Bionic Ring Grooves Design and Experiment of the Suction Cup Applied in Oil-Immersed Substrate

Abstract

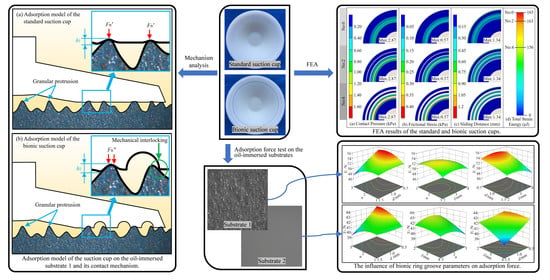

:1. Introduction

2. Materials and Methods

2.1. Design of Ring Groove Structure

2.2. Fabrication of Suction Cup Samples

2.3. Force Measurements of Suction Cup Samples

2.4. FEA of Suction Cups

3. Results

3.1. Test Results of the Adsorption Force

3.2. Influencing Laws of n, d, and l on Adsorption Force

3.2.1. Influencing laws of n, d, and l on Y1

3.2.2. Influencing laws of n, d, and l on Y2

3.3. Test Results of FEA

4. Discussion

5. Conclusions

- The maximum normal adsorption force of the bionic suction cup sample on the untreated and polished steel plate substrates increased by 32.31 % and 12.28 %, respectively, compared with the standard suction cup. The suction cups have stronger adsorption force on the untreated steel plate.

- The bionic ring grooves could improve the adsorption force of suction cups on oil-immersed substrates. The significant order of the influence of the test factors of the ring groove structure on the adsorption force of the sucker was groove diameter, spacing, and number.

- The bionic ring grooves improved the sealing performance of the bionic suction cup by dividing and increasing the contact pressure between the suction cup and the substrate to form multi-ring seals.

- The bionic ring grooves increased the frictional stress between the suction cup and the substrate.

- The ring grooves increased the adsorption area of the bionic suction cup.

- The ring grooves formed a mechanical interlocking with the granular protrusions on the substrate, which would effectively inhibit the radial contraction of the suction cup during the pull-off process and maintain the adsorption state.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| n | groove number |

| d | groove diameter |

| l | groove spacing |

| Y0 | the average adsorption force for the standard suction cup |

| Y1 | the average adsorption force of bionic suction cups on the untreated steel plate |

| Y2 | the average adsorption force of bionic suction cups on the polished steel plate |

| X1 | coding factors for the groove number |

| X2 | coding factors for the groove diameter |

| X3 | coding factors for the groove spacing |

| df | degree of freedom |

| R2 | the coefficient of determination |

| F | adsorption force |

| P | pressure |

| S | adsorption area |

| h, h1, h2 | the height of the granular protrusion embedded in the suction cup |

| f | friction |

| μ | dynamic friction factor |

| Fn, Fn′, Fn″ | normal pressure |

References

- Tiwari, A.; Persson, B.N.J. Physics of Suction Cups. Soft Matter 2019, 15, 9482–9499. [Google Scholar] [CrossRef]

- Fang, Y.; Wang, S.; Bi, Q.; Cui, D.; Yan, C. Design and Technical Development of Wall-Climbing Robots: A Review. J. Bionic Eng. 2022, 19, 877–901. [Google Scholar] [CrossRef]

- Liu, J.; Xu, L.; Chen, S.; Xu, H.; Cheng, G.; Xu, J. Development of a Bio-Inspired Wall-Climbing Robot Composed of Spine Wheels, Adhesive Belts and Eddy Suction Cup. Robotica 2021, 39, 3–22. [Google Scholar] [CrossRef]

- Brusell, A.; Andrikopoulos, G.; Nikolakopoulos, G. A Survey on Pneumatic Wall-Climbing Robots for Inspection. In Proceedings of the 2016 24th Mediterranean Conference on Control and Automation (MED), Athens, Greece, 21–24 June 2016; IEEE: New York, NY, USA, 2016; pp. 220–225. [Google Scholar]

