Influence of Selective Laser Melting Technological Parameters on the Mechanical Properties of Additively Manufactured Elements Using 316L Austenitic Steel

Abstract

:1. Introduction

- -

- “S_1” is the reference group, which was defined according to the recommended values given by the SLM device distributors,

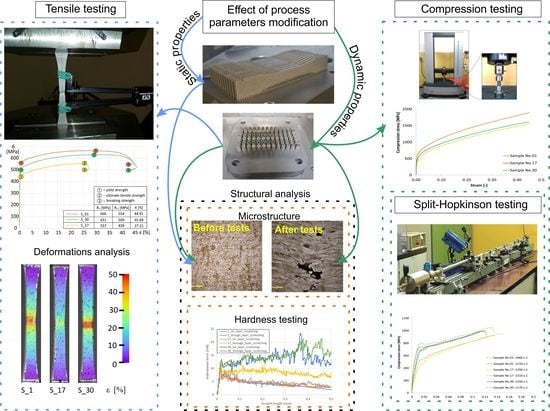

- -

- “S_17” is characterized by the lowest value of energy density used in preliminary research [17],

- -

2. Characteristics of Austenite 316L Material Specimens in the Manufacturing Process

Materials

- LP – laser power [W],

- ev – exposure velocity [mm/s],

- hd – hatching distance [mm], and

- lt – layer thickness [mm].

- S_1—default settings recommended for the processing of 316L steel with the SLM 125HL machine;

- S_17—10% higher exposure speed, 10% higher hatching distance, and 10% lower laser power relative to the reference S_1 group; in a previous study, it has been characterized by the lowest energy density and, as the result, a higher material porosity was obtained under these conditions [17];

3. Microstructural Analysis

4. Sclerometer Hardness and Instrumental Indenter Tests

4.1. Testing Method Description

4.2. Scratching Force Changes and Sclerometer Hardness Analysis

- -

- for the S_1 parameter group, the force fluctuations on the surface oriented perpendicular to the building platform occur in a small range and are higher than those on the surface oriented parallel to the building platform;

- -

- for the S_17 parameter group, the force fluctuations on the surface oriented perpendicular to the building platform are much higher than those on the surface oriented parallel to the building platform;

- -

- for the S_30 parameter group, the force fluctuations on the surface oriented perpendicular to the building platform are lower than those on the surface oriented parallel to the building platform.

4.3. Instrumental Hardness Analysis

5. Tensile Tests with Digital Image Correlation (DIC) Analysis

6. Static and Dynamic Compressive Tests

7. Conclusions

- Changing the exposure parameters (laser power, exposure speed, and hatching distance) affects the melt pool size and porosity of the structure of the produced material and consequently affects the mechanical properties of additively manufactured elements composed of 316L austenitic steel. All mentioned parameters significantly affect the process energy density which is introduced into a distributed powder layer. The value of the energy density directly affects the melting pool temperature, its size, and, at the end, all thermal history of the produced elements. All these factors significantly affect the mechanical properties, which was proven in this research paper.

- The results of microstructural analyses of the manufactured material before and after dynamic tests allow for an initial assessment of its static strength. The highest level of compression stress of S_1 samples is covered by the highest tensile strength of those samples. It was also registered in DIC images, where the area of high material deformations is much bigger than in the other, tested samples.

- Analysis of the microstructural and strength test results demonstrates the possibility of designing the fabricated material for specific applications. One of the most important examples could be porosity growth with decreasing the process of energy density. Forced porosity growth could be helpful in high-porous friction bearing or medical applications where it is necessary to assure tissue deposition in produced prostheses.

- The energy dissipation capacity of the resulting structures affects the observed mechanism of material cracking during dynamic loading, particularly in the areas on the border between adjacent layers. Registered different material behavior is strictly connected with its properties. These properties are connected with porosity types in which generation was caused by different process parameters. After dynamic tests, different material behavior was visible, wherein S_1 samples the deformation process was stable in the whole analyzed area. S_17 samples were characterized by a high amount of cracks, which were generated near non-fused powder grains. Different cracking behavior was presented in S_30 samples images, where cracks were mostly generated between melt pools. That type of phenomenon is connected with too high energy density, which directly influences the “key-hole” porosity generation in connections between melt pools.

