Improving Applicability for Information Model of an IFC-Based Steel Bridge in the Design Phase Using Functional Meanings of Bridge Components

Abstract

:1. Introduction

2. Related Works on Bridge Data Schemas

2.1. Bridge Data Schemas Using EXPRESS

2.1.1. STEP AP 203-Based Bridge Data Schema

2.1.2. IFC-Based Bridge Data Schema

2.1.3. Bridge Schema Elements in IFC

2.2. Bridge Data Schemas Using XML

2.2.1. Bridge Data Schema in CityGML

2.2.2. Bridge Data Schema in TransXML

- Interoperable and accessible: The schema must be software-independent, and the model data should be accessible in any situation

- Three-dimensional: The schema must be able to manage the information of the constituent elements of the bridge based on 3D geometry

- Semantic: The schema must include functional semantic information of the bridge components, and be capable of spatially and physically distinguishing the components

- Software-based data manageable: The schema must allow information modeling on BIM authoring software

2.3. User-Defined Property Sets at a Glance

- IfcObject is used as it is for the objects that represent the components themselves. During this process, IfcPropertySet and IfcObject can be linked by IfcRelDefinesByProperties, a subtype of IfcRelationship.

- The properties that form IfcPropertySet are represented using IfcProperty, an entity that implements “HasProperties”, an explicit attribute of IfcPropertySet.

- The semantic meaning of a property is defined through the explicit “Name” attribute of IfcProperty.

- A user-defined property is represented using IfcPropertyBoundedValue, IfcPropertyEnumeratedValue, IfcPropertyListValue, IfcPropertyReferenceValue, IfcPropertySingleValue, and IfcPropertyTableValue, all of which are subtypes of IfcProperty.

3. IFC Extension Using User-Defined Property Sets for Steel Box Girder Bridges

3.1. Required Information for a Steel Bridge Data Schema

3.2. IFC-Based Semantic Meanings for the Components of a Steel Box Girder Bridge

- Identification of the spatial arrangement of the structure: In building structures, space is extended vertically within the known range of the limited site. In contrast, in bridge structures, in addition to the vertical spatial arrangement of components with different functions, the arrangement of similar (or identical) elements in the spanwise direction is a highly important aspect. This affects not only the bridge structure, but also equally affects the road and tunnel structures that form the road system. Therefore, this study focused on enabling the identification of the spatial arrangement of each bridge component using its properties, rather than the alignment of the entire bridge. The advantage of this method is that the spatial identification method can be used unchanged, even if a new entity for alignment is added at a higher level of IFC.

- Identification of the structural components based on function and usage: Considering the aspect of structure, buildings and bridges can share most of the resources. IFC distinguishes such entities or types in the Resource Layer. The Resource Layer includes elements such as geometry and material, which do not have functional meaning. The physical aspect of the functional meaning of building components is handled by entities that belong to the IfcSharedBldgElements schema that are represented in the IFC physical file (IPF) through subtypes of the IfcBuildingElement entity. Therefore, for bridge information modeling, the function and usage must be represented similarly to those represented by the subtypes of the IfcBuildingElement.

- In supporting dynamic loads, a pier is largely affected by the dynamic load in the direction vertical to the ground, while a column is affected by the dynamic load in the direction parallel to the ground.

- In terms of general functional classification, a column is a necessary condition for a pier (i.e., pier ⊂ column).

- In terms of usage, the column of a bridge substructure is termed separately from a pier.

4. Naming Process for Bridge Components

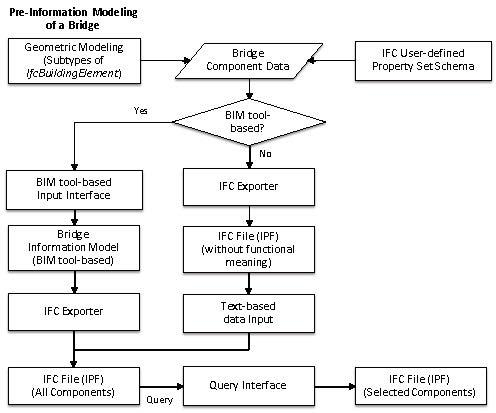

4.1. Basic Bridge Geometric Modeling and Information Reassigning

| Algorithm 1. Algorithm for creating the user-defined PSETs data in existing the IPF. |

