Machine Learning Models for Predicting and Classifying the Tensile Strength of Polymeric Films Fabricated via Different Production Processes

Abstract

:1. Introduction

2. Experimental Dataset Development

2.1. Extrusion-Blow Molding

2.2. Cryomilling/Compression Molding

2.3. Measurement of Tensile Strength

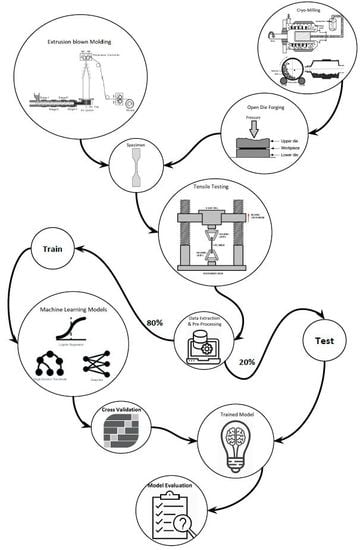

3. MLA Models Development

3.1. MLA: Background

3.2. Model Development

4. Results

4.1. Film Mechanical Perfomance

4.2. MLA Prediction Perfomance

4.3. MLA Classification Performance

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Siemann, U. Solvent cast technology–a versatile tool for thin film production. In Scattering Methods and the Properties of Polymer Materials; Springer: Berlin/Heidelberg, Germany, 2005; pp. 1–14. [Google Scholar]

- Callister, W.D.; Rethwisch, D.G. Materials Science and Engineering: An Introduction; John Wiley & Sons: New York, NY, USA, 2007; pp. 665–715. [Google Scholar]

- Yu, J.C.; Chen, X.X.; Hung, T.R.; Thibault, F. Optimization of extrusion blow molding processes using soft computing and Taguchi’s method. J. Intell. Manuf. 2004, 15, 625–634. [Google Scholar] [CrossRef] [Green Version]

- National Research Council. Polymer Science and Engineering: The Shifting Research Frontiers; The National Academies Press: Washington, DC, USA, 1994. [Google Scholar]

- Ong, P.; Ho, C.S.; Chin, D.D.V.S.; Sia, C.K.; Ng, C.H.; Wahab, M.S.; Bala, A.S. Diameter prediction and optimization of hot extrusion-synthesized polypropylene filament using statistical and soft computing techniques. J. Intell. Manuf. 2019, 30, 1957–1972. [Google Scholar] [CrossRef]

- Kotsiantis, S.B.; Zaharakis, I.; Pintelas, P. Supervised machine learning: A review of classification techniques. Emerg. Artif. Intell. Appl. Comput. Eng. 2007, 160, 3–24. [Google Scholar]

- Soundarya, M.; Balakrishnan, R. Survey on classification techniques in data mining. Int. J. Adv. Res. Comput. Commun. Eng. 2014, 3, 7550–7552. [Google Scholar]

- Krishnaiah, V.; Narsimha, G.; Chandra, N.S. Survey of classification techniques in data mining. Int. J. Comput. Sci. Eng. 2014, 2, 65–74. [Google Scholar]

- Larose, D.T.; Larose, C.D. Discovering Knowledge in Data: An Introduction to Data Mining; John Wiley & Sons: New York, NY, USA, 2014. [Google Scholar]

- Nikam, S.S. A comparative study of classification techniques in data mining algorithms. Orient J. Comput. Sci. Technol. 2015, 8, 13–19. [Google Scholar]

- Wuest, T.; Weimer, D.; Irgens, C.; Thoben, K.D. Machine learning in manufacturing: Advantages, challenges, and applications. Prod. Manuf. Res. 2016, 4, 23–45. [Google Scholar] [CrossRef]

- Ayodele, T.O. Types of machine learning algorithms. In New Advances in Machine Learning; InTech: Rijeka, Croatia, 2010; pp. 1–48. [Google Scholar]

