Methanol–Water Purification Control Using Multi-Loop PI Controllers Based on Linear Set Point and Disturbance Models

Abstract

:1. Introduction

2. Methods

2.1. Data Collection

2.2. Creating the Disturbance Model through System Identification

2.3. Controller Pairing

2.4. Controller Tuning

- -

- There are changes in output if the error is not zero. Because of its design, even in small error situations, this controller will eradicate errors.

- -

- The reset time (𝜏i) ensures that the output returns to the set stage.

- Calculating initial PI parameter values;

- BLT de-tuning:

- Assume factor F with a typical range of 1.5 < F < 4;

- Calculate new values of the controller’s parameter, where the detune controller gain is Kci, and the detune reset time is 𝛕ii:

- Determine the log modulus function (Lc) using a multivariable Nyquist plot (W):

- Reassume the F factor until the bode plot of W is stable, indicators are stated in Table 6 below.

2.5. Performance Evaluation

3. Results and Discussion

3.1. Disturbance Model

3.2. Controller Pairing

| RGA11 = | RGA21 = | RGA31 = | RGA41 = |

| 0.2452 | 15.8404 | 265.6956 | 0.1637 |

| RGA12 = | RGA22 = | RGA32 = | RGA42 = |

| 0.0555 | 0.6979 | −4.7820 | 0.1538 |

| RGA13 = | RGA23 = | RGA33 = | RGA43 = |

| −0.7833 | −50.8558 | −851.0568 | 0.2304 |

| RGA14 = | RGA24 = | RGA34 = | RGA44 = |

| −0.0915 | −6.7712 | −111.6737 | 1.0274 |

3.3. Multiloop PI Controller Tuning

3.4. Performance Test

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ministry of Energy and Mineral Resources Republic of Indonesia. Handbook of Energy & Economic Statistics of Indonesia; Head of Center for Data and Information Technology on Energy and Mineral Resources: Jakarta, Indonesia, 2018.

- Musalaiah, M.; Engineer, T.C.; Peddintaiah, K. A Theoretical Study on Dimethyl Ether: An Alternative Fuel for Future Generations. Int. Res. J. Eng. Technol. (IRJET) 2016, 3, 238–243. [Google Scholar]

- Takeishi, K. Dimethyl ether (DME): A clean fuel/energy for the 21st century and the low carbon society. Int. J. Energy Environ. 2016, 10, 238–242. [Google Scholar]

- Falco, M.D. Dimethyl Ether (DME) Production; University UCBM: Rome, Italy, 2017. [Google Scholar]

- Solichin, A.; Sari, M.; Rahmiyati, W.Y. Production of DME from Syngas (for Oxygenates in Diesel Oil and Blending LPG): Plant Design Report; Department of Chemical Engineering, Faculty of Engineering, Universitas Indonesia: Depok, Indonesia, 2011. [Google Scholar]

- Atef, G.; Almadani, A.; Noaman, S. Manufacturing of DME from Methanol; King Fahd University of Petroleum & Minerals: Dhahran, Saudi Arabia, 2015. [Google Scholar] [CrossRef]

- Dieterich, V.; Buttler, A.; Hanel, A.; Spliethoff, H.; Fendt, S. Power-to-liquid via synthesis of methanol, DME or Fischer–Tropsch-fuels: A review. R. Soc. Chem. 2020, 13, 3207–3252. [Google Scholar] [CrossRef]

- Khaleel, A. Methanol Dehydration to Dimethyl Ether over Highly Porous Xerogel Alumina Catalyst: Flow Rate Effect. Fuel Process Technol. 2010, 91, 1505–1509. [Google Scholar] [CrossRef]

- Dyrda, K.M.; Wilke, V.; Haas-Santo, K.; Dittmeyer, R. Experimental Investigation of the Gas/Liquid Phase Separation Using a Membrane-Based Micro Contactor. ChemEngineering 2018, 2, 55. [Google Scholar] [CrossRef] [Green Version]

- Liptak, B. Instrument Engineer’s Handbook: Process Control; CRC Taylor & Francis: Boca Raton, FL, USA, 2012. [Google Scholar] [CrossRef]

- Marlin, T. Process Control: Designing Processes and Control System for Dynamic Performance, 2nd ed.; McGraw Hill: Singapore, 2015; ISBN 9780070393622. [Google Scholar]