| Input 1: psetListNode - XML nodes type of Pset_SteelBoxBridgeComponentIdentification property set including name and value data of property. Input 2: GUID of an object - string type Input 3: Population of generated IFC file - schemaParser.Population type Output: Creating the Pset_SteelBoxBridgeComponentIdentification related entities 1 NodeList psetListNode 2 do (Node pset : end of psets) 3 relatedObject in Figure 2: IFC entity correlated to the GUID 4 psetGuid: new GUID of ifcPropertySet 5 psetName: getting property set name from the pset 7 Ifcpropertyset in Figure 2: IfcPropertySet class for inclusion in Population 9 //setting the IfcPropertySet attributes to the Ifcpropertyset class 10 Ifcpropertyset.setGlobalid(psetGuid) 11 Ifcpropertyset.setOwnerhistory(getIfcOwnerHistoryInPopulation(ref Population)) 12 Ifcpropertyset.setName(psetName) 13 SetIfcproperty: set of IfcProperty in Figure 2 14 NodeList properties: properties included in the pset 15 do (Node property : end of properties) 16 propertyName: getting a property name from the property 17 propertyValue: getting a property value from property 18 Ifcpropertyvalue that subtypes of IfcSimpleProperty in Figure 2: IfcPropertyValue class for inclusion in Population 19 //setting the IfcPropertyValue attributes to the Ifcpropertyvalue class 20 Ifcpropertyvalue.setName(propertyName) 21 Ifcpropertyvalue.setNominalvalue(propertyValue) 22 SetIfcProperty.add(Ifcpropertyvalue): adding the Ifcpropertyvalue to SetIfcProperty class 23 end do 24 Ifcpropertyset.setHasproperties(SetIfcProperty): setting the HasProperties attribute in Figure 2 25 createRelationship(relatedObject, Ifcpropertyset): creating the relationship entity 26 end do Function createRelationship(relatedObject, Ifcpropertyset) 27 SetIfcobjectdefinition: set of IfcObjectDefinition in Figure 2 28 SetIfcobjectdefinition.add(relatedObject): adding the relatedObject to SetIfcobjectdefinition class 29 Ifcpropertysetdefinitionselect in Figure 2: IfcPropertySetDefinitionSelect class for inclusion in Population 30 Ifcreldefinesbyproperties in Figure 2: IfcRelDefinesByProperties class for inclusion in Population 31 //setting the IfcRelDefinesByProperties attributes to the Ifcreldefinesbyproperties class 32 Ifcreldefinesbyproperties.setGlobalid(new GUID) 33 Ifcreldefinesbyproperties.setOwnerhistory(gettingIfcOwnerHistoryInPop(ref Population)) 34 Ifcreldefinesbyproperties.setRelatedobjects(SetIfcobjectdefinition) 35 Ifcreldefinesbyproperties.setRelatingpropertydefinition(Ifcpropertysetdefinitionselect) |

4.2. Automated Naming Algorithm for the Identification of Bridge Components

- A: Span_1-Girder_1-Section_4

- B: Span_1-Girder_2-Section_2-Diaphragm_2

- C: Span_1-Girder_2-Section_4-Diaphragm_1

- D: Span_1-Girder_1,Girder_2-Section_3-CrossBeam_1

- E: Span_2-Girder_2-Section_1

5. Discussion

5.1. IFC-Based Model Implementation of a Steel Box Girder Bridge Structure

5.2. Quantity Take-Off Check Using the Bridge Data Model

5.3. Estimation of Carbon Emission Using IFC-Based Bridge Information Model

- Quantity: Utilization of the volume from the viewpoint of the product, based on the design phase.

- Identification: Utilization of the IFC and the IFC user-defined PSET proposed in previous sections.

5.4. Extraction Test Based on Semantic Meaning of Steel Bridge Components

| Algorithm 2. Algorithm for responding results according to the query sentence. |

