Molecular level analyses of mechanical properties of basic medical used plastics irradiated by Co-60 gamma-ray for sterilization

-

1

Graduate School of Engineering, Osaka Prefecture University, Department of Quantum and Radiation Engineering, Japan

-

2

Graduate School of Biomedical Sciences, Hiroshima University, Department of Biomaterials Science, Japan

-

3

Jikei Institute, Graduate School of Health Care Sciences, Japan

-

4

Graduate School of Engineering, Osaka University, Division of Materials & Manufacturing Science, Japan

Introduction: Recently, Co-60 gamma-ray irradiation has become much popular as a medical sterilization technique due to the fact that materials can be irradiated in a sealed state, and radiation can deeply penetrate materials, contrary to electron beam irradiation, which is limited to the surface shallow layers. On the other hand, it has been reported that PTFE is depleted by irradiation. However, the effect of Co-60 gamma-ray irradiation on the properties of PTFE has not been sufficiently examined. In this study, the property change of PTFE after irradiation was analyzed physicochemically in comparison with common plastics such as PE, PP, and PVC.

Materials and Methods: For the tensile strength test, PE (polyethylene: Shin-Kobe Electric Machinery Co., Ltd., Japan), PP (polypropylene: Shin-Kobe Electric Machinery Co., Ltd., Japan), PVC (poly vinyl chloride: Kasai Industry Co., Ltd., Japan) and PTFE (polytetrafluoroethylene: Nichiasu Co. Ltd., Japan) were purchased as Dumbbell #7 form samples. Each sample (N = 5) was irradiated by Co-60 gamma-rays at 0 – 100 kGy at the Radiation Research Center, Osaka Prefecture University, Japan. The tensile test was carried out using Imada Digital gauge ZTS-500N and electric stand MX2-500N (Cross-head speed: 50 mm/min). XPS, Raman, and X-ray diffraction analyses for PE, PP, PVC, and PTFE samples were carried out before and after irradiation.

