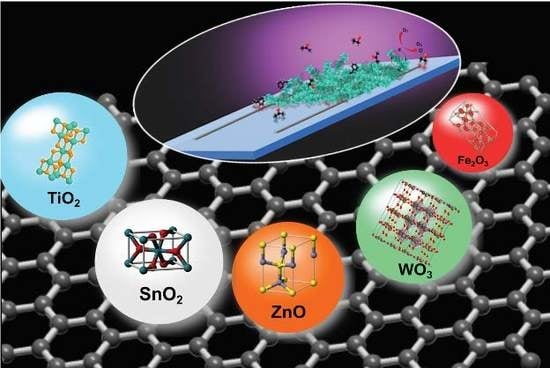

Breakthroughs in the Design of Novel Carbon-Based Metal Oxides Nanocomposites for VOCs Gas Sensing

Abstract

:1. Introduction

2. Chemoresistors Based on Pristine Graphene-Metal Oxides

3. Graphene Oxide-MOS Gas Sensors

4. Reduced Graphene Oxide-Based Chemoresistors

5. Carbon Nanotubes-Metal Oxides Sensing Materials

6. Conclusions and Future Outlooks

Author Contributions

Funding

Conflicts of Interest

References

- Singh, E.; Meyyappan, M.; Nalwa, H.S. Flexible Graphene-Based Wearable Gas and Chemical Sensors. ACS Appl. Mater. Interfaces 2017, 9, 34544–34586. [Google Scholar] [CrossRef] [PubMed]

- Tricoli, A.; Nasiri, N.; De, S. Wearable and Miniaturized Sensor Technologies for Personalized and Preventive Medicine. Adv. Funct. Mater. 2017, 27, 1605271. [Google Scholar] [CrossRef]

- Stepina, S.; Berzina, A.; Sakale, G.; Knite, M. BTEX detection with composites of ethylenevinyl acetate and nanostructured carbon. Beilstein J. Nanotechnol. 2017, 8, 982–988. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Garzón, J.P.; Huertas, J.I.; Magaña, M.; Huertas, M.E.; Cárdenas, B.; Watanabe, T.; Maeda, T.; Wakamatsu, S.; Blanco, S. Volatile organic compounds in the atmosphere of Mexico City. Atmos. Environ. 2015, 119, 415–429. [Google Scholar] [CrossRef] [Green Version]

- Lewis, G. Continuous Monitoring of Benzene, Toluene, Ethyl benzene, and Xylenes (BTEX) in Air with the Thermo Scientific Sentinel PRO Environmental Mass Spectrometer; Thermo Fisher Scientific: Waltham, MA, USA, 2014; p. 3. [Google Scholar]

- Tung, T.T.; Castro, M.; Kim, T.Y.; Suh, K.S.; Feller, J.-F. Graphene quantum resistive sensing skin for the detection of alteration biomarkers. J. Mater. Chem. 2012, 22, 21754. [Google Scholar] [CrossRef]

- Güntner, A.T.; Sievi, N.A.; Theodore, S.J.; Gulich, T.; Kohler, M.; Pratsinis, S.E. Noninvasive Body Fat Burn Monitoring from Exhaled Acetone with Si-doped WO3-sensing Nanoparticles. Anal. Chem. 2017, 89, 10578–10584. [Google Scholar] [CrossRef]

- Cao, W. Breath Analysis: Potential for Clinical Diagnosis and Exposure Assessment. Clin. Chem. 2006, 52, 800–811. [Google Scholar] [CrossRef] [Green Version]

- Wang, L.; Teleki, A.; Pratsinis, S.E.; Gouma, P.I. Ferroelectric WO3 Nanoparticles for Acetone Selective Detection. Chem. Mater. 2008, 20, 4794–4796. [Google Scholar] [CrossRef]

- Lawal, O.; Ahmed, W.M.; Nijsen, T.M.E.; Goodacre, R.; Fowler, S.J. Exhaled breath analysis: A review of ‘breath-taking’ methods for off-line analysis. Metabolomics 2017, 13, 110. [Google Scholar] [CrossRef]

- Zhang, L.; Khan, K.; Zou, J.; Zhang, H.; Li, Y. Recent Advances in Emerging 2D Material-Based Gas Sensors: Potential in Disease Diagnosis. Adv. Mater. Interfaces 2019, 6, 1901329. [Google Scholar] [CrossRef]

- Han, T.; Nag, A.; Chandra Mukhopadhyay, S.; Xu, Y. Carbon nanotubes and its gas-sensing applications: A review. Sens. Actuators A Phys. 2019, 291, 107–143. [Google Scholar] [CrossRef]

- Mukhopadhyay, R. Don’t waste your breath. Researchers are developing breath tests for diagnosing diseases, but how well do they work? Anal. Chem. 2004, 76, 273A–276A. [Google Scholar]

- Buszewski, B.; Kęsy, M.; Ligor, T.; Amann, A. Human exhaled air analytics: Biomarkers of diseases. Biomed. Chromatogr. 2007, 21, 553–566. [Google Scholar] [CrossRef]

- Righettoni, M.; Tricoli, A. Toward portable breath acetone analysis for diabetes detection. J. Breath Res. 2011, 5, 037109. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Righettoni, M.; Tricoli, A.; Gass, S.; Schmid, A.; Amann, A.; Pratsinis, S.E. Breath acetone monitoring by portable Si:WO3 gas sensors. Anal. Chim. Acta 2012, 738, 69–75. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Xie, F.; Lu, H.; Chen, D.; Ji, X.; Yan, F.; Zhang, R.; Zheng, Y.; Li, L.; Zhou, J. Ultra-Low Dark Current AlGaN-Based Solar-Blind Metal–Semiconductor–Metal Photodetectors for High-Temperature Applications. IEEE Sens. J. 2012, 12, 2086–2090. [Google Scholar] [CrossRef]