| Input 1: qs - Query sentence Input 2: Population of generated IFC file - schemaParser.Population typeOutput: Responses according to the qeury 1 EntityInstanceSet: set of EntityInstance of IfcPropertySet 2 while (EntityInstanceSet.hasNext()) 3 Ifcpropertyset in Figure 2: IfcPropertySet class included in the Population 4 if (Ifcpropertyset.getName() == qs.EntityType) 5 SetIfcproperty: set of IfcProperty in Figure 2 6 checking (HasProperties) in Figure 2 7 while (SetIfcproperty.hasNext()) 8 Ifcproperty in Figure 2: IfcProperty class included in the Population 9 queriedName = Ifcproperty.getName() 10 queriedValue = Ifcproperty.getNominalvalue() 11 checking (queriedName == qs.Var.Name) 12 checking (queriedValue == qs.Var.NominalValue) 13 findRelatedObjects(Ifcpropertyset) Function findRelatedObjects(Ifcpropertyset) 14 EntityInstanceSet relatingPropertyDefinition = Ifcpropertyset.usedin(Ifcreldefinesbyproperties.relatingpropertydefinition_ATT); 15 while (relatingPropertyDefinition.hasNext()) 16 Ifcreldefinesbyproperties in Figure 2: IfcRelDefinesByProperties class included in the Population 17 SetIfcobjectdefinition = ifcRelDefinesProperties.getRelatedobjects() 18 while (SetIfcobjectdefinition.hasNext()) 19 Domain of relatedObject = Ifcobjectdefinition.getLocalDomain() 20 getting geometric information using relatedObject class |

- SELECT $Var1.ALL WHERE $Var1.EntityType = IfcPropertySet AND $Var1.Name = “Pset_SteelBoxBridgeComponentIdentification”

- SELECT $Var2 := $Var1.Attribute.HasProperties

- SELECT $Var3 := $Var2.Attribute WHERE $Var3.Name = “Parts Assembly” AND $Var3.NominalValue = “Diaphragm*”

- SELECT $Var1.ALL WHERE $Var1.EntityType = IfcPropertySet AND $Var1.Name = “Pset_SteelBoxBridgeComponentIdentification”

- SELECT $Var2 := $Var1.Attribute.HasProperties

- SELECT $Var3 := $Var2.Attribute WHERE $Var3.Name = “Assembled Assembly” AND $Var3.NominalValue = “Section_2”

- SELECT $Var1.ALL WHERE $Var1.EntityType = IfcPropertySet AND $Var1.Name = “Pset_SteelBoxBridgeComponentIdentification”

- SELECT $Var2 := $Var1.Attribute.HasProperties

- 40) SELECT $Var3 := $Var2.Attribute WHERE $Var3.Name = “Span” AND $Var3.NominalValue = “Span_1”

- SELECT $Var4 := $Var2.Attribute WHERE $Var4.Name = “Girder” AND $Var4.NominalValue = “Girder_1,Girder_2”

- SELECT $Var5 := $Var2.Attribute WHERE $Var5.Name = “Assembled Assembly” AND $Var5.NominalValue = “Section_3”

- SELECT $Var6 := $Var2.Attribute WHERE $Var6.Name = “Parts Assembly” AND $Var6.NominalValue = “CrossBeam_2”

- SELECT $Var1 WHERE $Var1.EntityType = IfcPropertySet AND $Var1.Name = “Pset_SteelBoxBridgeComponentIdentification”

- SELECT $Var2 := $Var1.Attribute.HasProperties

- SELECT $Var3 := $Var2.Attribute WHERE $Var3.Name = “Span” AND $Var3.NominalValue = “Span_1”

- SELECT $Var4 := $Var2.Attribute WHERE $Var4.Name = “Girder” AND $Var4.NominalValue = “Girder_1”

- SELECT $Var5 := $Var2.Attribute WHERE $Var5.Name = “Assembled Assembly” AND $Var5.NominalValue = “Section_5”

- SELECT $Var6 := $Var2.Attribute WHERE $Var6.Name = “Parts Assembly” AND $Var6.NominalValue = “Diaphragm_1”

- SELECT $Var7 WHERE $Var7.EntityType = IfcPropertySet AND $Var7.Name = “Pset_CarbonManagement”

- SELECT $Var8 := $Var7.Attribute.HasProperties

- SELECT $Var9 := $Var8.Attribute WHERE $Var9.Name = “Estimated Carbon”

- SELECT $Var10 WHERE $Var9.NominalValue;

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Eadie, R.; Browne, M.; Odeyinka, H.; McKeown, C.; McNiff, S. BIM implementation throughout the UK construction project lifecycle: An analysis. Autom. Constr. 2013, 36, 145–151. [Google Scholar] [CrossRef]

- Borrmann, A.; Kolbe, T.H.; Donaubauer, A.; Steuer, H.; Jubierre, J.R.; Flurl, M. Multi-scale geometric-semantic modeling of shield tunnels for GIS and BIM applications. Comput.-Aided Civ. Infrastruct. Eng. 2015, 30, 263–281. [Google Scholar] [CrossRef]