- Xu, J.; Xu, L.; Liu, J.; Li, X.; Wu, X. Survey on Bioinspired Adhesive Methods and Design and Implementation of a Multi-Mode Biomimetic Wall-Climbing Robot. In Proceedings of the 2018 IEEE/ASME International Conference on Advanced Intelligent Mechatronics (AIM), Auckland, New Zealand, 9–12 July 2018; IEEE: New York, NY, USA, 2018; pp. 688–693. [Google Scholar]

- Kang, L.; Seo, J.-T.; Kim, S.-H.; Kim, W.-J.; Yi, B.-J. Design and Implementation of a Multi-Function Gripper for Grasping General Objects. Appl. Sci. 2019, 9, 5266. [Google Scholar] [CrossRef] [Green Version]

- Pham, H.; Pham, Q.-C. Critically Fast Pick-and-Place with Suction Cups. In Proceedings of the 2019 International Conference on Robotics and Automation (ICRA), Montreal, QC, Canada, 20–24 May 2019; IEEE: New York, NY, USA, 2019; pp. 3045–3051. [Google Scholar]

- Hemming, J.; van Tuijl, B.A.J.; Gauchel, W.; Wais, E. Field Test of Different End-Effectors for Robotic Harvesting of Sweet-Pepper. Acta Hortic. 2016, 1130, 567–574. [Google Scholar] [CrossRef]

- Kurpaska, S.; Sobol, Z.; Pedryc, N.; Hebda, T.; Nawara, P. Analysis of the Pneumatic System Parameters of the Suction Cup Integrated with the Head for Harvesting Strawberry Fruit. Sensors 2020, 20, 4389. [Google Scholar] [CrossRef]

- Gao, T.; Zhang, H.; Xu, J.; Ma, B.; Cong, Q. Effects of Cylindrical Pit Array on Tribological Property of Piston–Cylinder Sleeve Friction Pair in a BW-250 Slime Pump. Tribol. Int. 2020, 151, 106505. [Google Scholar] [CrossRef]

- Cong, Q.; Xu, J.; Fan, J.; Chen, T.; Ru, S. Insights into the Multilevel Structural Characterization and Adsorption Mechanism of Sinogastromyzon Szechuanensis Sucker on the Rough Surface. Life 2021, 11, 952. [Google Scholar] [CrossRef] [PubMed]

- Greco, G.; Bosia, F.; Tramacere, F.; Mazzolai, B.; Pugno, N.M. The Role of Hairs in the Adhesion of Octopus Suckers: A Hierarchical Peeling Approach. Bioinspir. Biomim. 2020, 15, 035006. [Google Scholar] [CrossRef]

- Xi, P.; Cong, Q.; Xu, J.; Sun, L. Surface Movement Mechanism of Abalone and Underwater Adsorbability of Its Abdominal Foot. Bioinspired Biomim. Nanobiomater. 2019, 8, 254–262. [Google Scholar] [CrossRef]

- Persson, B.N.J. Wet Adhesion with Application to Tree Frog Adhesive Toe Pads and Tires. J. Phys. Condens. Matter 2007, 19, 376110. [Google Scholar] [CrossRef]

- Sandoval, J.A.; Sommers, J.; Peddireddy, K.R.; Robertson-Anderson, R.M.; Tolley, M.T.; Deheyn, D.D. Toward Bioinspired Wet Adhesives: Lessons from Assessing Surface Structures of the Suction Disc of Intertidal Clingfish. ACS Appl. Mater. Interfaces 2020, 12, 45460–45475. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Yang, X.; Chen, Y.; Wainwright, D.K.; Kenaley, C.P.; Gong, Z.; Liu, Z.; Liu, H.; Guan, J.; Wang, T.; et al. A Biorobotic Adhesive Disc for Underwater Hitchhiking Inspired by the Remora Suckerfish. Sci. Robot. 2017, 2, eaan8072. [Google Scholar] [CrossRef] [Green Version]