- Sun, C.; Dutta, P.K. Selective detection of part per billion concentrations of ammonia using a p–n semiconducting oxide heterostructure. Sens. Actuators B Chem. 2016, 226, 156–169. [Google Scholar] [CrossRef]

- Weng, Y.-C.; Yang, Y.-H.; Lu, I.-T. Detection of 2-Butanone for the Diagnosis of Helicobacter Pylori Using Graphene and ZnO Nanorod Electrodes. J. Nanosci. Nanotechnol. 2016, 16, 7077–7084. [Google Scholar] [CrossRef]

- Naskar, A.; Narjinary, M.; Kundu, S. Unconventional Synthesis of γ-Fe2O3: Excellent Low-Concentration Ethanol Sensing Performance. J. Electron. Mater. 2017, 46, 478–487. [Google Scholar] [CrossRef]

- Moon, H.G.; Jung, Y.; Han, S.D.; Shim, Y.S.; Shin, B.; Lee, T.; Kim, J.-S.; Lee, S.; Jun, S.C.; Park, H.H.; et al. Chemiresistive Electronic Nose toward Detection of Biomarkers in Exhaled Breath. ACS Appl. Mater. Interfaces 2016, 8, 20969–20976. [Google Scholar] [CrossRef]

- Kahn, N.; Lavie, O.; Paz, M.; Segev, Y.; Haick, H. Dynamic Nanoparticle-Based Flexible Sensors: Diagnosis of Ovarian Carcinoma from Exhaled Breath. Nano Lett. 2015, 15, 7023–7028. [Google Scholar] [CrossRef] [PubMed]

- Grabowska-Polanowska, B.; Faber, J.; Skowron, M.; Miarka, P.; Pietrzycka, A.; Sliwka, I.; Amann, A. Detection of potential chronic kidney disease markers in breath using gas chromatography with mass-spectral detection coupled with thermal desorption method. J. Chromatogr. A 2013, 1301, 179–189. [Google Scholar] [CrossRef] [PubMed]

- Righettoni, M.; Amann, A.; Pratsinis, S.E. Breath analysis by nanostructured metal oxides as chemo-resistive gas sensors. Mater. Today 2015, 18, 163–171. [Google Scholar] [CrossRef]

- Wang, T.; Huang, D.; Yang, Z.; Xu, S.; He, G. A Review on Graphene-Based Gas/Vapor Sensors with Unique Properties and Potential Applications. Nano-Micro Lett. 2016, 8, 95–119. [Google Scholar] [CrossRef] [Green Version]

- Gupta Chatterjee, S.; Chatterjee, S.; Ray, A.K.; Chakraborty, A.K. Graphene–metal oxide nanohybrids for toxic gas sensor: A review. Sens. Actuators B Chem. 2015, 221, 1170–1181. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, X.; Neri, G.; Pinna, N. Nanostructured Materials for Room-Temperature Gas Sensors. Adv. Mater. 2016, 28, 795–831. [Google Scholar] [CrossRef]

- Keskinen, H.; Tricoli, A.; Marjamäki, M.; Mäkelä, J.M.; Pratsinis, S.E. Size-selected agglomerates of SnO2 nanoparticles as gas sensors. J. Appl. Phys. 2009, 106, 084316. [Google Scholar] [CrossRef] [Green Version]

- Tricoli, A.; Elmøe, T.D. Flame spray pyrolysis synthesis and aerosol deposition of nanoparticle films. AIChE J. 2012, 58, 3578–3588. [Google Scholar] [CrossRef]

- Pineau, N.J.; Kompalla, J.F.; Güntner, A.T.; Pratsinis, S.E. Orthogonal gas sensor arrays by chemoresistive material design. Microchim. Acta 2018, 185, 563. [Google Scholar] [CrossRef] [Green Version]

- Wang, D.; Chi, M.; Zhang, D.; Wu, D. Ammonia sensing properties of metal–Organic frameworks-derived zinc oxide/reduced graphene oxide nanocomposite. J. Mater. Sci. Mater. Electron. 2020, 31, 4463–4472. [Google Scholar] [CrossRef]

- Mirzaei, A.; Park, S.; Kheel, H.; Sun, G.; Lee, S.; Lee, C. ZnO-capped nanorod gas sensors. Ceram. Int. 2016, 42, 6187–6197. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, L.; Leng, D.; Ma, F.; Zhang, Z.; Zhang, Y.; Wang, W.; Liang, Q.; Gao, J.; Lu, H. Nanoscale Pd catalysts decorated WO3–SnO2 heterojunction nanotubes for highly sensitive and selective acetone sensing. Sens. Actuators B Chem. 2020, 306, 127575. [Google Scholar] [CrossRef]

- And, S.M.; Thangadurai, V. Semiconducting SnO2-TiO2 (S-T) Composites for Detection of SO2 Gas. Soil Mech. Found. Eng. 1978, 26, 73–78. [Google Scholar]

- Rella, R.; Spadavecchia, J.; Manera, M.G.; Capone, S.; Taurino, A.; Martino, M.; Caricato, A.P.; Tunno, T. Acetone and ethanol solid-state gas sensors based on TiO2 nanoparticles thin film deposited by matrix assisted pulsed laser evaporation. Sens. Actuators B Chem. 2007, 127, 426–431. [Google Scholar] [CrossRef]