- Yau, N.J.; Tsai, M.K.; Yulita, E.N. Improving efficiency for post-disaster transitional housing in Indonesia: An exploratory case study. Disaster Prev. Manag. 2014, 23, 157–174. [Google Scholar] [CrossRef]

- Irizarry, J.; Karan, E.P. Optimizing location of tower cranes on construction sites through GIS and BIM integration. ITcon 2012, 17, 351–366. [Google Scholar]

- Liu, X.; Wang, X.; Wright, G.; Cheng, J.; Li, X.; Liu, R. A State-of-the-art review on the integration of Building Information Modeling (BIM) and Geographic Information System (GIS). ISPRS Int. J. Geo-Inf. 2017, 6, 53. [Google Scholar] [CrossRef]

- Kim, K.R.; Kim, H.; Kim, W.; Kim, C.; Kim, J.; Yu, J. Integration of ifc objects and facility management work information using Semantic Web. Autom. Constr. 2018, 87, 173–187. [Google Scholar] [CrossRef]

- Pishdad-Bozorgi, P.; Gao, X.; Eastman, C.; Self, A.P. Planning and developing facility management-enabled building information model (FM-enabled BIM). Autom. Constr. 2018, 87, 22–38. [Google Scholar] [CrossRef]

- Mangal, M.; Cheng, J.C.P. Automated optimization of steel reinforcement in RC building frames using building information modeling and hybrid genetic algorithm. Autom. Constr. 2018, 90, 39–57. [Google Scholar] [CrossRef]

- Ramaji, I.J.; Memari, A.M. Interpretation of structural analytical models from the coordination view in building information models. Autom. Constr. 2018, 90, 117–133. [Google Scholar] [CrossRef]

- Ninić, J.; Koch, C.; Stascheit, J. An integrated platform for design and numerical analysis of shield tunnelling processes on different levels of detail. Adv. Eng. Softw. 2017, 112, 165–179. [Google Scholar] [CrossRef] [Green Version]

- ISO-TC184/SC4. ISO 16739:2013 Industry Foundation Classes (IFC) for Data Sharing in the Construction and Facility Management Industries. ISO, 2013. [Google Scholar]

- Hira, S. Bay Bridge Construction. Available online: http://beyonddesign.typepad.com/posts/2013/09/bay-bridge-construction.html (accessed on 1 November 2018).

- Choi, N.-J.; Kim, M.-C.; Kim, J.-G.; Kook, C.-G. Barriers and priorities analysis in case of introducing civil BIM into public organizations. Mag. Korean Soc. Civ. Eng. 2015, 63, 52–60. [Google Scholar]

- Moore, G.A. Crossing the Chasm, 1st ed.; Harper Business Essentials: New York, NY, USA, 1991. [Google Scholar]

- Rogers, E.M. Diffusion of Innovations, 1st ed.; Free Press: New York, NY, USA, 1962. [Google Scholar]

- Gartner Hype Cycle. Available online: http://www.gartner.com/technology/research/methodologies/hype-cycle.jsp (accessed on 1 November 2018).

- Naney, D.; Goser, C.; Azambuja, M. Accelerating the adoption of lean thinking in the construction industry. In Proceedings of the 20th Annual Conference of the International Group for Lean Construction, San Diego, CA, USA, 18–20 July 2012. [Google Scholar]

- Björk, B.-C.; Penttila, H. A scenario for the development and implementation of a building product model standard. Adv. Eng. Softw. Workstn. 1989, 11, 176–187. [Google Scholar] [CrossRef]

- Cerovsek, T. A review and outlook for a “Building Information Model” (BIM): A multi-standpoint framework for technological development. Adv. Eng. Inform. 2011, 25, 224–244. [Google Scholar] [CrossRef]

- Lee, S.-H.; Kim, B.-G. IFC extension for road structures and digital modeling. Procedia Eng. 2011, 14, 1037–1042. [Google Scholar] [CrossRef]

- ISO-TC184/SC4. ISO 10303-11: 2004 Industrial Automation Systems and Integration—Product Data Representation and Exchange—Part 11: Description Methods: The EXPRESS Language Reference Manual. ISO, 2004. [Google Scholar]

- W3C Extensible Markup Language (XML). Available online: http://www.w3.org/XML/ (accessed on 1 November 2018).