Author Contributions

Funding

Conflicts of Interest

References

- Du Plessis, A.; Broeckhoven, C.; Yadroitsava, I.; Yadroitsev, I.; Hands, C.H.; Kunju, R.; Bhate, D. Beautiful and Functional: A Review of Biomimetic Design in Additive Manufacturing. Addit. Manuf. 2019, 27, 408–427. [Google Scholar] [CrossRef]

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.; De, A.; Zhang, W. Additive manufacturing of metallic components – Process, structure and properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Herzog, D.; Seyda, V.; Wycisk, E.; Emmelmann, C. Additive manufacturing of metals. Acta Mater. 2016, 117, 371–392. [Google Scholar] [CrossRef]

- Strong, D.; Kay, M.; Conner, B.; Wakefield, T.; Manogharan, G. Hybrid manufacturing – integrating traditional manufacturers with additive manufacturing (AM) supply chain. Addit. Manuf. 2018, 21, 159–173. [Google Scholar] [CrossRef]

- Kluczyński, J.; Sniezek, L.; Grzelak, K.; Torzewski, J. The influence of layer re-melting on tensile and fatigue strength of selective laser melted 316L steel. In Proceedings of the 12th International Conference on Intelligent Technologies in Logistics and Mechatronics Systems, Panevezys, Lithuania, 26–27 April 2018; pp. 115–123. [Google Scholar]

- Śniezek, L.; Grzelak, K.; Torzewski, J.; Kluczyński, J. Study of the mechanical properties components made by SLM additive technology. In Proceedings of the 11th International Conference on Intelligent Technologies in Logistics and Mechatronics Systems, Panevezys, Lithuania, 28–29 April 2016; pp. 145–153. [Google Scholar]

- Sienkiewicz, J.; Płatek, P.; Jiang, F.; Sun, X.; Rusinek, A. Investigations on the Mechanical Response of Gradient Lattice Structures Manufactured via SLM. Metals 2020, 10, 213. [Google Scholar] [CrossRef] [Green Version]

- Harun, W.S.W.; Kamariah, M.S.I.N.; Muhamad, N.; Ghani, S.A.C.; Ahmad, F.; Mohamed, Z. A review of powder additive manufacturing processes for metallic biomaterials. Powder Technol. 2018, 327, 128–151. [Google Scholar] [CrossRef]

- Kluczyński, J.; Śnieżek, L.; Kravcov, A.; Grzelak, K.; Svoboda, P.; Szachogłuchowicz, I.; Franek, O.; Morozov, N.; Torzewski, J.; Kubeček, P. The examination of restrained joints created in the process of multi-material FFF additive manufacturing technology. Materials 2020, 13, 903. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part. B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Pinkerton, A.J. [INVITED] Lasers in additive manufacturing. Opt. Laser Technol. 2016, 78, 25–32. [Google Scholar] [CrossRef] [Green Version]

- Thompson, M.K.; Moroni, G.; Vaneker, T.; Fadel, G.; Campbell, R.I.; Gibson, I.; Bernard, A.; Schulz, J.; Graf, P.; Ahuja, B.; et al. Design for Additive Manufacturing: Trends, opportunities, considerations, and constraints. Cirp Ann. 2016, 65, 737–760. [Google Scholar] [CrossRef]

- Labeaga-Martínez, N.; Sanjurjo-Rivo, M.; Díaz-Álvarez, J.; Martínez-Frías, J. Additive manufacturing for a Moon village. Procedia Manuf. 2017, 13, 794–801. [Google Scholar] [CrossRef]