- Dey, A. Machine Learning Algorithms: A Review. Int. J. Comput. Sci. Inf. Technol. 2016, 7, 1174–1179. [Google Scholar]

- Altarazi, S.; Ammouri, M.; Hijazi, A. Artificial neural network modeling to evaluate polyvinylchloride composites’ properties. Comput. Mater. Sci. 2018, 153, 1–9. [Google Scholar] [CrossRef]

- Azmi, A.I.; Lin, R.J.T.; Bhattacharyya, D. Tool wear prediction models during end milling of glass fibre-reinforced polymer composites. Int. J. Adv. Manuf. Technol. 2013, 67, 701–718. [Google Scholar] [CrossRef]

- Altarazi, S. Enhancing conformance of injection blow molding by integrating machine learning modeling and Taguchi parameter design. Adv. Appl. Stat. 2018, 53, 519–535. [Google Scholar] [CrossRef]

- Mueller, T.; Kusne, A.G.; Ramprasad, R. Machine learning in materials science: Recent progress and emerging applications. Rev. Comput. Chem. 2016, 29, 186–273. [Google Scholar]

- Li, Y. Predicting materials properties and behavior using classification and regression trees. Mater. Sci. Eng. A 2006, 433, 261–268. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, W.; Sun, F.; Zhang, W. A comparison study of machine learning based algorithms for fatigue crack growth calculation. Materials 2017, 10, 543. [Google Scholar] [CrossRef] [PubMed]

- Ramprasad, R.; Batra, R.; Pilania, G.; Mannodi-Kanakkithodi, A.; Kim, C. Machine learning in materials informatics: Recent applications and prospects. NPJ Comput. Mater. 2017, 3, 54. [Google Scholar] [CrossRef]

- Wei, Q.; Melko, R.G.; Chen, J.Z. Identifying polymer states by machine learning. Phys. Rev. E 2017, 95, 32504. [Google Scholar] [CrossRef]

- Alhindawi, F.; Altarazi, S. Predicting the Tensile Strength of Extrusion-Blown High Density Polyethylene Film Using Machine Learning Algorithms. In Proceedings of the IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Bangkok, Thailand, 16–19 December 2018. [Google Scholar]

- Mallakpour, S.; Hatami, M.; Khooshechin, S.; Golmohammadi, H. Evaluations of thermal decomposition properties for optically active polymers based on support vector machine. J. Therm. Anal. Calorim. 2014, 116, 989–1000. [Google Scholar] [CrossRef]

- Wu, X.; Zhang, H.; Cui, H.; Ma, Z.; Song, W.; Yang, W.; Jia, L.; Zhang, H. Quantitative Relationship Analysis of Mechanical Properties with Mg Content and Heat Treatment Parameters in Al–7Si Alloys Using Artificial Neural Network. Materials 2019, 12, 718. [Google Scholar] [CrossRef]

- Ghaffari, A.; Abdollahi, H.; Khoshayand, M.R.; Bozchalooi, I.S.; Dadgar, A.; Rafiee-Tehrani, M. Performance comparison of neural network training algorithms in modeling of bimodal drug delivery. Int. J. Pharm. 2006, 327, 126–138. [Google Scholar] [CrossRef] [PubMed]

- Ghazanfari, N.; Gholami, S.; Emad, A.; Shekarchi, M. Evaluation of GMDH and MLP Networks for Prediction of Compressive Strength and Workability of Concrete. Bulletin de la Société Royale des Sciences de Liège 2017, 86, 855–868. [Google Scholar]

- Wellstead, P.E.; Heath, W.P.; Kjaer, A.P. Identification and control of web processes: Polymer film extrusion. Control Eng. Pract. 1998, 63, 321–331. [Google Scholar] [CrossRef]

- Costin, M.H.; Taylor, P.A.; Wright, J.D. A critical review of dynamic modeling and control of plasticizing extruders. Polym. Eng. Sci. 1982, 22, 393–401. [Google Scholar] [CrossRef]

