Silane-Functionalized Sheep Wool Fibers from Dairy Industry Waste for the Development of Plasticized PLA Composites with Maleinized Linseed Oil for Injection-Molded Parts

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

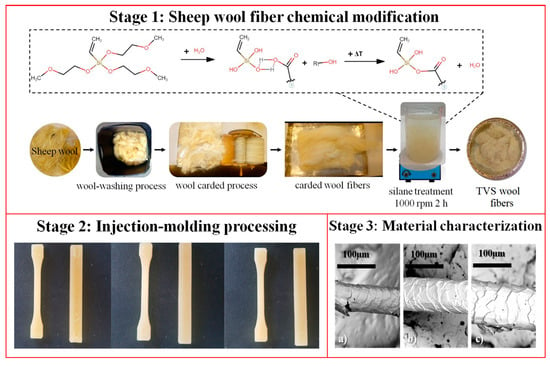

2.2.1. Silane Wool Fiber Treatment

2.2.2. Composite Manufacturing

2.2.3. Composites Characterization

Mechanical Properties Assessment

Thermal Characterization

X-ray Diffraction

Composites Surface Properties Evaluation

3. Results and Discussion

3.1. Silane Wool Fiber Treatment

3.2. Composite Charactarization

3.2.1. Mechanical Properties

3.2.2. XRD Diffraction Pattern

3.2.3. Thermal Properties

3.2.4. Composites Surface Characterization

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Arrieta, M.P.; Samper, M.D.; Aldas, M.; López, J. On the use of PLA-PHB blends for sustainable food packaging applications. Materials 2017, 10, 1008. [Google Scholar] [CrossRef] [PubMed]

- Armentano, I.; Dottori, M.; Fortunati, E.; Mattioli, S.; Kenny, J. Biodegradable polymer matrix nanocomposites for tissue engineering: A review. Polym. Degrad. Stab. 2010, 95, 2126–2146. [Google Scholar] [CrossRef]

- Grząbka-Zasadzińska, A.; Klapiszewski, Ł.; Borysiak, S.; Jesionowski, T. Thermal and mechanical properties of silica–lignin/polylactide composites subjected to biodegradation. Materials 2018, 11, 2257. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Raquez, J.-M.; Habibi, Y.; Murariu, M.; Dubois, P. Polylactide (PLA)-based nanocomposites. Prog. Polym. Sci. 2013, 38, 1504–1542. [Google Scholar] [CrossRef]

- Beltrán, F.R.; Arrieta, M.P.; Gaspar, G.; de la Orden, M.U.; Urreaga, J.M. Effect of lignocellulosic nanoparticles extracted from yerba mate (Ilex paraguariensis) on the structural, thermal, optical and barrier properties of mechanically recycled poly(lactic acid). Polymers 2020, 12, 1690. [Google Scholar] [CrossRef] [PubMed]

- Herrera, N.; Roch, H.; Salaberria, A.M.; Pino-Orellana, M.A.; Labidi, J.; Fernandes, S.C.; Radic, D.; Leiva, A.; Oksman, K. Functionalized blown films of plasticized polylactic acid/chitin nanocomposite: Preparation and characterization. Mater. Des. 2016, 92, 846–852. [Google Scholar] [CrossRef]

- Arrieta, M.P.; Fortunati, E.; Dominici, F.; López, J.; Kenny, J.M. Bionanocomposite films based on plasticized PLA–PHB/cellulose nanocrystal blends. Carbohydr. Polym. 2015, 121, 265–275. [Google Scholar] [CrossRef] [Green Version]

- Arrieta, M.; Peponi, L.; López, D.; Fernández-García, M. Recovery of yerba mate (Ilex paraguariensis) residue for the development of PLA-based bionanocomposite films. Ind. Crop. Prod. 2018, 111, 317–328. [Google Scholar] [CrossRef]

- Garcia-Garcia, D.; Carbonell-Verdu, A.; Arrieta, M.P.; López-Martínez, J.; Samper, M.D. Improvement of PLA film ductility by plasticization with epoxidized karanja oil. Polym. Degrad. Stab. 2020, 179. [Google Scholar] [CrossRef]

- Graupner, N. Application of lignin as natural adhesion promoter in cotton fibre-reinforced poly(lactic acid)(PLA) composites. J. Mater. Sci. 2008, 43, 5222–5229. [Google Scholar] [CrossRef]

