Abstract

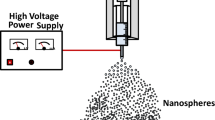

A laboratory electrospark system permits the creation of an overvoltage in the gap between dispersible electrodes. Conductive nanopowder may be produced by an electrospark method with a considerable overvoltage in the electrode gap. The production of small powder batches for additive technology by this means is promising and economical.

Similar content being viewed by others

REFERENCES

Popadyuk, S., Five features of metal powders for 3D printing, Fotonika, 2018, vol. 12, no. 3, pp. 308–311.

Scientists from Tomsk are developing new national materials for 3D printing: news, 2017. http:// fano.gov.ru/ru/press-center/card/?id_4=39207. Accessed December 26, 2017.

Makarov, M., Industrial 3D printers are expensive toy or real tool for modernization of engineering industry in Russia? Fotonika, 2015, no. 5 (53), pp. 20–32.

Gubin, S.P., Koksharov, Yu.A., Khomutov, G.B., and Yurkov, G.Yu., Magnetic nanoparticles: preparation, structure and properties, Russ. Chem. Rev., 2005, vol. 74, no. 6, pp. 489–520.

Lu, A.-H., Salabas, E.L., and Schuth, F., Magnetic nanoparticles: synthesis, protection, functionalization, and application, Angew. Chem., 2007, vol. 46, no. 8, pp. 1222–1244.

Rajput, N., Methods of preparation of nanoparticles—a review, Int. J. Adv. Eng. Technol., 2015, vol. 7, no. 4, pp. 1806–1811.

Berkowitz, A.E. and Walter, J.L., Spark erosion: a method for producing rapidly quenched fine powders, J. Mater. Res., 1987, vol. 2, no. 2, pp. 277–288.

Hong, J.I., Parker, F.T., Solomon, V.C., et al., Fabrication of spherical particles with mixed amorphous/crystalline nanostructured cores and insulating oxide shells, J. Mater. Res., 2008, vol. 23, pp. 1758–1763.

Nguyen, P.K., Lee, K.H., Moon, J., et al., Spark erosion: a high production rate method for producing Bi0.5Sb1.5Te3 nanoparticles with enhanced thermoelectric performance, Nanotechnology, 2012, vol. 23, no. 41.

Carrey, J., Radousky, H.B., and Berkowitz, A.E., Spark-eroded particles: influence of processing parameters, J. Appl. Phys., 2014, vol. 95, no. 3, pp. 823–829.

Monastyrsky, G., Nanoparticles formation mechanisms through the spark erosion of alloys in cryogenic liquids, Nanoscale Res. Lett., 2015, vol. 10, p. 503.

Shervani-Tabar, M.T. and Mobadersany, N., Numerical study on the hydrodynamic behavior of the dielectric fluid around an electrical discharge generated bubble in EDM, Theor. Comput. Fluid Dyn., 2013, vol. 27, pp. 701–719.

ACKNOWLEDGMENTS

Financial support was provided by the Russian Ministry of Education and Science (project 8.7552.2017/8.9).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by Bernard Gilbert

About this article

Cite this article

Sleptsov, V.V., Savkin, A.V., Trunova, E.A. et al. Electrospark Dispersion in Nanopowder Production for Additive Technologies. Russ. Engin. Res. 39, 133–136 (2019). https://doi.org/10.3103/S1068798X19020254

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068798X19020254