Tapioca Dextrin as an Alternative Carrier in the Spray Drying of Fruit Juices—A Case Study of Chokeberry Powder

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Spray Drying

2.3. Particle Size Distribution

2.4. Microstructure of Particles

2.5. Bulk Density, Flowability and Moisture Content

2.6. Apparent Particle Density and Bulk Porosity Powder Bed

2.7. Powder Yield

- mp, mf—mass of powder and feed solution; kgp, kgf, respectively;

- wdmp, wdmf—dry matter content in the powder and feed solution; kgdmp/kgp, kgdmf/kgf, respectively.

2.8. Total Polyphenol Content (TPC)

2.9. Antioxidant Capacity

2.10. Statistical Analysis

3. Results and Discussion

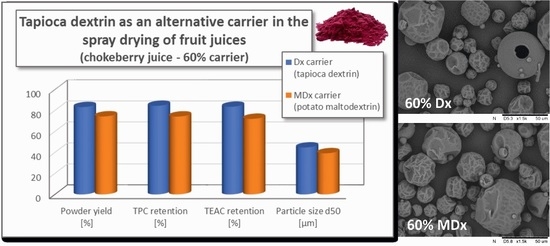

3.1. Particle Size

3.2. Microstructure of Powder Particles

3.3. Bulk Density, Flowability and Moisture Content

3.4. Apparent Particle Density and Bulk Porosity Powder Bed

3.5. Powder Yield

3.6. Total Polyphenol Content (TPC)

3.7. Antioxidant Capacity

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Przybył, K.; Gawałek, J.; Koszela, K. Application of artificial neural network for the quality-based classification of spray-dried rhubarb juice powders. J. Food Sci. Technol. 2020, 1–11. [Google Scholar] [CrossRef]

- FAO. The Future of Food and Agriculture—Trends and Challenges; Food and Agriculture Organization of the United Nations (FAO): Rome, Italy, 2017. [Google Scholar]

- Przybył, K.; Gawałek, J.; Koszela, K.; Przybył, J.; Rudzińska, M.; Gierz, Ł.; Domian, E. Neural Image Analysis and Electron Microscopy to Detect and Describe Selected Quality Factors of Fruit and Vegetable Spray-Dried Powders-Case Study: Chokeberry Powder. Sensors 2019, 19, 4413. [Google Scholar] [CrossRef] [Green Version]

- Hellström, J.K.; Shikov, A.N.; Makarova, M.N.; Pihlanto, A.M.; Pozharitskaya, O.N.; Ryhänen, E.-L.; Kivijärvi, P.; Makarov, V.G.; Mattila, P. Blood pressure-lowering properties of chokeberry (Aronia mitchurinii, var. Viking). J. Funct. Foods 2010, 2, 163–169. [Google Scholar] [CrossRef]

- Bermúdez-Soto, M.J.; Larrosa, M.; García-Cantalejo, J.M.; Espín, J.C.; Tomás-Barberán, F.A.; García-Conesa, M.T. Up-regulation of tumor suppressor carcinoembryonic antigen-related cell adhesion molecule 1 in human colon cancer Caco-2 cells following repetitive exposure to dietary levels of a polyphenol-rich chokeberry juice. J. Nutr. Biochem. 2007, 18, 259–271. [Google Scholar] [CrossRef] [PubMed]

- Valcheva-Kuzmanova, S.V.; Belcheva, A. Current knowledge of Aronia melanocarpa as a medicinal plant. Folia Medica 2006, 48, 11–17. [Google Scholar]

- Wawer, I. The Power of Nature. Aronia Melanocarpa, Mae’s Health and Wellness; LCC: Omaha, NE, USA, 2010. [Google Scholar]

- Kalt, W.; Hanneken, A.M.; Milbury, P.; Tremblay, F. Recent Research on Polyphenolics in Vision and Eye Health. J. Agric. Food Chem. 2010, 58, 4001–4007. [Google Scholar] [CrossRef]

- Kim, J.; Hwang, J.-S.; Cho, Y.-K.; Han, Y.; Jeon, Y.-J.; Yang, K.H. Protective Effects of (–)-Epigallocatechin-3-Gallate on UVA- and UVB-Induced Skin Damage. Ski. Pharmacol. Physiol. 2001, 14, 11–19. [Google Scholar] [CrossRef]