- Wahid, A.; Gunawan, T.A. Pengendalian Proses Purifikasi DME dan Metanol pada Pabrik DME dari Gas Sintesis. Sinergi 2015, 19, 57–66. [Google Scholar] [CrossRef] [Green Version]

- Wahid, A.; Brillianto, Z.H. Multivariable Model Predictive Control (4 × 4) of Methanol Water Separation in Dimethyl Ether Production. AIP Conf. Proc. 2015, 2255, 030055. [Google Scholar] [CrossRef]

- Nandong, J. Decentralized Control Systems; Curtin University: Curtin, Malaysia, 2020. [Google Scholar] [CrossRef]

- Vu Truong, N.; Lee, M. Optimal Design of Multi-loop PI Controllers for Enhanced Disturbance Rejection in Multivariable Processes; School of Chemical Engineering and Technology Yeungnam University: Gyeoungbuk, Korea, 2007; Available online: http://psdc.yu.ac.kr (accessed on 22 July 2020).

- Biyanto, T.; Sordi, N.; Sehamat, N.; Zabiri, H. PID Multivariable Tuning System Using BLT Method for Distillation Column; IOP Publishing: Tokyo, Japan, 2018. [Google Scholar] [CrossRef]

- Farsi, M. Dynamic Modeling and Controllability Analysis of DME Production in an Isothermal Fixed Bed Reactor; Department of Chemical Engineering, School of Chemical and Petroleum Engineering, Shiraz University: Shiraz, Iran, 2015. [Google Scholar] [CrossRef] [Green Version]

- Huang, H.; Jeng, J.; Chiang, C.; Pan, W. A Direct Method for Multi-Loop PI/PID Controller Design; Department of Chemical Engineering, National Taiwan University: Taipei, China, 2003. [Google Scholar] [CrossRef]

- Kumar, R.; Anand, S.; Khulbey, A.; Jha, A.N. Design of Fractional Order Controller for Wood-Berry Distillation Column; Department of Instrumentation and Control Engineering, Netaji Subhas University of Technology: New Delhi, India, 2020; ISBN 9781728169163. [Google Scholar]

- Kalpana, R.; Harukumar, K.; Senthukumar, J.; Balasubramanian, G.; Gour, A. Multivariable Static Output Feedback Control of a Binary Distillation Column Using Linear Matrix Inequalities and Genetic Algorithm; School of Electrical and Electronics Engineering, Sastra University: Thanjavur, India, 2017. [Google Scholar] [CrossRef]

- Kalhoro, A.; Memon, S. Design of Multivariable PID Controllers: A Comparative Study; Department of Electronic Engineering, Mehran University: Jamshoro, Pakistan, 2021. [Google Scholar] [CrossRef]

- Alawad, N.; Muter, A. Optimal Control of Model Reduction Binary Distillation Column; Department of Computer Engineering, Faculty of Engineering, Mustansiriyah University: Baghdad, Iraq, 2021. [Google Scholar] [CrossRef]

- Ogunnaike, B.A.; Ray, W.H. Multivarianle Design Controller Design for Linear Systems Having Multiple Time Delays; Department of Chemical Engineering, University of Winconsin: Madison, WI, USA, 1979. [Google Scholar]

- Smith, C. Digital Computer Process Control; Intext: Scranton, PA, USA, 1972; ISBN 0700224017/9780700224012. [Google Scholar]

- Camacho, E.F.; Bordons, C. Model Predictive Control, 2nd ed.; Springer: London, UK, 2007; ISBN 9780857293985. [Google Scholar]

- Vazquez, F.; Morilla, F. Tuning Decentralized PID Controllers for MIMO Systems with Decouplers. In Proceedings of the 15th Triennial World Congress, Barcelona, Spain, 21–26 July 2002. [Google Scholar] [CrossRef]

- Krishna, G.H.; Kiranmayi, R.; Rathaiah, M. Control System Design for 3 × 3 Processes Based on Effective Transfer Function and Fractional Order Filter. Int. J. Eng. Adv. Technol. (IJEAT) 2019, 8, 637–642. [Google Scholar]

- Chau, P.C. Chemical Process Control: A First Course with MATLAB; University of California: San Diego, CA, USA, 2001. [Google Scholar] [CrossRef]

