Economic Ripple Effects Analysis of Cross-Laminated Timber Manufacturing in Japan

Abstract

:1. Introduction

2. Methods

2.1. Target CLT Manufacturer

2.2. Evaluated Scopes and Processes

- Production value induced: the value of production generated by each industry to meet the final demand of an industry.

- Gross value added induced: the value newly generated by production activities and is part of production value induced.

- Employee income induced: the value of cash or in-kind income paid to employees and belongs to gross value added induced.

- Size of employment induced: the number of employees generated by each industry when the final demand is generated in an industry.

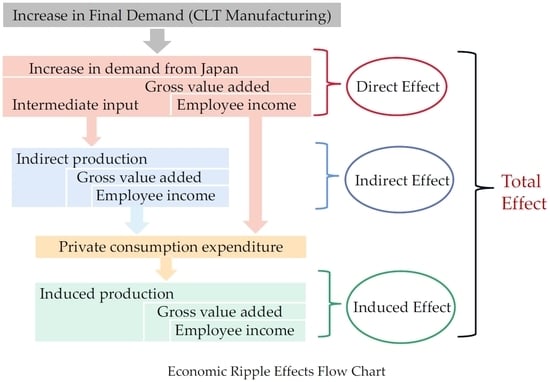

- Direct effect: increase in production in each industry generated by final demand.

- Indirect effect: the value of production generated by the direct effect.

- Induced effect: the value of production generated by the new consumption associated with the employees’ income generated by the direct and indirect effects.

- Ripple effect multiplier: the ratio of dividing the total ripple effect by the final demand increase.

2.3. New Sector

2.4. Revenue and Expenditure Data of CLT Manufacturing

2.5. Creating the Basic Transaction Table

2.6. Creating the Input Coefficient Table

2.7. Creating the Inverse Matrix Coefficient Table

2.8. Setting the Domestic Self-Sufficiency Ratio

2.9. Economic Ripple Effects

3. Results

3.1. Economic Ripple Effects of CLT Manufacturing and the GLT Sectors

3.2. Comparison after Unifying the Domestic Self-Sufficiency

4. Discussion

4.1. Comparison between the CLT Manufacturing and GLT Sectors

4.2. Domestic Self-Sufficiency Ratios and CLT Prices for CLT Manufacturing

4.3. Comparison with Previous Studies

5. Conclusions

- The total production ripple effect of the CLT manufacturing sector was JPY 2,304,651,000 (USD 20,050,464), with a production ripple multiplier of 2.49. The total production ripple effect of the GLT manufacturing sector was JPY 1,249,899,000 (USD 10,874,121), with a production ripple multiplier of 1.35. The results showed that CLT manufacturing had a significant economic impact on the timber and logs sectors.

- The employment ripple effect of the CLT manufacturing sector was 116.34 people, and the employment ripple multiplier was 3.53. In particular, the indirect effect of 63.82 people had the greatest impact on the employment of wood-related industries. CLT is still in the promotion stage in Japan, and the development of the CLT will contribute to the revitalization of forestry and wood-related industries.

- After unifying the logs, timber, and GLT sectors’ domestic self-sufficiency to 100%, the production ripple effect of the CLT manufacturing sector was still 4% higher than that of the GLT sector, indicating that the economic effects of CLT as a high-value-added material were underestimated. Therefore, it was necessary to consider adding the CLT manufacturing sector to the current input–output table to make it independent of the GLT sector. Moreover, we observed that domestic self-sufficiency had a significant economic effect in the CLT and GLT sectors; therefore, the focus should be on the domestic processing and manufacturing of the wood industry.

- If the price of CLT was reduced to 75,000 JPY/m3 (653 USD/m3) (half of the current price of 150,000 JPY/m3 (1305 USD/m3) while the manufacturing volume remained unchanged, the total production effect would be reduced by 63%. Therefore, while considering the reduction of CLT price, a corresponding manufacturing volume is required, but it is worth exploring whether manufacturing 500,000 m3 of CLT can achieve the maximum production effect under the trend of a decreasing growth rate of the total production effect.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Albee, R.R. Global Overview of the Cross-laminated Timber Industry. Master’s Thesis, Oregon State University, Corvallis, OR, USA, 2019. [Google Scholar]

- Brandner, R.; Flatscher, G.; Ringhofer, A.; Schickhofer, G.; Thiel, A. Cross laminated timber (CLT): Overview and development. Eur. J. Wood Wood Prod. 2016, 74, 331–351. [Google Scholar] [CrossRef]

