Structural Effects of Magnetostrictive Materials on the Magnetoelectric Response of Particulate CZFO/NKNLS Composites

Abstract

:1. Introduction

2. Experimental

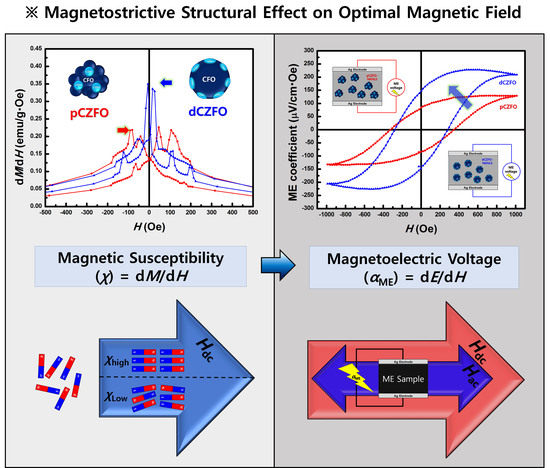

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Cheng, Y.; Peng, B.; Hu, Z.; Zhou, Z.; Liu, M. Recent development and status of magnetoelectric materials and devices. Phys. Lett. A 2018, 382, 3018–3025. [Google Scholar] [CrossRef]

- Palneedi, H.; Annapureddy, V.; Priya, S.; Ryu, J. Status and Perspectives of Multiferroic Magnetoelectric Composite Materials and Applications. Actuators 2016, 5, 9. [Google Scholar] [CrossRef]

- Ren, Y.; Ouyang, J.; Wang, W.; Wu, X.; Yang, X.; Zhang, Y.; Chen, S. Rotating Magnetoelectric Sensor for DC Magnetic Field Measurement. IEEE Trans. Magn. 2018, 54, 6001203. [Google Scholar]

- Yang, S.-C.; Ahn, C.-W.; Cho, K.-H.; Priya, S. Self-Bias Response of Lead-Free (1−x)[0.948 K0.5Na0.5NbO3–0.052 LiSbO3]-xNi0.8Zn0.2Fe2O4-Nickel Magnetoelectric Laminate Composites. J. Am. Ceram. Soc. 2011, 94, 3889–3899. [Google Scholar] [CrossRef]

- Eerenstein, W.; Mathur, N.D.; Scott, J.F. Multiferroic and magnetoelectric materials. Nature 2006, 442, 759–765. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Li, J.; Viehland, D. Magnetoelectrics for magnetic sensor applications: Status, challenges and perspectives. Mater. Today 2014, 17, 269–275. [Google Scholar] [CrossRef]

- Fiebig, M. Revival of the magnetoelectric effect. J. Phys. D-Appl. Phys. 2005, 38, R123–R152. [Google Scholar] [CrossRef]

- Nan, C.W.; Bichurin, M.I.; Dong, S.X.; Viehland, D.; Srinivasan, G. Multiferroic magnetoelectric composites: Historical perspective, status, and future directions. J. Appl. Phys. 2008, 103, 1. [Google Scholar] [CrossRef]

- Li, T.; Ma, D.; Li, K.; Hu, Z. Self-biased magnetoelectric coupling effect in the layered La0.7Sr0.3MnO3/BaTiO3/La0.7Sr0.3MnO3 multiferroic heterostructure. J. Alloy. Compd. 2018, 747, 558–562. [Google Scholar] [CrossRef]

- An, F.; Zhong, G.; Zhu, Q.; Huang, Y.; Yang, Y.; Xie, S. Synthesis and mechanical properties characterization of multiferroic BiFeO3-CoFe2O4 composite nanofibers. Ceram. Int. 2018, 44, 11617–11621. [Google Scholar] [CrossRef]

- Islam, R.A.; Priya, S. Effect of piezoelectric grain size on magnetoelectric coefficient of Pb(Zr0.52Ti0.48)O3-Ni0.8Zn0.2Fe2O4 particulate composites. J. Mater. Sci. 2008, 43, 3560–3568. [Google Scholar] [CrossRef]

- Gupta, A.; Chatterjee, R. Dielectric and magnetoelectric properties of BaTiO3-Co0.6Zn0.4Fe1.7Mn0.3O4 composite. J. Eur. Ceram. Soc. 2013, 33, 1017–1022. [Google Scholar] [CrossRef]