- Benvenuti, S.; Pellati, F.; Melegari, M.; Bertelli, D. Polyphenols, Anthocyanins, Ascorbic Acid, and Radical Scavenging Activity of Rubus, Ribes, and Aronia. J. Food Sci. 2006, 69, FCT164–FCT169. [Google Scholar] [CrossRef]

- Oszmiański, J.; Wojdyło, A. Aronia melanocarpa phenolics and their antioxidant activity. Eur. Food Res. Technol. 2005, 221, 809–813. [Google Scholar] [CrossRef]

- Jakobek, L.; Drenjančević, M.; Jukić, V.; Šeruga, M. Phenolic acids, flavonols, anthocyanins and antiradical activity of “Nero”, “Viking”, “Galicianka” and wild chokeberries. Sci. Hortic. 2012, 147, 56–63. [Google Scholar] [CrossRef]

- Šnebergrová, J.; Čížková, H.; Neradová, E.; Kapci, B.; Rajchl, A.; Voldrich, M. Variability of characteristic components of aronia. Czech J. Food Sci. 2014, 32, 25–30. [Google Scholar] [CrossRef] [Green Version]

- Jiang, H.; Zhang, M.; Adhikari, B. Fruit and vegetable powders. In Handbook of Food Powders: Processes and Properties; Woodhead Publishing: Cambridge, UK, 2013; pp. 532–552. [Google Scholar]

- Muzaffar, K.; Nayik, G.A.; Kumar, P. Production of Fruit Juice Powders by Spray Drying Technology. IJARSE 2018, 7, 59–67. [Google Scholar]

- Bhandari, B.; Datta, N.; Crooks, R.; Howes, T.; Rigby, S. A semi-empirical approach to optimise the quantity of drying aids required to spray dry sugar-rich foods. Dry. Technol. 1997, 15, 2509–2525. [Google Scholar] [CrossRef]

- Bhandari, B.; Senoussi, A.; Dumoulin, E.; Lebert, A. Spray drying of concentrated fruit juices. Dry. Technol. 1993, 11, 1081–1092. [Google Scholar] [CrossRef]

- Murugesan, R.; Orsat, V. Spray Drying for the Production of Nutraceutical Ingredients—A Review. Food Bioprocess Technol. 2011, 5, 3–14. [Google Scholar] [CrossRef]

- Moreno, T.; De Paz, E.; Navarro, I.; Rodriguez-Rojo, S.; Matias, A.A.; Duarte, C.M.M.; Sanz-Buenhombre, M.; Cocero, M. Spray Drying Formulation of Polyphenols-Rich Grape Marc Extract: Evaluation of Operating Conditions and Different Natural Carriers. Food Bioprocess Technol. 2016, 9, 2046–2058. [Google Scholar] [CrossRef]

- Bakar, J.; Ee, S.C.; Muhammad, K.; Hashim, D.M.; Adzahan, N. Spray-Drying Optimization for Red Pitaya Peel (Hylocereus polyrhizus). Food Bioprocess Technol. 2012, 6, 1332–1342. [Google Scholar] [CrossRef]

- Samantha, S.C.; Bruna, A.S.M.; Adriana, R.M.; Fabio, B.; Sandro, A.R.; Aline, R.C.A.; Costa, S.S.; Machado, B.A.S.; Martin, A.R.; Bagnara, F.; et al. Drying by spray drying in the food industry: Micro-encapsulation, process parameters and main carriers used. Afr. J. Food Sci. 2015, 9, 462–470. [Google Scholar] [CrossRef] [Green Version]

- Gharsallaoui, A.; Roudaut, G.; Chambin, O.; Voilley, A.; Saurel, R. Applications of spray-drying in microencapsulation of food ingredients: An overview. Food Res. Int. 2007, 40, 1107–1121. [Google Scholar] [CrossRef]

- Woo, M.; Bhandari, B. Spray drying for food powder production. In Handbook of Food Powders; Woodhead Publishing Limited: Cambridge, UK, 2013; pp. 29–56. [Google Scholar]