- Gusarov, A.V.; Grigoriev, S.N.; Volosova, M.A.; Melnik, Y.A.; Laskin, A.; Kotoban, D.V.; Okunkova, A.A. On productivity of laser additive manufacturing. J. Mater. Process. Technol. 2018, 261, 213–232. [Google Scholar] [CrossRef]

- Heeling, T.; Wegener, K. The effect of multi-beam strategies on selective laser melting of stainless steel 316L. Addit. Manuf. 2018, 22, 334–342. [Google Scholar] [CrossRef]

- Hanzl, P.; Zetek, M.; Bakša, T.; Kroupa, T. The influence of processing parameters on the mechanical properties of SLM parts. Procedia Eng. 2015, 100, 1405–1413. [Google Scholar] [CrossRef] [Green Version]

- Kluczyński, J.; Śniezek, L.; Grzelak, K.; Mierzyński, J. The influence of exposure energy density on porosity and microhardness of the SLM additive manufactured elements. Materials. 2018, 11, 2304. [Google Scholar] [CrossRef] [Green Version]

- Cherry, J.A.; Davies, H.M.; Mehmood, S.; Lavery, N.P.; Brown, S.G.R.; Sienz, J. Investigation into the effect of process parameters on microstructural and physical properties of 316L stainless steel parts by selective laser melting. Int. J. Adv. Manuf. Technol. 2014, 76, 869–879. [Google Scholar] [CrossRef] [Green Version]

- Schneider, J.; Lund, B.; Fullen, M. Effect of heat treatment variations on the mechanical properties of Inconel 718 selective laser melted specimens. Addit. Manuf. 2018, 21, 248–254. [Google Scholar] [CrossRef]

- Pleass, C.; Jothi, S. Influence of powder characteristics and additive manufacturing process parameters on the microstructure and mechanical behaviour of Inconel 625 fabricated by selective laser melting. Addit. Manuf. 2018, 24, 419–431. [Google Scholar] [CrossRef]

- Kasperovich, G.; Hausmann, J. Journal of Materials Processing Technology Improvement of fatigue resistance and ductility of TiAl6V4 processed by selective laser melting. J. Mater. Process. Tech. 2015, 220, 202–214. [Google Scholar] [CrossRef]

- Pisula, J.M.; Budzik, G.; Przeszłowski, Ł. An analysis of the surface geometric structure and geometric accuracy of cylindrical gear teeth manufactured with the direct metal laser sintering (DMLS) method. J. Mech. Eng. 2019, 65, 78–86. [Google Scholar] [CrossRef] [Green Version]

- Larimian, T.; Kannan, M.; Grzesiak, D.; AlMangour, B.; Borkar, T. Effect of energy density and scanning strategy on densification, microstructure and mechanical properties of 316L stainless steel processed via selective laser melting. Mater. Sci. Eng. A 2019, 770, 138455. [Google Scholar] [CrossRef]

- Opatová, K.; Zetková, I.; Kučerová, L. Relationship between the Size and Inner Structure of Particles of Virgin and Re-Used MS1 Maraging Steel Powder for Additive Manufacturing. Materials 2020, 13, 956. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liverani, E.; Toschi, S.; Ceschini, L.; Fortunato, A. Effect of selective laser melting (SLM) process parameters on microstructure and mechanical properties of 316L austenitic stainless steel. J. Mater. Process. Technol. 2017, 249, 255–263. [Google Scholar] [CrossRef]

- Mower, T.M.; Long, M.J. Mechanical behavior of additive manufactured, powder-bed laser-fused materials. Mater. Sci. Eng. A 2016, 651, 198–213. [Google Scholar] [CrossRef]

- Alsalla, H.H.; Smith, C.; Hao, L. Effect of build orientation on the surface quality, microstructure and mechanical properties of selective laser melting 316L stainless steel. Rapid Prototyp. J. 2018, 24, 9–17. [Google Scholar] [CrossRef]