- Janghorban, A.M.K.; Neri, B.H.G. Metal-core@metal oxide-shell nanomaterials for gas-sensing applications: A review. J. Nanoparticle Res. 2015, 17, 1–36. [Google Scholar]

- Kim, H.J.; Lee, J.H. Highly sensitive and selective gas sensors using p-type oxide semiconductors: Overview. Sens. Actuators B Chem. 2014, 192, 607–627. [Google Scholar] [CrossRef]

- Wang, W.; Tian, Y.; Wang, X.; He, H.; Xu, Y.; He, C.; Li, X. Ethanol sensing properties of porous ZnO spheres via hydrothermal route. J. Mater. Sci. 2013, 48, 3232–3238. [Google Scholar] [CrossRef]

- Zhang, P.; Pan, G.; Zhang, B.; Zhen, J.; Sun, Y. High sensitivity ethanol gas sensor based on Sn-doped ZnO under visible light irradiation at low temperature. Mater. Res. 2014, 17, 817–822. [Google Scholar] [CrossRef] [Green Version]

- Chang, S.-P.; Chen, K.-Y. UV Illumination Room-Temperature ZnO Nanoparticle Ethanol Gas Sensors. ISRN Nanotechnol. 2012, 2012, 1–5. [Google Scholar] [CrossRef] [Green Version]

- Meng, F.; Guo, Z.; Huang, X. Graphene-based hybrids for chemiresistive gas sensors. Trends Anal. Chem. 2015, 68, 37–47. [Google Scholar] [CrossRef]

- Acharyya, D.; Bhattacharyya, P. Highly Efficient Room-Temperature Gas Sensor Based on TiO2 Nanotube-Reduced Graphene-Oxide Hybrid Device. IEEE Electron Device Lett. 2016, 37, 656–659. [Google Scholar] [CrossRef]

- Varghese, S.S.; Lonkar, S.; Singh, K.K.; Swaminathan, S.; Abdala, A. Recent advances in graphene based gas sensors. Sens. Actuators B Chem. 2015, 218, 160–183. [Google Scholar] [CrossRef]

- Dai, M.; Zhao, L.; Gao, H.; Sun, P.; Liu, F.; Zhang, S.; Shimanoe, K.; Yamazoe, N.; Lu, G. Hierarchical Assembly of α-Fe2O3 Nanorods on Multiwall Carbon Nanotubes as a High-Performance Sensing Material for Gas Sensors. ACS Appl. Mater. Interfaces 2017, 9, 8919–8928. [Google Scholar] [CrossRef] [PubMed]

- Malik, R.; Tomer, V.K.; Mishra, Y.K.; Lin, L. Functional gas sensing nanomaterials: A panoramic view. Appl. Phys. Rev. 2020, 7, 021301. [Google Scholar] [CrossRef] [Green Version]

- Chavali, M.S.; Nikolova, M.P. Metal oxide nanoparticles and their applications in nanotechnology. SN Appl. Sci. 2019, 1, 607. [Google Scholar] [CrossRef] [Green Version]

- Saleh, T.A.; Fadillah, G. Recent trends in the design of chemical sensors based on graphene–metal oxide nanocomposites for the analysis of toxic species and biomolecules. TrAC Trends Anal. Chem. 2019, 120, 115660. [Google Scholar] [CrossRef]

- Latif, U.; Dickert, F. Graphene Hybrid Materials in Gas Sensing Applications. Sensors 2015, 15, 30504–30524. [Google Scholar] [CrossRef]

- Tripathi, K.M.; Kim, T.; Losic, D.; Tung, T.T. Recent advances in engineered graphene and composites for detection of volatile organic compounds (VOCs) and non-invasive diseases diagnosis. Carbon 2016, 110, 97–129. [Google Scholar] [CrossRef]

- Schedin, F.; Geim, A.K.; Morozov, S.V.; Hill, E.W.; Blake, P.; Katsnelson, M.I.; Novoselov, K.S. Detection of individual gas molecules adsorbed on graphene. Nat. Mater. 2007, 6, 652–655. [Google Scholar] [CrossRef]

- Tricoli, A.; Righettoni, M.; Teleki, A. Semiconductor Gas Sensors: Dry Synthesis and Application. Angew. Chem. Int. Ed. 2010, 49, 7632–7659. [Google Scholar] [CrossRef]

- Du, H.; Li, X.; Yao, P.; Wang, J.; Sun, Y.; Dong, L. Zinc Oxide Coated Tin Oxide Nanofibers for Improved Selective Acetone Sensing. Nanomaterials 2018, 8, 509. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Fusco, Z.; Rahmani, M.; Bo, R.; Verre, R.; Motta, N.; Käll, M.; Neshev, D.; Tricoli, A. Nanostructured Dielectric Fractals on Resonant Plasmonic Metasurfaces for Selective and Sensitive Optical Sensing of Volatile Compounds. Adv. Mater. 2018, 30, 1–11. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liang, S.; Zhu, J.; Wang, C.; Yu, S.; Bi, H.; Liu, X.; Wang, X. Fabrication of α-Fe2O3@graphene nanostructures for enhanced gas-sensing property to ethanol. Appl. Surf. Sci. 2014, 292, 278–284. [Google Scholar] [CrossRef]

