Standardization of Fatigue Characteristics of Cement-Treated Aggregate Base Materials under Different Stress States

Abstract

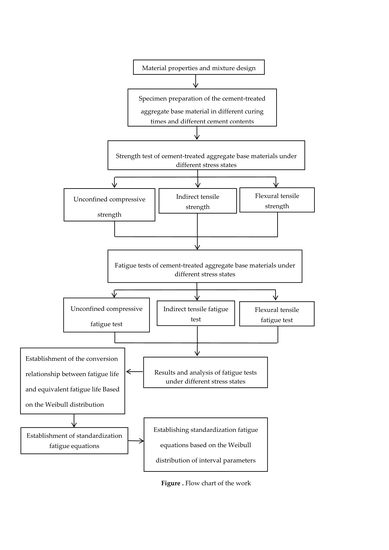

:1. Introduction

2. Specimen Formation and Test Preparation

2.1. Material Properties and Mixture Design

2.1.1. Cement

2.1.2. Aggregate

2.2. Specimen Shaping

3. Strength Test

3.1. Unconfined Compressive Strength

- (1)

- The Chinese Specification for Design of Highway Asphalt Pavement (JTG D50-2017) [37] has stipulated that the unconfined compressive strength of the cement-stabilized gravel base layer for 7 days under special traffic conditions is 5.0–7.0 MPa and that of the subbase layer is 3.0–5.0 MPa. From the existing test, an unconfined compressive strength at 7-day could meet the requirements.

- (2)

- The unconfined compressive strength of cement-treated aggregate base materials monotonously increased with the curing time and cement content. The effect of the cement content on the strength of the cement-treated aggregate base material is larger than the curing time. For example, the strength at a curing time of 90 days and 5% cement content was approximately 1.6 times higher than that of 3% cement content at a curing time of 90 days (from 9 to 14 MPa). The strength of the cement-treated aggregate base material is affected by the curing time significantly, but much less than the cement content. At 1–14 days, the unconfined compressive strength of cement-treated aggregate base materials rapidly increased, with a growth rate of ~1.6 times (from 6 MPa to 10 MPa). At 14–28 days, the unconfined compressive strength growth rate decreased by 1.2 times (from 10 to 12 MPa). After 28 days, the unconfined compressive strength approached stability. Therefore, the cement-treated aggregate base should be maintained for about 28 days after being paved.

3.2. Indirect Tensile Strength

- (1)

- The discreteness of indirect tensile strength was small, and basic control was within 15%. The discreteness of indirect tensile strength value was greater than 10% compared to the unconfined compressive strength. The indirect tensile strength showed good agreement with the increase in curing time between different cement contents, which was consistent with the unconfined compressive strength growth trend.

- (2)

- The indirect tensile strength of cement-treated aggregate base materials monotonously increased with the curing time and cement content. The cement content considerably affected the indirect tensile strength. The indirect tensile strength at 3% cement content and 28 days is ~1 MPa, the indirect tensile strength at 5% cement content and 28 days is ~2.2 MPa, i.e., the strength value increased by 2.2 times. At 1–14 days, the unconfined compressive strength of cement-treated aggregate base materials rapidly increased, with a growth rate of ~2 (from 0.8 to 1.6 MPa). At 14–90 days, the growth of indirect tensile strength decreased, but a certain growth trend was still observed (from 1.6 to 2.25 MPa). The Chinese Specification for Design of Highway Asphalt Pavement (JTG D50-2017) [37] has stipulated that the indirect tensile strength of the cement-treated aggregate base materials is about 10% of the unconfined compressive strength. From the test results, it can be observed that the indirect tensile strength at 3% cement content and 90 days is 1.1 MPa which is about 10% of the unconfined compressive strength at 3% cement content and 90 days.

3.3. Flexural Tensile Strength

- (1)

- A large variation coefficient for the flexural tensile strength of the large-scale beams specimen was obtained, which was difficult to control within 15%, and discreteness monotonously increased with the cement content. With the same cement content, the flexural tensile strength increased with the curing time. Before 28 days, the growth rate was relatively rapid, the strength value increased 2-fold (from 0.6 to 1.15 MPa), and after 28 days, the growth rate tended to be nearly stable, and the strength value increased by 0.85 times (from 1.15 to 1.35 MPa).