- Espinoza, O.; Buehlmann, U. Cross-laminated timber in the USA: Opportunity for hardwoods? Curr. For. Rep. 2018, 4, 1–12. [Google Scholar] [CrossRef]

- Muszynski, L.; Hansen, E.; Fernando, S.; Schwarzman, G.; Rainer, J. Insights into the global cross-laminated timber industry. BioProd. Bus. 2017, 22, 77–92. [Google Scholar]

- Muszynski, L.; Larasatie, P.; Guerrero, J.E.; Albe, R.; Hansen, E.N. Global CLT industry in 2020: Growth beyond the Alpine Region. In Proceedings of the 63rd International Convention of Society of Wood Science and Technology, Virtual Conference, 12–17 July 2020. [Google Scholar]

- Forest Products Annual Market Review 2020–2021; Food and Agriculture Organization of the United Nations: Rome, Italy, 2021; p. 70.

- Trends in Forests and Forestry in FY2020. 2021. Available online: https://www.rinya.maff.go.jp/j/kikaku/hakusyo/R2hakusyo/attach/pdf/zenbun-64.pdf (accessed on 1 June 2021).

- Supply and Demand Table of Wood in 2020. 2021. Available online: https://www.rinya.maff.go.jp/j/press/kikaku/attach/pdf/210930-2.pdf (accessed on 30 September 2021).

- New Roadmap for the Diffusion of CLT. 2021. Available online: https://www.cas.go.jp/jp/seisaku/cltmadoguchi/pdf/r3_roadmap.pdf (accessed on 25 March 2021).

- Evans, L. Cross-Laminated Timber: Taking Wood Buildings to the Next Level; Continuing Education Center: Statesville, NC, USA, 2013; Available online: https://studylib.net/doc/12742769/c-cross-laminated-timber-taking-wood-buildings-to-the-nex (accessed on 30 September 2018).

- Hassan, O.A.B.; Öberg, F.; Gezelius, E. Cross-laminated timber flooring and concrete slab flooring: A comparative study of structural design, economic and environmental consequences. J. Build. Eng. 2019, 26, 100881. [Google Scholar] [CrossRef]

- Huzita, T.; Sasaki, T.; Araki, S.; Kayo, C. Life cycle regional economic impacts of bridge repair using cross-laminated timber floor slabs: A case study in Akita Prefecture, Japan. Buildings 2022, 12, 158. [Google Scholar] [CrossRef]

- Japan CLT Association. Domestic CLT Manufacturing Enterprises. 2022. Available online: https://clta.jp/wp-content/uploads/2022/07/ce7fc35859a43bc2c96d218faa55bcff.pdf (accessed on 14 July 2022).

- Komata, H. Construction and Verification of Utilizing Models for Expansion of Domestic CLT. 2019. Available online: https://kaken.nii.ac.jp/en/file/KAKENHI-PROJECT-16H03128/16H03128seika.pdf (accessed on 20 June 2019).

- Albee, R.R.; Muszyński, L.; Hansen, E.N.; Knowles, C.D.; Larasatie, P.; Guerrero, J.E. Recent Developments in the Global Cross-laminated Timber (CLT) Market. In Proceedings of the WCTE 2018-World Conference on Timber Engineering: Seoul, Republic of Korea, 20–23 August 2018. [Google Scholar]

- Chen, C.X.; Pierobon, F.; Ganguly, I. Life cycle assessment (LCA) of cross-laminated timber (CLT) produced in Western Washington: The role of logistics and wood species mix. Sustainability 2019, 11, 1278. [Google Scholar] [CrossRef] [Green Version]

- Benedetti, F.; Rosales, V.; Jélvez, A.; Núñez, M.; Rebolledo, A.; Jara-Cisterna, A. Economic and technical analysis of CLT production facilities: An application to small and emerging markets. Eur. J. Wood Wood Prod. 2022, 80, 1247–1261. [Google Scholar] [CrossRef]

- Brandt, K.; Wilson, A.; Bender, D.; Dolan, J.D.; Wolcott, M.P. Techno-economic analysis for manufacturing cross-laminated timber. BioResources 2019, 14, 7790–7804. [Google Scholar] [CrossRef]

- Zhang, Z.; Lan, K. Understanding the impacts of plant capacities and uncertainties on the techno-economic analysis of cross-laminated timber production in the Southern U.S. J. Renew. Mater. 2022, 10, 53–73. [Google Scholar] [CrossRef]

