Abstract

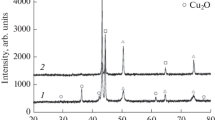

This article compares the microstructures of alloys formed upon the sintering of powdered mixtures of tungsten (PV2, average particle size 3.8–6.0 μm) and copper (PMS–11, particle-size fraction 45–60 μm) produced by various methods: the simple mixing of powdered metals, the mechanical activation (MA) of powdered metals, and the deposition of copper from a solution of its sulfate (Cu2SO4·5H2O) on powdered tungsten with simultaneous mechanical activation. The molar ratio in metals in mixtures is Cu/W = 1. The aqueous solution for copper deposition is comprised of diethylene glycol (up to 30%), glycerol (up to 8%), hydrofluoric acid (up to 0.1%), and the OP-10 wetting agent (up to 0.8%). Mechanical activation is carried out in an AGO-2 planetary mill with a drum load of 200 g of steel balls and a drum rotation speed of 2220 rpm for 5 min. Reduced copper in the solution and in air is rapidly oxidized to Cu2O; therefore, the composite powders were washed, dried, and stored in an argon environment. The samples pressed from the powders (tablets with a diameter of 3 mm, height of 1.5–2.0 mm, and density of 7.7–8.0 g/cm3) are sintered in argon at ambient pressure and in a temperature range from 1000 to 1500°C. During the sintering of Cu–W composite particles, it is possible to highlight several regions of the progress of the process. At temperatures below the melting point of copper, solid-phase sintering in the contact points of composite particles occurs. Upon heating from the melting points to 1200°C, the samples from the mixture of powdered metals are sintered according to the liquid-phase mechanism, forming a low porous cake. Sintering of composite powders produced by MA upon copper deposition and the MA of mixtures of powdered metals results in the segregation of samples with the formation of coarse pores extended perpendicularly to the axis of pressing and are partially filled with molten copper. Upon the heating of samples produced by the MA of powders above 1400°C, phase separation occurs and all copper is displaced from the sample to the surface.

Similar content being viewed by others

REFERENCES

Okamoto, H., Desk Handbook: Phase Diagrams for Binary Alloys, Materials Park, OH: ASM Int., 2010. https://www.asminternational.org.

Zhou Zhangjian and Kwon, Y.S., Fabrication of W–Cu composite by resistance sintering under ultra-high pressure, J. Mater. Process. Technol., 2005, vol. 168, no. 1, pp. 107–111. https://doi.org/10.1016/j.jmatprotec.2004.11.008

Zhou, Z.J., Du, J., Song, S.X., Zhong, Z.H., and Ge, C.C., Microstructural characterization of W/Cu functionally graded materials produced by a one-step resistance sintering method, J. Alloys Compd., 2007, vol. 428, nos. 1–2, pp. 146–150. https://doi.org/10.1016/j.jallcom.2006.03.073

Gupta, R., Kumar, R., Chaubey, A., Kanpara, S., Khirwadkar, S., and Bhoi, B., Development of W-Cu functionally graded material by Spark Plasma Sintering Process for plasma facing component application, Trans. Powder Metall. Assoc. India, 2017, vol. 43, no. 2, pp. 55–61.

Zhou, Z.J., Song, S.X., Du, J., Zhong, Z.H., and Ge, C.C., Performance of W/Cu FGM based plasma facing components under high heat load test, J. Nucl. Mater., 2007, vols. 363–365, pp. 1309–1314. https://doi.org/10.1016/j.jnucmat.2007.01.184

Jiang, G.S., Wang, Z.F., Gu, Y., Zhang, Q.W., Gao, Y., and Kuang, K., Fabrication of electronic packaging grade Cu-W materials by high-temperature and high-velocity compaction, IEEE Trans. Compon., Packag., Manuf. Technol., 2012, vol. 2, no. 6, pp. 1039–1042.

Kryachko, L.A., Laptev, A.V., Tolochin, A.I., Bega, N.D., Evich, Ya.I., Golovkova, M.E., and Lebed’, A.V., The structure and properties of the composite W–50%(vol.)Cu, prepared using a tungsten powder, activated by grinding in a ball mill, in Elektricheskie Kontakty i Electrody (Electrical Contacts and Electrodes), Kyiv: I.M. Frantsevich Institute for Problems of Materials Science, Natl. Acad. Sci. Ukraine, 2014, pp. 75–89. http://dspace.nbuv.gov.ua/handle/123456789/ 103988.

Johnson, J.L., Brezovsky, J.J., and German, R.M., Effects of tungsten particle size and copper content on densification of liquid-phase-sintered W–Cu, Metall. Mater. Trans. A, 2005, vol. 36, pp. 2807–2814. https://doi.org/10.1007/s11661-005-0277-y

Ghaderi Hamidi, A., Arabi, H., and Rastegari, S., Tungsten–copper composite production by activated sintering and infiltration, Int. J. Refract. Met. Hard Mater., 2011, vol. 29, no. 4, pp. 538–541. https://doi.org/10.1016/j.ijrmhm.2011.03.009

Jedamzik, R., Neubrand, A., and Rödel, J., Functionally graded materials by electrochemical processing and infiltration: application to tungsten/copper composites, J. Mater. Sci., 2000, vol. 35, pp. 477–486. https://doi.org/10.1023/A:1004735904984

Dirks, A.G. and Van den Broek, J.J., Metastable solid solutions in vapor deposited Cu–Cr, Cu–Mo, and Cu–W thin films, J. Vac. Sci. Technol., A, 1985, vol. 3, p. 2618. https://doi.org/10.1116/1.572799