- Yadollahi, A.; Shamsaei, N.; Thompson, S.M.; Elwany, A.; Bian, L. Effects of building orientation and heat treatment on fatigue behavior of selective laser melted 17-4 PH stainless steel. Int. J. Fatigue 2017, 94, 218–235. [Google Scholar] [CrossRef]

- Blinn, B.; Krebs, F.; Ley, M.; Teutsch, R.; Beck, T. Determination of the influence of a stress-relief heat treatment and additively manufactured surface on the fatigue behavior of selectively laser melted AISI 316L by using efficient short-time procedures. Int. J. Fatigue 2020, 131, 105301. [Google Scholar] [CrossRef]

- Blinn, B.; Klein, M.; Gläßner, C.; Smaga, M.; Aurich, J.C.; Beck, T. An investigation of the microstructure and fatigue behavior of additively manufactured AISI 316L stainless steel with regard to the influence of heat treatment. Metals 2018, 8, 220. [Google Scholar] [CrossRef] [Green Version]

- Leuders, S.; Lieneke, T.; Lammers, S.; Tröster, T.; Niendorf, T. On the fatigue properties of metals manufactured by selective laser melting - The role of ductility. J. Mater. Res. 2014, 29, 1911–1919. [Google Scholar] [CrossRef]

- Röttger, A.; Geenen, K.; Windmann, M.; Binner, F.; Theisen, W. Comparison of microstructure and mechanical properties of 316 L austenitic steel processed by selective laser melting with hot-isostatic pressed and cast material. Mater. Sci. Eng. A 2016, 678, 365–376. [Google Scholar] [CrossRef]

- Tolosa, I.; Garciandía, F.; Zubiri, F.; Zapirain, F.; Esnaola, A. Study of mechanical properties of AISI 316 stainless steel processed by “selective laser melting”, following different manufacturing strategies. Int. J. Adv. Manuf. Technol. 2010, 51, 639–647. [Google Scholar] [CrossRef]

- Ahmadi, A.; Mirzaeifar, R.; Moghaddam, N.S.; Turabi, A.S.; Karaca, H.E.; Elahinia, M. Effect of manufacturing parameters on mechanical properties of 316L stainless steel parts fabricated by selective laser melting: A computational framework. Mater. Des. 2016, 112, 328–338. [Google Scholar] [CrossRef]

- Liu, S.; Shin, Y.C. Additive manufacturing of Ti6Al4V alloy: A review. Mater. Des. 2019, 164, 107552. [Google Scholar] [CrossRef]

- Metelkova, J.; Kinds, Y.; Kempen, K.; de Formanoir, C.; Witvrouw, A.; Van Hooreweder, B. On the influence of laser defocusing in Selective Laser Melting of 316L. Addit. Manuf. 2018, 23, 161–169. [Google Scholar] [CrossRef]

- Rokicki, P.; Kozik, B.; Budzik, G.; Dziubek, T.; Bernaczek, J.; Przeszlowski, L.; Markowska, O.; Sobolewski, B.; Rzucidlo, A. Manufacturing of aircraft engine transmission gear with SLS (DMLS) method. Aircr. Eng. Aerosp. Technol. 2016, 88, 397–403. [Google Scholar] [CrossRef]

- Yang, Y.; Lu, J.B.; Luo, Z.Y.; Wang, D. Accuracy and density optimization in directly fabricating customized orthodontic production by selective laser melting. Rapid Prototyp. J. 2012, 18, 482–489. [Google Scholar] [CrossRef]

- Riemer, A.; Richard, H.A. Crack Propagation in Additive Manufactured Materials and Structures. Procedia Struct. Integr. 2016, 2, 1229–1236. [Google Scholar] [CrossRef] [Green Version]

- Spierings, A.B.; Starr, T.L.; Wegener, K. Fatigue performance of additive manufactured metallic parts. Rapid Prototyp. J. 2013, 19, 88–94. [Google Scholar] [CrossRef]