- Beltrán, F.R.; Gaspar, G.; Chomachayi, M.D.; Jalali-Arani, A.; Lozano-Pérez, A.A.; Cenis, J.L.; María, U.; Pérez, E.; Urreaga, J.M.M. Influence of addition of organic fillers on the properties of mechanically recycled PLA. Environ. Sci. Pollut. Res. 2020, 1–14. [Google Scholar] [CrossRef] [PubMed]

- Andrzejewski, J.; Szostak, M.; Barczewski, M.; Łuczak, P. Cork-wood hybrid filler system for polypropylene and poly(lactic acid) based injection molded composites. Structure evaluation and mechanical performance. Compos. Part B Eng. 2019, 163, 655–668. [Google Scholar] [CrossRef]

- Alam, J.; Alam, M.; Raja, M.; Abduljaleel, Z.; Dass, L.A. MWCNTs-reinforced epoxidized linseed oil plasticized polylactic acid nanocomposite and its electroactive shape memory behaviour. Int. J. Mol. Sci. 2014, 15, 19924–19937. [Google Scholar] [CrossRef] [PubMed]

- Ferri, J.; Garcia-Garcia, D.; Sánchez-Nacher, L.; Fenollar, O.; Balart, R. The effect of maleinized linseed oil (mlo) on mechanical performance of poly(lactic acid)-thermoplastic starch (PLA-TPS) blends. Carbohydr. Polym. 2016, 147, 60–68. [Google Scholar] [CrossRef] [PubMed]

- Arrieta, M.P.; Sessini, V.; Peponi, L. Biodegradable poly(ester-urethane) incorporated with catechin with shape memory and antioxidant activity for food packaging. Eur. Polym. J. 2017, 94, 111–124. [Google Scholar] [CrossRef]

- Odent, J.; Leclère, P.; Raquez, J.-M.; Dubois, P. Toughening of polylactide by tailoring phase-morphology with P[CL-co-LA] random copolyesters as biodegradable impact modifiers. Eur. Polym. J. 2013, 49, 914–922. [Google Scholar] [CrossRef]

- González-Ausejo, J.; Gámez-Pérez, J.; Balart, R.; Lagarón, J.M.; Cabedo, L. Effect of the addition of sepiolite on the morphology and properties of melt compounded PHVB/PLA blends. Polym. Compos. 2019, 40, E156–E168. [Google Scholar] [CrossRef]

- Carbonell-Verdu, A.; Ferri, J.; Dominici, F.; Boronat, T.; Sanchez-Nacher, L.; Balart, R.; Torre, L. Manufacturing and compatibilization of PLA/PBAT binary blends by cottonseed oil-based derivatives. Express Polym. Lett. 2018, 12, 808–823. [Google Scholar] [CrossRef]

- Luzi, F.; Fortunati, E.; Jiménez, A.; Puglia, D.; Pezzolla, D.; Gigliotti, G.; Kenny, J.; Chiralt, A.; Torre, L. Production and characterization of PLA_PBS biodegradable blends reinforced with cellulose nanocrystals extracted from hemp fibres. Ind. Crop. Prod. 2016, 93, 276–289. [Google Scholar] [CrossRef]

- Arrieta, M.; de Dicastillo, C.L.; Garrido, L.; Roa, K.; Galotto, M.J. Electrospun PVA fibers loaded with antioxidant fillers extracted from Durvillaea antarctica algae and their effect on plasticized pla bionanocomposites. Eur. Polym. J. 2018, 103, 145–157. [Google Scholar] [CrossRef]

- Burgos, N.; Tolaguera, D.; Fiori, S.; Jiménez, A. Synthesis and characterization of lactic acid oligomers: Evaluation of performance as poly(lactic acid) plasticizers. J. Polym. Environ. 2014, 22, 227–235. [Google Scholar] [CrossRef] [Green Version]

- Dobircau, L.; Delpouve, N.; Herbinet, R.; Domenek, S.; Le Pluart, L.; Delbreilh, L.; Ducruet, V.; Dargent, E. Molecular mobility and physical ageing of plasticized poly(lactide). Polym. Eng. Sci. 2015, 55, 858–865. [Google Scholar] [CrossRef]