- Qin, J.; Cao, M.; Li, N.; Hu, C. Graphene-wrapped WO3 nanoparticles with improved performances in electrical conductivity and gas sensing properties. J. Mater. Chem. 2011, 21, 17167. [Google Scholar] [CrossRef]

- Zhao, T.; Ren, Y.; Jia, G.; Zhao, Y.; Fan, Y.; Yang, J.; Zhang, X.; Jiang, W.; Wang, L.; Luo, W. Facile synthesis of mesoporous WO3@graphene aerogel nanocomposites for low-temperature acetone sensing. Chin. Chem. Lett. 2019, 30, 2032–2038. [Google Scholar] [CrossRef]

- Zhang, H.; Cen, Y.; Du, Y.; Ruan, S. Enhanced acetone sensing characteristics of ZnO/graphene composites. Sensors 2016, 16, 1876. [Google Scholar] [CrossRef] [Green Version]

- Singkammo, S.; Wisitsoraat, A.; Sriprachuabwong, C.; Tuantranont, A.; Phanichphant, S.; Liewhiran, C. Electrolytically Exfoliated Graphene-Loaded Flame-Made Ni-Doped SnO2 Composite Film for Acetone Sensing. ACS Appl. Mater. Interfaces 2015, 7, 3077–3092. [Google Scholar] [CrossRef]

- Ge, S.; Zheng, H.; Sun, Y.; Jin, Z.; Shan, J.; Wang, C.; Wu, H.; Li, M.; Meng, F. Ag/SnO2/graphene ternary nanocomposites and their sensing properties to volatile organic compounds. J. Alloys Compd. 2016, 659, 127–131. [Google Scholar] [CrossRef]

- Chen, Z.-W.; Hong, Y.-Y.; Lin, Z.-D.; Liu, L.-M.; Zhang, X.-W. Enhanced formaldehyde gas sensing properties of ZnO nanosheets modified with graphene. Electron. Mater. Lett. 2017, 13, 270–276. [Google Scholar] [CrossRef]

- Rodner, M.; Puglisi, D.; Ekeroth, S.; Helmersson, U.; Shtepliuk, I.; Yakimova, R.; Skallberg, A.; Uvdal, K.; Schütze, A.; Eriksson, J. Graphene decorated with iron oxide nanoparticles for highly sensitive interaction with volatile organic compounds. Sensors 2019, 19, 918. [Google Scholar] [CrossRef] [Green Version]

- Meng, F.-L.; Li, H.-H.; Kong, L.-T.; Liu, J.-Y.; Jin, Z.; Li, W.; Jia, Y.; Liu, J.-H.; Huang, X.-J. Parts per billion-level detection of benzene using SnO2/graphene nanocomposite composed of sub-6 nm SnO2 nanoparticles. Anal. Chim. Acta 2012, 736, 100–107. [Google Scholar] [CrossRef] [PubMed]

- Morsy, M.; Madbouly, A.I. Room temperature xylene sensor based on Co3O4/GF hybrid. Sens. Actuators A Phys. 2020, 305, 111921. [Google Scholar] [CrossRef]

- Gui, Y.; Liu, Z.; Fang, S.; Tian, J.; Gong, F. Synthesis of flower-like WO3/graphene nanocomposite by microwave-assisted hydrothermal method and the enhanced gas-sensing properties to aniline. J. Mater. Sci. Mater. Electron. 2016, 27, 2890–2895. [Google Scholar] [CrossRef]

- Kim, J.-H.; Kim, S.S. Realization of ppb-Scale Toluene-Sensing Abilities with Pt-Functionalized SnO2–ZnO Core–Shell Nanowires. ACS Appl. Mater. Interfaces 2015, 7, 17199–17208. [Google Scholar] [CrossRef]

- Lv, Y.-K.; Yao, B.-H.; Liu, Z.-Q.; Liang, S.; Liu, Q.-C.; Zhai, K.; Li, Z.-J.; Yao, H.-C. Hierarchical Au-Loaded WO3 Hollow Microspheres With High Sensitive and Selective Properties to Toluene and Xylene. IEEE Sens. J. 2019, 19, 5413–5420. [Google Scholar] [CrossRef]

- De Groot, A.C.; Flyvholm, M.A.; Lensen, G.; Menné, T.; Coenraads, P.J. Formaldehyde-releasers: Relationship to formaldehyde contact allergy. Contact allergy to formaldehyde and inventory of formaldehyde-releasers. Contact Dermat. 2009, 61, 63–85. [Google Scholar] [CrossRef] [Green Version]

- Pei, S.; Zhao, J.; Du, J.; Ren, W.; Cheng, H.M. Direct reduction of graphene oxide films into highly conductive and flexible graphene films by hydrohalic acids. Carbon 2010, 48, 4466–4474. [Google Scholar] [CrossRef]

- Moussa, H.; Girot, E.; Mozet, K.; Alem, H.; Medjahdi, G.; Schneider, R. ZnO rods/reduced graphene oxide composites prepared via a solvothermal reaction for efficient sunlight-driven photocatalysis. Appl. Catal. B Environ. 2016, 185, 11–21. [Google Scholar] [CrossRef]

- Pargoletti, E.; Tricoli, A.; Pifferi, V.; Orsini, S.; Longhi, M.; Guglielmi, V.; Cerrato, G.; Falciola, L.; Derudi, M.; Cappelletti, G. An electrochemical outlook upon the gaseous ethanol sensing by graphene oxide-SnO2 hybrid materials. Appl. Surf. Sci. 2019, 483, 1081–1089. [Google Scholar] [CrossRef]