- Gamel, K.M.; Garner, A.M.; Flammang, B.E. Bioinspired Remora Adhesive Disc Offers Insight into Evolution. Bioinspir. Biomim. 2019, 14, 056014. [Google Scholar] [CrossRef]

- Ditsche, P.; Summers, A. Learning from Northern Clingfish (Gobiesox maeandricus): Bioinspired Suction Cups Attach to Rough Surfaces. Philos. Trans. R. Soc. B 2019, 374, 20190204. [Google Scholar] [CrossRef] [Green Version]

- Sandoval, J.A.; Jadhav, S.; Quan, H.; Deheyn, D.D.; Tolley, M.T. Reversible Adhesion to Rough Surfaces Both in and out of Water, Inspired by the Clingfish Suction Disc. Bioinspir. Biomim. 2019, 14, 066016. [Google Scholar] [CrossRef] [PubMed]

- Tramacere, F.; Beccai, L.; Kuba, M.; Gozzi, A.; Bifone, A.; Mazzolai, B. The Morphology and Adhesion Mechanism of Octopus vulgaris Suckers. PLoS ONE 2013, 8, e65074. [Google Scholar] [CrossRef] [Green Version]

- Kier, W.M. The Structure and Adhesive Mechanism of Octopus Suckers. Integr. Comp. Biol. 2002, 42, 1146–1153. [Google Scholar] [CrossRef] [Green Version]

- Tramacere, F.; Appel, E.; Mazzolai, B.; Gorb, S.N. Hairy Suckers: The Surface Microstructure and Its Possible Functional Significance in the Octopus vulgaris Sucker. Beilstein J. Nanotechnol. 2014, 5, 561–565. [Google Scholar] [CrossRef] [Green Version]

- Baik, S.; Kim, D.W.; Park, Y.; Lee, T.-J.; Ho Bhang, S.; Pang, C. A Wet-Tolerant Adhesive Patch Inspired by Protuberances in Suction Cups of Octopi. Nature 2017, 546, 396–400. [Google Scholar] [CrossRef]

- Chun, S.; Kim, D.W.; Baik, S.; Lee, H.J.; Lee, J.H.; Bhang, S.H.; Pang, C. Conductive and Stretchable Adhesive Electronics with Miniaturized Octopus-Like Suckers against Dry/Wet Skin for Biosignal Monitoring. Adv. Funct. Mater. 2018, 28, 1805224. [Google Scholar] [CrossRef]

- Follador, M.; Tramacere, F.; Mazzolai, B. Dielectric Elastomer Actuators for Octopus Inspired Suction Cups. Bioinspir. Biomim. 2014, 9, 046002. [Google Scholar] [CrossRef] [PubMed]

- Tramacere, F.; Follador, M.; Pugno, N.M.; Mazzolai, B. Octopus-like Suction Cups: From Natural to Artificial Solutions. Bioinspir. Biomim. 2015, 10, 035004. [Google Scholar] [CrossRef]

- Xi, P.; Cong, Q.; Xu, J.; Qiu, K. Design, Experiment and Adsorption Mechanism Analysis of Bionic Sucker Based on Octopus Sucker. Proc. Inst. Mech. Eng. H 2019, 233, 1250–1261. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Ha, K.-H.; Qiao, S.; Lu, N. Suction Effects of Crater Arrays. Extrem. Mech. Lett. 2019, 30, 100496. [Google Scholar] [CrossRef]

- Xu, X.H.; He, M.Z. Experimental Design and Application of Design-Expert and SPSS; Science Press: Beijing, China, 2010. [Google Scholar]

- Ge, Y.Y. Experimental Design Method and Design-Expert Software Application; Harbin Institute of Technology Press: Harbin, China, 2015. [Google Scholar]

- Ren, L.Q. Experimental Design and Optimization, 1st ed.; Science Press: Beijing, China, 2009. [Google Scholar]