- (2)

- The flexural tensile strength of cement-treated aggregate base materials also monotonously increased with the curing time and cement content. The result was consistent with the growth trend of unconfined compressive strength and indirect tensile strength. The flexural tensile strength for the sample cured for 90 days tended to be stable, and with the increase in the cement content by 1%, the flexural tensile strength was multiplied, the flexural tensile strength at 3% cement content and 28 days is ~0.4 MPa, the flexural tensile strength at 5% cement content and 28 days is ~1.15 MPa. Simultaneously, the effect of the cement content on the strength of the cement-treated aggregate base material is larger than the curing time. The flexural tensile strength was also consistent with the growth trend of unconfined compressive strength. The Chinese Specification for Design of Highway Asphalt Pavement (JTG D50-2017) [37] has used the flexural tensile strength as the strength index of the inorganic binder. The flexural tensile strength at 90 days is ~1.35 MPa which is very close to the requirements.

4. Results and Analysis of Fatigue Tests of Cement-Treated Aggregate Base Materials under Different Stress States

4.1. Fatigue Test Results

- (1)

- The fatigue life of cement-treated aggregate base materials monotonously increased with the curing time and cement content, monotonously decreased with stress ratio and the fatigue life followed the order of unconfined compressive > indirect tensile > flexural tensile. The result was similar to the growth trend of cement-treated aggregate base materials strength. The fatigue life of unconfined compressive at 5% cement content and 90 days was the longest, and that of flexural tensile at 3% cement content and 28 days, the smallest. Test results revealed that the curing time, cement content and stress states considerably affected the fatigue life of cement-treated aggregate base materials. Test results were similar to former studies [3,7,24,38,39,40].

- (2)

- The magnitude of the parameters a and b of the fatigue equation varied in a wide range, and the curing time and cement content considerably affected the parameters a and b. Parameter a reflected the slope of the fatigue curve, and the parameter a followed the order of flexural tensile > indirect tensile > unconfined compressive. On the other hand, parameter b reflected the intercept of the fatigue curve, and parameter b was significantly different under different stress states. Parameter b followed the order of unconfined compressive > flexural tensile > indirect tensile. Furthermore, similar to previous researchers [14,16,17,38,39], the values of parameter a were accessible to change with the types of the test conditions and the stress states.

- (3)

- The fitting equation for unconfined compressive fatigue is far from the flexural tensile and indirect tensile strength curves, and the S-N single logarithmic fatigue equations of cement-treated aggregate base materials under different stress states exhibit large differences. The fitting correlation coefficient was too low as shown in Table 5, Table 6 and Table 7. Therefore, it was not possible to analyze the fatigue performance of cement-treated aggregate base materials by comparing the fatigue curve obtained under different stress conditions and to scientifically evaluate the fatigue characteristics of cement-treated aggregate base materials and realize scientific transformation from material fatigue to structural fatigue under different stress states.

4.2. Establishing the Fatigue Equation Based on the Weibull Distribution of Point Parameters

- (1)

- The results obtained from the fatigue tests of cement-treated aggregate base materials under different stress states revealed a good linear relationship in the P-S-N coordinate system, and the fitting correlation coefficient was extremely good. Compared to the conventional S-N fatigue curve, the logarithm equivalent fatigue life of cement-treated aggregate base materials also monotonously decreased with stress ratio, the difference of the fatigue curves under different stress states based on the new method of fatigue analysis has been greatly reduced, and it was hard to point out the fatigue tests results of one stress state from those of the other stress states. The data points were very close to each other. It was difficult to distinguish the fatigue data points under different stress states as a whole, standardization was realized.