- Wahid, A.; Tanuwijaya, R. Pemilihan Metode Penyetelan Pengendali PI pada Pengendalian Pabrik Regasifikasi LNG Menggunakan Metode Skor. In Proceedings of the Seminar Nasional Teknik Kimia UNPAR, Bandung, Indonesia, 19 November 2015. [Google Scholar]

| Unit | Code | Objectives | Initial | Final |

|---|---|---|---|---|

| Cooler | E-101 | Cools methanol distillates | 240 ℉ | 110 ℉ |

| Pump | P-101 | To increase the recycle flow pressure | 200 kPa | 3500 kPa |

| Process Parameters | T-103 |

|---|---|

| Number of Stages | 30 |

| Condenser Pressure | 14.69 psia |

| Reboiler Pressure | 14.69 psia |

| Stream Inlet Stage | 19 |

| No | Unit Process | Controller Type | Controlled Variable | Manipulated Variable | Set Point | Actuator | Disturbance |

|---|---|---|---|---|---|---|---|

| 1 | Condenser T-103 | Temperature control | Temperature | Heat flow | 58.81 °C | Control Valve Qcond1 | Changes in the inlet feed (methanol + water) temperature and molar flow |

| 2 | Cooler E-101 | Heat flow | 40.75 °C | Control Valve QcoolMeRecy | |||

| 3 | Condenser T-103 | Level control | Column Level | Methanol to recycle Flow | 49.96% | Actuator Desired Position VLV- 105 | |

| 4 | Column T-103 | Wastewater flow | 11.22% | Actuator Desired Position VLV- 106 |

| λ | Possible Pairing |

|---|---|

| λmn < 0 | Unstable interactions |

| λmn = 1 | No interaction exists |

| λmn = 0.5 | Strong interactions |

| λmn > 1 | Interactions in the opposite direction of the variables, and stronger as value increases |

| λmn < 1 | Interactions in the same direction of the variables, and stronger as the value decreases |

| Λ | Possible Pairing |

|---|---|

| No interaction. The controller design is a SISO system. | |

| Strong interaction if 𝛿 is close to 1; weak interaction if 𝛿 << 1. |

| Stable | Marginally Stable | Unstable |

|---|---|---|

| Phase over frequency > gain cross over frequency | Phase over frequency = gain cross over frequency | Phase over frequency < gain cross over frequency |

| Gain margin > 1 | Gain margin = 1 | Gain margin < 1 |

| Phase margin = positive | Phase margin = 0 | Phase margin = negative |

| Disturbance | Variable Process | |||

|---|---|---|---|---|

| CV1 | CV2 | CV3 | CV4 | |

| Inlet Flow | ||||

| Inlet Temperature | ||||

| Controlled Variable (CV) | Controller Parameter | Big Log-Modulus Tuning | Fine Tuning | Wahid and Gunawan (2015) | |

|---|---|---|---|---|---|

| 1 | Vessel Temperature of Condenser T-103 | P | 0.67 | 0.24 | 1 |

| I | 0.33 | 1.64 | 0.5 | ||

| 2 | MeRecy Temperature | P | 0.67 | 4.90 | 1 |

| I | 0.33 | 42.41 | 0.5 | ||

| 3 | Liquid Percent Level of Condenser T-103 | P | 0.01 | −67.01 | 0.01 |

| I | 2.16 | 6.75 × 10−19 | 1.80 | ||

| 4 | Total Liquid Volume Percent of T-103 | P | 9.00 | 3.49 | 13.50 |

| I | 1.59 | 3.56 | 2.38 | ||

| CV | Set Point | Increase 5% | Delta (Δ) |

|---|---|---|---|

| 1 | 58.81 ℃ | 61.75 ℃ | 2.94 |

| 2 | 40.75 ℃ | 42.79 ℃ | 2.04 |

| 3 | 49.96% | 52.46% | 2.5 |

| 4 | 11.22% | 11.78% | 0.56 |

| Disturbance | |||

| Feed Temperature | 81.74 °C | 85.83 °C | 4.09 |

| Feed Flow | 659.8 gmol/s | 692.72 gmol/s | 32.98 |

| CV | IAE | Improvement | |||||

|---|---|---|---|---|---|---|---|

| MMPC (Wahid and Brillianto 2020) | Multi-Loop PI | Multi-Loop PI | |||||

| Big Log-Modulus Tuning | Wahid & Gunawan (2015) | Fine-Tuning | Big Log-Modulus Tuning | Wahid & Gunawan (2015) | Fine-Tuning | ||