- Nie, J.W.; Xu, G.Y.; Yang, Y.; Cheng, C.W. Strong magnetoelectric coupling in CoFe2O4-BaTiO3 composites prepared by molten-salt synthesis method. Mater. Chem. Phys. 2009, 115, 400–403. [Google Scholar] [CrossRef]

- Negi, N.S.; Kumar, R.; Sharma, H.; Shah, J.; Kotnala, R.K. Structural, multiferroic, dielectric and magnetoelectric properties of (1-x) Ba0.85Ca0.15Ti0.90Zr0.10O3-(x)CoFe2O4 lead-free composites. J. Magn. Magn. Mater. 2018, 456, 292–299. [Google Scholar] [CrossRef]

- Walther, T.; Straube, U.; Koferstein, R.; Ebbinghaus, S.G. Hysteretic magnetoelectric behavior of CoFe2O4-BaTiO3 composites prepared by reductive sintering and reoxidation. J. Mater. Chem. C 2016, 4, 4792–4799. [Google Scholar] [CrossRef]

- Sreenivasulu, G.; Babu, V.H.; Markandeyulu, G.; Murty, B.S. Magnetoelectric effect of (100-x)BaTiO3-(x)NiFe1.98O4 (x = 20–80 wt %) particulate nanocomposites. Appl. Phys. Lett. 2009, 94, 112902. [Google Scholar] [CrossRef]

- Ryu, J.; Carazo, A.V.; Uchino, K.; Kim, H.E. Piezoelectric and magnetoelectric properties of Lead Zirconate Titanate/Ni-Ferrite particulate composites. J. Electroceram. 2001, 7, 17–24. [Google Scholar] [CrossRef]

- Islam, R.A.; Viehland, D.; Priya, S. Doping effect on magnetoelectric coefficient of Pb(Zr052Ti0.48)O3–Ni(1−x)ZnxFe2O4 particulate. J. Mater. Sci. 2008, 43, 1497–1500. [Google Scholar] [CrossRef]

- Yang, S.-C.; Kumar, A.; Petkov, V.; Priya, S. Room-temperature magnetoelectric coupling in single-phase BaTiO3-BiFeO3 system. J. Appl. Phys. 2013, 113, 144101. [Google Scholar] [CrossRef]

- Shovon, O.G.; Rahaman, M.D.; Tahsin, S.; Hossain, A.K.M.A. Synthesis and characterization of (100-x) Ba0.82Sr0.03Ca0.15Zr0.10Ti0.90O3 + (x) Mg0.25Cu0.25Zn0.5Mn0.05Fe1.95O4 composites with improved magnetoelectric voltage coefficient. J. Alloy. Compd. 2018, 735, 291–311. [Google Scholar] [CrossRef]

- Allaedini, G.; Tasirin, S.M.; Aminayi, P. Magnetic properties of cobalt ferrite synthesized by hydrothermal method. Int. Nano Lett. 2015, 5, 183–186. [Google Scholar] [CrossRef] [Green Version]

- Ben Ali, M.; El Maalam, K.; El Moussaoui, H.; Mounkachi, O.; Hamedoun, M.; Masrour, R.; Hlil, E.K.; Benyoussef, A. Effect of zinc concentration on the structural and magnetic properties of mixed Co–Zn ferrites nanoparticles synthesized by sol/gel method. J. Magn. Magn. Mater. 2016, 398, 20–25. [Google Scholar] [CrossRef]

- Ansari, S.M.; Sinha, B.B.; Pai, K.R.; Bhat, S.K.; Ma, Y.-R.; Sen, D.; Kolekar, Y.D.; Ramana, C.V. Controlled surface/interface structure and spin enabled superior properties and biocompatibility of cobalt ferrite nanoparticles. Appl. Surf. Sci. 2018, 459, 788–801. [Google Scholar] [CrossRef]

- Köseoğlu, Y.; Baykal, A.; Gözüak, F.; Kavas, H. Structural and magnetic properties of CoxZn1−xFe2O4 nanocrystals synthesized by microwave method. Polyhedron 2009, 28, 2887–2892. [Google Scholar] [CrossRef]