- (2)

- In the single logarithmic standardization fatigue equation, the difference in the fatigue equation parameters under different stress states based on the new method of fatigue analysis has been greatly also reduced. The value of parameter a determines the steepness of the fatigue curve, representing the mechanical sensitivity. The smaller the slope of the curve, the lower the mechanical sensitivity, the greater the overloading of the road surface, and the better the over-limit capability. The parameter b value reflects the height of the curve. The higher the intercept, the better the fatigue resistance of cement-treated aggregate base materials. The highest parameter b value was observed at a curing time of 28 days and a cement content of 5%; that is, the fatigue resistance was the best. This result revealed that the higher the cement content, and the better the fatigue resistance of cement-treated aggregate base materials. From the results obtained from the fatigue tests of the existing cement-treated aggregate base materials [3,7,38,39,40], the range of parameter a was typically considered to be 7–28, and the parameter a obtained by the test ranges from 9.2 to 10.8 meet the range of parameter a.

- (3)

- The average of the parameters for the standardized fatigue equation at a curing time of 28 days and a cement content of 3–5% was expressed as follows:a: (9.5423 + 10.4689 + 10.7645)/3 = 10.2584b: (10.3342 + 11.4540 + 11.7037)/3 = 11.1637According to the obtained parameter average of (6) and (7), the unified expression for the standardized fatigue equation at a curing time of 28 days with different cement content can be expressed as lgNi = 11.1637 − 10.2584(σ/Sf).

- (4)

- The average parameters for the standardized fatigue equation at a curing time of 90 days and a cement content of 3–5% were expressed as follows:a: (9.2115 + 9.8136 + 9.5517)/3 = 9.5256b: (10.4075 + 10.8184 + 10.8485)/3 = 10.6914According to the obtained parameter average of (8) and (9), a unified expression for the standardized fatigue equation at a curing time of 90 days with different cement content can be expressed as lgNi = 10.6914 − 9.5256(σ/Sf)

- (5)

- From the standardization equation at a curing time of 28 days with different cement contents, lgNi = 11.1637 − 10.2584(σ/Sf); the standardization equation at a curing time of 90 days with different cement contents was lgNi = 10.6914 − 9.5256(σ/Sf), and the standardized fatigue equations for different cement content at different curing times were expressed as lgNi = 10.9274 − 9.8920(σ/Sf). The standardization of fatigue characteristics reduced or even eliminated the uncertainty of the stress states, curing time, cement content, and the size of specimen in the fatigue test results.

4.3. Establishing Fatigue Equations Based on the Weibull Distribution of Interval Parameters

4.3.1. Interval Analysis Method

4.3.2. Interval Value Theory

4.3.3. Establishing the Interval Fatigue Equation under the Weibull Distribution

4.3.4. Example of Calculation Analysis

5. Conclusions

- (1)

- Strength tests of cement-treated aggregate base materials under different stress states with 3–5% cement content at different curing times were carried out, the strength value of cement-treated aggregate base materials under different stress states monotonously increased with the curing time and cement content. The effect of the cement content on the strength of the cement-treated aggregate base material is larger than the curing time.

- (2)

- Fatigue tests of cement-treated aggregate base materials under different stress states were carried out with 3–5% cement content at 28 days and 90 days curing time, which clearly affected the analysis of their fatigue properties. It was difficult to compare the fatigue tests results under different stress states for cement-treated aggregate base materials.

- (3)

- The standardization equation of the fatigue characteristics under different stress states for cement-treated aggregate base materials was proposed, which could reduce or even eliminate the effect of the stress states, cement content, curing time and the shape and size of the specimen.

- (4)

- The form of point numerical did not completely reflect the complex properties, including the variability and uncertainty of parameters and indicators. The interval parameter value included the true value of the point parameter value, which conformed to the actual situation.

- (5)

- The standardization fatigue equation of interval parameters under different stress states was established, which solved the uncertainty of accuracy and stability of test equipment and the representative problem of test sampling, as well as reduced the error related to the materials, structure, construction, environment, and load.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Judycki, J.; Jaskula, P. Structural Design and Sensitivity Analysis of Semi-Rigid Pavement of a Motorway. Eng. J. 2012, 16, 117–126. [Google Scholar] [CrossRef] [Green Version]

- Sun, J.S.; Xiao, T.; Dou, Y.M.; Yang, C.F. Study on the Rational Thickness of Surface Course on Semi-Rigid Base Asphalt Pavement. In Proceedings of the GeoHunan International Conference 2011, Hunan, China, June 9–11 2011; pp. 37–44. [Google Scholar]