Gu, D., Laser Additive Manufacturing of High-Performance Materials, Berlin, Heidelberg: Springer, 2015. https://doi.org/10.1007/978-3-662-46089-4

Ardestani, M., Rafiei, M., Salehian, S., Reza Raoufi, M., and Zakeri, M., Compressibility and solid-state sintering behavior of W–Cu composite powders, Sci. Eng. Compos. Mater., 2015, vol. 22, no. 3, pp. 257–261. https://doi.org/10.1515/secm-2013-0159

Aydinyan, S.V., Kirakosyan, H.V., Zakaryan, M.K., Abovyan, L.S., Kharatyan, S.L., Peikrishvili, A., Mamniashvili, G., Godibadze, B., Chagelishvili, E.Sh., Lesuer, D.R., and Gutierrez, M., Fabrication of Cu–W nanocomposites by integration of self-propagating high-temperature synthesis and hot explosive consolidation technologies, Eurasian Chem.-Technol. J., 2018, no. 4, pp. 301–309. https://doi.org/10.18321/ectj763

Ding, L., Xiang, D.P., Li, Y.Y., Li, C., and Li, J.B., Effects of sintering temperature on fine-grained tungsten heavy alloy produced by high-energy ball milling assisted spark plasma sintering, Int. J. Refract. Met. Hard Mater., 2012, vol. 33, pp. 65–69. https://doi.org/10.1016/j.ijrmhm.2012.02.017

Maneshian, M.H., Simchi, A., and Razavi Hesabi, Z., Structural changes during synthesizing of nanostructured W–20 wt % Cu composite powder by mechanical alloying, Mater. Sci. Eng., A, 2007, vols. 445–446, pp. 86–93. https://doi.org/10.1016/j.msea.2006.09.005

Chuvil'deev, V.N., Nokhrin, A.V., Baranov, G.V., Moskvicheva, A.V., Lopatin, Yu.G., Kotkov, D.N., Blagoveshchenskii, Yu.V., Kozlova, N.A., Shotin, S.V., Konychev, D.A., and Piskunov, A.V., Investigation of the structure and mechanical properties of nano- and ultrafine mechanically activated tungsten pseudo-alloys, Vestn. Nizhegorod. Univ. im. N. I. Lobachevskogo. Ser.: Fiz. Tverd. Tela, 2010, no. 2 (1), pp. 47–59.

Yang, X., Zou, J., Xiao, P., and Wang, X., Effects of Zr addition on properties and vacuum arc characteristics of Cu–W alloy, Vacuum, 2014, vol. 106, pp. 16–20. https://doi.org/10.1016/j.vacuum.2014.03.009

Vadchenko, S.G., Suvorova, E.V., Mukhina, N.I., and Kovalev, I.D., Copper deposition from its sulfate solution onto titanium powder with the simultaneous mechanical activation of the mixture, Russ. J. Non-Ferrous Met., 2020, vol. 61, no. 5, pp. 534–539. https://doi.org/10.3103/S1067821220050144

Vadchenko, S.G., Suvorova, E.V., Mukhina, N.I., Kovalev, I.D., and Illarionova, E.V., Preparing CuCr pseudo-alloys by deposition of copper from a solution onto chromium powders with simultaneous mechanical activation of the mixture, Russ. J. Non-Ferrous Met., 2021, vol. 62, no. 2, pp. 233–238. https://doi.org/10.3103/S1067821221020140

Zherebtsov, D.A., Archugov, S.A., and Mikhailov, G.G., Calibration of thermocouples at the melting point of copper, Izv. Chelyab. Nauchn. Tsentra Ural. Otd. Ross. Akad. Nauk, 1999, no. 2, pp. 91–100.

Winegard, W.C., An Introduction to the Solidification of Metals, London: Institute of Metals, 1964.

Gomes, U.U., Da Costa, F.A., and Da Silva, A.G.P., On sintering of W–Cu composite alloys, Proc. 15th Int. Plansee Seminar “Powder Metallurgical High Performance Materials”, Reutte, May 2001, Reutte: High Performance P/M Metals, 2001, vol. 1, pp. 177–189.

Ignat’eva, T. and Borovinskaya, I., Chemical dispersion as a method for segregation of ultrafine and nanosized powders of SHS refractory compounds, Eurasian Chem.-Technol. J., 2013, vol. 15, pp. 111–116. https://doi.org/10.18321/ectj148

Prasitskii, G.V. and Inyukhin, M.V., Parameters and techniques for the production of heat sink materials for semiconductor devices, Naukoemkie Tekhnol., 2014, vol. 15, no. 2, pp. 10–19.

Hafed, I., Azizan, A., and Azmi, R., Enhanced liquid-phase sintering of W–Cu composites by liquid infiltration, Int. J. Refract. Met. Hard Mater., 2014, vol. 43, pp. 222–226. https://doi.org/10.1016/j.ijrmhm.2013.12.004

Loktyushin, V.A., Adamenko, N.A., and Gurevich, L.M., Kontaktnye vzaimodeistviya v kompozitsionnykh materialakh. Uchebnoe posobie (Contact Interactions in Composite Materials. Student’s Book), Volgograd: Volgograd State Technical Univ., 2003.

ACKNOWLEDGMENTS

The studies were performed using equipment from the ISMAN Core Facility Center.

Funding

This work was supported by the Russian Foundation for Basic Research, project no. 18-03-00438.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated by I. Moshkin

About this article

Cite this article

Vadchenko, S.G., Suvorova, E.V., Mukhina, N.I. et al. Structure Formation of Cu–W Pseudo Alloys Upon Various Methods of Their Production. Russ. J. Non-ferrous Metals 62, 466–472 (2021). https://doi.org/10.3103/S1067821221040143

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1067821221040143