Correlation between the Microstructures of Bonding Interfaces and the Shear Strength of Cu-to-Cu Joints Using (111)-Oriented and Nanotwinned Cu

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussions

3.1. Grain Growth Evolution for Different Bonding Temperatures

3.2. Bonded Interfaces Characterization

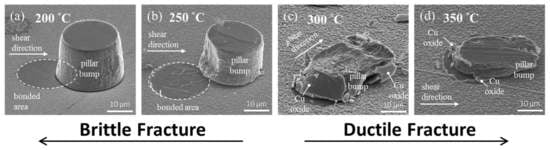

3.3. Shear Strength and Fracture Mode of the Bonded Cu Joints

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Gösele, U.; Tong, Q.Y.; Schumacher, A.; Kräuter, G.; Reiche, M.; Plößl, A.; Kopperschmidt, P.; Lee, T.H.; Kim, W.J. Wafer bonding for microsystems technologies. Sens. Actuators A Phys. 1999, 74, 161–168. [Google Scholar] [CrossRef] [Green Version]

- Tong, Q.-Y.; Gösele, U.M. Wafer Bonding and Layer Splitting for Microsystems. Adv. Mater. 1999, 11, 1409–1425. [Google Scholar] [CrossRef]

- Suga, T.; Yuuki, F.; Hosoda, N. A New Approach to Cu-cu Direct Bump Bonding. In Proceedings of the IEMT/IMC Symposium, 1st Joint International Electronic Manufacturing Symposium and the International Microelectronics Conference, Tokyo, Japan, 16–18 April 1997; IEEE: Middlesex, NJ, USA, 1997; pp. 146–151. [Google Scholar]

- Suga, T.; Itoh, T.; Xu, Z.; Tomita, M.; Yamauchi, A. Surface activated bonding for new flip chip and bumpless interconnect systems. In Proceedings of the 52nd Electronic Components and Technology Conference 2002. (Cat. No. 02CH37345), San Diego, CA, USA, 28–31 May 2002; IEEE: Middlesex, NJ, USA, 2002; pp. 105–111. [Google Scholar] [CrossRef]

- Knickerbocker, J.U.; Andry, P.S.; Dang, B.; Horton, R.R.; Interrante, M.J.; Patel, C.S.; Polastre, R.J.; Sakuma, K.; Sirdeshmukh, R.; Sprogis, E.J.; et al. Three-dimensional silicon integration. IBM J. Res. Dev. 2008, 52, 553–569. [Google Scholar] [CrossRef]

- Juang, J.-Y.; Lu, S.-T.; Zhan, C.-J.; Chung, S.-C.; Fan, C.-W.; Peng, J.-S.; Chen, T.-H. Development of 30 μm pitch Cu/Ni/SnAg micro-bump-bonded chip-on-chip (COC) interconnects. In Proceedings of the 2010 5th International Microsystems Packaging Assembly and Circuits Technology Conference, Taipei, Taiwan, 20–22 October 2010; IEEE: Middlesex, NJ, USA, 2010; pp. 1–4. [Google Scholar]

- Lu, S.-T.; Juang, J.-Y.; Cheng, H.-C.; Tsai, Y.-M.; Chen, T.-H.; Chen, W.-H. Effects of Bonding Parameters on the Reliability of Fine-Pitch Cu/Ni/SnAg Micro-Bump Chip-to-Chip Interconnection for Three-Dimensional Chip Stacking. IEEE Trans. Device Mater. Reliab. 2012, 12, 296–305. [Google Scholar] [CrossRef]

- Juang, J.-Y.; Huang, S.-Y.; Zhan, C.-J.; Lin, Y.-M.; Huang, Y.-W.; Fan, C.-W.; Chung, S.-C.; Chen, S.-M.; Peng, J.-S.; Lu, Y.-L.; et al. Effect of metal finishing fabricated by electro and Electroless plating process on reliability performance of 30μm-pitch solder micro bump interconnection. In Proceedings of the 2013 IEEE 63rd Electronic Components and Technology Conference, Las Vegas, NV, USA, 28–31 May 2013; IEEE: Middlesex, NJ, USA, 2013; pp. 653–659. [Google Scholar]

- Chang, Y.-W.; Hu, C.; Peng, H.-Y.; Liang, Y.-C.; Chen, C.; Chang, T.; Zhan, C.-J.; Juang, J.-Y. A new failure mechanism of electromigration by surface diffusion of Sn on Ni and Cu metallization in microbumps. Sci. Rep. 2018, 8, 5935. [Google Scholar] [CrossRef] [PubMed]

- Pan, Q.; Zhou, H.; Lu, Q.; Gao, H.; Lu, L. History-independent cyclic response of nanotwinned metals. Nature 2017, 551, 214. [Google Scholar] [CrossRef] [PubMed]