- Jiang, Y.J.; Cao, F.; Chen, Z.J.; Fang, J. Fatigue Performance and Application of Cement Stabilized Macadam Shaped with Vertical Vibration Test Method. J. Chang’an Univ. (Nat. Sci. Ed.) 2017, 36. [Google Scholar] [CrossRef]

- Preteseille, M.; Lenoir, T. Mechanical Fatigue Behavior in Treated/Stabilized Soils Subjected to a Uniaxial Flexural test. Int. J. Fatigue 2015, 77, 41–49. [Google Scholar] [CrossRef]

- Schneider, S.; Herrmann, R.; Marx, S. Development of a Resonant Fatigue Testing Facility for Large-scale Beams in Flexural Tensile. Int. J. Fatigue 2018, 113, 171–183. [Google Scholar] [CrossRef]

- Wang, Y.; Ni, F.J.; Li, Z.X. Fatigue Performance of Cement-stabilized Macadam Mixture. J. Traffic Transp. Eng. 2009, 9, 10–15. [Google Scholar]

- Jia, K. Study on the Fatigue Performance of Semi-rigid Base Course Materials. Ph.D. Thesis, Chang’an University, Xi’an, China, 17 June 2008. [Google Scholar]

- Lv, S.; Liu, C.; Lan, J.; Zhang, H.; Zheng, J.; You, Z. Fatigue Equation of Cement-Treated Aggregate Base Materials under a True Stress Ratio. Appl. Sci. 2018, 8, 691. [Google Scholar] [CrossRef]

- Jameson, G.; Sharp, K.; Potter, D. New Guidelines for the Design of Flexible Pavements for Australia Conditions. In Proceedings of the International Conference on Asphalt Pavements, Copenhagen, Denmark, 17–22 August 2002. [Google Scholar]

- Theyse, H.; De Beer, M.; Rust, F. Overview of the South African Mechanistic Pavement Design Analysis Method. Transp. Res. Rec. J. Transport. Res. Board 1996, 1539. [Google Scholar] [CrossRef]

- Han, D.; Huang, X. Fatigue Analysis of Cement-stabilized Macadam aggregate with Failure Mechanics. Civ. Eng. Environ. Syst. Eng. 2009, 31, 78–82. [Google Scholar]

- Judycki, J. Comparison of Fatigue Criteria for Flexible and Semi-Rigid Pavements. In Proceedings of the 8th Conference on Asphalt Pavements-International Society of Asphalt Pavements, Seattle, WA, USA, 10–14 August 1997; pp. 919–937. [Google Scholar]

- Geoff, A. Priority issues for performance and durability. In Proceedings of the 8th International Society for Concrete Pavements: 8th International Conference on Concrete Pavements (ICCP), Colorado Springs, CO, USA, 14–18 August 2005; pp. 181–207. [Google Scholar]

- Li, N.; Molenaar, A.A.A.; Pronk, A.C.; van de Ven, M.F.C.; Wu, S. Effect of Specimen Size on Fatigue Behavior of Asphalt Mixture in Laboratory Fatigue Tests. In Proceedings of the 7th RILEM International Conference on Cracking in Pavements, Delft, The Netherlands, 20–22 June 2012; pp. 827–836. [Google Scholar]

- Li, N.; Molenaar, A.A.A.; Pronk, A.C.; van de Ven, M.F.C. Investigation into the Size Effect on Four Point Flexural Tensile Fatigue Tests. In Proceedings of the 3rd workshop on 4PB, Davis, CA, USA, 17–18 September 2012; pp. 444–489. [Google Scholar]

- Lv, S.; Liu, C.; Chen, D.; Zheng, J.; You, Z. Normalization of fatigue characteristics for asphalt mixtures under different stress states. Constr. Build. Mater. 2018, 177, 33–42. [Google Scholar] [CrossRef]

- Li, N.; Molenaar, A.A.A.; Ven, M.F.C.; Wu, S. Characterization of Fatigue Performance of Asphalt Mixture Using a New Fatigue Analysis Approach. Constr. Build. Mater. 2013, 45, 45–52. [Google Scholar] [CrossRef]