| Feed Temperature Disturbance | |||||||

| 1 | 3.70 × 101 | 1.05 × 101 | 4.71 | 6.65 | 71.58% | 87.27% | 82.01% |

| 2 | 7.96 × 101 | 1.24 | 2.98 × 10 | 1.62 × 10−1 | 98.45% | 96.26% | 99.80% |

| 3 | 6.18 | 6.26 × 10−9 | 6.84 × 102 | 7.93 × 10−5 | 100.00% | −1.10 × 104% | 100.00% |

| 4 | 2.04 × 102 | 2.47 × 10−2 | 1.10 × 10−2 | 2.82 × 10−2 | 99.99% | 99.99% | 99.97% |

| Feed Flow Disturbance | |||||||

| 1 | 3.75 × 101 | 3.11 × 10−1 | 1.53 × 10−1 | 2.09 × 10−1 | 99.17% | 99.59% | 99.44% |

| 2 | 1.55 × 102 | 4.97 × 10−1 | 9.20 × 10−1 | 1.18 × 10−2 | 99.68% | 99.41% | 99.99% |

| 3 | 3.32 | 1.46 × 10−6 | 1.62 × 101 | 1.87 × 10−6 | 100.00% | −385.80% | 100.00% |

| 4 | 7.41 × 101 | 1.16 × 10−2 | 5.15 × 10−3 | 1.33 × 10−2 | 99.98% | 99.99% | 99.98% |

| Feed Flow and Temperature Disturbance | |||||||

| 1 | 2.24 × 101 | 1.02 × 101 | 4.59 | 6.48 | 54.19% | 79.49% | 71.02% |

| 2 | 1.64 × 102 | 1.47 | 2.66 | 1.70 × 10−1 | 99.11% | 98.38% | 99.90% |

| 3 | 1.24 × 101 | 6.12 × 10−5 | 6.69 × 102 | 7.74 × 10−5 | 100.00% | −5.31 × 103% | 100.00% |

| 4 | 2.04 × 102 | 2.47 × 10−2 | 1.10 × 10−2 | 2.82 × 10−2 | 99.98% | 99.99% | 99.98% |

| CV | ISE | Improvement | |||||

|---|---|---|---|---|---|---|---|

| MMPC (Wahid and Brillianto 2020) | Multi-Loop PI | Multi-Loop PI | |||||

| Big Log-Modulus Tuning | Wahid & Gunawan (2015) | Fine-Tuning | Big Log-Modulus Tuning | Wahid & Gunawan (2015) | Fine-Tuning | ||

| Feed Temperature Disturbance | |||||||

| 1 | 2.30 × 101 | 2.03 | 8.01 × 10−1 | 1.41 | 91.20% | 96.52% | 93.89% |

| 2 | 1.06 × 102 | 9.90 × 10−2 | 1.58 × 10−1 | 7.03 × 10−4 | 99.91% | 99.85% | 100.00% |

| 3 | 6.41 × 10−1 | 8.31 × 10−5 | 9.53 × 102 | 1.29 × 10−4 | 99.99% | −1.49 × 105% | 99.98% |

| 4 | 6.94 × 102 | 1.01 × 10−4 | 2.39 × 10−5 | 1.63 × 10−4 | 100.00% | 100.00% | 100.00% |

| Feed Flow Disturbance | |||||||

| 1 | 6.62 × 101 | 1.33 × 10−3 | 5.47 × 10−4 | 1.02 × 10−3 | 100.00% | 100.00% | 100.00% |

| 2 | 4.43 × 102 | 2.17 × 10−2 | 4.20 × 10−1 | 1.62 × 10−5 | 100.00% | 99.91% | 100.00% |

| 3 | 7.68 × 10−1 | 4.66 × 10−8 | 5.41 × 10−1 | 7.31 × 10−8 | 100.00% | 29.57% | 100.00% |

| 4 | 9.64 × 101 | 2.23 × 10−5 | 5.35 × 10−6 | 3.70 × 10−5 | 100.00% | 100.00% | 100.00% |