- Gielingh, W. General AEC Reference Model (GARM): An aid for the integration of application specific product definition models. In Proceedings of the CIB Seminar Conceptual Modeling of Buildings, Lund, Sweden, 25–27 October 1988; pp. 165–178. [Google Scholar]

- Aoyama, N. Development and application of STEP for bridges maintenance. In Proceedings of the 23rd symposium on Civil Engineering Information Processing System, Tokyo, Japan, 27–28 October 1998; pp. 149–152. [Google Scholar]

- Mikami, I.; Tanaka, S.; Kubota, S.; Ishii, Y. Construction of database for highway bridges’ product data models using internet technology. J. Struct. Eng. JSCE 1999, 45, 511–522. [Google Scholar]

- Halfawy, M.R.; Hadipriono, F.C.; Duane, J.; Larew, R. Development of model-based systems for integrated design of highway bridges. In Proceedings of the International Conference on Civil, Structural and Environmental Engineering Computing, Rome, Italy, 30 August–2 September 2005. Paper 30. [Google Scholar] [CrossRef]

- Crowley, A.J.; Watson, A.S. CIMsteel Integration Standards Release 2: Overview; Steel Construction Institute: Berkshire, UK, 2000. [Google Scholar]

- Lee, S.-H.; Jeong, Y.-S. A system integration framework through development of ISO 10303-based product model for steel bridges. Autom. Constr. 2006, 15, 212–228. [Google Scholar] [CrossRef]

- Eastman, C.M.; Teicholz, P.; Sacks, R.; Liston, K. BIM Handbook: A Guide to Building Information Modeling for Owners, Managers, Designers, Engineers, and Contractors; John Wiley and Sons: Hoboken, NJ, USA, 2008. [Google Scholar]

- Arthaud, G.; Lebegue, E. IFC-Bridge V2 Data Model Edition R7; IAI French Chapter. 2007.

- Yabuki, N.; Lebegue, E.; Gual, J.; Shitani, T. International collaboration for developing the bridge product model “IFC-BRIDGE”. In Proceedings of the Joint International Conference on Computing and Decision Making in Civil and Building Engineering, Montreal, QC, Canada, 14–16 June 2006; pp. 1927–1936. [Google Scholar]

- Lee, S.-H.; Park, S.I.; Park, J. BIM and Its Application to Civil Engineering: How to Overcome the Limitations of Current BIM Technologies. In Proceedings of the 6th Civil Engineering Conference in Asia Region (CECAR6), Jakarta, Indonesia, 20–22 August 2013. [Google Scholar]

- Liebich, T. IFC for INFRAstructure. In Proceedings of the INFRA-BIM Workshop, Helsinki, Finland, 19 November 2013. [Google Scholar]

- buildingSMART International IFC Alignment. Available online: http://www.buildingsmart-tech.org/infrastructure/projects/alignment (accessed on 2 August 2018).

- P6 Project Team IFC Alignment Project–IFC Extension Development Version 1.0. buildingSMART MSG, 2015; 20p.

- KICT. IfcRoad Ch.9 Infra IFC Specifications with IfcRoad V0.6. Available online: https://www.buildingsmart.org/standards/standards-tools-services/ (accessed on 1 November 2018).

- China Railway BIM Alliance (CRBIM). Railway BIM Data Standard Version 1.0. China Railway BIM Alliance, 2015; 218p. [Google Scholar]

- Kolbe, T.H. Representing and exchanging 3D city models with CityGML. In 3D Geo-Information Sciences; Springer: Berlin/Heidelberg, Germany, 2009; pp. 15–31. [Google Scholar]

- Gröger, G.; Kolbe, T.H.; Nagel, C.; Häfele, K.-H. OGC City Geography Markup Language (CityGML) Encoding Standard V2.0. Open Geospatial Consortium, 2012. [Google Scholar]

- Cambridge Systematics Inc.; Bentley Systems Inc.; Info Tech Inc.; Michael Baker Jr. Inc; Campbell, C.E. XML Schemas for Exchange of Transportation Data–Final Report; Transportation Research Board of the National Academies: Washington, DC, USA, 2006. [Google Scholar]

- Ma, Z.; Wei, Z.; Song, W.; Lou, Z. Application and extension of the IFC standard in construction cost estimating for tendering in China. Autom. Constr. 2011, 20, 196–204. [Google Scholar] [CrossRef]

- Wix, J. User Defined Property Sets; The Offices of the Engineer Research and Development Center, Construction Engineering Research Laboratory: Champaign, IL, USA, 2009. [Google Scholar]