- Tarifa, M.; Ruiz, G.; Poveda, E.; Zhang, X.X.; Vicente, M.A.; González, D. Effect of uncertainty on load position in the fatigue life of steel-fiber reinforced concrete under compression. Mater. Struct. 2018, 51. [Google Scholar] [CrossRef]

- Chen, Y.; Zheng, M.; Wang, B. Establishment and Application of the Fatigue Equation of Porous Cement-based Concrete. J. Chin. Ceram. Soc. 2005, 7, 827–831. [Google Scholar]

- Shi, X. Study on Flexural Fatigue Behavior of Cement Concrete. Civ. Eng. J. 1990, 23, 11–22. [Google Scholar]

- Zheng, M.; Sun, J.; Wang, B. Establishment and Application of Fatigue Equation for Lean Concrete. J. Xi’an Univ. Architect. Technol. (Nat. Sci. Ed.) 2007, 3, 92–97. [Google Scholar]

- Rinne, H. The Weibull Distribution A Handbook, 1st ed; CRC Press: Boca Raton, FL, USA, 2008. [Google Scholar]

- Ou, Z.; Lu, S. Flexural fatigue-life reliability of frost-damaged concrete. J. Zhejiang Univ. 2017, 51, 1074–1081. [Google Scholar]

- Sha, A.M.; Kan, J.; Li, X. Fatigue Performances of Semi-rigid Base Course Materials. J. Traffic Transp. Eng. 2009, 9, 29–33. [Google Scholar]

- Ortega, J.J.; Ruiz, G.; Yu, R.C.; Afanador-García, N.; Tarifa, M.; Poveda, E.; Zhang, X.X.; Evangelista, F.J. Number of tests and corresponding error in concrete fatigue. Int. J. Fatigue 2018, 116, 210–219. [Google Scholar] [CrossRef]

- Ganesan, N.; Raj, J.B.; Shashikala, A.P. Flexural fatigue behavior of selfcompacting rubberized concrete. Constr. Build. Mater. 2013, 44, 7–14. [Google Scholar] [CrossRef]

- Moore, R.E. Interval Arithmetic and Automatic Error Analysis in Digital Computing. Ph.D. Thesis, Stanford University, Stanford, CA, USA, 1962. [Google Scholar]

- Moore, R.E. Interval Analysis; Prentice-Hall: Englewood Cliffs, NJ, USA, 1966. [Google Scholar]

- Moore, R.E.; Kearfott, R.B.; Cloud, M.J. Introduction to Interval Analysis; Society for Industrial and Applied Mathematics (SIAM): Philadelphia, PA, USA, 2009. [Google Scholar]

- García, O.; Ehí, J.V.; Iguel, M.; Sainz, A.; Campos, J.; Atos, M. Application of Interval Analysis to Solve Civil Engineering problems—Some Examples. In Proceedings of the Second International Conference on Structural Engineering, Mechanics and Computation, Cape Town, South Africa, 4–7 July 2004. [Google Scholar]

- Chen, R. On Interval Fuzzy Evaluation Analysis of Highway Roadbed Stability in Karst Area. Value Eng. 2014, 6, 72–73. [Google Scholar]

- Dodagoudar, G.R.; Venkatachalam, G. Reliability Analysis of Slopes Using Fuzzy Sets Theory. Comput. Geotech. 2015, 363, 135–143. [Google Scholar] [CrossRef]

- Donald, I.B.; Chen, Z. Slope Stability Analysis by the Upper Bound Approach: Fundamentals and methods. Can. Geotech. J. 2011, 34, 853–862. [Google Scholar] [CrossRef]

- Giasi, C.I.; Masi, P.; Cherubini, C. Probabilistic and Fuzzy Reliability Analysis of a Sample Slope near Aliano. Eng. Geol. 2003, 67, 391–402. [Google Scholar] [CrossRef]

- JTG/T F20-2015 Technical Guidelines for Construction of Highway Road Bases; Renmin Communication Press: Beijing, China, 2015; Available online: http://www.doc88.com/p-5728953349302.html (accessed on 30 August 2017).

- JTG E51-2009 The Chinese Test Methods of Materials Stabilized with Inorganic Binders for Highway Engineering; Renmin Communication Press: Beijing, China, 2009; Available online: https://doc.mbalib.com/view/f4212ef102cc21709e000db4f04ae593.html (accessed on 30 August 2017).