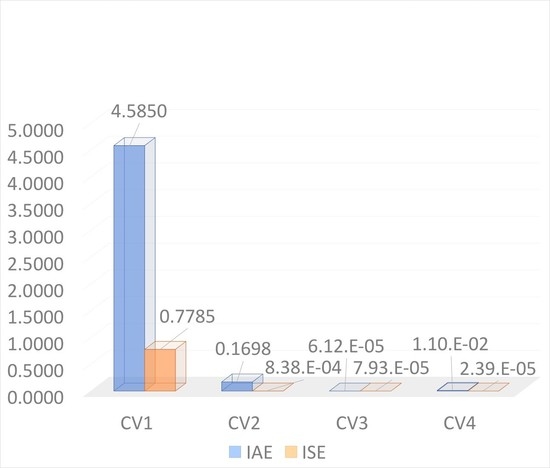

| Feed Flow and Temperature Disturbance | |||||||

| 1 | 2.68 × 101 | 1.95 | 7.79 × 10−1 | 1.36 | 92.71% | 97.09% | 94.91% |

| 2 | 3.85 × 102 | 1.08 × 10−1 | 1.29 × 10−1 | 8.38 × 10−4 | 99.97% | 99.97% | 100.00% |

| 3 | 1.83 | 7.93 × 10−5 | 9.10 × 102 | 1.22 × 10−4 | 100.00% | −4.96 × 104% | 99.99% |

| 4 | 6.94 × 102 | 1.01 × 10−4 | 2.39 × 10−5 | 1.63 × 10−4 | 100.00% | 100.00% | 100.00% |

| CV | IAE | Improvement | |||||

|---|---|---|---|---|---|---|---|

| MMPC (Wahid and Brillianto 2020) | Multi-Loop PI | Multi-Loop PI | |||||

| Big Log-Modulus Tuning | Wahid & Gunawan (2015) | Fine-Tuning | Big Log-Modulus Tuning | Wahid & Gunawan (2015) | Fine-Tuning | ||

| CV1 Setpoint Change | |||||||

| 1 | 1.81 × 102 | 6.61 × 101 | 2.96 × 101 | 4.17 × 101 | 63.51% | 83.66% | 77.02% |

| 2 | 4.28 | 8.97 | 9.26 | 1.04 | −109.63% | −116.24% | 75.70% |

| 3 | 4.36 | 4.08 × 103 | 4.16 × 103 | 4.82 × 103 | −93,386.24% | −9.53 × 104% | −1.10 × 105% |

| 4 | 2.00 × 10−2 | 2.29 × 10−3 | 1.37 × 10−3 | 1.65 × 10−2 | 88.54% | 93.16% | 17.70% |

| CV2 Setpoint Change | |||||||

| 1 | 4.10 × 10−1 | 7.34 × 10−1 | 3.28 × 10−1 | 4.60 × 10−1 | −79.02% | 19.95% | −12.15% |

| 2 | 5.64 × 101 | 1.83 × 101 | 8.20 | 2.71 × 10−1 | 67.48% | 85.46% | 99.52% |

| 3 | 3.20 × 10−1 | 3.59 × 101 | 3.73 × 101 | 4.35 × 101 | −11,112.50% | −11,546.88% | −13,493.75% |

| 4 | 2.00 × 10−2 | 1.68 × 10−4 | 8.12 × 10−5 | 6.45 × 10−4 | 99.16% | 99.59% | 96.78% |

| CV | IAE | Improvement | |||||

|---|---|---|---|---|---|---|---|

| MMPC (Wahid and Brillianto 2020) | Multi-Loop PI | Multi-Loop PI | |||||

| Big Log-Modulus Tuning | Wahid & Gunawan (2015) | Fine-Tuning | Big Log-Modulus Tuning | Wahid & Gunawan (2015) | Fine-Tuning | ||

| CV3 Setpoint Change | |||||||

| 1 | 7.32 | 7.51 | 5.80 | 6.97 | −2.60% | 20.71% | 4.77% |

| 2 | 4.67 | 9.21 × 10−1 | 2.20 | 3.80 × 10−1 | 80.29% | 52.89% | 91.86% |

| 3 | 5.59 × 101 | 4.16 × 102 | 3.92 × 102 | 1.34 × 103 | −643.43% | −601.59% | −2301.22% |

| 4 | 5.00 × 10−2 | 1.43 × 10−1 | 4.61 × 10−1 | 1.27 | −185.20% | −821.40% | −2430.00% |