- Villacrez, J.L.; Carriazo, J.G.; Osorio, C. Microencapsulation of Andes Berry (Rubus glaucus Benth.) Aqueous Extract by Spray Drying. Food Bioprocess Technol. 2013, 7, 1445–1456. [Google Scholar] [CrossRef]

- Silva, D.M.; Nunes, C.; Pereira, I.; Moreira, A.S.; Domingues, M.R.M.; Coimbra, M.A.; Gama, M.; Gama, M. Structural analysis of dextrins and characterization of dextrin-based biomedical hydrogels. Carbohydr. Polym. 2014, 114, 458–466. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bhandari, B.R.; Hartel, W. Phase transition Turing food powder production and powder stability. In Encapsulated and Powdered Foods; Onwulata, C., Ed.; Taylor & Francis Group: Boca Raton, FL, USA, 2005; pp. 261–292. [Google Scholar]

- Bhandari, B.R. Stickiness and Caking in Food Preservation. In Handbook of Food Preservation; Rahman, M.S., Ed.; Taylor & Francis: New York, NY, USA, 2007; pp. 387–401. [Google Scholar]

- Ortega-Rivas, E. Handling and Processing of Food Powders and Particulates. In Encapsulated and Powdered Foods; Taylor & Francis Group: Boca Raton, FL, USA, 2005; pp. 75–144. [Google Scholar]

- Yousefi, S.; Emam-Djomeh, Z.; Mousavi, M. Effect of carrier type and spray drying on the physicochemical properties of powdered and reconstituted pomegranate juice (Punica Granatum L.). J. Food Sci. Technol. 2010, 48, 677–684. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wesołowski, P.; Gawałek, J. Comparison of the energy consumption on the production of highly concentrated maltodextrin concentrates. Pol. J. Chem. Technol. 2006, 8, 47–49. [Google Scholar]

- De Jong, J.A.; Hoffmann, A.C.; Finkers, H.J. Properly determine powder flowability to maximie plant output. Chem. Eng. Progr. 1999, 95, 25–34. [Google Scholar]

- Gawałek, J.; Domian, E.; Ryniecki, A.; Bakier, S. Effects of the spray drying conditions of chokeberry (Aronia melanocarpaL.) juice concentrate on the physicochemical properties of powders. Int. J. Food Sci. Technol. 2017, 52, 1933–1941. [Google Scholar] [CrossRef]

- Re, R.; Pellegrini, N.; Proteggente, A.; Pannala, A.; Yang, M.; Rice-Evans, C. Antioxidant activity applying an improved ABTS radical cation decolorization assay. Free Radic. Biol. Med. 1999, 26, 1231–1237. [Google Scholar] [CrossRef]

- Barbosa-Cánovas, G.; Ortega-Rivas, E.; Juliano, P.; Yan, H. Food Powders: Physical Properties, Processing, and Functionality; Kluwer Academic Publishers: New York, NY, USA; Plenum Publishers: New York, NY, USA, 2005. [Google Scholar]

- Phisut, N. Spray drying technique of fruit juice powder: Some factors influencing the properties of product. Int. Food Res. J. 2014, 19, 1297–1306. [Google Scholar]

- Bednarska, M.A.; Janiszewska-Turak, E. The influence of spray drying parameters and carrier material on the physico-chemical properties and quality of chokeberry juice powder. J. Food Sci. Technol. 2019, 57, 564–577. [Google Scholar] [CrossRef] [Green Version]

- Tonon, V.R.; Brabet, C.; Hubinger, M. Spray drying of acai juice: Effect of inlet temperature and type of carrier agent. J. Food Process. Pres. 2011, 5, 691–700. [Google Scholar] [CrossRef]

- Santhalakshmy, S.; Bosco, S.J.D.; Francis, S.; Sabeena, M. Effect of inlet temperature on physicochemical properties of spray-dried jamun fruit juice powder. Powder Technol. 2015, 274, 37–43. [Google Scholar] [CrossRef]

- Shishir, M.R.I.; Taip, F.; Aziz, N.A.; Talib, R.; Sarker, S.H. Optimization of spray drying parameters for pink guava powder using RSM. Food Sci. Biotechnol. 2016, 25, 461–468. [Google Scholar] [CrossRef] [PubMed]