- JTG D50-2017 The Chinese Specification for Design of Highway Asphalt Pavement; Renmin Communication Press: Beijing, China, 2017; Available online: https://www.doc88.com/p-6912879474197.html (accessed on 22 March 2018).

- Lv, S.; Zheng, J.L.; Zhong, W.L. Characteristics of Strength, Modulus and Fatigue Damage for Cement Stabilized Macadam in Curing Period. China J. Highw. Transp. 2015, 28, 9–15. [Google Scholar]

- Wang, Y.; Ni, F.; Li, Z. Study on transverse shrink-curing time crack control of cement-stabilized macadam base. In Proceedings of the 4th Japan/China Workshop on Pavement Technologies, Sapporo, Japan, 25–27 July 2007; pp. 437–446. [Google Scholar]

- Lim, S.; Dan, G.Z. Estimation of the Compressive Strength and Modulus of Elasticity of Cement-Treated Aggregate Base Materials. J. Transp. Res. Rec. 2003, 1837. [Google Scholar] [CrossRef]

- Tang, L.; Zheng, J. Interval Analysis Theory and Method of Geotechnical Engineering; Science Press: Beijing, China, 2017. [Google Scholar]

| Test Projects | Test Results | Technical Requirement | |

|---|---|---|---|

| Fineness detection | 1.8 | ≤10% | |

| Setting time (min) | initial setting /min | 285 | ≥180 |

| final setting /min | 422 | ≥360 | |

| Stability (mm) | 2.8 | ≤5 | |

| Strength of cement mortar(MPa) | 3 days flexural strength | 5.2 | ≥2.5 |

| 3 days unconfined compressive strength | 21.9 | ≥10 | |

| MgO content (%) | 3.5 | ≤5% | |

| SO3 content (%) | 1.6 | ≤3.5% | |

| Loss on ignition | 0.7 | ≤3.0% | |

| Specific surface area (selectivity indicator) | 390 | 300 m2/kg–450 m2/kg | |

| Initial setting time | 120 | ≥90 min | |

| Final setting time | 660 | ≤720 min | |

| Sieve Size (mm) | 26.5 | 19 | 16 | 13.2 | 9.5 | 4.75 | 2.36 | 1.18 | 0.6 | 0.3 | 0.15 | 0.075 | Total Content (g) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Aggtregate Content (g) | 1036.8 | 622.1 | 553 | 829.5 | 1451.5 | 829.5 | 483.8 | 345.6 | 241.9 | 172.8 | 103.7 | 241.9 | 6912.1 |

| Sieve Size (mm) | 26.5 | 19 | 16 | 13.2 | 9.5 | 4.75 | 2.36 | 1.18 | 0.6 | 0.3 | 0.15 | 0.075 | Total Content (g) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Aggtregate Content (g) | 4247.9 | 2565 | 2280 | 3420 | 5984.9 | 3420 | 1995 | 1425 | 997.5 | 712.5 | 427.5 | 997.5 | 28499.6 |

| Test Projects | Test Results | Technical Requirement [20] |

|---|---|---|

| Content of flat and elongated particles in coarse aggregate (%) | 13.8% | ≤20% |

| Crushed stone value (%) | 22.5% | ≤30% |

| Less than 0.6mm particle Liquid limit/plastic index | liquid limit ≤27% | 26.5% |