- Courgneau, C.; Domenek, S.; Guinault, A.; Avérous, L.; Ducruet, V. Analysis of the structure-properties relationships of different multiphase systems based on plasticized poly(lactic acid). J. Polym. Environ. 2011, 19, 362–371. [Google Scholar] [CrossRef]

- Arrieta, M.P.; López, J.; Rayón, E.; Jiménez, A. Disintegrability under composting conditions of plasticized PLA–PHB blends. Polym. Degrad. Stabil. 2014, 108, 307–318. [Google Scholar] [CrossRef] [Green Version]

- Arrieta, M.P.; Perdiguero, M.; Fiori, S.; Kenny, J.M.; Peponi, L. Biodegradable electrospun PLA-PHB fibers plasticized with oligomeric lactic acid. Polym. Degrad. Stab. 2020, 179, 109226. [Google Scholar] [CrossRef]

- Arrieta, M.P.; Samper, M.; Jiménez-López, M.; Aldas, M.; López, J. Combined effect of linseed oil and gum rosin as natural additives for PVC. Ind. Crop. Prod. 2017, 99, 196–204. [Google Scholar] [CrossRef]

- Aldas Carrasco, M.F.; Rouault, N.J.; Ferri Azor, J.M.; López-Martínez, J.; Samper Madrigal, M.D. A new bio-based fibre-reinforced polymer obtained from sheep wool short fibres and PLA. Green Mater. 2020, 8, 79–91. [Google Scholar] [CrossRef]

- Pawlak, F.; Aldas, M.; López-Martínez, J.; Samper, M.D. Effect of different compatibilizers on injection-molded green fiber-reinforced polymers based on poly(lactic acid)-maleinized linseed oil system and sheep wool. Polymers 2019, 11, 1514. [Google Scholar] [CrossRef] [Green Version]

- Samper, M.; Petrucci, R.; Sánchez-Nacher, L.; Balart, R.; Kenny, J. New environmentally friendly composite laminates with epoxidized linseed oil (ELO) and slate fiber fabrics. Compos. Part B 2015, 71, 203–209. [Google Scholar] [CrossRef]

- Samper, M.; Petrucci, R.; Sanchez-Nacher, L.; Balart, R.; Kenny, J. Properties of composite laminates based on basalt fibers with epoxidized vegetable oils. Mater. Des. 2015, 72, 9–15. [Google Scholar] [CrossRef]

- Aluigi, A.; Tonetti, C.; Rombaldoni, F.; Puglia, D.; Fortunati, E.; Armentano, I.; Santulli, C.; Torre, L.; Kenny, J.M. Keratins extracted from merino wool and brown alpaca fibres as potential fillers for PLLA-based biocomposites. J. Mater. Sci. 2014, 49, 6257–6269. [Google Scholar] [CrossRef]

- Baghaei, B.; Skrifvars, M.; Berglin, L. Manufacture and characterisation of thermoplastic composites made from PLA/hemp co-wrapped hybrid yarn prepregs. Compos. Part A 2013, 50, 93–101. [Google Scholar] [CrossRef]

- Meenakshi, C.; Krishnamoorthy, A. Study on the effect of surface modification on the mechanical and thermal behaviour of flax, sisal and glass fiber-reinforced epoxy hybrid composites. J. Renew. Mater. 2019, 7, 153–169. [Google Scholar] [CrossRef] [Green Version]

- Wang, F.; Zhou, S.; Yang, M.; Chen, Z.; Ran, S. Thermo-mechanical performance of polylactide composites reinforced with alkali-treated bamboo fibers. Polymers 2018, 10, 401. [Google Scholar] [CrossRef] [Green Version]

- Sormunen, P.; Kärki, T. Compression molded thermoplastic composites entirely made of recycled materials. Sustainability 2019, 11, 631. [Google Scholar] [CrossRef] [Green Version]

- Conzatti, L.; Giunco, F.; Stagnaro, P.; Patrucco, A.; Tonin, C.; Marano, C.; Rink, M.; Marsano, E. Wool fibres functionalised with a silane-based coupling agent for reinforced polypropylene composites. Compos. Part A 2014, 61, 51–59. [Google Scholar] [CrossRef]