- Vafaeenezhad, H.; Asadolahpour, S.R.; Nayebpashaee, N.; Seyedein, S.H.; Aboutalebi, M.R. Intelligent use of data to optimize compressive strength of cellulose-derived composites. Appl. Soft Comput. 2016, 40, 594–602. [Google Scholar] [CrossRef]

- Chen, L.; Raman, K. A subjective design framework for conceptual design of polymeric processes with multiple parameters. Res. Eng. Des. 2000, 12, 220–234. [Google Scholar] [CrossRef]

- Wu, D.; Jennings, C.; Terpenny, J.; Gao, R.X.; Kumara, S. A comparative study on machine learning algorithms for smart manufacturing: Tool wear prediction using random forests. J. Manuf. Sci. Eng. 2017, 139, 71018. [Google Scholar] [CrossRef]

- Altarazi, S.A.; Allaf, R.M. Designing and analyzing a mixture experiment to optimize the mixing proportions of polyvinyl chloride composites. J. Appl. Stat. 2017, 44, 1441–1465. [Google Scholar] [CrossRef]

- Singh, S.; Gupta, P. Comparative study ID3, cart and C4. 5 decision tree algorithm: A survey. Int. J. Adv. Inf. Sci. Technol. 2014, 27, 97–103. [Google Scholar]

- Haykin, S. Neural Networks: A Comprehensive Foundation; Prentice Hall PTR: Upper Saddle River, NJ, USA, 1994. [Google Scholar]

- Shi, H.; Gao, Y.; Wang, X. Optimization of injection molding process parameters using integrated artificial neural network model and expected improvement function method. Int. J. Adv. Manuf. Technol. 2010, 48, 955–962. [Google Scholar] [CrossRef]

- Ademujimi, T.T.; Brundage, M.P.; Prabhu, V.V. A Review of Current Machine Learning Techniques Used in Manufacturing Diagnosis. In Proceedings of the IFIP International Conference on Advances in Production Management Systems, Hamburg, Germany, 3–7 September 2017. [Google Scholar]

- Scikit-learn, Machine Learning in Python: User Guide. Available online: http://scikit-learn.org/stable/modules/sgd.html (accessed on 5 January 2019).

- Bottou, L. Large-scale machine learning with stochastic gradient descent. In Proceedings of the COMPSTAT’2010, Paris, France, 22–27 August 2010. [Google Scholar]

- Gupta, P.; Sharma, A.; Jindal, R. Scalable machine-learning algorithms for big data analytics: A comprehensive review. Wiley Interdiscip. Rev. Data Min. Knowl. Discov. 2016, 6, 194–214. [Google Scholar] [CrossRef]

- Demšar, J.; Curk, T.; Erjavec, A.; Gorup, Č.; Hočevar, T.; Milutinovič, M.; Mozina, M.; Polajnar, M.; Toplak, M.; Staric, A.; et al. Orange: Data mining toolbox in Python. J. Mach. Learn. Res. 2013, 14, 2349–2353. [Google Scholar]

- Standard Test Method for Tensile Properties of Thin Plastic Sheeting; ASTM D882 - 18; American Society for Testing and Materials (ASTM): Washington, DC, USA, 2018.

- Wu, X.; Kumar, V.; Quinlan, J.R.; Ghosh, J.; Yang, Q.; Motoda, H.; McLachlan, G.J.; Ng, A.; Liu, B.; Yu, P.S.; et al. Top 10 algorithms in data mining. Knowl. Inf. Syst. 2008, 14, 1–37. [Google Scholar] [CrossRef]

- Analytics Vidhya, A Complete Tutorial on Tree Based Modeling from Scratch (in R & Python). Available online: https://www.analyticsvidhya.com/blog/2016/04/complete-tutorial-tree-based-modeling-scratch-in-python/ (accessed on 5 January 2019).