| plastic index ≤8 | 6.2 | |

| Content of soft stone (%) | 1.2 | ≤3 |

| Curing Times (days) | Stress States | a | b | R2 |

|---|---|---|---|---|

| 28 | Unconfined compressive | −2.0258 × 106 | 1.66789 × 106 | 0.5638 |

| Flexural tensile | −1.4729 × 106 | 1.19269 × 106 | 0.5092 | |

| Indirect tensile | −1.5517 × 106 | 1.25961 × 106 | 0.5431 | |

| 90 | Unconfined compressive | −2.3598 × 106 | 1.95095 × 106 | 0.6512 |

| Flexural tensile | −1.4028 × 106 | 1.13783 × 106 | 0.4943 | |

| Indirect tensile | −1.7705 × 106 | 1.4483 × 106 | 0.5648 |

| Curing Times (days) | Stress States | a | b | R2 |

|---|---|---|---|---|

| 28 | Unconfined compressive | −4.4579 × 106 | 3.6650 × 106 | 0.5965 |

| Flexural tensile | −1.7026 × 106 | 1.4041 × 106 | 0.7053 | |

| Indirect tensile | −2.9069 × 106 | 2.3819 × 106 | 0.5853 | |

| 90 | Unconfined compressive | −5.1242 × 106 | 4.2909 × 106 | 0.6611 |

| Flexural tensile | −2.2351 × 106 | 1.8415 × 106 | 0.6934 | |

| Indirect tensile | −3.5573 × 106 | 2.9092 × 106 | 0.5976 |

| Curing Times (days) | Stress States | a | b | R2 |

|---|---|---|---|---|

| 28 | Unconfined compressive | −5.5173 × 106 | 4.7240 × 106 | 0.8152 |

| Flexural tensile | −2.4064 × 106 | 1.9855 × 106 | 0.6848 | |

| Indirect tensile | −3.4806 × 106 | 2.8836 × 106 | 0.7094 | |

| 90 | Unconfined compressive | −7.7162 × 106 | 6.5691 × 106 | 0.7258 |

| Flexural tensile | −2.5573 × 106 | 2.1357 × 106 | 0.7700 | |

| Indirect tensile | −4.2797 × 106 | 3.5978 × 106 | 0.7489 |

| Stress Ratio | Stress States | Curing Times (days) | Cement Content (%) | m | lnt0 | R2 |

|---|---|---|---|---|---|---|

| 0.5 | Unconfined compressive | 28 | 3 | 38.0303 | 227.5346 | 0.8728 |

| 0.6 | Indirect tensile | 90 | 4 | 3.0914 | 17.5668 | 0.6628 |

| 0.7 | Flexural tensile | 28 | 5 | 2.1103 | 10.6800 | 0.7861 |

| 0.8 | Indirect tensile | 90 | 3 | 4.7462 | 18.1532 | 0.9388 |

| 0.9 | Unconfined compressive | 28 | 4 | 1.5475 | 5.7722 | 0.8406 |

| Cement Content (%) | Curing Times (days) | Standardized Fatigue Equation | R2 |

|---|---|---|---|

| 3 | 28 | 0.8472 | |

| 90 | 0.9257 | ||

| 4 | 28 | 0.9615 | |

| 90 | 0.8956 | ||

| 5 | 28 | 0.9134 | |

| 90 | 0.9321 |

| Curing Times (days) | Cement Content (%) | Parameter a | Parameter b |

|---|---|---|---|

| 28 | 3 | 9.5423 | 10.3342 |

| 4 | 10.4689 | 11.4541 | |

| 5 | 10.7642 | 11.7034 | |

| 90 | 3 | 9.2115 | 10.4075 |

| 4 | 9.8136 | 10.8184 | |

| 5 | 9.5517 | 10.8485 |

| Curing Times (days) | Cement Content (%) | Point Parameter Fatigue Equation | Interval Parameter Fatigue Equation |

|---|---|---|---|

| 28 | 3.5 | ||

| 4.5 | |||

| 90 | 3.5 | ||

| 4.5 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xie, J.; Tang, L.; Lv, S.; Zhang, N.; Huang, T.; Liu, H. Standardization of Fatigue Characteristics of Cement-Treated Aggregate Base Materials under Different Stress States. Appl. Sci. 2018, 8, 1500. https://doi.org/10.3390/app8091500

Xie J, Tang L, Lv S, Zhang N, Huang T, Liu H. Standardization of Fatigue Characteristics of Cement-Treated Aggregate Base Materials under Different Stress States. Applied Sciences. 2018; 8(9):1500. https://doi.org/10.3390/app8091500

Chicago/Turabian StyleXie, Jiawei, Limin Tang, Songtao Lv, Naitian Zhang, Tuo Huang, and Hongfu Liu. 2018. "Standardization of Fatigue Characteristics of Cement-Treated Aggregate Base Materials under Different Stress States" Applied Sciences 8, no. 9: 1500. https://doi.org/10.3390/app8091500