Abstract—

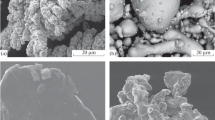

The results of studying the effect of the additive powder of the iron-chromium alloy PH-30 on the tribological properties of a composite friction material based on copper operating in the conditions of boundary friction are presented. It is shown that the introduction of 10 to 40 vol % PH-30 powder helps to increase the coefficient of friction from 0.042 to 0.075. It is found that at 10 vol % PH-30 the material’s wear is minimal and is 4 μm/km, while at 40 vol %, catastrophic wear is observed, exceeding 20 μm/km. The limit value of the material’s wear of 9 μm/km is noted with the powder content of PH-30 of less than 28 vol %. The increase in the tribotechnical properties of copper-based friction material with the addition of PH-30 powder is explained by the action of not only the PH-30 powder itself but also Fe4Cu3, FeSn intermetallide, and solid ceramic particles of chromium carbide Cr23C6 formed on the surface after sintering.

Similar content being viewed by others

REFERENCES

Dyachkova, L.N., Production of antifriction composite powder infiltrated materials based on iron for heavily loaded friction units, Doctoral (Eng.) Dissertation, Minsk, 2013.

Dmitrovich, A.A., Liashok, A.V., Rogovoi, A.N., and Saroka, D.I., Composite friction materials: main types and requirements for them, in Poroshkovaya metallurgiya (Powder Metallurgy), Minsk: Belarusskaya Nauka, 2015, no. 38.

Fedorchenko, I.M., Sovremennye friktsionnye materialy (Modern Friction Materials), Kiev: Naukova Dumka, 1975.

Balakin, V.A. and Sergeenko, V.P., Teplovye raschety tormozov i uzlov treniya (Thermal Calculations of Breaks and Friction Units), Gomel, 1999.

Ilyushchanka, A.Ph., Liashok, A.V., Rogovoi, A.N., and Sharipov, V.M., Use of the term “sintered powder friction material,” Trakt. Sel’khozmash., 2016, no. 9.

Ilyushchanka, A.Ph., Rogovoi, A.N., Dmitrovich, A.A., and Liashok, A.V., Sintered frictional materials, in Poroshkovaya metallurgiya v Belarusi: vyzovy vremeni (Powder Metallurgy in Belarus: New Challenges), Ilyushchanka, A.Ph., Ed., Minsk: Belarusskaya Navuka, 2017, pp. 113–121.

Ilyushchanka, A.Ph., Dmitrovich, A.A., Shapovalova, O.A., and Liashok, A.V., Friction materials for hydromechanical transmissions, Trakt. Sel’khozmash., 2011, no. 6, 41.

Netrebko, V.V., Specific carbide formation and distribution of Cr, Mn and Ni in white cast irons, Lit’e Metall., 2015, no. 3 (80).

Kulu, P., Iznosostoikost’ poroshkovykh materialov i pokrytii (Wear-Resistance of Powder Materials and Coatings), Tallinn: Valgus, 1988.

Pripisnov, O.N., Shelekhov, E.V., Rupasov, S.I., and Medvedev, A.S., The mechanism of phase formation and the mechanochemical synthesis of chromium carbide, Izv. VUZov, Poroshk. Metall. Funkts. Pokrytiya, 2014, no. 3, pp. 8–15.

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Leshok, A.V., Ilyushchanka, A.P., Dyachkova, L.N. et al. Tribotechnical Properties of a Copper-Based Powder Friction Material with the Addition of Iron-Chromium Alloy Powder. J. Frict. Wear 42, 1–6 (2021). https://doi.org/10.3103/S1068366621010049

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068366621010049