- Lee, D.E.; Song, J.H.; Song, S.O.; Yoon, E.S. Weighted support vector machine for quality estimation in the polymerization process. Ind. Eng. Chem. Res. 2005, 44, 2101–2105. [Google Scholar] [CrossRef]

- Juutilainen, I.; Röning, J.; Myllykoski, L. Modelling the strength of steel plates using regression analysis and neural networks. In Proceedings of the International Conference on Computational Intelligence for Modelling, Control and Automation, Vienna, Austria, 12–14 February 2003. [Google Scholar]

- Müller, A.C.; Guido, S. Introduction to Machine Learning with Python: A Guide for Data Scientists; O’Reilly Media, Inc.: Sebastopol, CA, USA, 2016. [Google Scholar]

| HDPE film Component Proportions (wt %) | virgin HDPE | 34 ≤ X1 ≤ 70 |

| recycled HPDE | 10 ≤ X2 ≤ 40 | |

| CaCO3 | 0 ≤ X3 ≤ 20 | |

| copolymer | 1 ≤ X4 ≤ 6 | |

| Processing Parameters | CaCO3 mean particle size (µm) | Z1 = 6, 12 |

| T1 (°C) | 162 ≤ Z2 ≤ 196 | |

| T1 (°C) | 164 ≤ Z3 ≤ 183 | |

| T3 (°C) | 163 ≤ Z4 ≤ 195 | |

| T4 (°C) | 150 ≤ Z5 ≤ 188 | |

| mixing speed (rpm) | 20 ≤ Z6 ≤ 48.2 | |

| bubble drawing speed (m/min) | 2.1 ≤ Z7 ≤ 6.5 |

| Film Component Proportions | Processing Parameters | |||||

|---|---|---|---|---|---|---|

| PCL (wt %) | PEO (wt %) | Wood SD (wt %) | Milling Time (min) | Molding Temperature (°C) | Molding Time (min) | Cooling Technique |

| 100–0 | 0–100 | 0 | 27 | 100 | 0.5, 5 | water |

| 50 | 50 | 0 | 27, 54, 81 | 100, 125, 150 | 5 | machine, water, LN2 |

| 90, 70, 50 | 0 | 10, 30, 50 | 27 | 100, 125, 150 | 5 | water |

| 45, 35, 25 | 45, 35, 25 | 10, 30, 50 | 27 | 100, 125, 150 | 5 | water |

| 45, 35, 25 | 45, 35, 25 | 10, 30, 50 | 27 | 100 | 0.5 | water, LN2 |

| MLA | MLA Parameters | |

|---|---|---|

| Extrusion-Blow Molding | Cryomilling/Compression Molding | |

| kNN | Number of neighbors: 11 Metric: Mahalanobis Weight: distance | Number of neighbors: 21 Metric: Mahalanobis Weight: distance |

| DT (CART) | Pruning: at least three instances in internal nodes, maximum depth 100 Splitting: stop splitting when majority reaches 95% (classification only) Binary trees: yes | Pruning: at least three instances in leaves (terminal nodes), at least three instances in internal nodes, maximum depth 100 Splitting: stop splitting when majority reaches 95% (classification only) Binary trees: no |

| RF | Number of trees: 14 Maximal number of considered features: unlimited Fixed random seed: three (four for classification) Maximal tree depth: unlimited Stop splitting nodes with maximum instances: (two for classification) | Number of trees: 21 Maximal number of considered features: unlimited Fixed random seed: three Maximal tree depth: six Stop splitting nodes with maximum instances: 5 |

| AB | Base estimator: tree Number of estimators: 45 (100 for classification) Algorithm (classification): Samme.r Loss (regression): linear | Base estimator: tree Number of estimators: 4 Algorithm (classification): Samme.r Loss (regression): linear |