| CV4 Setpoint Change | |||||||

| 1 | 5.20 × 10−1 | 7.19 | 1.31 | 1.84 | −1282.31% | −151.15% | −254.42% |

| 2 | 5.30 × 10−1 | 2.98 × 10−1 | 7.42 × 10−1 | 4.31 × 10−2 | 43.70% | −39.91% | 91.87% |

| 3 | 5.79 | 1.73 × 102 | 1.89 × 102 | 2.19 × 102 | −2886.18% | −3.17 × 103% | −3.68 × 103% |

| 4 | 5.74 × 101 | 1.42 × 10−1 | 1.03 × 10−1 | 2.84 × 10−1 | 99.75% | 99.82% | 99.51% |

| CV | ISE | Improvement | |||||

|---|---|---|---|---|---|---|---|

| MMPC (Wahid and Brillianto 2020) | Multi-Loop PI | Multi-Loop PI | |||||

| Big Log-Modulus Tuning | Wahid & Gunawan (2015) | Fine-Tuning | Big Log-Modulus Tuning | Wahid & Gunawan (2015) | Fine-Tuning | ||

| CV1 Setpoint Change | |||||||

| 1 | 4.35 × 102 | 8.90 × 101 | 3.92 × 101 | 6.42 × 101 | 79.54% | 90.99% | 85.23% |

| 2 | 4.00 × 10−2 | 1.72 × 10−1 | 1.77 × 10−1 | 3.37 × 10−2 | −328.75% | −343.50% | 15.80% |

| 3 | 6.00 × 10−2 | 3.39 × 104 | 3.49 × 104 | 4.71 × 104 | −5.65 × 107% | −5.82 × 107% | −7.84 × 107% |

| 4 | 5.36 × 10−7 | 9.18 × 10−8 | 4.40 × 10−8 | 9.48 × 10−6 | 82.88% | 91.79% | −1669.03% |

| CV2 Setpoint Change | |||||||

| 1 | 5.00 × 10−4 | 7.45 × 10−3 | 3.07 × 10−3 | 6.63 × 10−3 | −1389.60% | −514.60% | −1226.20% |

| 2 | 7.11 × 101 | 1.44 × 101 | 5.94 | 2.49 × 10−1 | 79.68% | 91.6425% | 99.65% |

| 3 | 2.00 × 10−4 | 2.73 | 2.88 | 3.91 | −1.37 × 106% | −1.44 × 106% | −1.95 × 106% |

| 4 | 8.30 × 10−7 | 4.43 × 10−9 | 3.29 × 10−9 | 2.17 × 10−7 | 99.47% | 99.60% | 73.86% |

| CV3 Setpoint Change | |||||||

| 1 | 1.00 × 10−2 | 4.86 × 10−1 | 1.85 | 1.90 | −4759% | −18,370.00% | −18,930.00% |

| 2 | 6.00 × 10−2 | 7.18 × 10−3 | 1.70 × 10−1 | 7.38 × 10−2 | 88.04% | −182.83% | −23.00% |

| 3 | 3.10 × 101 | 3.71 × 102 | 3.19 × 102 | 1.22 × 103 | −1099.23% | −930.68% | −3845.75% |

| 4 | 5.80 × 10−6 | 4.27 × 10−2 | 5.69 × 10−1 | 1.59 | −7.36 × 105% | −9.82 × 106% | −2.73 × 107% |

| CV4 Setpoint Change | |||||||

| 1 | 4.00 × 10−4 | 4.79 × 10−1 | 9.19 × 10−2 | 1.35 × 10−1 | −1.20 × 105% | −2.29 × 104% | −3.37 × 104% |

| 2 | 5.00 × 10−4 | 6.56 × 10−3 | 9.32 × 10−3 | 6.75 × 10−5 | −1.21 × 103% | −1764.80% | 86.51% |

| 3 | 1.30 × 10−1 | 6.29 × 101 | 7.23 × 101 | 9.73 × 101 | −48,30% | −5.55 × 104% | −7.47 × 104% |

| 4 | 2.50 × 101 | 4.20 × 10−2 | 2.80 × 10−2 | 7.99 × 10−2 | 99.83% | 99.89% | 99.68% |

| Controlled Variable (CV) | Tuning Method | P | I | |

|---|---|---|---|---|

| 1 | Vessel Temperature of Condenser T-103 | WG | 0.67 | 0.33 |

| 2 | MeRecy Temperature | FT | 4.90 | 42.41 |

| 3 | Liquid Percent Level of Condenser T-103 | BLT | 0.01 | 2.16 |

| 4 | Total Liquid Volume Percent of T-103 | WG | 13.50 | 2.38 |

| CV | IAE | Improvement | ISE | Improvement | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| MMPC (Wahid & Brillianto 2020) | Multi-Loop | MMPC (Wahid & Brillianto 2020) | Multi-Loop | ||||||||

