Abstract

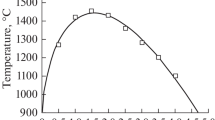

Uniform coke heating within coke ovens is of great importance. The temperature difference along the axis of the coke cake increases with increase in oven length and height and may reach 300°C or more, depending on the coke-battery design and technological factors. The introduction of control devices is a well-established approach to more uniform heating of the coke cake, in combination with methods of temperature calculation at the wall of the heating channel. However, this approach depends on information determined experimentally. That introduces more error in determining the temperature distribution over the channel height. Accordingly, attempts are made in the present work to describe the combustion of the heating gas on the basis of the minimum number of simply and reliably measurable factors. A three-parameter equation is obtained. Its structure is universal in terms of the set of factors. Adopting that equation as a model, the action of various factors on the temperature distribution over the height of the heating channel may be studied.

Similar content being viewed by others

REFERENCES

Barsky, V.D. and Vlasov, G.A., Khimicheskii potentsial tverdogo topliva (Chemical Potential of Solid Fuel), Donetsk: Donetsk. Nats. Tekh. Univ., 2014.

Spravochnik koksokhimika. Tom 2. Proizvodstvo koksa (Handbook of Coke Chemist, Vol. 2: Coke Production), Rudyka, V.I. and Zingerman, Yu.E., Eds., Kharkov: Inzhek, 2014.

Miroshnichenko, D.V. and Golovko, M.B., Vpliv elementnogo ta petrografichnogo skladiv vugillya i shikht na vikhid osnovnikh produktiv koksuvannya (Effect of Elemental and Petrographic Compositions of Coal and Charge on the Yield of Main Coking Products), Kharkov: Planeta-Pint, 2020.

Vlasov, G.A., Zublev, D.G., Barsky, V.D., et al., Uniform heating of coal charge in a coke oven, Part 1: Temperature distribution over the chamber height, Metall. Gornorudn. Prom-st., 2003, no. 2, pp. 20–24.

Vlasov, G.A., Zublev, D.G., and Barsky, V.D., Uniform heating of coal charge in a coke oven, Part 2: Temperature distribution over the length of the coke cake, Metall. Gornorudn. Prom-st., 2003, no. 3, pp. 13–18.

Vlasov, G.A., Zublev, D.G., Barsky, V.D., and Rudnitskii, A.G., Uniform heating of coal charge in a coke oven, Part 3: Heating regulation of coke batteries, Metall. Gornorudn. Prom-st., 2003, no. 4, pp. 14–17.

Narushev, S.I., Zublev, D.G., and Barsky, V.D., Influence of the thermal mode of coke oven batteries on the mechanical strength of produced coke, Metall. Gornorudn. Prom-st’., 2005, no. 1, pp. 12–14.

Zubilin, I.G., Density distribution of the coal charge in an experimental large-capacity furnace chamber, Koks Khim., 1961, no. 6, pp. 23–28.

Pinchuk, S.I., Kontroliruemaya tekhnologiya koksovaniya (Controlled Coking Technology), Kyiv: Tekhnika, 1994.

Vlasov, G.A., Zublev, D.G., Barsky, V.D., and Rudnitskii, A.G., Uniform heating of coal charge in a coke oven. Part 4: Flame formation in heating channels, Metall. Gornorudn. Prom-st’., 2003, no. 5, pp. 12–17.

Zublev, D.G., Barsky, V.D., and Kravchenko, A.V., Optimal oven heating of coke cake: a review, Coke Chem., 2016, vol. 59, no. 11, pp. 411–413.

Zublev, D.G., Barsky, V.D., and Kravchenko, A.V., Optimal oven heating of coke cake: a review, Koks Khim., 2016, no. 11, pp. 16–18.

Zublev, D.G., Barsky, V.D., and Kravchenko, A.V., Optimal oven heating of coke cake. 2. Selection of inert gas, Coke Chem., 2018, vol. 61, no. 8, pp. 291–296.

Zublev, D.G., Barsky, V.D., and Kravchenko, A.V., Optimal oven heating of coke cake. 2. Selection of inert gas, Koks Khim., 2018, no. 8, pp. 13–18.

Zublev, D.G., Barsky, V.D., and Kravchenko, A.V., Optimal oven heating of coke cake. 3. Theory of pulsating combustion, Coke Chem., 2019, vol. 62, no. 6, pp. 230–233.

Zublev, D.G., Barsky, V.D., and Kravchenko, A.V., Optimal oven heating of coke cake. 3. Theory of pulsating combustion, Koks Khim., 2019, no. 6, pp. 12–16.

Levenspiel, O., Chemical Reaction Engineering: An Introduction to the Design of Chemical Reactors, Chichester: Wiley, 1962.

Barsky, V.D., Obshchie osnovy khimicheskoi tekhnologii. Chast’ 1. Matematicheskoe modelirovanie kak nauchnyi metod khimicheskoi tekhnologii (General Principles of Chemical Technology, Part 1: Mathematical Modeling as a Scientific Method of Chemical Technology), Dnepr: Lira, 2020.

Zublev, D.G., Improvement of the thermal regime of the coal charge coking, Cand. Sci. (Tech.) Dissertation, Kharkov, 2007.

Agroskin, A.A., Dvizhenie gazov i teplootdacha v koksovykh pechakh (Gas Motion and Heat Transfer in Coke Ovens), Moscow: Akad. Nauk SSSR, Moscow: Akad. Nauk SSSR, 1949.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated by B. Gilbert

About this article

Cite this article

Zublev, D.G., Barsky, V.D. & Trikilo, A.I. 1. Temperature Distribution over the Height of the Heating Channels. Coke Chem. 64, 194–198 (2021). https://doi.org/10.3103/S1068364X21050070

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068364X21050070