| SVM | SVM type: SVM, C (penalty parameter) = 100.8, ε (kernel coefficient) = 1.5 Kernel: RBF, exp.(−2.12|x−y|2) Numerical tolerance: 0.001 Iteration limit: 100 | SVM type: SVM, C = 16.30, ε = 1.1 Kernel: RBF, exp.(−0.35|x−y|2) Numerical tolerance: 0.001 Iteration limit: 100 |

| SGD | Classification loss function: hinge Regression loss function: squared loss Regularization: none (“elastic net” for classification) Regularization strength (α): 0.00053 (for classification) Elastic net mixing parameter (L1 ratio): 0.16100 (for classification) Learning rate: Inverse scaling (“optimal” for classification) Initial learning rate (η0): 0.0001 Inverse scaling exponent (t): 0.0104 Shuffle data after each iteration: yes | Classification loss function: Huber Epsilon (ε) for classification: 0.92 Regression loss function: squared loss Regularization: elastic net Regularization strength (α): 0.05 Elastic Net mixing parameter (L1 ratio): 0.1 Learning rate: inverse scaling Initial learning rate (η0): 0.0008 Inverse scaling exponent (t): 0.0142 Shuffle data after each iteration: yes |

| ANN | Hidden layers: 80, 80 Activation: tanh (“ReLu” for classification) Solver: L-BFGS-B (“Adam” for classification) Alpha: 0.0001 Max iterations: 300 | Hidden layers: 50, 50 Activation: logistic Solver: L-BFGS-B Alpha: 0.0001 Max iterations: 300 |

| LR | Regularization: no regularization (only for regression) | Regularization: no regularization |

| LoR | Regularization: lasso (L1), C = 0.8 (Only for classification) | - |

| MLA | R2 (%) | MAPE (%) | ||

|---|---|---|---|---|

| Extrusion-Blow Molding | Cryomilling/Compression Molding | Extrusion-Blow Molding | Cryomilling/Compression Molding | |

| RF | 87 | 76 | 7 | 11 |

| SVM | 96 | 81 | 4 | 11 |

| LR | 24 | 76 | 19 | 11 |

| kNN | 94 | 73 | 4 | 13 |

| ANN | 93 | 73 | 4 | 13 |

| ABt | 91 | 71 | 5 | 14 |

| SGD | 24 | 77 | 19 | 11 |

| CART | 94 | 73 | 4 | 13 |

| MLA | AUC | Accuracy 1 | Precision 2 | Recall |

|---|---|---|---|---|

| ANN | 0.901 | 0.808 | 0.796 | 1 |

| kNN | 0.876 | 0.923 | 0.907 | 1 |

| AdaBoost | 0.872 | 0.942 | 0.929 | 1 |

| SVM | 0.862 | 0.923 | 0.907 | 1 |

| LoR | 0.852 | 0.750 | 0.771 | 0.949 |

| RF | 0.840 | 0.923 | 0.907 | 1 |

| CART | 0.754 | 0.827 | 0.857 | 0.923 |

| SGD | 0.641 | 0.769 | 0.814 | 0.897 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Altarazi, S.; Allaf, R.; Alhindawi, F. Machine Learning Models for Predicting and Classifying the Tensile Strength of Polymeric Films Fabricated via Different Production Processes. Materials 2019, 12, 1475. https://doi.org/10.3390/ma12091475

Altarazi S, Allaf R, Alhindawi F. Machine Learning Models for Predicting and Classifying the Tensile Strength of Polymeric Films Fabricated via Different Production Processes. Materials. 2019; 12(9):1475. https://doi.org/10.3390/ma12091475

Chicago/Turabian StyleAltarazi, Safwan, Rula Allaf, and Firas Alhindawi. 2019. "Machine Learning Models for Predicting and Classifying the Tensile Strength of Polymeric Films Fabricated via Different Production Processes" Materials 12, no. 9: 1475. https://doi.org/10.3390/ma12091475