- Muzaffar, K.; Kumar, P. Spray Drying of Tamarind Pulp: Effect of Process Parameters Using Protein as Carrier Agent. J. Food Process. Preserv. 2016, 41, 1–10. [Google Scholar] [CrossRef]

- Chegini, G.R.; Ghobadian, B. Effect of Spray-Drying Conditions on Physical Properties of Orange Juice Powder. Dry. Technol. 2005, 23, 657–668. [Google Scholar] [CrossRef]

- Shishir, M.R.I.; Chen, W. Trends of spray drying: A critical review on drying of fruit and vegetable juices. Trends Food Sci. Technol. 2017, 65, 49–67. [Google Scholar] [CrossRef]

- Li, Y.; Tang, B.; Chen, J.; Lai, P. Microencapsulation of plum (Prunus salicina Lindl.) phenolics by spray drying technology and storage stability. Food Sci. Technol. 2017, 38, 530–536. [Google Scholar] [CrossRef] [Green Version]

- Mishra, P.; Brahma, A.; Seth, D. Physicochemical, functionality and storage stability of hog plum (Spondia pinnata) juice powder produced by spray drying. J. Food Sci. Technol. 2017, 54, 1052–1061. [Google Scholar] [CrossRef] [Green Version]

- Moghaddam, A.D.; Pero, M.; Askari, G.R. Optimizing spray drying conditions of sour cherry juice based on physicochemical properties, using response surface methodology (RSM). J. Food Sci. Technol. 2017, 54, 174–184. [Google Scholar] [CrossRef] [Green Version]

- Domian, E.; Brynda-Kopytowska, A.; Cenkier, J.; Świrydow, E. Selected properties of microencapsulated oil powders with commercial preparations of maize OSA starch and trehalose. J. Food Eng. 2015, 152, 72–84. [Google Scholar] [CrossRef]

- Westergaard, V. Milk Powder Technology—Evaporation and Spray Dryer; GEA: Kopenhagen, Denmark, 2004. [Google Scholar]

- Schubert, H. Food particle technology. Part I: Properties of particles and particulate food systems. J. Food Eng. 1987, 6, 1–32. [Google Scholar] [CrossRef]

- Fazaeli, M.; Emam-Djomeh, Z.; Ashtari, A.K.; Omid, M. Effect of spray drying conditions and feed composition on the physical properties of black mulberry juice powder. Food Bioprod. Process. 2012, 90, 667–675. [Google Scholar] [CrossRef]

- Goula, A.M.; Adamopoulos, K.G. A new technique for spray drying orange juice concentrate. Innov. Food Sci. Emerg. Technol. 2010, 11, 342–351. [Google Scholar] [CrossRef]

- Sharifi, A.; Niakousari, M.; Maskooki, A.; Mortazavi, S.A. Effect of spray drying conditions on the physicochemical properties of barberry (Berberis vulgaris) extract powder. Int. Food Res. J. 2015, 22, 2364–2370. [Google Scholar]

- Zareifard, M.R.; Niakousari, M.; Shokrollahi, Z.; Javadian, S. A Feasibility Study on the Drying of Lime Juice: The Relationship between the Key Operating Parameters of a Small Laboratory Spray Dryer and Product Quality. Food Bioprocess Technol. 2011, 5, 1896–1906. [Google Scholar] [CrossRef]

- Patil, V.; Chauhan, A.K.; Singh, S.P. Influence of Spray Drying Technology on the Physical and Nutritional Properties of Guava Powder. IJCMAS 2014, 3, 1224–1237. [Google Scholar]

- Hayes, G.D. Food Engineering Data Handbook; John Wiley & Sons: New York, NY, USA, 1987. [Google Scholar]

- Domian, E.; Sułek, A.; Cenkier, J.; Kerschke, A. Influence of agglomeration on physical characteristics and oxidative stability of spray-dried oil powder with milk protein and trehalose wall material. J. Food Eng. 2014, 125, 34–43. [Google Scholar] [CrossRef]

- Soottitantawat, A.; Peigney, J.; Uekaji, Y.; Yoshii, H.; Furuta, T.; Ohgawara, M.; Linko, P. Structural analysis of spray-dried powders by confocal laser scanning microscopy. Asia-Pac. J. Chem. Eng. 2007, 2, 41–46. [Google Scholar] [CrossRef]