- Nanthananon, P.; Seadan, M.; Pivsa-Art, S.; Hamada, H.; Suttiruengwong, S. Reactive compatibilization of short-fiber reinforced poly(lactic acid) biocomposites. J. Renew. Mater. 2018, 6, 573–583. [Google Scholar] [CrossRef]

- Sessini, V.; Navarro-Baena, I.; Arrieta, M.P.; Dominici, F.; López, D.; Torre, L.; Kenny, J.M.; Dubois, P.; Raquez, J.-M.; Peponi, L. Effect of the addition of polyester-grafted-cellulose nanocrystals on the shape memory properties of biodegradable PLA/PCL nanocomposites. Polym. Degrad. Stab. 2018, 152, 126–138. [Google Scholar] [CrossRef]

- Rusmirović, J.; Trifkovic, K.; Bugarski, B.; Pavlović, V.B.; Džunuzović, J.; Tomić, M.; Marinkovic, A. High performance unsaturated polyester based nanocomposites: Effect of vinyl modified nanosilica on mechanical properties. Express Polym. Lett. 2016, 10, 139–159. [Google Scholar] [CrossRef]

- Salgado, C.; Arrieta, M.P.; Peponi, L.; López, D.; Fernández-García, M. Photo-crosslinkable polyurethanes reinforced with coumarin modified silica nanoparticles for photo-responsive coatings. Prog. Org. Coat. 2018, 123, 63–74. [Google Scholar] [CrossRef]

- Abdel-Gawad, N.M.; El Dein, A.Z.; Mansour, D.-E.A.; Ahmed, H.M.; Darwish, M.; Lehtonen, M. Enhancement of dielectric and mechanical properties of polyvinyl chloride nanocomposites using functionalized TiO2 nanoparticles. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 3490–3499. [Google Scholar] [CrossRef]

- Abdelmouleh, M.; Boufi, S.; ben Salah, A.; Belgacem, M.N.; Gandini, A. Interaction of silane coupling agents with cellulose. Langmuir 2002, 18, 3203–3208. [Google Scholar] [CrossRef]

- Peng, H.; Lu, M.; Lv, F.; Niu, M.; Wang, W. Understanding the effect of silane crosslinking reaction on the properties of pp/poe blends. Polym. Bull. 2019, 76, 6413–6428. [Google Scholar] [CrossRef]

- Xie, Y.; Hill, C.A.S.; Xiao, Z.; Militz, H.; Mai, C. Silane coupling agents used for natural fiber/polymer composites: A review. Compos. Part A 2010, 41, 806–819. [Google Scholar] [CrossRef]

- Côto, T.; Moura, I.; de Sá, A.; Vilarinho, C.; Machado, A.V. Sustainable materials based on cellulose from food sector agro-wastes. J. Renew. Mater. 2018, 6, 688–696. [Google Scholar]

- Ku, H.; Wang, H.; Pattarachaiyakoop, N.; Trada, M. A review on the tensile properties of natural fiber reinforced polymer composites. Compos. Part B 2011, 42, 856–873. [Google Scholar] [CrossRef] [Green Version]

- International Standards Organization. ISO 527-1:2012—Plastics—Determination of Tensile Properties—Part 1: General Principles; International Standards Organization: Geneva, Switzerland, 2012. [Google Scholar]

- International Standards Organization. ISO 179-1:2010—Plastics—Determination of Charpy Impact Properties/Part 1: Non-Instrumented Impact Test; International Standards Organization: Geneva, Switzerland, 2010. [Google Scholar]

- International Standards Organization. ISO 868:2003—Plastics and Ebonite—Determination of Indentation Hardness by Means of a Durometer (Shore Hardness); International Standards Organization: Geneva, Switzerland, 2003. [Google Scholar]

- Turner Ii, J.F.; Riga, A.; O’Connor, A.; Zhang, J.; Collis, J. Characterization of drawn and undrawn poly-L-lactide films by differential scanning calorimetry. J. Therm. Anal. Calorim. 2004, 75, 257–268. [Google Scholar] [CrossRef]

- Fombuena, V.; Balart, J.; Boronat, T.; Sánchez-Nácher, L.; Garcia-Sanoguera, D. Improving mechanical performance of thermoplastic adhesion joints by atmospheric plasma. Mater. Des. 2013, 47, 49–56. [Google Scholar] [CrossRef]

