Abstract

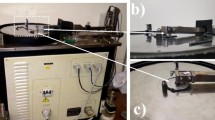

This paper describes friction tests of 3D printing materials in vacuum. The tests were conducted on reciprocally moving samples placed in vacuum at temperatures of up to 130°C. The samples were made from commercially available 3D printing materials (SBS, ABS, PETG, PLA, NYLON SUPER CARBON 2). The dependences of the in-vacuum friction coefficient of the samples on the sample temperature and critical temperatures of using the samples in vacuum were derived. Polymers PETG, NYLON SUPER CARBON 2 can be used in friction assemblies operated in vacuum because these materials have a low friction coefficient at room and high temperatures. The lowest friction coefficient at room temperature and the greatest thermal resistance are exhibited by NYLON SUPER CARBON 2. The research results can be applied in manufacturing 3D printing devices parts for use in vacuum.

Similar content being viewed by others

REFERENCES

Attaran, M., The rise of 3-D printing: The advantages of additive manufacturing over traditional manufacturing, Bus. Horiz., 2017, vol. 60, no. 5, pp. 677–688.

Dizon, J.R.C., et al., Mechanical characterization of 3D-printed polymers, Addit. Manuf., 2018, vol. 20, pp. 44–67.

Additive Manufacturing for the Aerospace Industry, Froes, F. and Boyer, R., Eds., Amsterdam: Elsevier, 2019.

Daminabo, S.C., et al., Fused deposition modeling-based additive manufacturing (3D printing): techniques for polymer material systems, Mater. Today: Chem., 2020, vol. 16, art. ID 100 248.

Jia, B.-B., et al., Tribological behaviors of several polymer–polymer sliding combinations under dry friction and oil-lubricated conditions, Wear, 2007, vol. 262, nos. 11–12, pp. 1353–1359.

Mohamed, O.A., et al., Investigation on the tribological behavior and wear mechanism of parts processed by fused deposition additive manufacturing process, J. Manuf. Process., 2017, vol. 29, pp. 149–159.

3D printing materials: What to choose? Printing Watson. https://bestfilament.ru/blog/publ/materialy-dlya-3d-pechati-chto-vybrat-pechataem-watson/. Accessed April 30, 2020.

Plastic for 3D printer. https://u3print.com. Accessed April 30, 2020.

Lay, M., et al., Comparison of physical and mechanical properties of PLA, ABS and nylon 6 fabricated using fused deposition modeling and injection molding, Composites, Part B, 2019, vol. 176, art. ID 107 341.

Abeykoon, C., Sri-Amphorn, P., and Fernando, A., Optimization of fused deposition modeling parameters for improved PLA and ABS 3D printed structures, Int. J. Lightweight Mater. Manuf., 2020, vol. 3, no. 3, pp. 284–297.

Butmanov, D.D., Bannikov, M.V., and Bayandin, Yu.V., The mechanical properties of thermoplastic materials for 3D printing, Materialy XII Mezhdunarodnoi konferentsii “Mekhanika, resurs i diagnostika materialov i konstruktsii,” Ekaterinburg, 21–25 maya 2018 g. (Proc. XII Int. Conf. “Mechanics, Resource, and Testing of Materials and Constructions,” Yekaterinburg, May 21–25, 2018), Yekaterinburg: Inst. Mashinostr., Ural. Otd., Ross. Akad. Nauk, 2018, p. 33.

Ramesh, V., van Kuilenburg, J., and Wits, W.W., Experimental analysis and wear prediction model for unfilled polymer-polymer sliding contacts, Tribol. Trans., 2019, vol. 62, no. 2, pp. 176–188.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by S. Kuznetsov

About this article

Cite this article

Prozhega, M.V., Reschikov, E.O., Shirshov, A.D. et al. Frictional Properties of 3D Printing Polymers in Vacuum. J. Frict. Wear 41, 565–570 (2020). https://doi.org/10.3103/S1068366620060173

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068366620060173