- Moreira, G.; Éder, G.; Costa, M.G.M.; De Souza, A.C.R.; De Brito, E.S.; Medeiros, M.D.F.D.D.; Azeredo, H.M.C. Physical properties of spray dried acerola pomace extract as affected by temperature and drying aids. LWT 2009, 42, 641–645. [Google Scholar] [CrossRef] [Green Version]

- Vardin, H.; Yasar, M. Optimisation of pomegranate (Punica Granatum L.) juice spray-drying as affected by temperature and maltodextrin content. Int. J. Food Sci. Technol. 2011, 47, 167–176. [Google Scholar] [CrossRef]

- Troya, D.; Tupuna-Yerovi, D.S.; Ruales, J. Effects of Wall Materials and Operating Parameters on Physicochemical Properties, Process Efficiency, and Total Carotenoid Content of Microencapsulated Banana Passionfruit Pulp (Passiflora tripartite var. mollissima) by Spray-Drying. Food Bioprocess Technol. 2018, 11, 1828–1839. [Google Scholar] [CrossRef]

- Chegini, G.R.; Ghobadian, B. Spray Dryer Parameters for Fruit Juice Drying. World J. Agric. Sci. 2007, 3, 230–236. [Google Scholar]

- Konczak, I.; Zhang, W. Anthocyanins—More than nature’s colours. J. Biomed. Biotechnol. 2004, 5, 239–240. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sójka, M.; Kołodziejczyk, K.; Milala, J. Polyphenolic and basic chemical composition of black chokeberry industrial by-products. Ind. Crop. Prod. 2013, 51, 77–86. [Google Scholar] [CrossRef]

- Ramírez, M.J.; Giraldo, G.I.; Orrego, C. Modeling and stability of polyphenol in spray-dried and freeze-dried fruit encapsulates. Powder Technol. 2015, 277, 89–96. [Google Scholar] [CrossRef]

- Nambiar, R.B.; Perumal, A.B.; Sellamuthu, P.S. Microencapsulation of Tender Coconut Water by Spray Drying: Effect of Moringa oleifera Gum, Maltodextrin Concentrations, and Inlet Temperature on Powder Qualities. Food Bioprocess Technol. 2017, 10, 1668–1684. [Google Scholar] [CrossRef]

- Silva, P.I.; Stringheta, P.C.; Teófilo, R.F.; Oliveira, I. Parameter optimization for spray-drying microencapsulation of jaboticaba (Myrciaria jaboticaba) peel extracts using simultaneous analysis of responses. J. Food Eng. 2013, 117, 538–544. [Google Scholar] [CrossRef] [Green Version]

| Drying Conditions/Carrier Type and Content | D10 (μm) | D50 (μm) | D90 (μm) | Span |

|---|---|---|---|---|

| Dx, T = 150 °C | 16.3 ± 0.5 a | 39.6 ± 0.8 a | 64.5 ± 1.9 a | 1.22 ± 0.01 a |

| Dx, T = 160 °C | 15.7 ± 0.7 a | 41.7 ± 1.4 a | 69.3 ± 2.5 a | 1.29 ± 0.00 b |

| Dx, T = 170 °C | 18.6 ± 0.9 b | 48.4 ± 1.1 b | 81.5 ± 2.9 b | 1.30 ± 0.01 b |

| Dx, n = 12,000 rpm | 15.7 ± 0.7 a | 41.7 ± 1.4 a | 69.3 ± 2.5 a | 1.30 ± 0.00 b |

| Dx, n = 13,500 rpm | 15.8 ± 0.4 a | 41.8 ± 0.5 a | 68.3 ± 1.3 a | 1.26 ± 0.01 a |

| Dx, n = 15,000 rpm | 14.9 ± 0.5 a | 40.2 ± 0.6 a | 65.9 ± 1.8 a | 1.27 ± 0.01 ab |