- Burback, B.; Pei, S. Cross-laminated timber for single-family residential construction: Cost comparative study. J. Archit. Eng. 2017, 23, 06017002. [Google Scholar] [CrossRef]

- Cazemier, D.S. Comparing cross laminated timber with concrete and steel: A financial analysis of two buildings in Australia. In Modular and Offsite Construction (MOC) Summit Proceedings; University of Alberta Library: Edmonton, AB, Canada, 2017. [Google Scholar]

- Iwase, T.; Sasaki, T.; Araki, S.; Huzita, T.; Kayo, C. Environmental and economic evaluation of small-scale bridge repair using cross-laminated timber floor slabs. Sustainability 2020, 12, 3424. [Google Scholar] [CrossRef] [Green Version]

- Scouse, A.; Kelley, S.S.; Liang, S.; Bergman, R. Regional and net economic impacts of high-rise mass timber construction in Oregon. Sustain. Cities Soc. 2020, 61, 102154. [Google Scholar] [CrossRef]

- Ministry of Internal Affairs and Communications. 2015 Input-Output Tables for Japan, Basic Transaction Tables (Producer Price Valuation) (Integrated Sub-Categories). Available online: https://www.e-stat.go.jp/stat-search/files?page=1&layout=datalist&toukei=00200603&tstat=000001130583&cycle=0&year=20150&month=0&stat_infid=000031839446&tclass1val=0 (accessed on 27 June 2019).

- Ministry of Internal Affairs and Communications. 2015 Input-Output Tables for Japan, Explanatory Report. Chapter Ⅶ Concept, Definition, and Scope by Sector. Available online: https://www.soumu.go.jp/main_content/000732915.pdf (accessed on 31 January 2021).

- Read This to Understand CLT. 2016. Available online: https://clta.jp/wp-content/uploads/2017/04/CLT_BOOK_28P_FIX_9MB.pdf (accessed on 15 April 2016).

- Survey of Wood Distribution Statistics. 2022. Available online: https://www.maff.go.jp/j/tokei/kouhyou/mokuryu/kakaku/attach/pdf/index-15.pdf (accessed on 5 September 2022).

- MEIKEN LAMWOOD Corp. 2022. Available online: https://www.meikenkogyo.com/company/ (accessed on 25 March 2022).

- Huzita, T.; Noda, R.; Kayo, C. Regional economic impacts from timber check dam construction—A comparison with concrete check dam construction. Forests 2020, 11, 1073. [Google Scholar] [CrossRef]

- Watson, P.; Wilson, J.; Thilmany, D.; Winter, S. Determining economic contributions and impacts: What is the difference and why do we care? J. Reg. Anal. 2007, 37, 140–146. [Google Scholar]

- Ministry of Internal Affairs and Communications. 2015 Input-Output Tables for Japan, Output Tables (Integrated Sub-Categories). Available online: https://www.e-stat.go.jp/stat-search/files?page=1&layout=datalist&toukei=00200603&tstat=000001130583&cycle=0&year=20150&month=0&stat_infid=000031839444&tclass1val=0 (accessed on 27 June 2019).

- Ministry of Internal Affairs and Communications. 2015 Input-Output Tables for Japan. Explanatory Report. Chapter Ⅳ Coefficients for Input-Output Analysis and Computation Methods. Available online: https://www.soumu.go.jp/main_content/000732915.pdf (accessed on 31 January 2021).

- Ministry of Internal Affairs and Communications. 2015 Input-Output Tables for Japan. Import Coefficients, Import Input Coefficients, Aggregate Import Coefficients, and Aggregate Gross Value Added Coefficients Table (Integrated Sub-Categories). Available online: https://www.e-stat.go.jp/stat-search/files?page=1&layout=datalist&toukei=00200603&tstat=000001130583&cycle=0&year=20150&month=0&stat_infid=000031839507&tclass1val=0 (accessed on 27 June 2019).

- Ministry of Internal Affairs and Communications. 2020 Family Income and Expenditure Survey. Yearly Average of Monthly Receipts and Disbursements Per Household (Workers’ Households of Total Households). Available online: https://www.e-stat.go.jp/statsearch/files?page=1&layout=datalist&toukei=00200561&tstat=000000330001&cycle=7&year=20200&month=0&tclass1=000000330001&tclass2=000000330019&tclass3=000000330021&stat_infid=000032106657&result_back=1&cycle_facet=tclass1%3Atclass2%3Atclass3%3Acycle&tclass4val=0 (accessed on 27 June 2019).