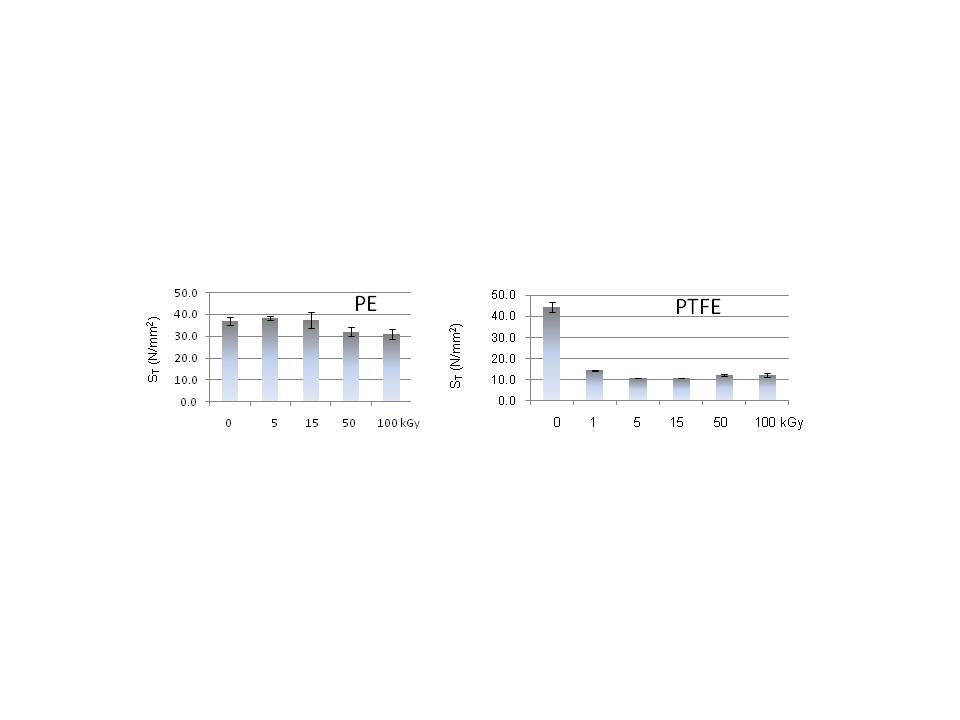

Results and Discussion: At lower dosages, tensile breaking strengths of PE, PP, and PVC did not change and gradually decreased above 50 kGy. In contrast, the tensile breaking strengths of PTFE markedly decreased at 1 kGy and maintained almost one quarter of the original value (44.3 ± 2.5 N/mm2) from 5 until 100 kGy (Fig. 1).

XPS analysis indicated that the atomic concentrations of carbon (C) and fluorine (F) of PTFE were not different among the irradiation dosages. Raman spectra of PTFE showed a slight increase of the absorption peak intensity at 731 cm-1 according to the irradiation dosage. X-ray diffraction showed that the crystal size of PTFE (56.7 ± 1.0 nm) became smaller after the 100-kGy irradiation (48.5 ± 0.6 nm). These results were consistent with the above results of Raman analysis.

Conclusion: The tensile strength of PTFE markedly decreased with the increase of the Co-60 gamma-ray irradiation dosage, in contrast to those of PE, PP, and PVC. It is suggested that this mechanical property change of PTFE may be due to the nano-scale C-C bond cutting by irradiation, and not due to micro-scale cracks.

Keywords:

polymer,

fracture toughness,

mechanical property

Conference:

10th World Biomaterials Congress, Montréal, Canada, 17 May - 22 May, 2016.

Presentation Type:

Poster

Topic:

Mechanical properties of biomaterials

Citation:

Furuta

M,

Matsugaki

A,

Nakano

T,

Hirata

I,

Kato

K and

Okazaki

M

(2016). Molecular level analyses of mechanical properties of basic medical used plastics irradiated by Co-60 gamma-ray for sterilization.

Front. Bioeng. Biotechnol.

Conference Abstract:

10th World Biomaterials Congress.

doi: 10.3389/conf.FBIOE.2016.01.00995

Copyright:

The abstracts in this collection have not been subject to any Frontiers peer review or checks, and are not endorsed by Frontiers.

They are made available through the Frontiers publishing platform as a service to conference organizers and presenters.

The copyright in the individual abstracts is owned by the author of each abstract or his/her employer unless otherwise stated.

Each abstract, as well as the collection of abstracts, are published under a Creative Commons CC-BY 4.0 (attribution) licence (https://creativecommons.org/licenses/by/4.0/) and may thus be reproduced, translated, adapted and be the subject of derivative works provided the authors and Frontiers are attributed.

For Frontiers’ terms and conditions please see https://www.frontiersin.org/legal/terms-and-conditions.

Received:

27 Mar 2016;

Published Online:

30 Mar 2016.

*

Correspondence:

Dr. Masakazu Furuta, Graduate School of Engineering, Osaka Prefecture University, Department of Quantum and Radiation Engineering, Sakai, Japan, Email1

Dr. Aira Matsugaki, Graduate School of Biomedical Sciences, Hiroshima University, Department of Biomaterials Science, Hiroshima, Japan, matsugaki@mat.eng.osaka-u.ac.jp

Dr. Takayoshi Nakano, Graduate School of Biomedical Sciences, Hiroshima University, Department of Biomaterials Science, Hiroshima, Japan, nakano@mat.eng.osaka-u.ac

Dr. Isao Hirata, Jikei Institute, Graduate School of Health Care Sciences, Osaka, Japan, isao@hiroshima-u.ac.jp

Dr. Koichi Kato, Jikei Institute, Graduate School of Health Care Sciences, Osaka, Japan, kokato@hiroshima-u.ac.jp

Dr. Masayuki Okazaki, Graduate School of Engineering, Osaka University, Division of Materials & Manufacturing Science, Suita, Japan, m-okazaki@ghsj.ac.jp