| 50% Dx | 19.4 ± 1.1 D | 49.4 ± 1.3 C | 81.6 ± 3.4 C | 1.26 ± 0.02 AB |

| 60% Dx | 15.7 ± 0.7 AB | 41.7 ± 1.4 AB | 69.3 ± 2.5 AB | 1.29 ± 0.00 BC |

| 70% Dx | 17.8 ± 0.5 CD | 47.9 ± 0.8 C | 78.6 ± 1.9 C | 1.28 ± 0.01 ABC |

| 50% MDx | 16.7 ± 0.7 BC | 43.8 ± 0.9 B | 71.6 ± 1.9 B | 1.25 ± 0.01 A |

| 60% MDx | 14.3 ± 0.3 A | 39.2 ± 0.6 A | 64.2 ± 1.7 A | 1.27 ± 0.02 ABC |

| 70% MDx | 14.9 ± 0.3 A | 41.9 ± 0.5 A | 69.3 ± 1.2 AB | 1.30 ± 0.01 C |

| Drying Conditions/Carrier Type and Content | ρL (kg/m3) | ρT100 (kg/m3) | ρT500 (kg/m3) | HR100 (-) | HR500 (-) | ρ (kg/m3) | εL (-) |

|---|---|---|---|---|---|---|---|

| Dx, T = 150 °C | 520.7 ± 3.8 a | 639.5 ± 4.1 a | 735.4 ± 3.4 a | 1.23 ± 0.01 b | 1.41 ± 0.02 b | 1325.2 ± 2.1a | 0.39 ± 0.00a |

| Dx, T = 160 °C | 546.2 ± 2.1 b | 662.8 ± 4.2 b | 756.3 ± 2.6 b | 1.21 ± 0.01 b | 1.38 ± 0.01 b | 1343.3 ± 0.4c | 0.41 ± 0.00b |

| Dx, T = 170 °C | 593.4 ± 2.3 c | 679.2 ± 2.7 c | 764.1 ± 1.7 c | 1.14 ± 0.02 a | 1.29 ± 0.01 a | 1333.8 ± 0.7b | 0.45 ± 0.00c |

| Dx, n = 12,000 rpm | 546.2 ± 2.1 b | 662.8 ± 4.2 b | 756.3 ± 2.6 b | 1.21 ± 0.01 a | 1.38 ± 0.01 ab | 1343.3 ± 0.4c | 0.41 ± 0.00a |

| Dx, n = 13,500 rpm | 522.9 ± 3.7 a | 641.1 ± 2.7 a | 737.8 ± 3.7 a | 1.23 ± 0.03 a | 1.41 ± 0.02 b | 1290.7 ± 0.4a | 0.41 ± 0.00a |

| Dx, n = 15,000 rpm | 545.2 ± 4.9 b | 648.2 ± 4.5 a | 738.4 ± 5.2 a | 1.19 ± 0.01 a | 1.35 ± 0.02 a | 1310.9 ± 1.0b | 0.42 ± 0.00b |

| 50% Dx | 549.2 ± 7.8 AB | 697.0 ± 9.8 C | 777.4 ± 7.5 C | 1.27 ± 0.02 C | 1.42 ± 0.03 B | 1357.0 ± 0.3D | 0.41 ± 0.01A |

| 60% Dx | 546.2 ± 2.1 AB | 662.8 ± 4.2 B | 756.3 ± 2.6 B | 1.21 ± 0.01 B | 1.38 ± 0.01 AB | 1343.3 ± 0.4C | 0.41 ± 0.00AB |

| 70% Dx | 551.4 ± 2.9 AB | 660.4 ± 2.9 B | 742.0 ± 2.9 A | 1.20 ± 0.01 B | 1.35 ± 0.01 A | 1312.3 ± 1.8A | 0.42 ± 0.00C |

| 50% MDx | 556.9 ± 5.5 B | 696.0 ± 5.0 C | 771.4 ± 6.2 AB | 1.25 ± 0.01 B | 1.39 ± 0.02 A | 1380.7 ± 1.3E | 0.40 ± 0.00A |

| 60% MDx | 552.7 ± 7.5 AB | 662.8 ± 2.8 B | 746.2 ± 2.9 AB | 1.20 ± 0.02 B | 1.35 ± 0.01 A | 1359.6 ± 2.4D | 0.40 ± 0.00A |