- Ministry of Internal Affairs and Communications. 2015 Input-Output Tables for Japan. Business, Household, Economy (187 Sectors). Available online: https://www.e-stat.go.jp/en/stat-search/files?page=1&layout=datalist&toukei=00200603&tstat=000001130583&cycle=0&year=20150&month=0&stat_infid=000031839522&tclass1val=0 (accessed on 27 June 2019).

- Huzita, T.; Kayo, C. Regional economic impacts from timber check dam construction—A comparison with concrete check dam construction, Part II: The question of premium vouchers. Forests 2021, 12, 347. [Google Scholar] [CrossRef]

- Higuma, Y.; Tachibana, S.; Ujiie, K. Economic ripple impact of utilization of local wood products on a public building: A case study of Sugito kindergarten-nursery school in Saitama Prefecture. J. Jpn. For. Soc. 2019, 101, 115–121. [Google Scholar] [CrossRef] [Green Version]

- Fuchigami, Y.; Nakai, T. Economic ripple effect analysis of using wood grown in Oita Prefecture, Japan, to build conventional wooden houses. Trans. Mat. Res. Soc. Jpn. 2020, 45, 103–108. [Google Scholar] [CrossRef]

- Komata, H.; Kato, Y.; Ohashi, Y.; Ishikawa, Y.; Ishiko, S.; Yamamoto, N. Economic repercussion effects using local wood products for wood frame construction in Hokkaido. J. Jpn. Wood Res. Soc. 2019, 58, 209–215. [Google Scholar] [CrossRef] [Green Version]

- Fuchigami, Y.; Kimura, Y.; Komata, H.; Sasaki, F.; Furuta, Y. Economic repercussions of using local wood products for public buildings-discussion of a case for Kyoto prefecture. J. Jpn. Wood Res. Soc. 2015, 61, 326–334. [Google Scholar] [CrossRef] [Green Version]

| Materials and Expenditures | Sectors | |

|---|---|---|

| Intermediate Sector | Gross Value Added | |

| Material cost (lamina) | Timber | |

| Material cost (adhesive) | Miscellaneous final chemical products | |

| Material cost (some transportation costs) | Road freight transport (except self-transport) | |

| Salary allowance | Wages and salaries | |

| Excess work allowance | ||

| Bonuses | ||

| Legal welfare expenses | Consumption expenditure of households | |

| Welfare expenses | ||

| Freight | Road freight transport (except self-transport) | |

| Consumables expenses | Office supplies | |

| Vehicle-related expenses | Petroleum refinery products 40% Machine repair services 60% | |

| Rental expenses | Goods rental and leasing (except car rental) | |

| Insurance expenses | Insurance | |

| Repair expenses | Machine repair services | |

| Fuel expenses | Petroleum products | |

| Utility expenses | Electricity 94% Steam and hot water supply 5% Water supply 1% | |

| Packaging | Packaging | |

| Tax and rent | Indirect taxes (except custom duties and commodity taxes on imported goods) | |

| Travel and transportation expenses | Consumption expenditure of households | |

| Depreciation and amortization | Consumption of fixed capital | |

| Small depreciable assets | ||

| Lump-sum depreciable assets | ||

| Storage charges | Storage facility service | |

| Communication expenses | Communications | |

| Business fees | Miscellaneous business services | |

| Security and cleaning expenses | Wages and salaries | |

| Recruitment and training expenses | ||

| Meeting expenses | Office supplies | |

| Allocation to other departments | Wages and salaries | |

| Expense transfer (dry steam, etc.) | Activities not elsewhere classified | |

| Direct Effect | Indirect Effect | Induced Effect | Total Effect | Ripple Effect Multiplier | |

|---|---|---|---|---|---|

| Production induced | 923,868,000 (8,037,652) | 1,115,699,000 (9,706,581) | 265,084,000 (2,306,231) | 2,304,651,000 (20,050,464) | 2.49 |

| Gross value-added induced | 319,640,000 (2,780,868) | 547,385,000 (4,762,250) | 155,167,000 (1,349,953) | 1,022,193,000 (8,893,079) | |

| Employee income induced | 143,767,000 (1,250,773) | 179,836,000 (1,564,573) | 51,789,000 (450,564) | 375,392,000 (3,265,910) | |