- Ministry of Land, Transport and Maritime Affairs of Korea. Construction Information Classification System of Korea, 2012 ed.; MLTMA: Seoul, Korea, 2012; 59p. (In Korean)

- KSSC. Detailed Design Guide for Steel Bridge; Ministry of Construction and Transportation: Seoul, Korea, 2006. (In Korean)

- Oh, J.T. Plan and Design of Bridge; Bansuk Tech: Seoul, Korea, 2003. (In Korean) [Google Scholar]

- Kim, B.-G.; Lee, S.-H. Enhancement of spatial and physical elements for IFC-based bridge data model. In Proceedings of the 28th International Symposium on Automation and Robotics in Construction (ISARC 2011), Seoul, Korea, 29 June–2 July 2011; pp. 375–376. [Google Scholar] [CrossRef]

- ISO-TC59/SC2. ISO 6707-1:2014 Buildings and Civil Engineering Works—Vocabulary—Part 1: General Terms, ISO: Geneva, Switzerland, 2014.

- Ministry of Land, Infrastructure and Transport of Korea. IPCC Guideline of Korea; MLIT: Sejong, Korea, 2011. (In Korean)

- See, R.; Liebich, T.; Hietanen, J. Design to QTO/Cost Estimating. 2009. Available online: http://www.blis-project.org/IAI-MVD/reporting/listMVDs_4.php?SRT=Name&MVD=GSA-004&DV=2 (accessed on 1 November 2018).

- Choi, J.; Choi, J.; Kim, H.; Kim, I. Open BIM-based quantity take-off system for schematic estimation of building frame in early design stage. J. Comput. Des. Eng. 2015, 2, 16–25. [Google Scholar] [CrossRef]

- Mazairac, W.; Beetz, J. BIMQL—An open query language for building information models. Adv. Eng. Inform. 2013, 27, 444–456. [Google Scholar] [CrossRef]

| Bridge Data Model | Feature | Limitations |

|---|---|---|

| AP 203-based Models | Initial bridge data model based on open data schema |

|

| IFC-Bridge | Adding new entities for the bridge structure based on current IFC resources |

|

| CityGML | One of the facilities of the city information model |

|

| TransXML | Included as a highway bridge structure in the data model for the transportation data exchange |

|

| IFC4 (without user-defined PSETs) | The standard data schema of BIM Various BIM authoring software packages |

|

| IFC4 with user-defined PSETs (in this study) |

| |

| IFC5 | Currently in early planning phase including the infrastructure domains | |

| Project Phase | |||||

|---|---|---|---|---|---|

| Basic Components (Planning Phase) | Main Components (Preliminary Design) | Detailed Components Accurate Geometric Shape (Detailed Design) | |||

| Super structure | Floor slab part | Slab | Pavement, Curb, Slab, Expansion joint, Median strip | Pavement | |

| Curb | Outward, Reinforcement | ||||

| Slab | Outward, Reinforcement, Spacer, Chair block, Stud, Shear connector | ||||

| Expansion joint | Outward, Reinforcement, Pin bearing, Anchor bolt, Steel plate, Rubber component | ||||

| Median barrier | Outward, Reinforcement, Steel pole, Rivet, Steel plate | ||||

| Main member | - | Main girder | Main girder | Flange, Web, Stiffener (vertical, horizontal, support, jack-up), Splice plate, Rivet | |

| Rib | Vertical rib, Horizontal rib, Rib plate | ||||

| Sub member | - | Diaphragm,Cross beam | Diaphragm | Diaphragm plate, Vertical stiffener, Horizontal stiffener, Opening stiffener | |

| Bracing | Section steel, Flange, Web, Rib, Bracing stiffener | ||||

| Cross beam | Plate, Flange, Bracket, Stiffener, Joint bar, Steel plate, Slab anchor, Stringer | ||||

| Bearing | - | Shoe, Sole plate | Bearing concrete | Outward, Reinforcement | |

| Shoe | Support, Steel plate | ||||

| Sole plate | Steel plate, Rivet | ||||

| Sub structure | Abutment part | Abutment | Abutment body, Abutment wing, Abutment parapet | Abutment body | Outward, Reinforcement |

| Abutment wing | Outward, Reinforcement | ||||

| Abutment parapet | Outward, Reinforcement | ||||

| Pier part | Pier | Column part, Coping part | Column part | Outward, Reinforcement | |

