2.5. | [55] |

| Pebax®1657/[emim][BF4] gel membranes in the form of thin film composite hollow fiber membranes | Separation of CO2 mixed-gas containing traces of water vapor and NOx | Excellent mechanical durability, potential application for CO2 capture with real gas feed. | [54] |

| Modified air plasma and the Piranha etch PTMSP-PSF | CO2 permeance | High permeance (3.3 × 105 GPU) in comparison with unmodified membranes including highest surface energy. | [56] |

| PDMS containing Cu3(BTC)2 MOF-PSF | Gas permeation properties | CO2 permeance increased from 69.7 to 109.2 × 10−6 cm3 (STP)/cm2 s cmHg. CO2/CH4 and CO2/N2 selectivity increased. | [57] |

| SO2 Removal | |||

| PEBAX/PEI | Removal SO2 from mixed gases | Permeance of SO2 and CO2 increased. | [58] |

| PVC-g-POEM-PEI | Separation of gases. (SO2, CO2, N2) | Permeation of SO2 105–2705 GPU, Selectivity SO2/CO2—3.9–175.6. Mixed gas separation SO2 removal efficiency reached up to 84.5%. | [59] |

| O2/N2 separation | |||

| PDMS or PEBAX-PSF (DCo) | Oxygen enrichment | Higher permeance O2 and N2. | [60] |

| PDMS-PAN (DCo) | Gas separation | N2 permeance 280 GPU, O2/N2 selectivity of 2.2, water vapor permeance 800 to 3700 GPU. | [62] |

| PVDMS-PVDF (DCo) | Gas separation (N2/O2 separation) | Permeability and selectivity were in good agreement with the theoretical results. | [61] |

| PDMS-ceramic (DCo) | Oxygen enrichment from air | Permeance of 104 GPU with O2/N2 ideal selectivity of 2.0. | [64] |

| PIM-CD/PDMS/PAN | Gas separation O2, N2 and CO2 | O2/N2 and CO2/N2 selectivity, 3.2 and 22.5, respectively. | [63] |

| Water vapor transport | |||

| PDA-PES (DCo) | Water vapor/N2 mixtures | Excellent selectivity. Permeance 3185 GPU, selectivity 195. | [65] |

| MOF incorporated TFN NH2-MIL-125 (Ti)-PSF | Water vapor separation from flue gas | Water vapor permeance increased from 785 GPU (TFC) to 2244 GPU (MOF@TFN3). Selectivity 116 to 542 with NH2-MIL-125 (Ti) MOF. | [66] |

| ABn-NH-TFN-PSf | Water vapor/N2 | Vapor permeance 2809 GPU, vapor/N2 selectivity 913. | [69] |

| Carboxylated TiO2 + PA-HF | Flue gas dehydration | Permeance 1340 GPU, selectivity 486. | [68] |

| BDT, MPD, BTT), PIP-PES (4 monomers used for IP) | Water vapor/N2 | BDT exhibited superior results, water vapor permeance 2054 GPU and the water vapor/N2 selectivity 119. | [71] |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khulbe, K.C.; Matsuura, T. Thin Film Composite and/or Thin Film Nanocomposite Hollow Fiber Membrane for Water Treatment, Pervaporation, and Gas/Vapor Separation. Polymers 2018, 10, 1051. https://doi.org/10.3390/polym10101051

Khulbe KC, Matsuura T. Thin Film Composite and/or Thin Film Nanocomposite Hollow Fiber Membrane for Water Treatment, Pervaporation, and Gas/Vapor Separation. Polymers. 2018; 10(10):1051. https://doi.org/10.3390/polym10101051

Chicago/Turabian StyleKhulbe, Kailash Chandra, and Takeshi Matsuura. 2018. "Thin Film Composite and/or Thin Film Nanocomposite Hollow Fiber Membrane for Water Treatment, Pervaporation, and Gas/Vapor Separation" Polymers 10, no. 10: 1051. https://doi.org/10.3390/polym10101051