- Phan, D.T.; Chung, G.S. P-n junction characteristics of graphene oxide and reduced graphene oxide on n-type Si(111). J. Phys. Chem. Solids 2013, 74, 1509–1514. [Google Scholar] [CrossRef]

- Yeh, T.-F.; Cihlář, J.; Chang, C.-Y.; Cheng, C.; Teng, H. Roles of graphene oxide in photocatalytic water splitting. Mater. Today 2013, 16, 78–84. [Google Scholar] [CrossRef]

- Siyar, M.; Maqsood, A.; Khan, S.B. Synthesis of mono layer graphene oxide from sonicated graphite flakes and their Hall effect measurements. Mater. Sci. 2014, 32, 292–296. [Google Scholar] [CrossRef] [Green Version]

- Peter, C.N.; Anku, W.W.; Shukla, S.K.; Govender, P.P. Theoretical studies of the interfacial charge transfer and the effect of VdW correction on the interaction energy of non-metal doped ZnO and graphene oxide interface. Theor. Chem. Acc. 2018, 137, 75. [Google Scholar] [CrossRef]

- Song, H.; Yan, S.; Yao, Y.; Xia, L.; Jia, X.; Xu, J. 3D α-Fe2O3 nanorods arrays@graphene oxide nanosheets as sensing materials for improved gas sensitivity. Chem. Eng. J. 2019, 370, 1331–1340. [Google Scholar] [CrossRef]

- Jia, X.; Lian, D.; Shi, B.; Dai, R.; Li, C.; Wu, X. Facile synthesis of α-Fe2O3@graphene oxide nanocomposites for enhanced gas-sensing performance to ethanol. J. Mater. Sci. Mater. Electron. 2017, 28, 12070–12079. [Google Scholar] [CrossRef]

- Reddy, C.S.; Murali, G.; Reddy, A.S.; Park, S.; In, I. GO incorporated SnO2 nanotubes as fast response sensors for ethanol vapor in different atmospheres. J. Alloys Compd. 2020, 813, 152251. [Google Scholar] [CrossRef]

- Wan, K.; Yang, J.; Wang, D.; Wang, X. Graphene Oxide@3D Hierarchical SnO2 Nanofiber/Nanosheets Nanocomposites for Highly Sensitive and Low-Temperature Formaldehyde Detection. Molecules 2019, 25, 35. [Google Scholar] [CrossRef] [Green Version]

- Kalidoss, R.; Umapathy, S.; Sivalingam, Y. An investigation of GO-SnO2-TiO2 ternary nanocomposite for the detection of acetone in diabetes mellitus patient’s breath. Appl. Surf. Sci. 2018, 449, 677–684. [Google Scholar] [CrossRef]

- Pargoletti, E.; Verga, S.; Chiarello, G.L.; Longhi, M.; Cerrato, G.; Giordana, A.; Cappelletti, G. Exploring SnxTi1−xO2 Solid Solutions Grown onto Graphene Oxide (GO) as Selective Toluene Gas Sensors. Nanomaterials 2020, 10, 761. [Google Scholar] [CrossRef] [Green Version]

- Vessalli, B.A.; Zito, C.A.; Perfecto, T.M.; Volanti, D.P.; Mazon, T. ZnO nanorods/graphene oxide sheets prepared by chemical bath deposition for volatile organic compounds detection. J. Alloys Compd. 2017, 696, 996–1003. [Google Scholar] [CrossRef] [Green Version]

- Wang, P.; Wang, D.; Zhang, M.; Zhu, Y.; Xu, Y.; Ma, X.; Wang, X. ZnO nanosheets/graphene oxide nanocomposites for highly effective acetone vapor detection. Sens, Actuators B Chem. 2016, 230, 477–484. [Google Scholar] [CrossRef]

- Pargoletti, E.; Hossain, U.H.; Di Bernardo, I.; Chen, H.; Tran-Phu, T.; Lipton-Duffin, J.; Cappelletti, G.; Tricoli, A. Room-temperature photodetectors and VOC sensors based on graphene oxide–ZnO nano-heterojunctions. Nanoscale 2019, 11, 22932–22945. [Google Scholar] [CrossRef]

- Gurlo, A. Interplay between O2 and SnO2: Oxygen ionosorption and spectroscopic evidence for adsorbed oxygen. ChemPhysChem 2006, 7, 2041–2052. [Google Scholar] [CrossRef] [PubMed]

- Moldovan, O.; Iñiguez, B.; Deen, M.J.; Marsal, L.F. Graphene electronic sensors—Review of recent developments and future challenges. IET Circuits Devices Syst. 2015, 9, 446–453. [Google Scholar] [CrossRef]

- Modenes-Junior, M.A.; Zito, C.A.; Perfecto, T.M.; Volanti, D.P. Ethanol detection using composite based on reduced graphene oxide and CuO hierarchical structure under wet atmosphere. Mater. Sci. Eng. B 2019, 248, 114385. [Google Scholar] [CrossRef]

- Perfecto, T.M.; Zito, C.A.; Mazon, T.; Volanti, D.P. Flexible room-temperature volatile organic compound sensors based on reduced graphene oxide–WO3·0.33H2O nano-needles. J. Mater. Chem. C 2018, 6, 2822–2829. [Google Scholar] [CrossRef]

- Tian, M.; Miao, J.; Cheng, P.; Mu, H.; Tu, J.; Sun, J. Layer-by-layer nanocomposites consisting of Co3O4 and reduced graphene (rGO) nanosheets for high selectivity ethanol gas sensors. Appl. Surf. Sci. 2019, 479, 601–607. [Google Scholar] [CrossRef]