- Valadez-Gonzalez, A.; Cervantes-Uc, J.M.; Olayo, R.; Herrera-Franco, P.J. Chemical modification of henequén fibers with an organosilane coupling agent. Compos. Part B 1999, 30, 321–331. [Google Scholar] [CrossRef]

- Hanoosh, W.S. Synthesis and polymerization of new silane coupling agent and used it as impact modifier of silica filled unsaturated polyester. Asian J. Appl. Sci. 2016, 4, 370–378. [Google Scholar]

- Liu, X.; Nie, Y.; Meng, X.; Zhang, Z.; Zhang, X.; Zhang, S. Dbn-based ionic liquids with high capability for the dissolution of wool keratin. RSC Adv. 2017, 7, 1981–1988. [Google Scholar] [CrossRef] [Green Version]

- Montazer, M.; Behzadnia, A.; Moghadam, M.B. Superior self-cleaning features on wool fabric using TiO2/Ag nanocomposite optimized by response surface methodology. J. Appl. Polym. Sci. 2012, 125, E356–E363. [Google Scholar] [CrossRef]

- Yu, T.; Jiang, N.; Li, Y. Study on short ramie fiber/poly(lactic acid) composites compatibilized by maleic anhydride. Compos. Part A 2014, 64, 139–146. [Google Scholar] [CrossRef]

- Silverajah, V.; Ibrahim, N.A.; Yunus, W.M.Z.W.; Hassan, H.A.; Woei, C.B. A comparative study on the mechanical, thermal and morphological characterization of poly(lactic acid)/epoxidized palm oil blend. Int. J. Mol. Sci. 2012, 13, 5878–5898. [Google Scholar] [CrossRef] [Green Version]

- Chu, Z.; Zhao, T.; Li, L.; Fan, J.; Qin, Y. Characterization of antimicrobial poly(lactic acid)/nano-composite films with silver and zinc oxide nanoparticles. Materials 2017, 10, 659. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Maiza, M.; Benaniba, M.T.; Quintard, G.; Massardier-Nageotte, V. Biobased additive plasticizing polylactic acid (PLA). Polimeros 2015, 25, 581–590. [Google Scholar] [CrossRef]

- Islam, M.; Pickering, K.; Foreman, N. Influence of alkali treatment on the interfacial and physico-mechanical properties of industrial hemp fibre reinforced polylactic acid composites. Compos. Part A 2010, 41, 596–603. [Google Scholar] [CrossRef]

- Alam, A.M.; Mina, M.; Beg, M.; Mamun, A.; Bledzki, A.; Shubhra, Q. Thermo-mechanical and morphological properties of short natural fiber reinforced poly(lactic acid) biocomposite: Effect of fiber treatment. Fibers Polym. 2014, 15, 1303–1309. [Google Scholar] [CrossRef] [Green Version]

- Arrieta, M.P.; Peltzer, M.A.; López, J.; Peponi, L. PLA-based nanocomposites reinforced with CNC for food packaging applications: From synthesis to biodegradation. In Industrial Applications of Renewable Biomass Products: Past, Present and Future; Springer Nature: Cham, Switzerland, 2017; pp. 265–300. [Google Scholar]

- Balart, J.; Fombuena, V.; Boronat, T.; Reig, M.; Balart, R. Surface modification of polypropylene substrates by uv photografting of methyl methacrylate (MMA) for improved surface wettability. J. Mater. Sci. 2012, 47, 2375–2383. [Google Scholar] [CrossRef]

- Arrieta, M.P.; Peltzer, M.A.; López, J.; del Carmen Garrigós, M.; Valente, A.J.; Jiménez, A. Functional properties of sodium and calcium caseinate antimicrobial active films containing carvacrol. J. Food Eng. 2014, 121, 94–101. [Google Scholar] [CrossRef] [Green Version]