| Coping part | Outward, Reinforcement | ||||

| Foundation | - | - | Outward, Reinforcement | ||

| Pile | - | - | Outward, Reinforcement, Steel plate, Steel pipe | ||

| Facility | - | - | Hand rail | Outward, Reinforcement, Steel pole, Anchor bolt, Rivet, Steel plate | |

| Soundproof wall | Soundproof panel, Pillar, Steel plate, Rib, Rivet | ||||

| Drainage facility | Steel plate, Shape steel, Spacer | ||||

| Emergency shelter | Outward, Reinforcement, Spacer, Rhomb fence, Gate, Shape steel, Steel plate, Stiffener, Anchor, Sleeve, Rivet | ||||

| Inspection facility | Pillar, Handrail pole, Pipe, Foothold, Steel plate, Elbow, Sleeve, Anchor, Rivet | ||||

| Lighting facility | Street lighting, Fog lamp, Fixture | ||||

| Road sign | Steel plate, Rivet, Steel pole | ||||

| Bridge nameplate, Sidewalk, Decoration | |||||

| Other components | - | - | Internal door | Steel plate, Shape steel, Rivet, Round hole, Steel pipe | |

| Ventilation | Steel plate, Stainless net, Rivet | ||||

| Scaffold, Catch basin, Staging, Staging ring | |||||

| … | |||||

| PropertySet Name | Pset_SteelBoxBridgeComponentIdentification | |||

| Applicable Entities | IfcObject | |||

| Definition | A property set to generate the semantic information of steel box girder bridge components | |||

| Name | Property Type | Data Type | Definition | Example |

| Structural System | IfcPropertySingleValue | IfcLabel | Classification of super-sub structure of bridge | Super structure |

| Girder | IfcPropertySingleValue | IfcLabel | Horizontal direction of bridge component | Girder_1 |

| Span | IfcPropertySingleValue | IfcLabel | Longitudinal direction of bridge component | Span_1 |

| Assembled Assembly | IfcPropertySingleValue | IfcLabel | An assembly of assemblies | Section_5 |

| Parts Assembly | IfcPropertySingleValue | IfcLabel | An assembly of parts | Diaphragm_3 |

| Part | IfcPropertySingleValue | IfcLabel | A basic product component | H_stiffener |

| Project Stage | IfcPropertySingleValue | IfcLabel | Information of construction phase | Design development |

| Model Element Author | IfcPropertySingleValue | IfcLabel | Author information of modeled product | Prime Designer (J. Park) |

| Description | IfcPropertySingleValue | IfcLabel | Informative text to explain the property | - |

| Component Name | Qty (EA) | Volume (m3) | |

|---|---|---|---|

| Diaphragm | Diaphragm plate | 1 | 0.1392 |

| Horizontal stiffener | 2 | 0.0210 | |

| Opening stiffener (left) | 2 | 0.0010 | |

| Opening stiffener (right) | 2 | 0.0014 | |

| Cross Beam | Main Plate | 1 | 0.0110 |

| Upper Flange | 1 | 0.0032 | |

| Lower Flange | 1 | 0.0032 | |

| Bracket | 2 | 0.0096 | |

| Upper Bracket Flange | 2 | 0.0029 | |

| Lower Bracket Flange | 2 | 0.0038 | |

| Bracket Stiffener | 2 | 0.0083 | |

| Vertical Stiffener | 2 | 0.0044 | |

| Upper Joint Bar | 2 | 0.0029 | |

| Joint Bar | 12 | 0.0072 | |

| Shear Joint Bar | 4 | 0.0165 | |

| Span | Girder | AA | PA | Part | Count (EA) | Volume (m3) | |

|---|---|---|---|---|---|---|---|

| Span_1 | Girder_1 | Section_1 | Diaphragm_1 | Diaphragm_Plate_1 | 1 | 0.1392 | 0.1392 |