- Lu, K.; Lu, L.; Suresh, S. Strengthening Materials by Engineering Coherent Internal Boundaries at the Nanoscale. Science 2009, 324, 349–352. [Google Scholar] [CrossRef] [PubMed]

- Qin, E.W.; Lu, L.; Tao, N.R.; Lu, K. Enhanced fracture toughness of bulk nanocrystalline Cu with embedded nanoscale twins. Scr. Mater. 2009, 60, 539–542. [Google Scholar] [CrossRef]

- Suganuma, K. Advances in lead-free electronics soldering. Curr. Opin. Solid State Mater. Sci. 2001, 5, 55–64. [Google Scholar] [CrossRef]

- Chen, Y.J.; Chung, C.K.; Yang, C.R.; Kao, C.R. Single-joint shear strength of micro Cu pillar solder bumps with different amounts of intermetallics. Microelectron. Reliab. 2013, 53, 47–52. [Google Scholar] [CrossRef]

- Hu, X.; Li, Y.; Liu, Y.; Liu, Y.; Min, Z. Microstructure and shear strength of Sn37Pb/Cu solder joints subjected to isothermal aging. Microelectron. Reliab. 2014, 54, 1575–1582. [Google Scholar] [CrossRef]

- Zhao, Q.; Hu, A.; Li, M.; Sun, J. Effect of electroplating layer structure on shear property and microstructure of multilayer electroplated Sn–3.5Ag solder bumps. Microelectron. Reliab. 2013, 53, 321–326. [Google Scholar] [CrossRef]

- Liu, C.M.; Lin, H.W.; Chu, Y.C.; Chen, C.; Lyu, D.R.; Chen, K.N.; Tu, K.N. Low-temperature direct copper-to-copper bonding enabled by creep on highly (111)-oriented Cu surfaces. Scr. Mater. 2014, 78–79, 65–68. [Google Scholar] [CrossRef]

- Liu, C.-M.; Lin, H.-W.; Huang, Y.-S.; Chu, Y.-C.; Chen, C.; Lyu, D.-R.; Chen, K.-N.; Tu, K.-N. Low-temperature direct copper-to-copper bonding enabled by creep on (111) surfaces of nanotwinned Cu. Sci. Rep. 2015, 5, 9734. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chen, C.; Liu, C.-M.; Lin, H.; Huang, Y.-S.; Chu, Y.-C.; Lyu, D.-R.; Chen, K.-N.; Tu, K.N. Low-temperature and low-pressure direct copper-to-copper bonding by highly (111)-oriented nanotwinned Cu. In Proceedings of the 2016 Pan Pacific Microelectronics Symposium (Pan Pacific), Big Island, HI, USA, 25–28 January 2016; IEEE: Middlesex, NJ, USA, 2016; pp. 1–5. [Google Scholar]

- Hsiao, H.-Y.; Liu, C.-M.; Lin, H.-W.; Liu, T.-C.; Lu, C.-L.; Huang, Y.-S.; Chen, C.; Tu, K.N. Unidirectional Growth of Microbumps on (111)-Oriented and Nanotwinned Copper. Science 2012, 336, 1007–1010. [Google Scholar] [CrossRef] [PubMed]

- Juang, J.-Y.; Lu, C.-L.; Chen, K.-J.; Chen, C.-C. A.; Hsu, P.-N.; Chen, C.; Tu, K.N. Copper-to-copper direct bonding on highly (111)-oriented nanotwinned copper in no-vacuum ambient. Sci. Rep. 2018, 8, 13910. [Google Scholar] [CrossRef] [PubMed]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Juang, J.-Y.; Lu, C.-L.; Li, Y.-J.; Tu, K.N.; Chen, C. Correlation between the Microstructures of Bonding Interfaces and the Shear Strength of Cu-to-Cu Joints Using (111)-Oriented and Nanotwinned Cu. Materials 2018, 11, 2368. https://doi.org/10.3390/ma11122368

Juang J-Y, Lu C-L, Li Y-J, Tu KN, Chen C. Correlation between the Microstructures of Bonding Interfaces and the Shear Strength of Cu-to-Cu Joints Using (111)-Oriented and Nanotwinned Cu. Materials. 2018; 11(12):2368. https://doi.org/10.3390/ma11122368

Chicago/Turabian StyleJuang, Jing-Ye, Chia-Ling Lu, Yu-Jin Li, K. N. Tu, and Chih Chen. 2018. "Correlation between the Microstructures of Bonding Interfaces and the Shear Strength of Cu-to-Cu Joints Using (111)-Oriented and Nanotwinned Cu" Materials 11, no. 12: 2368. https://doi.org/10.3390/ma11122368