| Coding of Formulation | PLA (phr) | MLO (phr) | Wool (phr) | TVS (phr) |

|---|---|---|---|---|

| PLA | 100 | - | - | - |

| PLA/MLO | 100 | 10 | - | - |

| PLA/MLO-1W | 100 | 10 | 1 | - |

| PLA/MLO-1W-1TVS | 100 | 10 | 1 | 1 |

| PLA/MLO-1W-2.5TVS | 100 | 10 | 1 | 2.5 |

| PLA/MLO-5W | 100 | 10 | 5 | - |

| PLA/MLO-5W-1TVS | 100 | 10 | 5 | 1 |

| PLA/MLO-5W-2.5TVS | 100 | 10 | 5 | 2.5 |

| PLA/MLO-10W | 100 | 10 | 10 | - |

| PLA/MLO-10W-1TVS | 100 | 10 | 10 | 1 |

| PLA/MLO-10W-2.5TVS | 100 | 10 | 10 | 2.5 |

| DSC | TGA | |||||||

|---|---|---|---|---|---|---|---|---|

| Formulation | Tg (°C) | Tcc (°C) | Tm (°C) | Xc (%) | T5% (°C) | Tmax (°C) | Mass Loss at 300 °C (%) | Mass Loss at 350 °C (%) |

| PLA | 63.6 ± 0.6 a | 103.3 ± 0.7 a | 171.1 ± 0.6 a | 16.7 ± 0.2 a,d | 331.0 ± 1.0 a | 357.3 ± 1.2 a,c | 0.05 ± 0.0a | 21.3 ± 0.9 a |

| PLA/MLO | 60.5 ± 0.6 b | 101.8 ± 1.3 a | 170.1 ± 0.3 a,b | 21.8 ± 0.3 b | 326.0 ± 1.0 a,c | 362.7 ± 0.6 b,d | 1.2 ± 0.1a,b | 22.9 ± 2.2 a |

| PLA/MLO-1W | 60.2 ± 0.4 b | 103.1 ± 0.1 a | 168.8 ± 0.3 a,b | 18.6 ± 1.1 a,e | 326.3 ± 0.6 a,c | 361.7 ± 1.6 b,c,d,e | 1.2 ± 0.1ª,b | 22.5 ± 2.2 a |

| PLA/MLO-1W-1TVS | 60.4 ± 0.4 b | 106.5 ± 0.1 a,b | 170.4 ± 0.9 a,b | 13.1 ± 0.6 c | 313.0 ± 3.0 b,c | 358.3 ± 1.5 a,c | 3.3 ± 0.6 b,c,d | 27.0 ± 6.1 a,b |

| PLA/MLO-1W-2.5TVS | 60.8 ± 0.1 b | 106.8 ± 1.2 a,b | 170.1 ± 0.3 a,b | 14.1 ± 0.4 c,d,g | 314.7 ± 4.2 b,c | 359.3 ± 1.2 c,e,f,g | 3.3 ± 1.2 b,c,d | 27.6 ± 6.5 a,b,d |

| PLA/MLO-5W | 60.1 ± 0.3 b | 104.1 ± 0.5 a,b | 169.4 ± 1.1 a,b | 20.2 ± 0.5 b,e | 305.7 ± 3.5 b,c,d | 361.0 ± 1.0 b,c,e,f | 4.1 ± 0.8 c,d,e | 29.8 ± 3.5 a,b,c,d |

| PLA/MLO-5W-1TVS | 59.5 ± 0.9 b | 105.4 ± 0.2 a,b | 168.9 ± 1.2 a,b | 16.4 ± 1.7 a,g | 316.3 ± 0.6 c | 364.3 ± 1.5 d | 2.9 ± 0.1 b,c | 29.2 ± 1.0 a,b,c,d |

| PLA/MLO-5W-2.5TVS | 59.5 ± 0.3 b | 105.9 ± 0.4 a,b | 168.5 ± 0.3 b | 16.5 ± 0.4 a,g | 300.0 ± 3.0 d,e | 359.0 ± 1.0 a,e,f,g | 4.6 ± 1.4 c,d,e | 32.2 ± 2.3 b,c,d |

| PLA/MLO-10W | 60.4 ± 0.8 b | 104.1 ± 1.3 a,b | 169.8 ± 1.4 a,b | 21.4 ± 2.4b,e | 297.3 ± 4.0 d,e | 358.3 ± 0.6 a,f,g | 5.3 ± 0.7 d,e | 37.8 ± 1.1 c,d |