| Employment induced | 33.00 | 63.82 | 19.51 | 116.34 | 3.53 |

| Employees induced | 33.00 | 47.07 | 15.87 | 95.94 |

| Direct Effect | Indirect Effect | Induced Effect | Total Effect | Ripple Effect Multiplier | |

|---|---|---|---|---|---|

| Production induced | 602,341,000 (5,240,367) | 510,290,000 (4,439,523) | 137,268,000 (1,194,232) | 1,249,899,000 (10,874,121) | 1.35 |

| Gross value-added induced | 220,659,000 (1,919,733) | 241,363,000 (2,099,858) | 80,352,000 (699,062) | 543,387,000 (4,727,467) | |

| Employee income induced | 75,189,000 (654,144) | 92,407,000 (803,941) | 26,818,000 (233,317) | 194,524,000 (1,692,359) | |

| Employment induced | 33.00 | 35.86 | 10.10 | 78.96 | 2.39 |

| Employees induced | 33.00 | 23.77 | 8.33 | 65.10 |

| Employment Induced | Employees Induced | |||

|---|---|---|---|---|

| 1 | Timber | 12.20 | Timber | 9.51 |

| 2 | Silviculture | 11.62 | Road freight transport (except self-transport) | 8.21 |

| 3 | Road freight transport (except self-transport) | 8.65 | Logs | 5.90 |

| 4 | Logs | 8.28 | Miscellaneous business services | 5.11 |

| 5 | Miscellaneous business services | 5.94 | Wholesale trade | 4.36 |

| Employment Induced | Employees Induced | |||

|---|---|---|---|---|

| 1 | Silviculture | 8.33 | Logs | 4.23 |

| 2 | Logs | 5.94 | Wholesale trade | 3.53 |

| 3 | Wholesale trade | 3.65 | Road freight transport (except self-transport) | 2.80 |

| 4 | Road freight transport (except self-transport) | 2.95 | Miscellaneous business services | 2.23 |

| 5 | Timber | 2.72 | Retail trade | 2.21 |

| Direct Effect | Indirect Effect | Induced Effect | Total Effect | Ripple Effect Multiplier | |

|---|---|---|---|---|---|

| Production induced | 602,341,000 (5,240,367) | 606,104,000 (5,273,105) | 153,617,000 (1,336,468) | 1,362,063,000 (11,849,948) | 1.47 |

| Gross value-added induced | 220,659,000 (1,919,733) | 291,675,000 (2,537,573) | 89,920,000 (782,304) | 603,268,000 (5,248,432) | |

| Employee income induced | 75,189,000 (654,144) | 112,340,000 (977,358) | 30,012,000 (261,104) | 217,652,000 (1,893,572) | |

| Employment induced | 33.00 | 47.24 | 11.31 | 91.55 | 2.77 |

| Employees induced | 33.00 | 29.52 | 9.32 | 71.85 |

| Direct Effect | Indirect Effect | Induced Effect | Total Effect | Ripple Effect Multiplier | |

|---|---|---|---|---|---|

| Production induced | 923,868,000 (8,037,652) | 1,036,152,000 (9,014,522) | 249,198,000 (2,168,023) | 2,209,218,000 (19,220,197) | 2.39 |

| Gross value-added induced | 338,446,000 (2,944,480) | 492,526,000 (4,284,976) | 145,862,000 (1,268,999) | 978,478,000 (8,512,759) | |

| Employee income induced | 115,324,000 (1,003,319) | 188,836,000 (1,642,873) | 48,684,000 (423,551) | 353,023,000 (3,071,300) | |

| Employment induced | 33.00 | 78.66 | 18.34 | 130.01 | 3.94 |

| Employees induced | 33.00 | 49.77 | 15.12 | 97.89 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, M.; Huzita, T.; Murano, A.; Goh, C.S.; Kayo, C. Economic Ripple Effects Analysis of Cross-Laminated Timber Manufacturing in Japan. Forests 2023, 14, 492. https://doi.org/10.3390/f14030492

Liu M, Huzita T, Murano A, Goh CS, Kayo C. Economic Ripple Effects Analysis of Cross-Laminated Timber Manufacturing in Japan. Forests. 2023; 14(3):492. https://doi.org/10.3390/f14030492

Chicago/Turabian StyleLiu, Mengyuan, Tomohumi Huzita, Akito Murano, Chun Sheng Goh, and Chihiro Kayo. 2023. "Economic Ripple Effects Analysis of Cross-Laminated Timber Manufacturing in Japan" Forests 14, no. 3: 492. https://doi.org/10.3390/f14030492