| Tuning Method | Simulink | Unisim | Simulink | Unisim | Simulink | Unisim | Simulink | Unisim | |||

| CV1 Setpoint Change | |||||||||||

| 1 | 1.81 × 102 | WG | 2.96 × 101 | 2.08 × 10−3 | 83.66% | 100.00% | 4.35 × 102 | 3.92 × 101 | 2.65 × 10−4 | 90.99% | 100.00% |

| 2 | 4.28 | FT | 1.04 | 1.15 × 10−2 | 75.70% | 99.73% | 4.00 × 10−2 | 3.37 × 10−2 | 1.92 × 10−4 | 15.80% | 99.52% |

| 3 | 4.36 | BLT | 4.08 × 103 | 1.34 × 10−2 | −93,386.24% | 99.69% | 6.00 × 10−2 | 3.39 × 104 | 1.83 × 10−4 | −5.65 × 107% | 99.69% |

| 4 | 2.00 × 10−2 | WG | 1.37 × 10−3 | 1.37 × 10−3 | 93.16% | 93.16% | 5.36 × 10−7 | 4.40 × 10−8 | 2.89 × 10−7 | 91.79% | 46.18% |

| CV2 Setpoint Change | |||||||||||

| 1 | 4.10 × 10−1 | WG | 3.28 × 10−1 | 1.27 × 10−2 | 19.95% | 96.91% | 5.00 × 10−4 | 3.07 × 10−3 | 2.45 × 10−4 | −514.60% | 51.05% |

| 2 | 5.64 × 101 | FT | 2.71 × 10−1 | 2.76 × 10−1 | 99.52% | 99.51% | 7.11 × 101 | 2.49 × 10−1 | 6.43 × 10−1 | 99.65% | 99.10% |

| 3 | 3.20 × 10−1 | BLT | 3.59 × 101 | 3.25 × 10−3 | −11,112.50% | 98.99% | 2.00 × 10−4 | 2.73 | 1.48 × 10−5 | −1.37 × 106% | 92.59% |

| 4 | 2.00 × 10−2 | WG | 8.12 × 10−5 | 1.36 × 10−3 | 99.59% | 93.22% | 8.30 × 10−7 | 3.29 × 10−9 | 2.78 × 10−7 | 99.60% | 66.51% |

| CV3 Setpoint Change | |||||||||||

| 1 | 7.32 | WG | 5.80 | 1.25 × 10−2 | 20.71% | 99.83% | 1.00 × 10−2 | 1.85 | 2.40 × 10−4 | −18370.00% | 97.60% |

| 2 | 4.67 | FT | 3.80 × 10−1 | 1.11 × 10−2 | 91.86% | 99.76% | 6.00 × 10−2 | 7.38 × 10−2 | 1.83 × 10−4 | −23.00% | 99.70% |

| 3 | 5.59 × 101 | BLT | 4.16 × 102 | 2.66 × 10−3 | −643.43% | 100.00% | 3.10 × 101 | 3.71 × 102 | 1.47 × 10−5 | −1099.23% | 100.00% |

| 4 | 5.00 × 10−2 | WG | 4.61 × 10−1 | 8.26 × 10−4 | −821.40% | 98.35% | 5.80 × 10−6 | 5.69 × 10−1 | 1.10 × 10−6 | −9.82 × 106% | 81.06% |

| CV4 Setpoint Change | |||||||||||

| 1 | 5.20 × 10−1 | WG | 1.31 | 1.28 × 10−2 | −151.15% | 97.53% | 4.00 × 10−4 | 9.19 × 10−2 | 2.51 × 10−4 | −2.29 × 104% | 37.25% |

| 2 | 5.30 × 10−1 | FT | 4.31 × 10−2 | 1.14 × 10−2 | 91.87% | 97.84% | 5.00 × 10−4 | 6.75 × 10−5 | 1.91 × 10−4 | 86.51% | 61.80% |

