Abstract

It is shown that in conditions of significant increase of railway transport speeds, requirements for the safety of the friction–mechanical “wheel–rail” subsystem are increased. In order to solve the above problem, a method is proposed for metal plating “wheel–rail” friction surfaces by applying thin films of soft metal, for example, aluminum, with different values of hardness, on surfaces of rolling wheels and wheel ridges of locomotives. On the basis of quantum-chemical calculations, it has been proved that metal plating of the friction surfaces of the “wheel–rail” system provides a chemical bond between wheel steel and aluminum and the formation of a strong protective film. The performed bench tests of the “wheel–rail” model friction subsystem by methods of tribospectration identification of friction processes and dynamic monitoring of changes in elastic-dissipative bonds confirmed the formation of stable dynamic bonds in friction contact. The results of the research formed the basis of the creation of the algorithm of axial control of “wheel–rail” interaction processes at realization of forces of longitudinal and transverse creep, as well as at optimization of modes of vibrodynamic metal plating working surfaces of other tribosystems, of vehicles operating in heavy load–speed conditions of operation.

Similar content being viewed by others

REFERENCES

Verigo, M.F. and Kogan, A.Ya., Vzaimodeistvie puti i podvizhnogo sostava (Interaction of Rails and Rolling Stock), Moscow: Transport, 1986.

Kohn, W., Becke, A.D., and Parr, R.G., Density functional theory of electronic structure, J. Phys. Chem., 1996, vol. 100, pp. 12974–12980.

Kolesnikov, I.V., Sistemnyi analiz i sintez protsessov, proizkhodyashchikh v metallopolimernykh uzlakh treniya friktsionnogo i antifriktsionnogo naznacheniya (System Analysis and Processes Ocurring in Metal Polymeric Friction and Anti-Friction Units), Moscow: Vseross. Inst. Nauchn. Tekh. Inf., Ross. Akad. Nauk, 2017.

Migal’, Yu.F., Kolesnikov, V.I., and Kolesnikov, I.V., Impurity and alloying elements on grain surface in iron: periodic dependence of binding energy on atomic number and influence on wear resistance, Comput. Mater. Sci., 2016, vol. 111, pp. 503–512.

te Velde, G., Bickelhaupt, F.M., Baerends, E.J., Fonseca Guerra, C., van Gisbergen, S.J.A., Snijders, J.G., and Ziegler, T., Chemistry with ADF, J. Comput. Chem., 2001, vol. 22, pp. 931–967.

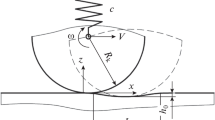

Ozyabkin, A.L., Theory of dynamic monitoring of friction mobile system, Trenie Smazka Mash. Mekh., 2011, no. 10, pp. 17–28.

Pupkov, K.A., Metody klassicheskoi i sovremennoi teorii avtomaticheskogo upravleniya: uchebnik. Tom 1. Matematicheskie modeli, dinamicheskie kharakteristiki i analiz sistem avtomaticheskogo upravleniya (Traditional and Modern Theory of Automatic Control, Vol. 1: Mathematical Models, Dynamic Characteristics, and Analysis of Automatic Control Systems), Pupkov, K.A. and Egupov, N.D., Eds., Moscow: Mosk. Gos. Tekh. Univ. im. N.E. Baumana, 2004, 2nd ed.

Zadeh, L. and Desoer, C., Linear System Theory: The State Space Approach, New York: McGraw-Hill, 1963.

Shapovalov, V.V., et al., RF Patent 2 517 946, Byull. Izobret., 2014, no. 16.

Shapovalov, V.V., et al., RF Patent 2 479 455, Byull. Izobret., 2013, no. 11.

Shapovalov, V.V., et al., RF Patent 2 674 899, Byull. Izobret., 2018, no. 35.

Shapovalov, V.V., Shcherbak, P.N., Bogdanov, V.M., et al., Improved efficiency of wheel-rail friction system, Vestn. Nauchno-Issled.Inst. Zheleznodorozhn. Transp., 2019, vol. 78, no. 3, pp. 177–182.

Funding

This work was carried out in the framework of the federal target program “Research and Development in Priority Areas of Development of Scientific and Technological Complex of Russia for 2014–2020” with financial support from the state represented by the Ministry of Science and Higher Education of Russia, project no. RFMEFI60718X0203.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by Sh. Galyaltdinov

About this article

Cite this article

Shapovalov, V.V., Migal, Y.F., Ozyabkin, A.L. et al. Metal Plating of Friction Surfaces of the “Wheel–Rail” Pair. J. Frict. Wear 41, 338–346 (2020). https://doi.org/10.3103/S1068366620040121

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068366620040121