| PLA/MLO-10W-1TVS | 60.8 ± 0.5 b | 107.4 ± 1.7 b | 170.4 ± 1.1 a,b | 15.8 ± 2.0 a,c | 296.7 ± 7.6 d,e | 357.3 ± 0.6 a,g | 4.6 ± 1.5 c,d,e | 36.9 ± 1.6 d |

| PLA/MLO-10W-2.5TVS | 60.4 ± 0.1 b | 107.1 ± 2.5 b | 169.6 ± 0.9 a,b | 15.3 ± 0.7 c,d,g | 293.0 ± 5.2 e | 360.0 ± 1.0 a,b,c | 5.8 ± 0.8 e | 36.0 ± 1.0 b,c,d |

| Wettability | Color | ||||

|---|---|---|---|---|---|

| Formulation | WCA (°) | L | a* | b* | ∆E |

| PLA | 77.2 ± 1.4 a | 37.55 ± 0.81 a | −0.19 ± 0.04 a | 2.54 ± 0.08 a | - |

| PLA/MLO | 67.7 ± 1.2 b | 43.58 ± 0.71 b,e | −1.91 ± 0.10 a | 2.38 ± 0.18 a | - |

| PLA/MLO-1W | 83.7 ± 2.1 c,f | 47.23 ± 0.34 c | 0.48 ± 0.97 b | 18.76 ± 0.64 b | 17.0 ± 0.7 c |

| PLA/MLO-1W-1TVS | 80.9 ± 1.3 d | 51.16 ± 0.46 d | −1.41 ± 0.83 a | 15.16 ± 0.17 c | 14.9 ± 0.4 d |

| PLA/MLO-1W-2.5TVS | 83.8 ± 1.6 c,f | 47.18 ± 1.34 c,e | −0.41 ± 0.85 a | 14.19 ± 0.55 c | 12.5 ± 0.9 e |

| PLA/MLO-5W | 83.8 ± 1.5 c,f | 44.05 ± 0.55 b,e | 5.35 ± 1.14 c | 22.11 ± 0.43 d | 21.1 ± 0.1 f,g |

| PLA/MLO-5W-1TVS | 83.9 ± 2.1 c | 44.01 ± 1.54 b,e | 5.66 ± 1.09 c,e | 21.59 ± 0.99 d | 20.7 ± 1.0 f |

| PLA/MLO-5W-2.5TVS | 81.6 ± 0.7 d | 46.54 ± 1.01 c,e | 4.60 ± 1.09 c | 21.49 ± 0.54 d | 20.4 ± 0.7 f |

| PLA/MLO-10W | 85.2 ± 0.7 e | 37.73 ± 1.78 a | 8.60 ± 1.02 d,e | 19.46 ± 1.42 b | 21. ± 0.8 f,g |

| PLA/MLO-10W-1TVS | 81.4 ± 1.7 d | 45.04 ± 0.98 e | 7.86 ± 1.46 d,e | 22.82 ± 1.32 d,e | 22.7 ± 1.7 g,h |

| PLA/MLO-10W-2.5TVS | 83.3 ± 2.1 f | 45.24 ± 0.35 b,c,e | 7.51 ± 1.07 e | 23.81 ± 0.41 e | 23.5 ± 0.1 h |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pawlak, F.; Aldas, M.; Parres, F.; López-Martínez, J.; Arrieta, M.P. Silane-Functionalized Sheep Wool Fibers from Dairy Industry Waste for the Development of Plasticized PLA Composites with Maleinized Linseed Oil for Injection-Molded Parts. Polymers 2020, 12, 2523. https://doi.org/10.3390/polym12112523

Pawlak F, Aldas M, Parres F, López-Martínez J, Arrieta MP. Silane-Functionalized Sheep Wool Fibers from Dairy Industry Waste for the Development of Plasticized PLA Composites with Maleinized Linseed Oil for Injection-Molded Parts. Polymers. 2020; 12(11):2523. https://doi.org/10.3390/polym12112523

Chicago/Turabian StylePawlak, Franciszek, Miguel Aldas, Francisco Parres, Juan López-Martínez, and Marina Patricia Arrieta. 2020. "Silane-Functionalized Sheep Wool Fibers from Dairy Industry Waste for the Development of Plasticized PLA Composites with Maleinized Linseed Oil for Injection-Molded Parts" Polymers 12, no. 11: 2523. https://doi.org/10.3390/polym12112523