- Gorb, S.N. Biological Attachment Devices: Exploring Nature’s Diversity for Biomimetics. Philos. Trans. R. Soc. A 2008, 366, 1557–1574. [Google Scholar] [CrossRef] [PubMed]

| Test Number | n | d/mm | l/mm | Test Number | n | d/mm | l/mm |

|---|---|---|---|---|---|---|---|

| 0 | 0 | 0 | 0 | 9 | 2 | 0.5 | 2.0 |

| 1 | 1 | 0.5 | 3.0 | 10 | 2 | 1.5 | 2.0 |

| 2 | 3 | 0.5 | 3.0 | 11 | 2 | 0.5 | 4.0 |

| 3 | 1 | 1.5 | 3.0 | 12 | 2 | 1.5 | 4.0 |

| 4 | 3 | 1.5 | 3.0 | 13 | 2 | 1.0 | 3.0 |

| 5 | 1 | 1.0 | 2.0 | 14 | 2 | 1.0 | 3.0 |

| 6 | 3 | 1.0 | 2.0 | 15 | 2 | 1.0 | 3.0 |

| 7 | 1 | 1.0 | 4.0 | 16 | 2 | 1.0 | 3.0 |

| 8 | 3 | 1.0 | 4.0 | 17 | 2 | 1.0 | 3.0 |

| Source | Adsorption Force on the Untreated Steel Plate | Adsorption Force on the Polished Steel Plate | ||||||

|---|---|---|---|---|---|---|---|---|

| Sum of Squares | df | F Value | p Value | Sum of Squares | df | F Value | p Value | |

| Model | 65.98 | 9 | 30.43 | <0.01 | 23.44 | 9 | 38.85 | <0.01 |

| X1-n | 0.41 | 1 | 1.70 | >0.05 | 0.20 | 1 | 3.01 | >0.05 |

| X2-d | 33.42 | 1 | 138.73 | <0.01 | 8.57 | 1 | 127.82 | <0.01 |

| X3-l | 2.31 | 1 | 9.60 | <0.05 | 4.49 | 1 | 66.90 | <0.01 |

| X1X2 | 11.16 | 1 | 46.31 | <0.01 | 5.52 | 1 | 82.37 | <0.01 |

| X1X3 | 0.53 | 1 | 2.18 | >0.05 | 1.03 | 1 | 15.37 | <0.01 |

| X2X3 | 2.06 | 1 | 8.55 | <0.05 | 1.08 | 1 | 16.13 | <0.01 |

| X12 | 9.49 | 1 | 39.41 | <0.01 | 2.15 | 1 | 32.13 | <0.01 |

| X22 | 0.42 | 1 | 1.75 | >0.05 | 0.06 | 1 | 0.94 | >0.05 |

| X32 | 4.95 | 1 | 20.54 | <0.01 | 0.29 | 1 | 4.25 | >0.05 |

| Residual | 1.69 | 7 | 0.47 | 7 | ||||

| Lake of fit | 1.27 | 3 | 4.08 | >0.05 | 0.08 | 3 | 0.28 | >0.05 |

| Pure error | 0.42 | 4 | 0.39 | 4 | ||||

| Total | 67.66 | 16 | 23.91 | 16 | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, J.; Wang, L.; Zhang, D.; Shi, X.; Chen, T.; Cong, Q.; Liu, C. Bionic Ring Grooves Design and Experiment of the Suction Cup Applied in Oil-Immersed Substrate. Lubricants 2023, 11, 152. https://doi.org/10.3390/lubricants11040152

Xu J, Wang L, Zhang D, Shi X, Chen T, Cong Q, Liu C. Bionic Ring Grooves Design and Experiment of the Suction Cup Applied in Oil-Immersed Substrate. Lubricants. 2023; 11(4):152. https://doi.org/10.3390/lubricants11040152

Chicago/Turabian StyleXu, Jin, Lin Wang, Dexue Zhang, Xiaojie Shi, Tingkun Chen, Qian Cong, and Chaozong Liu. 2023. "Bionic Ring Grooves Design and Experiment of the Suction Cup Applied in Oil-Immersed Substrate" Lubricants 11, no. 4: 152. https://doi.org/10.3390/lubricants11040152