- Vaidyanathan, G.; Sendhilnathan, S. Characterization of Co1−xZnxFe2O4 nanoparticles synthesized by co-precipitation method. Phys. B 2008, 403, 2157–2167. [Google Scholar] [CrossRef]

- Anjum, S.; Khurram, R.; Bashir, F.; Nazli, H. Fabrication and Investigation of Structural, Magnetic and Dielectrical Properties of Zn Substituted Co-ferrites. Mater. Today Proc. 2015, 2, 5515–5521. [Google Scholar] [CrossRef]

- Praveena, K.; Sadhana, K.; Liu, H.-L.; Murthy, S.R. Effect of Zn substitution on structural, dielectric and magnetic properties of nanocrystalline Co1−xZnxFe2O4 for potential high density recording media. J. Mater. Sci.-Mater. Electron. 2016, 27, 12680–12690. [Google Scholar] [CrossRef]

- Bill, A.; Braun, H.B. Magnetic properties of exchange springs. J. Magn. Magn. Mater. 2004, 272–276, 1266–1267. [Google Scholar] [CrossRef]

- Chithra, M.; Anumol, C.N.; Sahu, B.; Sahoo, S.C. Exchange spring like magnetic behavior in cobalt ferrite nanoparticles. J. Magn. Magn. Mater. 2016, 401, 1–8. [Google Scholar] [CrossRef]

- Lavorato, G.; Winkler, E.; Rivas-Murias, B.; Rivadulla, F. Thickness dependence of exchange coupling in epitaxial Fe3O4/CoFe2O4soft/ard magnetic bilayers. Phys. Rev. B 2016, 94, 054405. [Google Scholar] [CrossRef]

| Magnetostrictive Powders | Zn Ratio | Saturation Magnetization | Remanant Magnetization | Coercive Field | Magnetic Susceptibility |

|---|---|---|---|---|---|

| Ms (emu/g) | Mr (emu/g) | Hc (Oe) | χmax (emu/g·Oe) | ||

| CFO | Zn = 0 | 74.5 ± 0.75 | 16.8 ± 0.17 | 366.2 ± 3.66 | 0.05 |

| pCZFO | Zn = 0.1 | 77.1 ± 0.77 | 18.5 ± 0.19 | 101.6 ± 1.02 | 0.22 |

| Zn = 0.2 | 75.9 ± 0.76 | 0.5 ± 0.01 | 2.4 ± 0.02 | 0.42 | |

| dCZFO | Zn = 0.1 | 86.3 ± 0.86 | 9.3 ± 0.09 | 36.2 ± 0.36 | 0.34 |

| Zn = 0.2 | 82.6 ± 0.83 | 2.3 ± 0.02 | 10.8 ± 0.11 | 0.35 |

| Magnetoelectric Composites | Zn Ratio | Optimal Magnetic Field | Magnetoelectric Voltage |

|---|---|---|---|

| Hopt. (Oe) | αME (μV/cm·Oe) | ||

| CFO-NKNLS | Zn = 0 | 966 | 140 ± 21.0 |

| pCZFO-NKNLS | Zn = 0.1 | 689 | 130 ± 19.5 |

| Zn = 0.2 | 828 | 179 ± 26.9 | |

| dCZFO-NKNLS | Zn = 0.1 | 481 | 228 ± 34.2 |

| Zn = 0.2 | 458 | 184 ± 27.6 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Choi, M.H.; Ko, K.; Yang, S.C. Structural Effects of Magnetostrictive Materials on the Magnetoelectric Response of Particulate CZFO/NKNLS Composites. Materials 2019, 12, 1053. https://doi.org/10.3390/ma12071053

Choi MH, Ko K, Yang SC. Structural Effects of Magnetostrictive Materials on the Magnetoelectric Response of Particulate CZFO/NKNLS Composites. Materials. 2019; 12(7):1053. https://doi.org/10.3390/ma12071053

Chicago/Turabian StyleChoi, Moon Hyeok, Kyujin Ko, and Su Chul Yang. 2019. "Structural Effects of Magnetostrictive Materials on the Magnetoelectric Response of Particulate CZFO/NKNLS Composites" Materials 12, no. 7: 1053. https://doi.org/10.3390/ma12071053