- Meng, F.; Chang, Y.; Qin, W.; Yuan, Z.; Zhao, J.; Zhang, J.; Han, E.; Wang, S.; Yang, M.; Shen, Y.; et al. ZnO-Reduced Graphene Oxide Composites Sensitized with Graphitic Carbon Nitride Nanosheets for Ethanol Sensing. ACS Appl. Nano Mater. 2019, 2, 2734–2742. [Google Scholar] [CrossRef]

- Meng, F.; Zheng, H.; Chang, Y.; Zhao, Y.; Li, M.; Wang, C.; Sun, Y.; Liu, J. One-Step Synthesis of Au/SnO2/RGO Nanocomposites and Their VOC Sensing Properties. IEEE Trans. Nanotechnol. 2018, 17, 212–219. [Google Scholar] [CrossRef]

- Yin, F.; Li, Y.; Yue, W.; Gao, S.; Zhang, C.; Chen, Z. Sn3O4/rGO heterostructure as a material for formaldehyde gas sensor with a wide detecting range and low operating temperature. Sens. Actuators B Chem. 2020, 312, 127954. [Google Scholar] [CrossRef]

- Hu, J.; Chen, M.; Rong, Q.; Zhang, Y.; Wang, H.; Zhang, D.; Zhao, X.; Zhou, S.; Zi, B.; Zhao, J.; et al. Formaldehyde sensing performance of reduced graphene oxide-wrapped hollow SnO2 nanospheres composites. Sens. Actuators B Chem. 2020, 307, 127584. [Google Scholar] [CrossRef]

- Sun, J.; Bai, S.; Tian, Y.; Zhao, Y.; Han, N.; Luo, R.; Li, D.; Chen, A. Hybridization of ZnSnO3 and rGO for improvement of formaldehyde sensing properties. Sens. Actuators B Chem. 2018, 257, 29–36. [Google Scholar] [CrossRef]

- Wang, C.; Zhu, J.; Liang, S.; Bi, H.; Han, Q.; Liu, X.; Wang, X. Reduced graphene oxide decorated with CuO–ZnO hetero-junctions: Towards high selective gas-sensing property to acetone. J. Mater. Chem. A 2014, 2, 18635–18643. [Google Scholar] [CrossRef]

- Perfecto, T.M.; Zito, C.A.; Volanti, D.P. Room-temperature volatile organic compounds sensing based on WO3·0.33H2O, hexagonal-WO3, and their reduced graphene oxide composites. RSC Adv. 2016, 6, 105171–105179. [Google Scholar] [CrossRef]

- Zhang, S.; Zhang, B.; Sun, G.; Li, Y.; Zhang, B.; Wang, Y.; Cao, J.; Zhang, Z. One-step synthesis of Ag/SnO2/rGO nanocomposites and their trimethylamine sensing properties. Mater. Res. Bull. 2019, 114, 61–67. [Google Scholar] [CrossRef]

- Yuan, Z.; Zhao, J.; Meng, F.; Qin, W.; Chen, Y.; Yang, M.; Ibrahim, M.; Zhao, Y. Sandwich-like composites of double-layer Co3O4 and reduced graphene oxide and their sensing properties to volatile organic compounds. J. Alloys Compd. 2019, 793, 24–30. [Google Scholar] [CrossRef]

- Abideen, Z.U.; Kim, J.-H.; Mirzaei, A.; Kim, H.W.; Kim, S.S. Sensing behavior to ppm-level gases and synergistic sensing mechanism in metal-functionalized rGO-loaded ZnO nanofibers. Sens. Actuators B Chem. 2018, 255, 1884–1896. [Google Scholar] [CrossRef]

- Ashraf, M.A.; Liu, Z.; Peng, W.; Parsaee, Z. Design, preparation and evaluation of a high performance sensor for formaldehyde based on a novel hybride nonocomposite ZnWO3/rGO. Anal. Chim. Acta 2019, 1051, 120–128. [Google Scholar] [CrossRef]

- Iijima, S.; Ichihashi, T. Single-shell carbon nanotubes of 1-nm diameter. Nature 1993, 363, 603–605. [Google Scholar] [CrossRef]

- Bethune, D.S.; Kiang, C.H.; de Vries, M.S.; Gorman, G.; Savoy, R.; Vazquez, J.; Beyers, R. Cobalt-catalysed growth of carbon nanotubes with single-atomic-layer walls. Nature 1993, 363, 605–607. [Google Scholar] [CrossRef]

- Clément, P.; Hafaiedh, I.; Parra, E.J.; Thamri, A.; Guillot, J.; Abdelghani, A.; Llobet, E. Iron oxide and oxygen plasma functionalized multi-walled carbon nanotubes for the discrimination of volatile organic compounds. Carbon 2014, 78, 510–520. [Google Scholar] [CrossRef]

- Morsy, M.; Yahia, I.S.; Zahran, H.Y.; Ibrahim, M. Hydrothermal Synthesis of CNTs/Co3O4@rGO Mesopours Nanocomposite as a Room Temperature Gas Sensor for VOCs. J. Inorg. Organomet. Polym. Mater. 2019, 29, 416–422. [Google Scholar] [CrossRef]

- Wongchoosuk, C.; Wisitsoraat, A.; Tuantranont, A.; Kerdcharoen, T. Portable electronic nose based on carbon nanotube-SnO2 gas sensors and its application for detection of methanol contamination in whiskeys. Sens. Actuators B Chem. 2010, 147, 392–399. [Google Scholar] [CrossRef]