| Horizontal_Stiffener_1 | 1 | 0.0105 | 0.0210 | ||||

| Horizontal_Stiffener_2 | 1 | 0.0105 | |||||

| Opening_Stiffener_1 | 1 | 0.0005 | 0.0024 | ||||

| Opening_Stiffener_2 | 1 | 0.0005 | |||||

| Opening_Stiffener_3 | 1 | 0.0007 | |||||

| Opening_Stiffener_4 | 1 | 0.0007 | |||||

| Bracket_1 | 1 | 0.0048 | 0.0096 | ||||

| Bracket_2 | 1 | 0.0048 | |||||

| Bracket_Stiffener_1 | 1 | 0.0041 | 0.0083 | ||||

| Bracket_Stiffener_2 | 1 | 0.0041 | |||||

| Lower_Bracket_Flange_1 | 1 | 0.0019 | 0.0038 | ||||

| Lower_Bracket_Flange_2 | 1 | 0.0019 | |||||

| Lower_Flange_1 | 1 | 0.0032 | 0.0032 | ||||

| Lower_Joint_Bar_1 | 1 | 0.0006 | 0.0072 | ||||

| Lower_Joint_Bar_2 | 1 | 0.0006 | |||||

| … | … | … | |||||

| Lower_Joint_Bar_12 | 1 | 0.0006 | |||||

| Main_Plate_1 | 1 | 0.0110 | 0.0110 | ||||

| Upper_Bracket_Flange_1 | 1 | 0.0015 | 0.0029 | ||||

| Upper_Bracket_Flange_2 | 1 | 0.0015 | |||||

| Upper_Flange_1 | 1 | 0.0032 | 0.0032 | ||||

| Upper_Joint_Bar_1 | 1 | 0.0015 | 0.0029 | ||||

| Upper_Joint_Bar_2 | 1 | 0.0015 | |||||

| Shear_Joint_Bar_1 | 1 | 0.0041 | 0.0165 | ||||

| … | … | … | |||||

| Shear_Joint_Bar_4 | 1 | 0.0041 | |||||

| Vertical_Stiffner_1 | 1 | 0.0022 | 0.0044 | ||||

| Vertical_Stiffner_2 | 1 | 0.0022 | |||||

| PropertySet Name | Pset_CarbonManagement | |

| Applicable Entities | IfcObject | |

| Definition | A property set to manage the carbon-related information of facilities | |

| Name | Data Type | Definition |

| Unit Weight | IfcReal | Unit weight of material |

| Material Type | IfcLabel | A type of material |

| Emission Factor | IfcReal | Carbon emission factor |

| Estimated Caron | IfcReal | Estimated carbon emission |

| Identifier | Mat. | Vol. | UW | E.Factor | Carbon |

|---|---|---|---|---|---|

| Span_1,Span2-Girder1,Girder2-$-Pier_1-$ | Conc. | 156.39 | - | 430.87 | 67,383.40 |

| Span_1,Span2-Girder1,Girder2-$-Foundation_1-$ | Conc. | 202.50 | - | 430.87 | 87,251.18 |

| Span_1-Girder_1,Girder_2-Section_7-CrossBeam_1-JointBar_8 | Steel | 0.000603 | 7850 | 0.4 | 1.89342 |

| Span_1-Girder_1-Section_1-UpperRib_4-$ | Steel | 0.02999 | 7850 | 0.4 | 94.162 |

| Span_1-Girder_1-Section_1-Diaphragm_2-VerticalStiffener_1 | Steel | 0.013920 | 7850 | 0.4 | 43.7088 |

| Span_1-Girder_1-Section_7-Web_1-$ | Steel | 0.195925 | 7850 | 0.4 | 615.2045 |

| … | … | … | |||

| Total | 1382.22 | 1,068,649.97 |

| Identifier | |

|---|---|

| Span_1-Girder_1-Section_1 | 76,911.84 |

| Span_1-Girder_1-Section_2 | 11,996.88 |

| Span_1-Girder_1,Girder_2-Section_1 | 411.98 |

| Span_1-Girder_1-Section_2-Diaphram_2 | 3672.31 |

| Span_1-Girder_1-Section_2-Diaphram_2-V_Stiffener* | 164.90 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, S.I.; Park, J.; Kim, B.-G.; Lee, S.-H. Improving Applicability for Information Model of an IFC-Based Steel Bridge in the Design Phase Using Functional Meanings of Bridge Components. Appl. Sci. 2018, 8, 2531. https://doi.org/10.3390/app8122531

Park SI, Park J, Kim B-G, Lee S-H. Improving Applicability for Information Model of an IFC-Based Steel Bridge in the Design Phase Using Functional Meanings of Bridge Components. Applied Sciences. 2018; 8(12):2531. https://doi.org/10.3390/app8122531

Chicago/Turabian StylePark, Sang I., Junwon Park, Bong-Geun Kim, and Sang-Ho Lee. 2018. "Improving Applicability for Information Model of an IFC-Based Steel Bridge in the Design Phase Using Functional Meanings of Bridge Components" Applied Sciences 8, no. 12: 2531. https://doi.org/10.3390/app8122531