| 70% MDx | 541.7 ± 2.2 A | 598.8 ± 8.1 A | 738.5 ± 5.5 AB | 1.11 ± 0.01 A | 1.36 ± 0.01 AB | 1327.1 ± 1.1B | 0.42 ± 0.01BC |

| Drying Conditions/Carrier Type and Content | Y (%) | TPC in Solution before Drying (mg GA/100 g d.m.) | TPC in Powder (mg GA/100 g d.m.) | RTPC (%) | TEAC in Solution before Drying (mg TE/100 g d.m.) | TEAC in Powder (mg TE/100 g d.m.) | RTEAC (%) |

|---|---|---|---|---|---|---|---|

| Dx, T = 150 °C | 79.8 ± 1.9 a | 2080 | 2036 ± 17 c | 97.9 ± 0.8 c | 20.5 | 14.5 ± 0.5 b | 70.8 ± 2.4 b |

| Dx, T = 160 °C | 86.1 ± 2.6 ab | 2080 | 1756 ± 17 b | 84.4 ± 0.8 b | 20.5 | 17.1 ± 0.6 c | 83.5 ± 2.7 c |

| Dx, T = 170 °C | 88.9 ± 2.2 b | 2080 | 1643 ± 11 a | 79.0 ± 0.5 a | 20.5 | 10.1 ± 0.4 a | 49.3 ± 1.9 a |

| Dx, n = 12,000 rpm | 86.1 ± 2.6 a | 2080 | 1756 ± 17 a | 84.4 ± 0.8 a | 20.5 | 17.1 ± 0.6 a | 83.5 ± 2.7 a |

| Dx, n = 13,500 rpm | 84.8 ± 1.7 a | 2080 | 1826 ± 28 b | 87.8 ± 1.3 b | 20.5 | 19.2 ± 0.4 b | 94.1 ± 2.2 b |

| Dx, n = 15,000 rpm | 81.0 ± 2.0 a | 2080 | 2024 ± 7 c | 97.3 ± 0.3 c | 20.5 | 19.4 ± 0.3 b | 95.0 ± 1.5 b |

| 50% Dx | 35.3 ± 4.1 B | 2600 | 2014 ± 11 E | 77.5 ± 0.4 C | 25.6 | 15.5 ± 0.5 D | 60.6 ± 1.9 B |

| 60% Dx | 83.2 ± 1.9 D | 2080 | 1756 ± 17 C | 84.4 ± 0.8 D | 20.5 | 17.1 ± 0.6 E | 83.5 ± 2.7 D |

| 70% Dx | 95.3 ± 1.6 E | 1560 | 1549 ± 25 B | 99.3 ± 1.6 E | 15.3 | 13.3 ± 0.3 C | 86.9 ± 2.1 D |

| 50% MDx | 25.4 ± 3.9 A | 2600 | 1854 ± 14 D | 71.3 ± 0.5 A | 25.6 | 7.8 ± 0.3 A | 30.6 ± 1.1 A |

| 60% MDx | 74.3 ± 1.6 C | 2080 | 1543 ± 6 B | 74.2 ± 0.3 B | 20.5 | 14.7 ± 0.4 D | 72.0 ± 2.1 C |

| 70% MDx | 80.1 ± 2.7 CD | 1560 | 1309 ± 9 A | 83.9 ± 0.6 D | 15.3 | 11.6 ± 0.3 B | 75.5 ± 2.0 C |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gawałek, J.; Domian, E. Tapioca Dextrin as an Alternative Carrier in the Spray Drying of Fruit Juices—A Case Study of Chokeberry Powder. Foods 2020, 9, 1125. https://doi.org/10.3390/foods9081125

Gawałek J, Domian E. Tapioca Dextrin as an Alternative Carrier in the Spray Drying of Fruit Juices—A Case Study of Chokeberry Powder. Foods. 2020; 9(8):1125. https://doi.org/10.3390/foods9081125

Chicago/Turabian StyleGawałek, Jolanta, and Ewa Domian. 2020. "Tapioca Dextrin as an Alternative Carrier in the Spray Drying of Fruit Juices—A Case Study of Chokeberry Powder" Foods 9, no. 8: 1125. https://doi.org/10.3390/foods9081125