- Parmar, M.; Bhatia, R.; Prasad, V.; Rajanna, K. Ethanol sensing using CuO/MWNT thin film. Sens. Actuators B Chem. 2011, 158, 229–234. [Google Scholar] [CrossRef]

- Wang, J.; Liu, L.; Cong, S.-Y.; Qi, J.Q.; Xu, B.K. An enrichment method to detect low concentration formaldehyde. Sens. Actuators B Chem. 2008, 134, 1010–1015. [Google Scholar] [CrossRef]

- Bhat, P.; K., N.K.S.; Nagaraju, P. Synthesis and characterization of ZnO-MWCNT nanocomposites for 1-butanol sensing application at room temperature. Phys. B Condens. Matter 2019, 570, 139–147. [Google Scholar] [CrossRef]

- Byoun, Y.; Park, S.; Jin, C.; Song, Y.-J.; Choi, S.-W. Highly sensitive and selective ethanol detection at room temperature utilizing holey SWCNT-Sn/SnO2 nanocomposites synthesized by microwave irradiation. Sens. Actuators B Chem. 2019, 290, 467–476. [Google Scholar] [CrossRef]

- Gao, Z.; Lou, Z.; Chen, S.; Li, L.; Jiang, K.; Fu, Z.; Han, W.; Shen, G. Fiber gas sensor-integrated smart face mask for room-temperature distinguishing of target gases. Nano Res. 2018, 11, 511–519. [Google Scholar] [CrossRef]

- Kwon, Y.J.; Mirzaei, A.; Kang, S.Y.; Choi, M.S.; Bang, J.H.; Kim, S.S.; Kim, H.W. Synthesis, characterization and gas sensing properties of ZnO-decorated MWCNTs. Appl. Surf. Sci. 2017, 413, 242–252. [Google Scholar] [CrossRef]

- Güntner, A.T.; Abegg, S.; Königstein, K.; Gerber, P.A.; Schmidt-Trucksäss, A.; Pratsinis, S.E. Breath Sensors for Health Monitoring. ACS Sens. 2019, 4, 268–280. [Google Scholar] [CrossRef]

- Van den Broek, J.; Abegg, S.; Pratsinis, S.E.; Güntner, A.T. Highly selective detection of methanol over ethanol by a handheld gas sensor. Nat. Commun. 2019, 10, 4220. [Google Scholar] [CrossRef] [PubMed]

| Biomarker | Purpose | Levels | Sensor Technology | Ref. |

|---|---|---|---|---|

| Acetone | Hyperglycemia Diabetes type 1 | 30 ppb >1800 ppb | Si-doped WO3 nanoparticle films | [15,16] |

| Ammonia | Liver failure | 50 ppb | Chemoresistive nano-metal oxides | [17] |

| 10 ppb | p-n oxide semiconductor heterostructures | [18] | ||

| 2-Butanone | Helicobacter pylori | 500 ppb | Chemoresistive graphene-ZnO | [19] |

| Ethanol/Toluene | Alcohol consumption | <100 ppm | Metal oxides | [20] |

| H2S | Asthma | 534 ppt | Chemoresistive | [21] |

| NO | Lung injury | 206 ppt | ||

| C7H14O, C10H20O, C16H34 | Ovarian cancer | 400 ppb | Chemoresistive flexible metal oxides sensor array | [22] |

| Trimethylamine | Chronic kidney disease | 1.76 ppb | Gas Chromatography-Mass Spectrometry | [23] |

| Metal oxide@G | Synthetic Route | VOC | Operating T (°C) | LOD (ppm) | Response at LOD (Rair/Ranalyte) | Response/Recovery Times (s) | Ref. |

|---|---|---|---|---|---|---|---|

| α-Fe2O3@(2 wt%) | One-step hydrothermal | Ethanol | 280 | 1 | 5.0 | n.d. | [54] |

| WO3 | UV-assisted photoreduction of WO3/GO | Alcohols | 372 | 100 | ~10.0 a | n.d. | [55] |

| Mesoporous WO3 | Interface-induced co-assembly process | Acetone | 150 | 2 | ~3.5a | 13/65 | [56] |

| ZnO | Hydrothermal | Acetone | 280 | 10 | 2.8 | ~2/1 | [57] |

| 0.1 wt% Ni-doped SnO2 | Flame-spray pyrolysis | Acetone | 350 | 2.5 | < 5 | 7/30 | [58] |

| Ag/SnO2 | Wet-chemical | Acetone | 300 | 0.005 | 0.007 | 2/8 | [59] |

| ZnO | Hydrothermal | Formaldehyde | 200 | 2 | ~10.0 a | 10/29 | [60] |

| Fe3O4 | Physical growth | Formaldehyde | 150 | 0.1 | < 0.1 | n.d. | [61] |

| SnO2 | Wet chemical | Benzene | 210 | 0.005 | ~0.002 | n.d. | [62] |

| Co3O4 | Impregnation followed by calcination | Xylene | 26 | 0.5 | ~0.18 a | 160/235 | [63] |

| WO3 | Microwave-assisted hydrothermal | Aniline | 80 | 1 | ~5.0 a | n.d. | [64] |

| Metal oxide@GO | Synthetic Route | VOC | Operating T (°C) | LOD (ppm) | Response at LOD (Rair/Ranalyte) | Response/Recovery Times (s) | Ref. |

|---|---|---|---|---|---|---|---|

| α-Fe2O3 | In situ fluorine directed solution process/heat treatment | Acetone | 220 | 5 | < 10.0 a | 7/8 | [75] |