| 3 | 5.79 | BLT | 1.73 × 102 | 3.26 × 10−3 | −2886.18% | 99.94% | 1.30 × 10−1 | 6.29 × 101 | 1.50 × 10−5 | −4.83 × 104% | 99.99% |

| 4 | 5.74 × 101 | WG | 1.03 × 10−1 | 4.04 × 10−4 | 99.82% | 100.00% | 2.50 × 101 | 2.80 × 10−2 | 2.83 × 10−7 | 99.89% | 100.00% |

| Feed Temperature Disturbance | |||||||||||

| 1 | 3.70 × 101 | WG | 4.71 | 1.61 × 10−1 | 87.27% | 99.56% | 2.30 × 101 | 8.01 × 10−1 | 2.78 × 10−2 | 96.52% | 99.88% |

| 2 | 7.96 × 101 | FT | 1.62 × 10−1 | 1.07 × 10−2 | 99.80% | 99.99% | 1.06 × 102 | 7.03 × 10−4 | 1.14 × 10−4 | 100.00% | 100.00% |

| 3 | 6.18 | BLT | 6.26 × 10−9 | 9.44 × 10−3 | 100.00% | 99.85% | 6.41 × 10−1 | 8.31 × 10−5 | 9.06 × 10−5 | 99.99% | 99.99% |

| 4 | 2.04 × 102 | WG | 1.10 × 10−2 | 2.52 × 10−3 | 99.99% | 100.00% | 6.94 × 102 | 2.39 × 10−5 | 1.17 × 10−5 | 100.00% | 100.00% |

| Feed Flow Disturbance | |||||||||||

| 1 | 3.75 × 101 | WG | 1.53 × 10−1 | 1.67 × 10−1 | 99.59% | 99.56% | 6.62 × 101 | 5.47 × 10−4 | 4.22 × 10−5 | 100.00% | 100.00% |

| 2 | 1.55 × 102 | FT | 1.18 × 10−2 | 1.38 × 10−2 | 99.99% | 99.99% | 4.43 × 102 | 1.62 × 10−5 | 1.15 × 10−4 | 100.00% | 100.00% |

| 3 | 3.32 | BLT | 1.46 × 10−6 | 7.36 × 10−4 | 100.00% | 99.98% | 7.68 × 10−1 | 4.66 × 10−8 | 6.73 × 10−7 | 100.00% | 100.00% |

| 4 | 7.41 × 101 | WG | 5.15 × 10−3 | 9.42 × 10−3 | 99.99% | 99.99% | 9.64 × 101 | 5.35 × 10−6 | 9.45 × 10−5 | 100.00% | 100.00% |

| Feed Flow and Temperature Disturbance | |||||||||||

| 1 | 2.24 × 101 | WG | 4.59 | 1.70 × 10−1 | 79.49% | 99.24% | 2.68 × 101 | 7.79 × 10−1 | 3.01 × 10−2 | 97.09% | 99.89% |

| 2 | 1.64 × 102 | FT | 1.70 × 10−1 | 1.14 × 10−2 | 99.90% | 99.99% | 3.85 × 102 | 8.38 × 10−4 | 1.14 × 10−4 | 100.00% | 100.00% |

| 3 | 1.24 × 101 | BLT | 6.12 × 10−5 | 3.42 × 10−3 | 100.00% | 99.97% | 1.83 | 7.93 × 10−5 | 2.96 × 10−5 | 100.00% | 100.00% |

| 4 | 2.04 × 102 | WG | 1.10 × 10−2 | 3.27 × 10−2 | 99.99% | 99.98% | 6.94 × 102 | 2.39 × 10−5 | 1.43 × 10−3 | 100.00% | 100.00% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wahid, A.; Rikimata, M. Methanol–Water Purification Control Using Multi-Loop PI Controllers Based on Linear Set Point and Disturbance Models. ChemEngineering 2021, 5, 70. https://doi.org/10.3390/chemengineering5040070

Wahid A, Rikimata M. Methanol–Water Purification Control Using Multi-Loop PI Controllers Based on Linear Set Point and Disturbance Models. ChemEngineering. 2021; 5(4):70. https://doi.org/10.3390/chemengineering5040070

Chicago/Turabian StyleWahid, Abdul, and Monica Rikimata. 2021. "Methanol–Water Purification Control Using Multi-Loop PI Controllers Based on Linear Set Point and Disturbance Models" ChemEngineering 5, no. 4: 70. https://doi.org/10.3390/chemengineering5040070