- Tucho, W.M.; Lysne, V.H.; Austbø, H.; Sjolyst-Kverneland, A.; Hansen, V. Investigation of effects of process parameters on microstructure and hardness of SLM manufactured SS316L. J. Alloy. Compd. 2018, 740, 910–925. [Google Scholar] [CrossRef]

- Wang, D.; Liu, Y.; Yang, Y.; Xiao, D. Theoretical and experimental study on surface roughness of 316L stainless steel metal parts obtained through selective laser melting. Rapid Prototyp. J. 2016, 22, 706–716. [Google Scholar] [CrossRef]

- Turner, B.N.; Gold, S.A. A review of melt extrusion additive manufacturing processes: II. Materials, dimensional accuracy, and surface roughness. Rapid Prototyp. J. 2015, 21, 250–261. [Google Scholar] [CrossRef]

- ISO 6892-1:2010 Metallic Materials - Tensile Testing - Part 1: Method of Test at Room Temperature; International Organization for Standardization: Geneva, Switzerland, 2010.

| C | Mn | Si | P | S | N | Cr | Mo | Ni |

|---|---|---|---|---|---|---|---|---|

| weight [%] | ||||||||

| max. 0.03 | max. 2.00 | max. 0.75 | max. 0.04 | max. 0.03 | max. 0.10 | 16.00-18.00 | 2.00- 3.00 | 10.00-14.00 |

| Parameter Sets | Laser Power, LP [W] | Exposure Velocity, ev [mm/s] | Hatching Distance, hd [mm] | Energy Density, ρE [J/mm3] |

|---|---|---|---|---|

| S_1 | 190 | 900 | 0.12 | 58.64 |

| S_17 | 180 | 990 | 0.13 | 46.62 |

| S_30 | 120 | 300 | 0.08 | 166.67 |

| Sample Description | Sclerometer Hardness [GPa] |

|---|---|

| S_1—measurement in parallel surface (regarding to build platform) | 4.16 |

| S_1—measurement in perpendicular surface (regarding to build platform) | 4.44 |

| S_17—measurement in parallel surface (regarding to build platform) | 3.67 |

| S_17—measurement in perpendicular surface (regarding to build platform) | 4.04 |

| S_30—measurement in parallel surface (regarding to build platform) | 3.85 |

| S_30—measurement in perpendicular surface (regarding to build platform) | 3.53 |

| Sample Description | Instrumental Hardness [GPa] |

|---|---|

| S_1—measurement in parallel surface (regarding to build platform) | 1.74 |

| S_17—measurement in parallel surface (regarding to build platform) | 1.31 |

| S_30—measurement in parallel surface (regarding to build platform) | 1.37 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kluczyński, J.; Śnieżek, L.; Grzelak, K.; Janiszewski, J.; Płatek, P.; Torzewski, J.; Szachogłuchowicz, I.; Gocman, K. Influence of Selective Laser Melting Technological Parameters on the Mechanical Properties of Additively Manufactured Elements Using 316L Austenitic Steel. Materials 2020, 13, 1449. https://doi.org/10.3390/ma13061449

Kluczyński J, Śnieżek L, Grzelak K, Janiszewski J, Płatek P, Torzewski J, Szachogłuchowicz I, Gocman K. Influence of Selective Laser Melting Technological Parameters on the Mechanical Properties of Additively Manufactured Elements Using 316L Austenitic Steel. Materials. 2020; 13(6):1449. https://doi.org/10.3390/ma13061449

Chicago/Turabian StyleKluczyński, Janusz, Lucjan Śnieżek, Krzysztof Grzelak, Jacek Janiszewski, Paweł Płatek, Janusz Torzewski, Ireneusz Szachogłuchowicz, and Krzysztof Gocman. 2020. "Influence of Selective Laser Melting Technological Parameters on the Mechanical Properties of Additively Manufactured Elements Using 316L Austenitic Steel" Materials 13, no. 6: 1449. https://doi.org/10.3390/ma13061449