| α-Fe2O3 | One-step low temperature hydrothermal | Ethanol | 260 | 5 | < 5.0 a | 7/6 | [76] |

| SnO2 | One-step electrospinning | Ethanol | 300 | 50 | 30.7 | n.d. | [77] |

| Hierarchical SnO2 | Electrospinning/hydrothermal | Formaldehyde | 60 | 0.25 | 6.3 | n.d. | [78] |

| SnO2 | Hydrothermal | Ethanol | 25 (UV) | 0.1 | 1.7 | 310/320 | [70] |

| SnO2-TiO2 | Solvothermal | Acetone | 200 | 0.25 | 6.3 | 10/12 | [79] |

| SnxTi1-xO2 | Hydrothermal | Toluene | 350 | 0.1 | < 1.2 a | 20–35/30–60 | [80] |

| ZnO | Chemical bath deposition | Acetone | 450 | 10 | 2.5 | ~8–12/n.d. | [81] |

| ZnO | Impregnation | Acetone | 240 | 1 | < 2.0 | 13/7 | [82] |

| ZnO | Hydrothermal | Ethanol | 25 (UV) | 0.1 | ~1.1 a | 80/90 | [83] |

| Metal oxide@RGO | Synthetic Route | VOC | Operating T (°C) | LOD (ppm) | Response at LOD (Rair/Ranalyte) | Response/Recovery Times (s) | Ref. |

|---|---|---|---|---|---|---|---|

| CuO | One-step microwave-assisted | Ethanol | 250 | 5 | ~0.1a | 29/n.d. | [86] |

| WO3·0.33H2O | Ultrasonic spray nozzle/microwave-assisted hydrothermal | 2-propanol | 22 | 1 | < 1.5 a | n.d. | [87] |

| Co3O4 | Hydrothermal | Ethanol | 200 | 20 | ~3.0 a | n.d. | [88] |

| ZnO/g-C3N4 | Ultrasonic dispersion/electrostatic self-assembly strategy | Ethanol | 300 | 0.5 | < 5.0 a | 76/6 | [89] |

| Au/SnO2 | One-step wet chemical | Ethanol | 200 | 1 | ~3.0 a | 14/10 | [90] |

| Sn3O4 | One-step hydrothermal | Formaldehyde | 150 | 1 | ~6.0 a | 4/125 | [91] |

| Hollow SnO2 | One-step hydrothermal | Formaldehyde | 130 | 5 | ~60.0 a | n.d. | [92] |

| ZnSnO3 | Self-assembly | Formaldehyde | 103 | 1 | ~3.0 a | 31/n.d. | [93] |

| CuO-ZnO | One-step hydrothermal | Ethanol | 340 | 10 | < 20.0 a | 10/14 | [94] |

| WO3·0.33H2O | One-pot microwave-assisted hydrothermal | Acetone | 25 | 1 | ~1.0 a | 14/n.d. | [95] |

| Ag/SnO2 | One-step hydrothermal | Triethylamine | 220 | 0.5 | ~5.0 a | 11/n.d. | [96] |

| Double-layer Co3O4 | One-step hydrothermal | Triethylamine | 200 | 1 | < 4.0 a | 30/32 | [97] |

| Pd/ZnO | Sol-gel/electrospinning methods | Benzene | 400 | 1 | ~23.0 a | 100/330 | [98] |

| Au/ZnO | ~30.0 a | 150/75 |

| Class of CNTs | Metal Oxide | Synthetic Route | VOC | Operating T (°C) | LOD (ppm) | Response at LOD (Rair/Rgas) | Response/Recovery Times (s) | Ref. |

|---|---|---|---|---|---|---|---|---|

| Multi-Wall | α-Fe2O3 | Hydrolysis/annealing | Acetone | 225 | 0.5 | < 2.0 a | 2/35 | [44] |

| Co3O4 | Hydrothermal | Ethanol | 25 | 5 | ~0.5 a | n.d. | [103] | |

| CuO | DC magnetron sputtering | Ethanol | 407 | 100 | ~2.0 a | 200/n.d. | [105] | |

| SnO2 | Sol-gel | Formaldehyde | 250 | 0.05 | ~1.0 a | 100/90 | [106] | |

| ZnO | Wet-chemical | 1-butanol | 27 | 50 | ~1.0 a | 20/30 | [107] | |

| Single-Wall | Sn/SnO2 | Microwave irradiation-assisted | Ethanol | 25 | 1 | ~3.5 a | 250/400 | [108] |

| ZnO Quantum Dots | Impregnation | Ethanol | 25 | 100 | ~1.0 a | 992/301 | [109] |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pargoletti, E.; Cappelletti, G. Breakthroughs in the Design of Novel Carbon-Based Metal Oxides Nanocomposites for VOCs Gas Sensing. Nanomaterials 2020, 10, 1485. https://doi.org/10.3390/nano10081485

Pargoletti E, Cappelletti G. Breakthroughs in the Design of Novel Carbon-Based Metal Oxides Nanocomposites for VOCs Gas Sensing. Nanomaterials. 2020; 10(8):1485. https://doi.org/10.3390/nano10081485

Chicago/Turabian StylePargoletti, Eleonora, and Giuseppe Cappelletti. 2020. "Breakthroughs in the Design of Novel Carbon-Based Metal Oxides Nanocomposites for VOCs Gas Sensing" Nanomaterials 10, no. 8: 1485. https://doi.org/10.3390/nano10081485